Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Avoid white spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

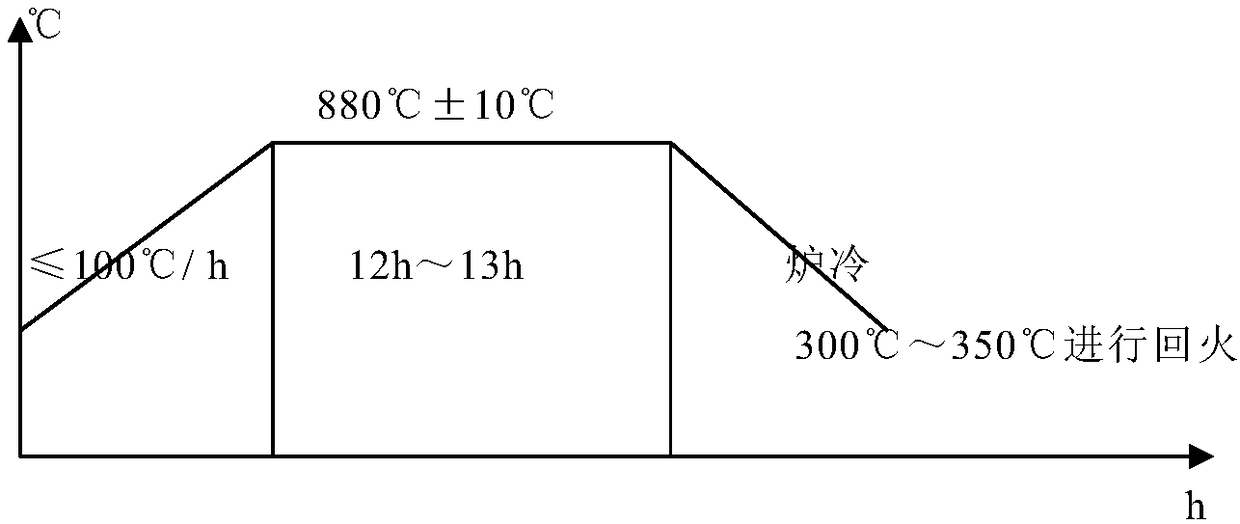

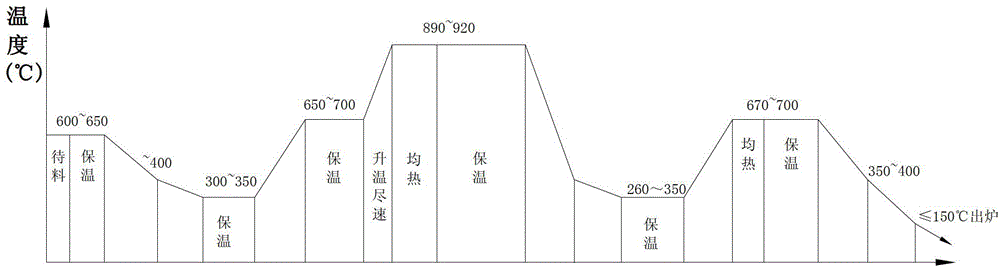

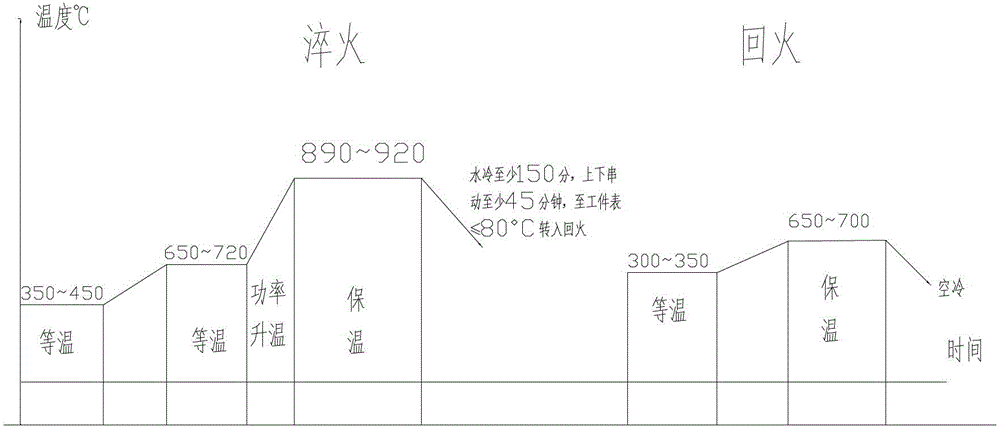

Post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills

InactiveCN102417965AAvoid white spotsFurnace typesHeat treatment process controlHeat treatingCrystallite

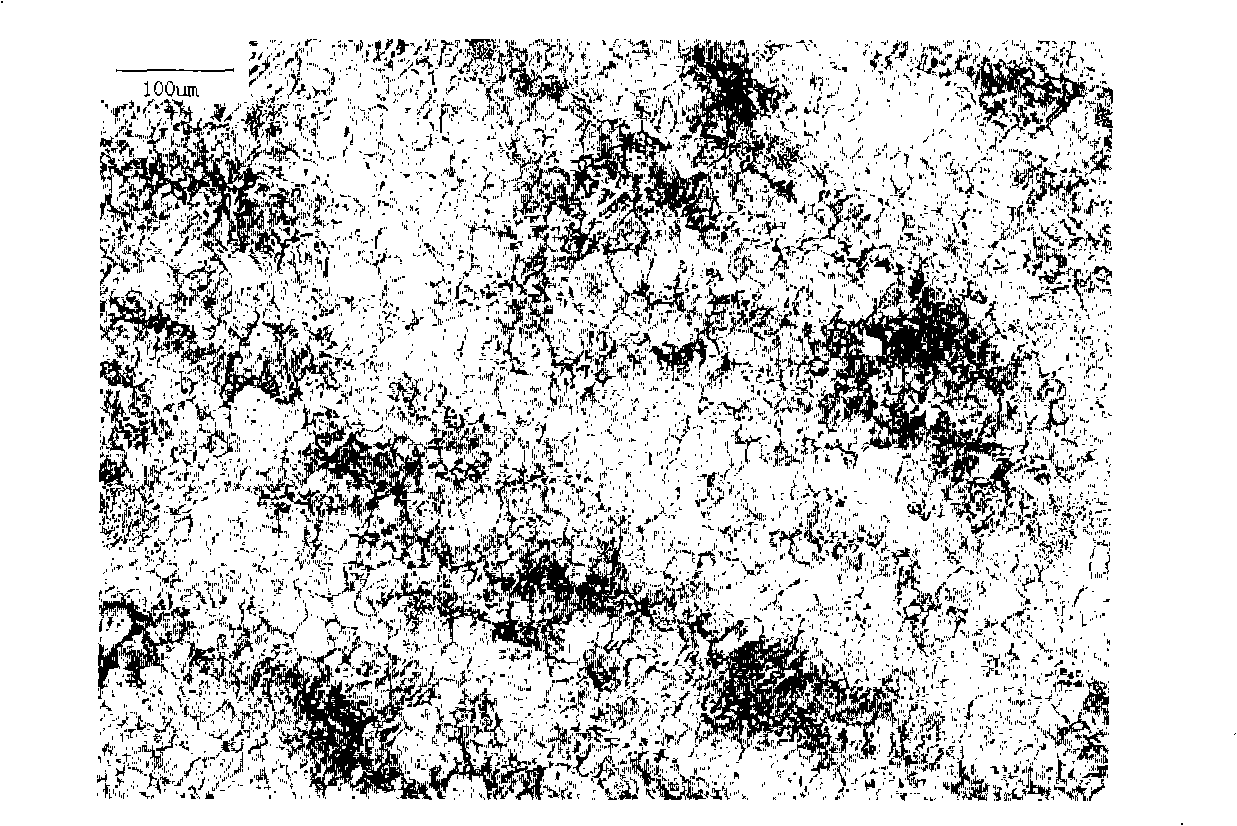

The invention belongs to the technical field of large forging heat treatment processes, and mainly relates to a post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills. A forged back-up roll is cooled to 400 DEG C to 500 DEG C by the air and put into a furnace, and the material temperature in the heat treatment furnace is not lower than 600 DEG C; a high-temperature normalizing plus low-temperature normalizing plus spheroidizing annealing plus high-temperature tempering process is adopted, and air cooling is carried out. The adopted post-forging heat treatment process disclosed by the invention is characterized in that: crystalline grains are thinned; the structure is regulated, so that the network structure is removed; the carbon segregation ofthe upper part of the large steel ingot is considerable, temperature higher than Ac1 is kept for a long time, consequently, part of carbide is remelted, the remaining unmelted carbide is spheroidized, and a granular pearlite structure is obtained during cooling; consequently, the structure toughness is high, and structure preparation is done for the next step of heat treatment; and fish eyes are prevented.

