Molybdenum disulfide diaphragm of lithium-sulfur battery and preparation method therefor

A molybdenum disulfide, lithium-sulfur battery technology, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve problems such as affecting the gas permeability of the diaphragm, reducing battery capacity, etc., to improve cycle life and low cost , the effect of simple experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

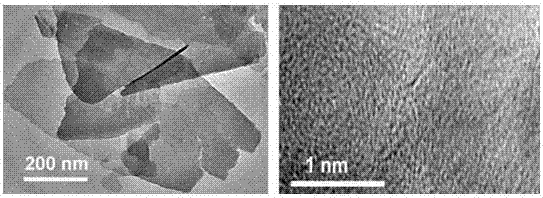

[0022] A kind of preparation method of molybdenum disulfide diaphragm of lithium-sulfur battery of the present invention, specific operation process is as follows: take the molybdenum disulfide powder that particle diameter is 0.5-1.2 μ m, refer to literature (H. Tang, J. Wang, H. Yin, H. . Zhao, D. Wang, Z. Tang. Growth of Polypyrrole Ultrathin Filmson MoS 2 Monolayers as High-Performance Supercapacitor Electrodes

[0023] .Adv.Mater.2015, 27, 1117.) method to prepare molybdenum disulfide nanosheets, mix the prepared molybdenum disulfide nanosheets with ethanol at a mass volume ratio of 0.2:1, ultrasonically disperse for 30min at room temperature, and then Suction filtration at a vacuum degree of 0.04Mpa to deposit molybdenum disulfide nanosheets on the surface of the lithium-sulfur battery separator to form a molybdenum disulfide film, and dry in a vacuum oven at 40°C for 16 hours to obtain MoS 2 The thickness of the molybdenum disulfide film in the / Celgard separator is 26...

Embodiment 2

[0025] The mixing mass volume ratio of molybdenum disulfide nanosheets and ethanol is 0.25:1, ultrasonically disperse at room temperature for 35min, and then suction filter at a vacuum of 0.05Mpa; the vacuum drying condition is: dry at 45°C for 15h, and other conditions are the same as in Implementation 1 , the prepared MoS 2 The thickness of the molybdenum disulfide film in the / Celgard separator is 300nm.

Embodiment 3

[0027] The mixing mass volume ratio of molybdenum disulfide nanosheets and ethanol is 0.3:1, ultrasonically disperse at room temperature for 35min, and then filter under a vacuum of 0.06Mpa; the vacuum drying condition is: dry at 50°C for 13h, and other conditions are the same as in Implementation 1. , the prepared MoS 2 The thickness of the molybdenum disulfide film in the / Celgard diaphragm is 245nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com