Owner:洛阳中创重型机械有限公司

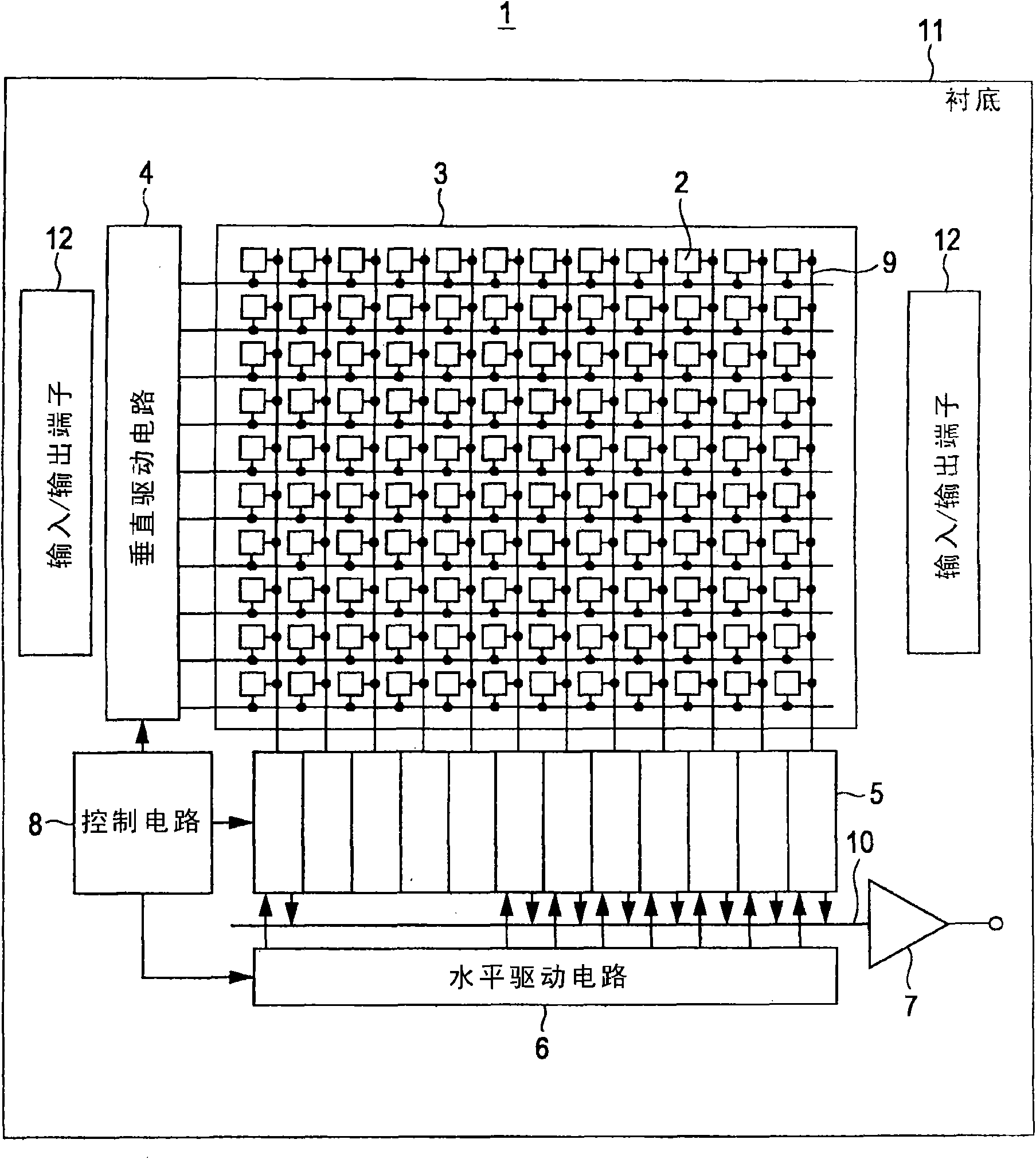

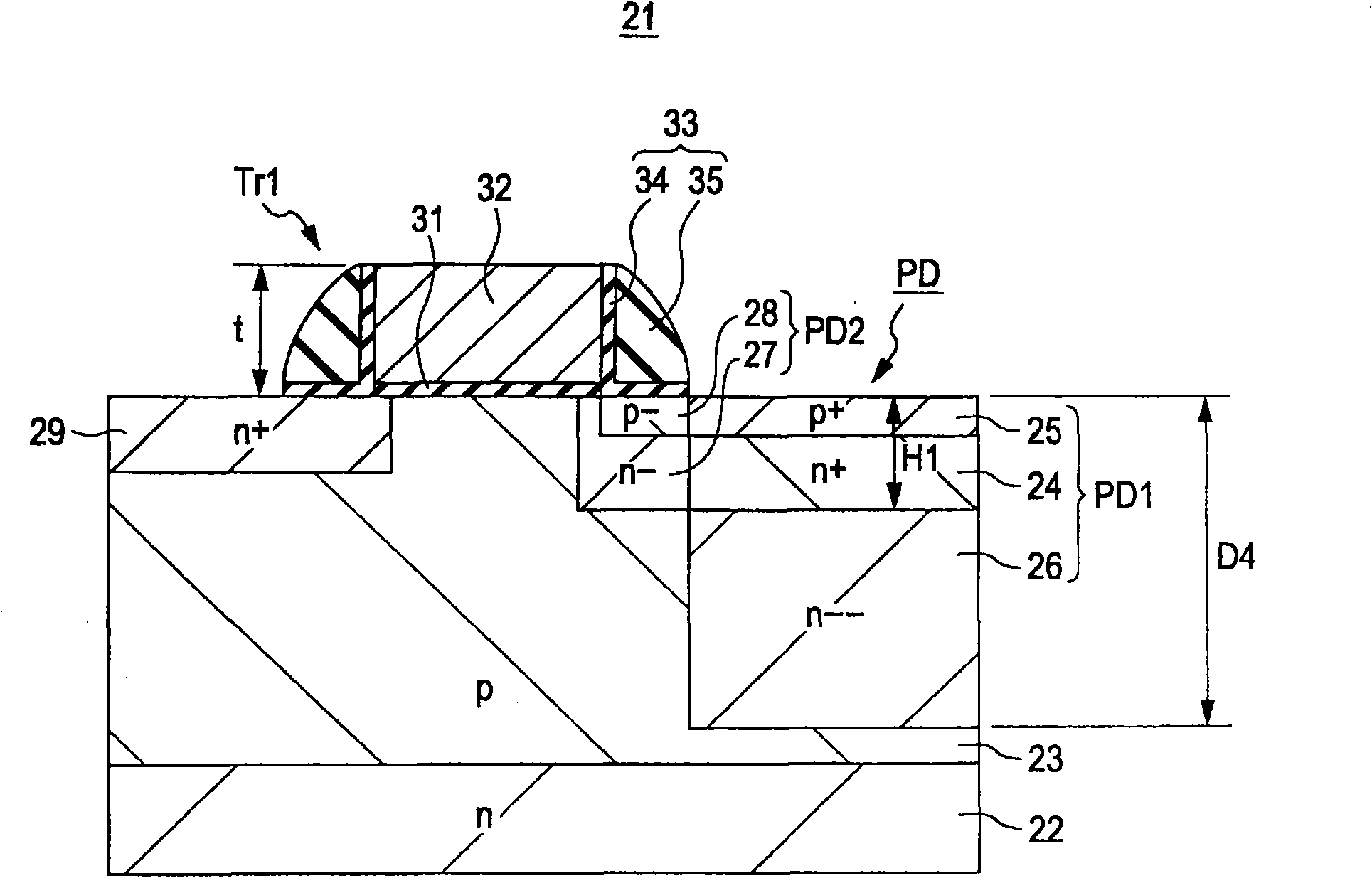

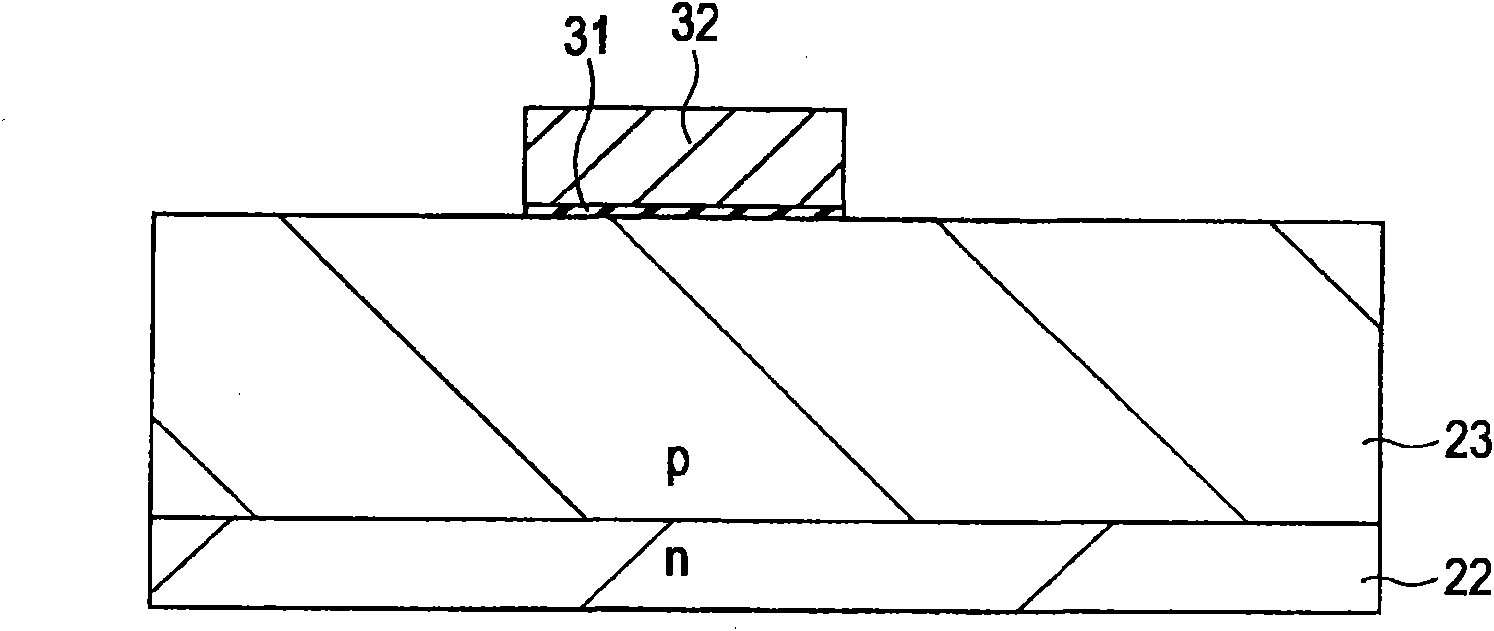

Solid-state imaging device, manufacturing method of the same, and electronic apparatus

InactiveCN101853867AAvoid white spotsImprove reading characteristicsTransistorTelevision system detailsEngineeringPhotodiode

A solid-state imaging device includes plural photodiodes which are formed in a photodiode area of a unit pixel with no element separating area interposed therebetween and in which impurity concentrations of pn junction areas are different from each other.

Owner:SONY CORP

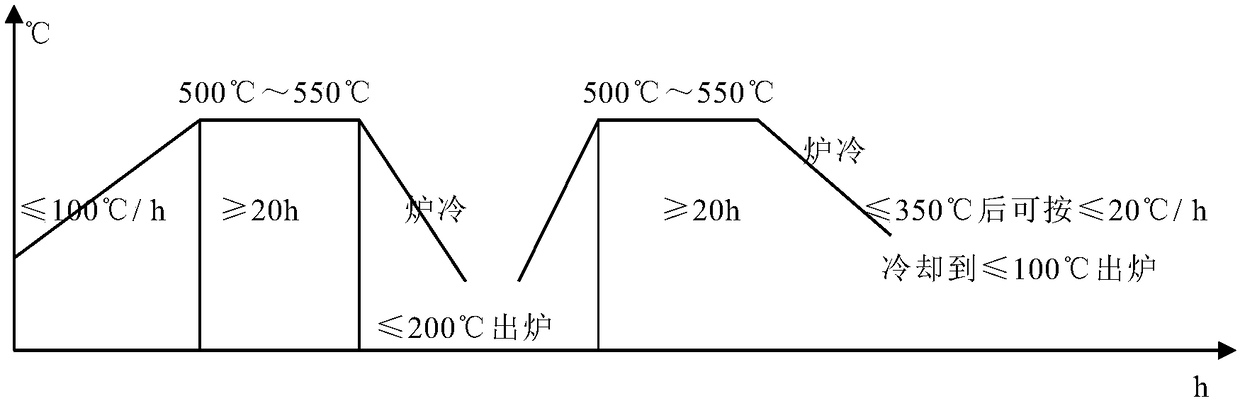

Manufacturing process for manufacturing large ship-used shafting forge pieces

InactiveCN108453202AEfficient crushingReasonable upsetting processMetal-working apparatusFurnace typesSolubilityHydrogen

The invention provides a manufacturing process for manufacturing large ship-used shafting forge pieces and belongs to the field of ship-used shafting forge pieces. The manufacturing process for manufacturing large ship-used shafting forge pieces specifically comprises the following steps: heat treatment before forging; two-time upsetting and stretching and forging (a WHF method); and thermal treatment on the forged shafting forge pieces. The two-time upsetting and stretching process is reasonable. Cast state tissues can be crushed effectively in first time stretching, and inner hole defects are forged; strip-type plastic inclusions of a core of a blank are fractured to smaller impurities in second time upsetting; the impurities are stretched to disperse impurity granules in the second stretching process, and the action of white points is eliminated effectively by the two-time upsetting process. As a result of temperature change condition in the two-time upsetting and stretching process, the solubility of hydrogen in the forge pieces changes continuously, and distribution and diffusion of hydrogen are facilitated well.

Owner:WUXI HONGDA HEAVY IND

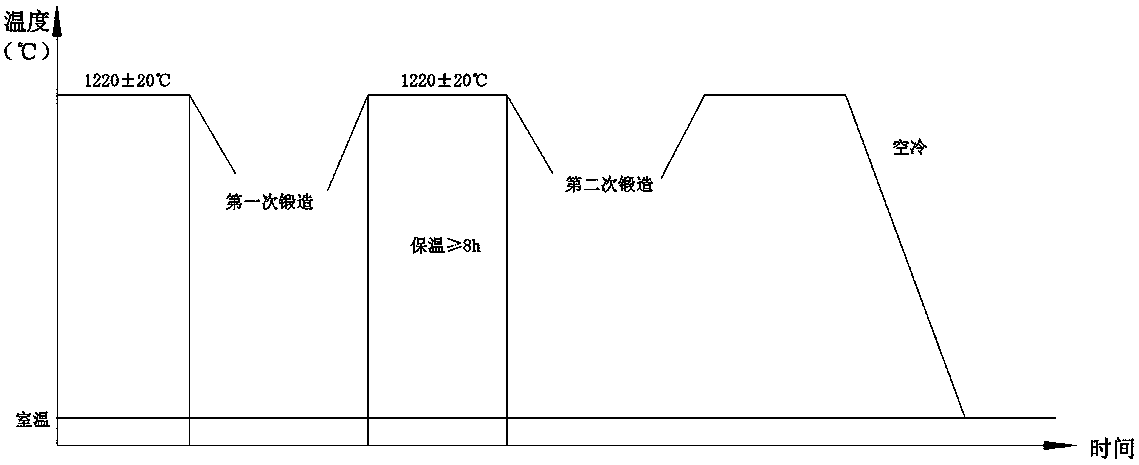

Anti-H2S stress corrosion high pressure resistant forgings and method for manufacturing same

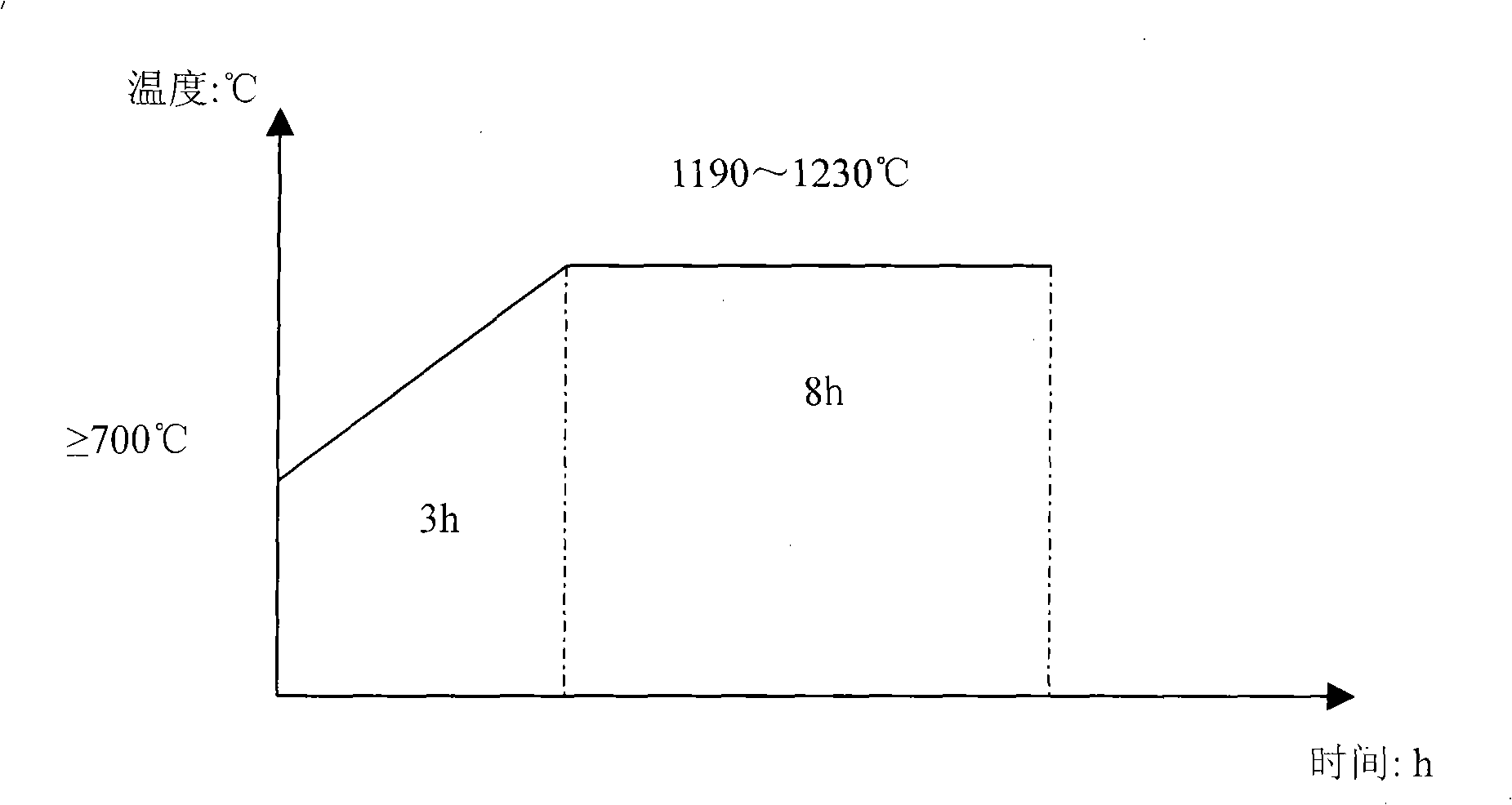

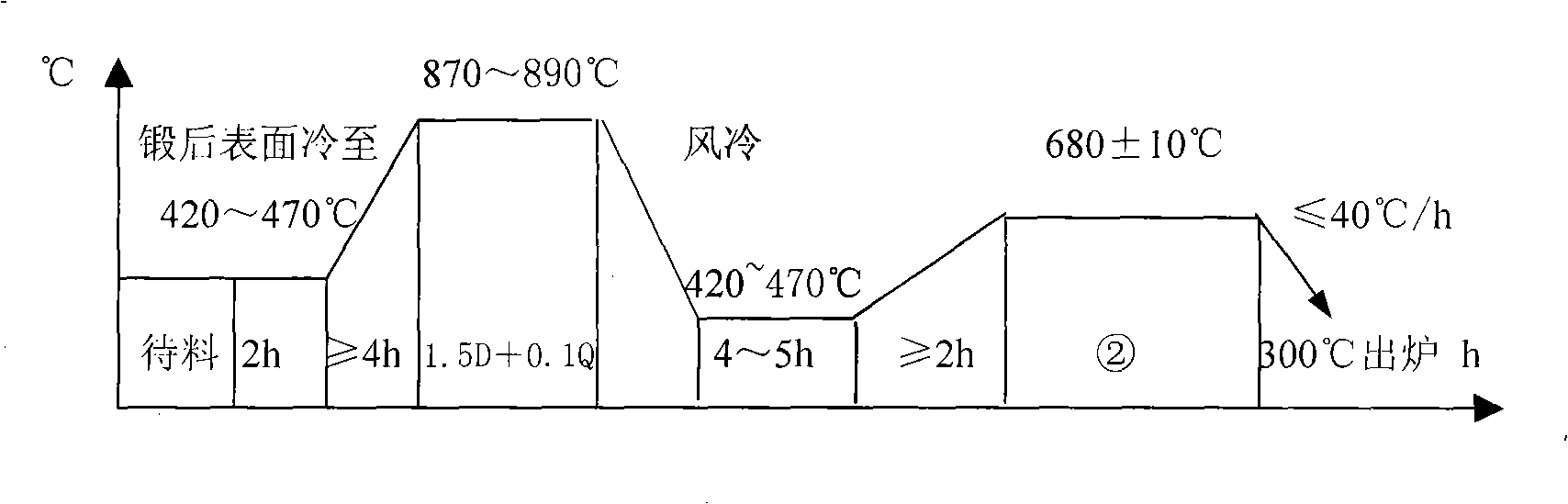

Disclosed is a sulfureted hydrogen-proof stress corrosion high pressure-resistant forge piece, comprising the compositions, in weight percent: C: 0.26 to 0.30, Mn: 0.80 to 1.00, Cr: 0.80 to 1.00, Si: 0.20 to 0.35, Ni: 0.50 to 0.95, Mo: 0.20 to 0.30, P<=0.012, S<=0.010, Cu<=0.20, H<=2ppm, O<=50ppm, N<=85ppm, balance Fe; and a manufacturing method comprises the following steps of: secondary refining and smelting by an electric furnace, and casting for forming ingot; heating and forging, with a heating speed of 100 to 150DEG C / h to rise the temperature to 1190 to 1230DEG C, and then preserving the heat for over 8 hours; forging steel ingot to have the size of a finished product; forging temperature range: 800DEG C to 1130 DEG C; adopting an upsetting drawing process, with a forging ratio >=6; and air cooling to reach a temperature of between 420 and 470DEG C after the forging and preserving the heat for over 2 hours, normalizing, with a temperature of between 870 and 890DEG C, and annealing, with a temperature of between 670 and 690DEG C. The indexes such as yielding, tensile strength, grain size and non-metallic inclusion of the forge piece meet the designed 105MPa pressure demand, and the forge piece is corrosion resistant.

Owner:宝武特种冶金有限公司

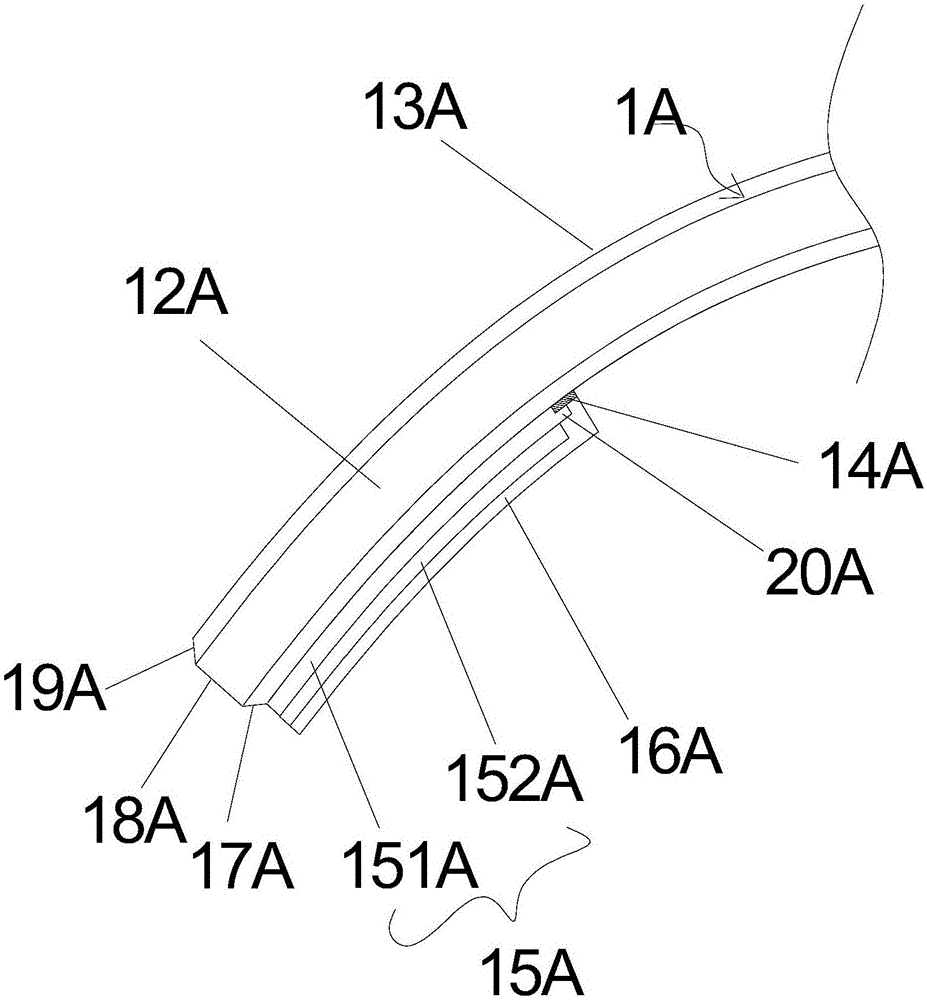

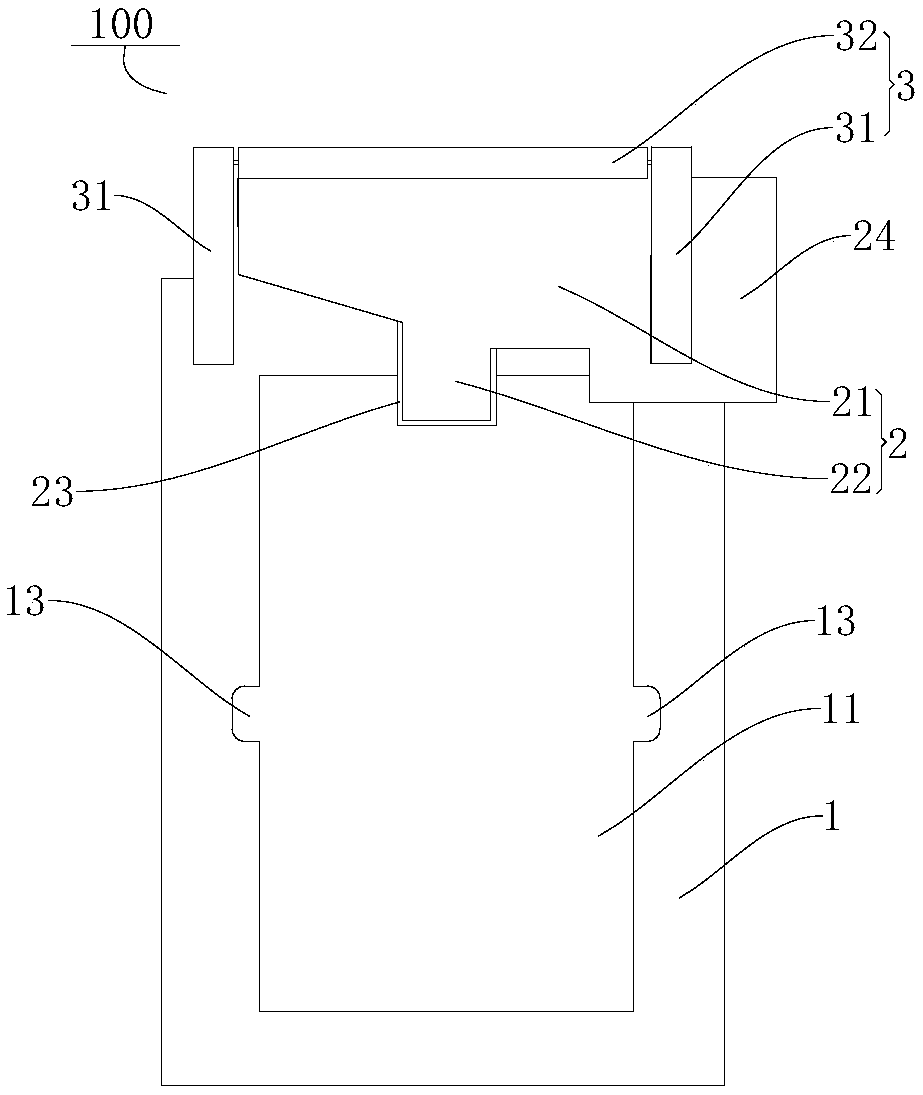

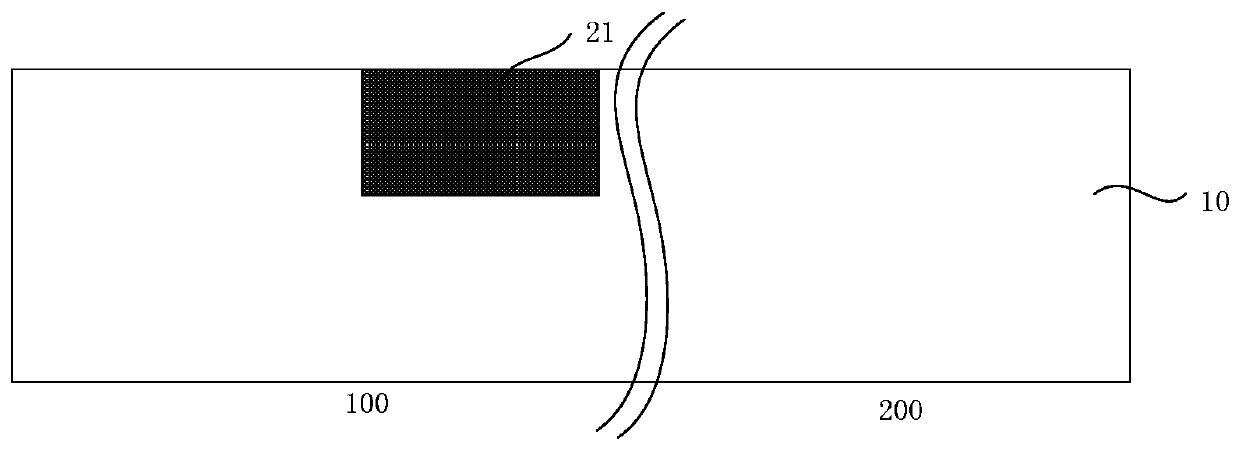

Mobile terminal 3D glass cover and production method thereof

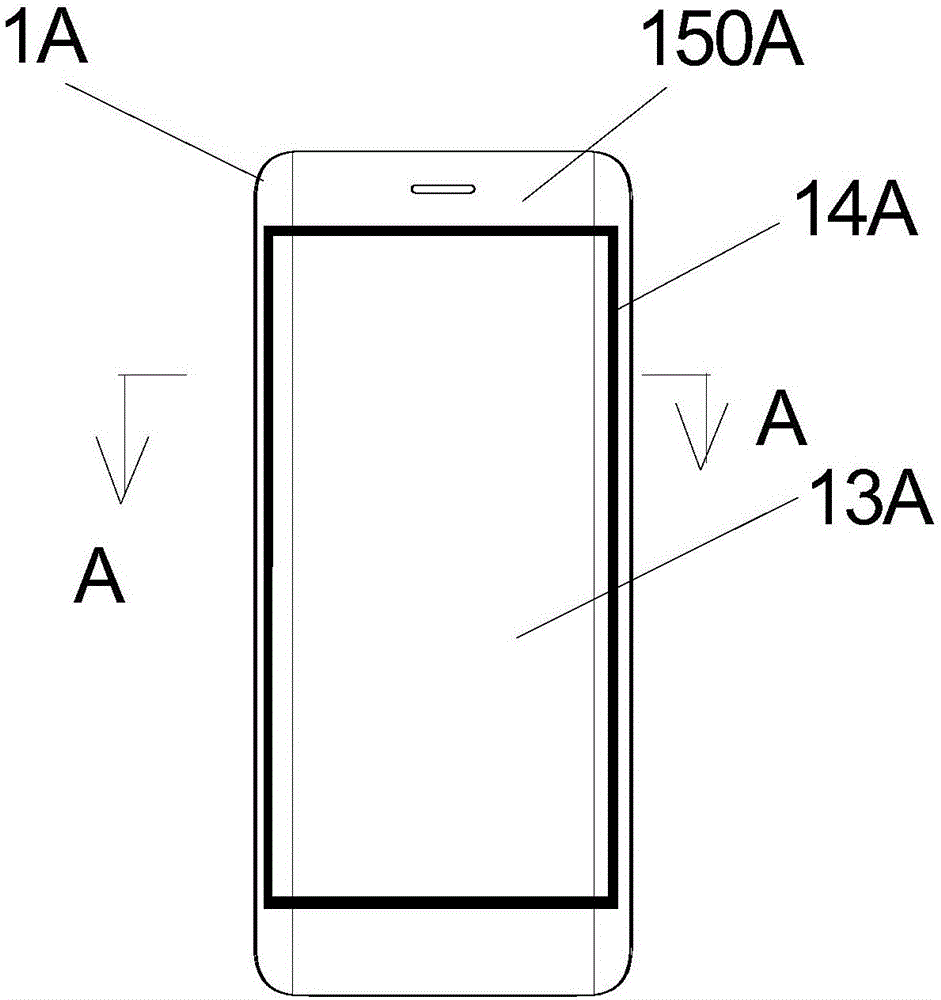

ActiveCN106708185AAvoid white spotsAvoid missing teethDigital data processing detailsCoatingsGlass coverComputer terminal

The invention relates to a mobile terminal 3D glass cover and production method thereof. The mobile terminal 3D glass cover includes the main body of a glass cover (1), an ink overlay (2) mounted on the glass cover bottom (15). The lateral 3D surface (15) includes an inward bevel surface (161), a straight upward surface (162), and an outward bevel surface (163).).The glass cover invention has the characteristics as below: the ink overlay(2) includes a layer of common white ink coating (221), which extends to and covers the inward bevel surface(161) and straight upward surface (162). Because the common white ink coating is resistant to UV light, it shows no change when UV light shine on the 3D glass cover. The virtue of the coating protects the 3D glass cover by preventing appearance defect problems like scratches; white marks appearing on the 3D glass cover edge, and so on, improving product quality.

Owner:VIVO MOBILE COMM CO LTD

Steelmaking process capable of improving quality of U71Mn heavy rail steel product

InactiveCN105132627AEasy to loosenImprove center shrinkage defectManufacturing convertersProcess efficiency improvementPorositySteelmaking

The invention discloses a steelmaking process capable of improving the quality of a U71Mn heavy rail steel product, and belongs to the technical field of steelmaking processes. The steelmaking process comprises the process steps of molten iron desulfurization, converter smelting, LF refining, RH refining and special-shaped blank continuous casting, and is characterized in that a deep desulfurization mode is adopted for the molten iron desulfurization, wherein the desulfurization time is 30-40 min; and after the treatment, S is not more than 0.005% (mass fraction), [P] is not more than 0.120% (mass fraction), and T is not lower than 1250 DEG C. As the steelmaking process is adjusted and controlled according to the invention, the defects of center segregation, center porosity and center hole shrinkage of heavy rail steel cast blanks are prominently alleviated; the crack low-power defect of the cast blanks is effectively prevented; and the surface defectless rate of the heavy rail steel continuous cast blanks reaches 100%. The rolled heavy rail steel low-power structure prevents white dots, shrinkage residues, internal cracks, skull patches, delamination and inclusion visible to the naked eyes; the steel rail tensile strength is averagely higher than or equal to 900 MPa; and the steel rail tread hardness is higher than or equal to 260 HB.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Flake prevention control method for age hardening type plastic mold steel

ActiveCN108441613AFully remove residual stressReduce occupancySolution treatmentHydrogen concentration

the invention discloses a flake prevention control method for age hardening type plastic mold steel. The method aims to prevent flakes from being generated after forging. In order to achieve the aim,the technical scheme of the method is characterized in that dehydrogenation annealing is not carried out after forging, solid solution treatment is directly carried out, the solid solution treatment process is directly carried out, so that hydrogen in the steel is directly and uniformly fixed in the steel before being accumulated, the hydrogen concentration for generating the flakes is not reached, and therefore the occurrence of the defects of the flakes can be avoided; and a proper tempering process is coordinated, residual stress in the steel is fully removed, and therefore the occurrence of the flakes can be prevented. Compared with the prior art, the method has the following advantages that 1, the dehydrogenation annealing process after forging is omitted, solid solution treatment isdirectly carried out after forging, then through a proper tempering process after solid solution treatment, the flakes can be prevented from being generated, meanwhile, the finished flat steel is pre-hardened, and the hardness is uniform; and 2, the production time is saved, the occupation of a furnace platform is reduced, the energy consumption is reduced, and therefore the production cost is lowered.

Owner:FUSHUN SPECIAL STEEL SHARES

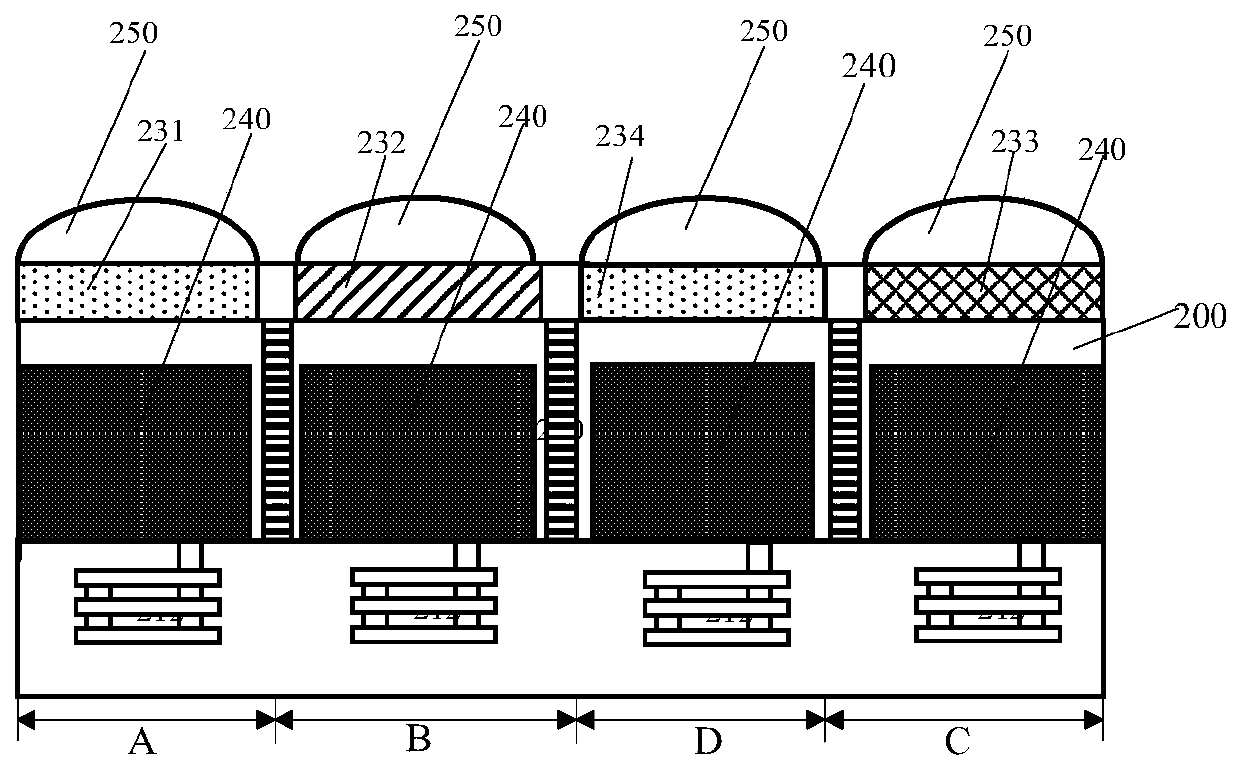

COMS (complementary metal-oxide semiconductor) image sensor and manufacturing method thereof

InactiveCN103474442AAvoid damageAvoid white spotsRadiation controlled devicesPhotoresistIon implantation

The invention provides a COMS (complementary metal-oxide semiconductor) image sensor and a manufacturing method thereof. The manufacturing method comprises the following steps: forming a first doped area on the surface of a semiconductor substrate; sequentially forming a gate oxidation layer and gate polycrystalline silicon; forming a second doped area in the semiconductor substrate; depositing a dielectric layer and forming a side wall through an exposure and etching process; forming a third doped area on the surface of the semiconductor substrate; removing the dielectric layer on the surface of the semiconductor substrate; and forming a fourth doped area in the first doped area. According to the manufacturing method provided by the invention, the gate side wall is formed by etching, ion injection is performed after removal of a photoresist to form the third doped area on the surface of the semiconductor substrate, and then the dielectric layer on the surface of the semiconductor substrate is removed to prevent secondary ion injection from damaging the semiconductor substrate on the surface of a light-sensitive diode, so that white points of the CMOS image sensor caused by damage of a semiconductor are avoided, and the quality of the CMOS image sensor is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Forging process for GCr15 roller sleeve

ActiveCN106064221AExtendedIncrease the lengthMetal-working apparatusEngine componentsPunchingMachining process

The invention aims to provide a forging process for a GCr15 roller sleeve. The forging process comprises the steps that firstly, a forge piece is heated; secondly, the roller sleeve is subjected to four-time heating forming forging, specifically, four-time heating forming is adopted as the forging technique of forging of the GCr15 roller sleeve, namely ejection and upsetting, punching, drawing-out and round rolling reshaping; and thirdly, annealing and cooling are conducted. The machining process is improved, so that the length of drawing-out and punching during forging is prolonged, straightening of the forge piece during punching forging is improved, the uniformity of the wall thickness is improved, white dots in the sleeve are prevented, and the performance of the forge piece is improved.

Owner:ANHUI RUIJIE FORGING

Thermal dye sublimation transfer paper

InactiveCN109228714AAvoid white spotsAvoid precisionDuplicating/marking methodsWater basedSilicate minerals

The invention discloses thermal dye sublimation transfer paper. The paper comprises a body paper layer and a coating layer smeared on the body paper layer, wherein the coating layer contains a film forming material and an adsorption material used for adsorbing water-based and oil-based ink, the film forming material is used for receiving thermal dye sublimation ink and release a pigment dye in thethermal dye sublimation ink into a transfer base material, the film forming material is at least prepared from polyacrylamide, and the adsorption material is prepared from an inorganic filler, modified starch and silicate mineral substances. The thermal dye sublimation transfer paper not only can receive water-based thermal dye sublimation transfer ink to print, but also can adapt to oil-based thermal dye sublimation ink printing, widens the application range of the transfer paper, and solves the problem that permeation in water-based thermal dye sublimation ink is large, the transfer rate islow, white spots in the oil-based thermal dye sublimation ink are more, and the precision is low.

Owner:赵慧哲

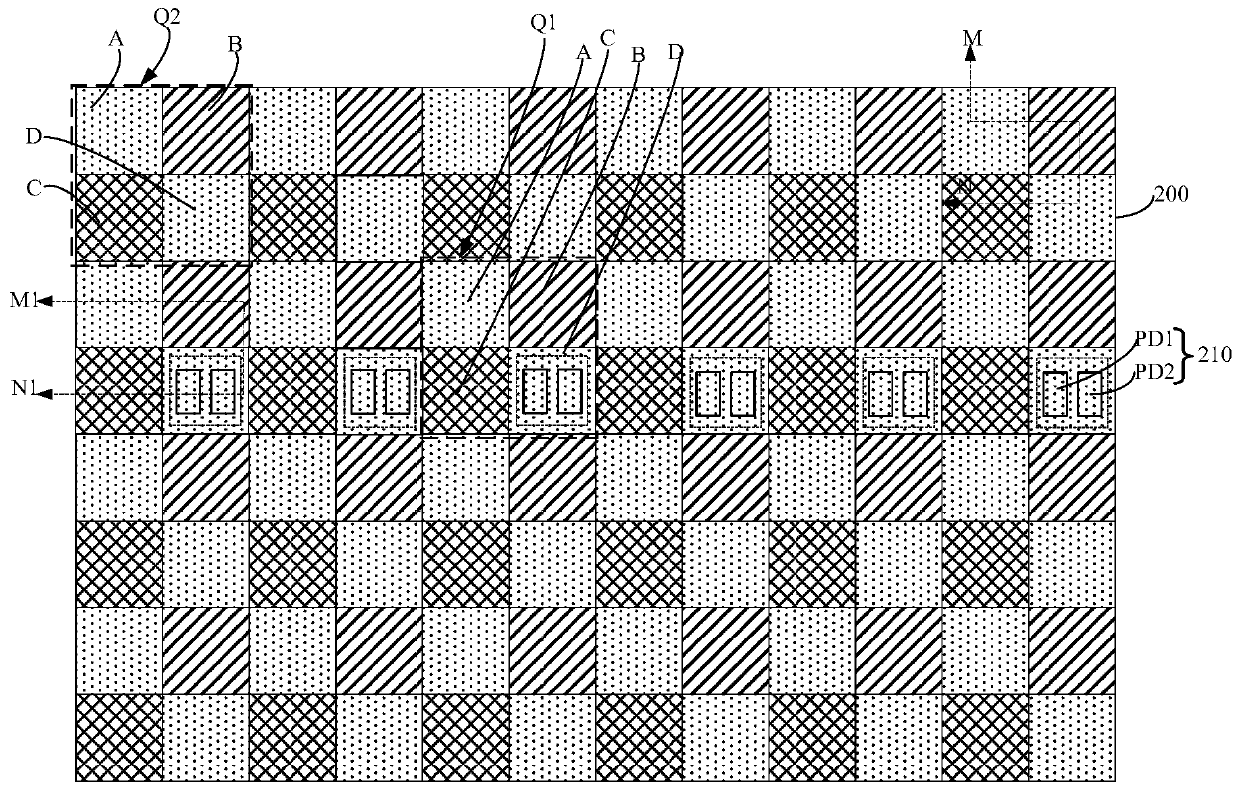

Phase focusing image sensor and forming method and working method thereof

InactiveCN110062144AImprove performanceAvoid white spotsTelevision system detailsSolid-state devicesSemiconductorImage capture

The invention discloses a phase focusing image sensor and a forming method and a working method thereof. The phase focusing image sensor comprises a semiconductor substrate, the semiconductor substrate comprising a plurality of image capture regions, each image capture region comprising a first sub-pixel region, a second sub-pixel region, a third sub-pixel region and a fourth sub-pixel region, anda part of the image capture regions are first-class image capture regions; a focusing photosensitive unit positioned in a fourth sub-pixel region of the first type of image capture region and comprising a first focusing photosensitive structure and a second focusing photosensitive structure which are separated from each other; and a main photosensitive structure respectively positioned in each first sub-pixel region, each second sub-pixel region and each third sub-pixel region. The performance of the phase focusing image sensor is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

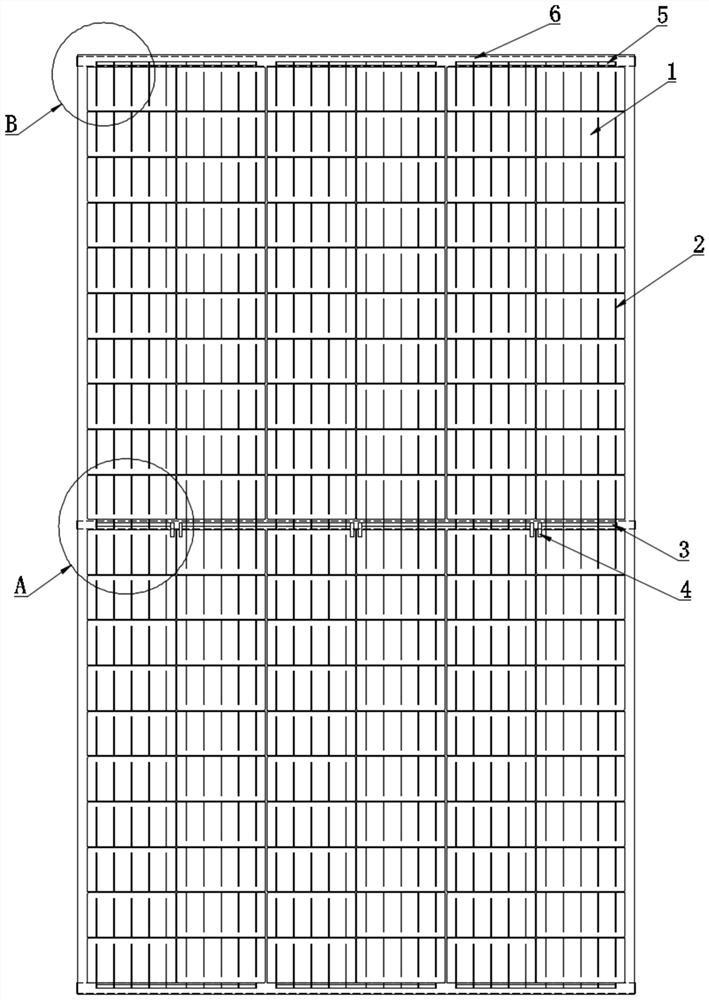

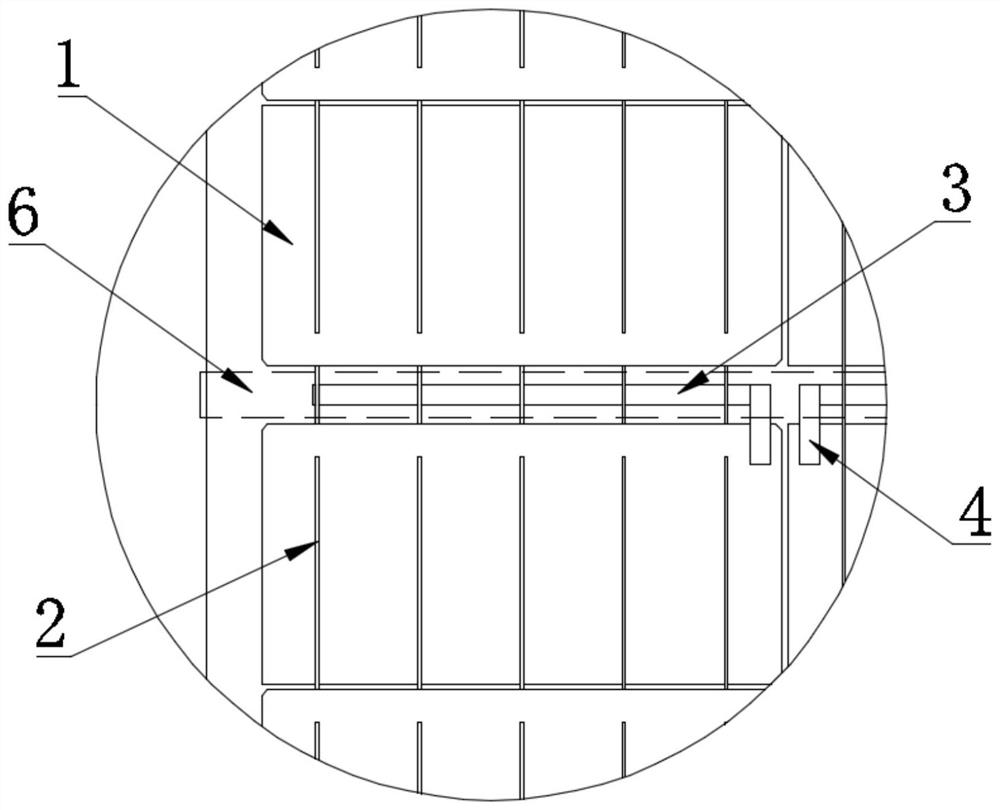

All-black solar photovoltaic module and manufacturing method thereof

PendingCN112331730AImprove qualityImprove market competitivenessFinal product manufacturePhotovoltaic energy generationPhysicsElectrical battery

The invention discloses an all-black solar photovoltaic module and a manufacturing method thereof, and the all-black solar photovoltaic module sequentially comprises a light transmission layer, a first EVA adhesive film layer, a cell array, a second EVA adhesive film layer and a backboard from the top to the bottom. The battery array comprises a plurality of battery pieces arranged in a matrix, wherein each column of battery pieces are sequentially connected into a battery string through an interconnection strip solder strip, and a gap is formed between every two battery pieces in the middle of each battery string; the interconnection strip solder strips in the gaps are connected through a first bus bar which is connected with a second bus bar being perpendicular to the first bus bar in the horizontal direction and penetrating through the back plate; the interconnection strip solder strips at the two ends of the battery string are connected through a third bus bar; the front surfaces of the first bus bar and the third bus bar are completely covered by the black isolating bar; one end of the second bus bar is fixed on the back surface of the first bus bar, and the other end obliquely penetrates through the backboard. According to the invention, a real all-black appearance effect can be achieved, and the quality and the market competitiveness are improved.

Owner:JIANGSU SUNRISE ENERGY CO LTD

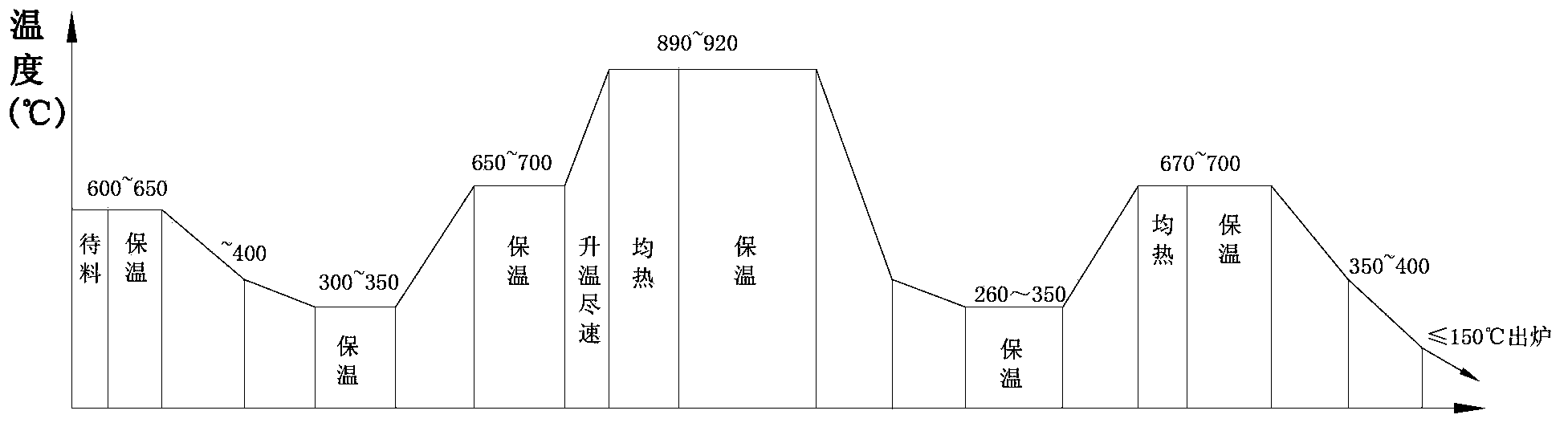

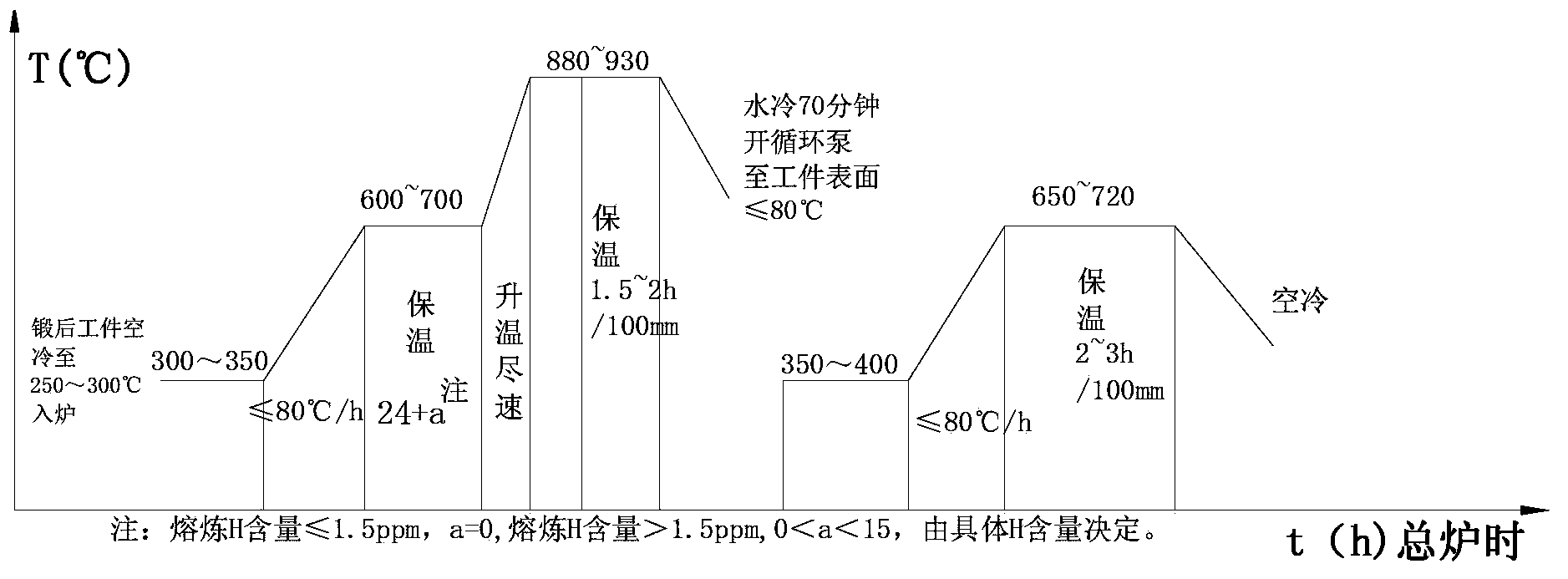

Post-forging thermal treatment method for heavy forging of hot-wall hydrogenation reactor

ActiveCN103849745AShorten the production cycleReduce manufacturing costFurnace typesHeat treatment process controlWater coolingHeating furnace

The invention discloses a post-forging thermal treatment method for a heavy forging of a hot-wall hydrogenation reactor. The method is used for performing post-forging thermal treatment on the heavy forging, which is made of 12Cr2Mo1 and is 1,500-4,500 millimeters in outer diameter and 100-300 millimeters in wall thickness, of the hot-wall hydrogenation reactor. The post-forging thermal treatment method is characterized by comprising the following steps: I, controlling the final forging temperature, performing air cooling until the surface temperature of a forging is 250-350 DEG C, and feeding the forging into a heating furnace; II, raising the temperature of the heating furnace to 600-700 DEG C at a speed of less than or equal to 80 DEG C per hour, and preserving heat; III, raising the temperature of the heating furnace to 880-930 DEG C at the maximum power of the heating furnace, and preserving heat; IV, discharging a workpiece, and cooling the workpiece in water until the surface temperature of the workpiece is lower than or equal to 80 DEG C; V, feeding the workpiece into the heating furnace for later use, raising the cavity temperature of the heating furnace to 650-720 DEG C at a speed of less than or equal to 80 DEG C per hour, preserving heat, discharging and performing air cooling. By adopting the post-forging thermal treatment method, the performance is preserved in a post-forging thermal treatment process while the quality of the forging is ensured, the production period of the forging of the hot-wall hydrogenation reactor is effectively shortened, and the cost is reduced.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

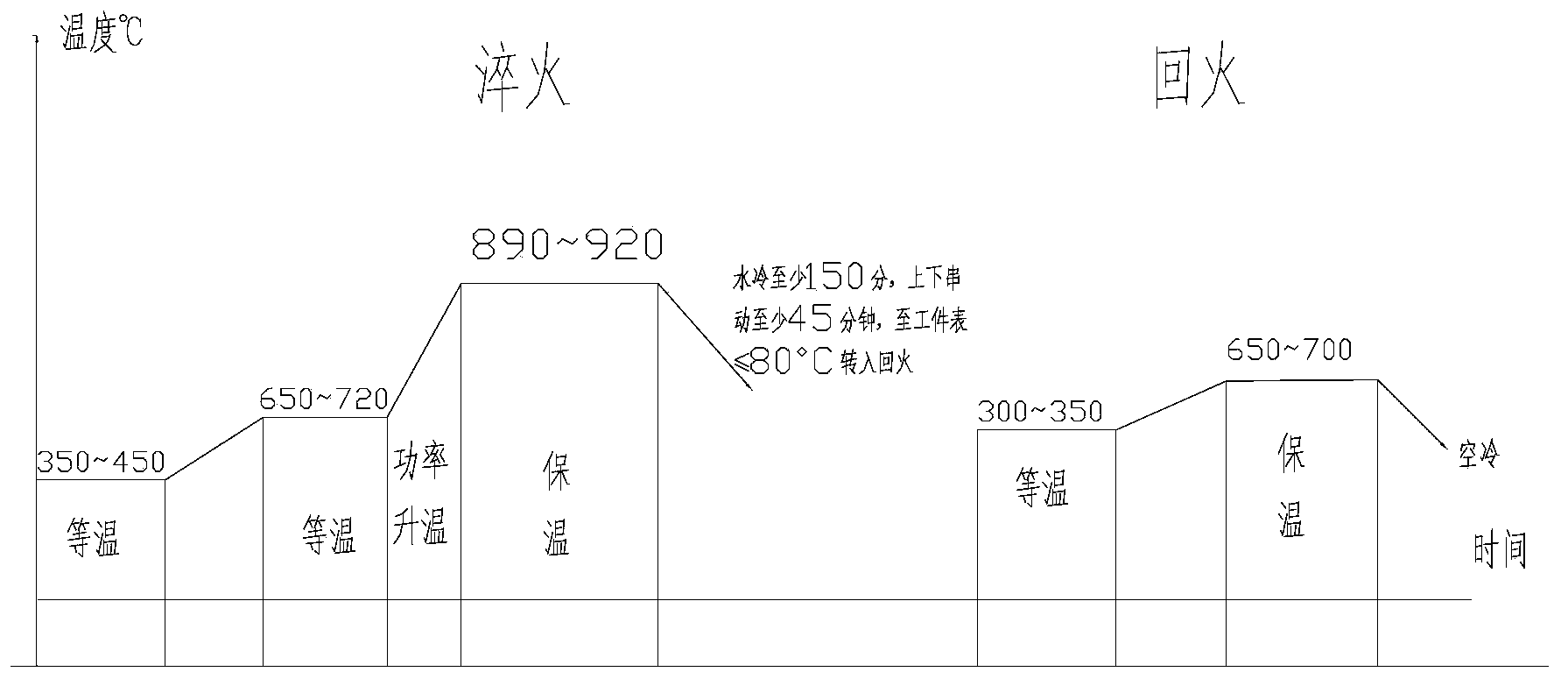

Post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills

InactiveCN102417965BAvoid white spotsFurnace typesHeat treatment process controlHeat treatingCrystallite

The invention belongs to the technical field of large forging heat treatment processes, and mainly relates to a post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills. A forged back-up roll is cooled to 400 DEG C to 500 DEG C by the air and put into a furnace, and the material temperature in the heat treatment furnace is not lower than 600 DEG C; a high-temperature normalizing plus low-temperature normalizing plus spheroidizing annealing plus high-temperature tempering process is adopted, and air cooling is carried out. The adopted post-forging heat treatment process disclosed by the invention is characterized in that: crystalline grains are thinned; the structure is regulated, so that the network structure is removed; the carbon segregation ofthe upper part of the large steel ingot is considerable, temperature higher than Ac1 is kept for a long time, consequently, part of carbide is remelted, the remaining unmelted carbide is spheroidized, and a granular pearlite structure is obtained during cooling; consequently, the structure toughness is high, and structure preparation is done for the next step of heat treatment; and fish eyes are prevented.

Owner:洛阳中创重型机械有限公司

Lycium ruthenicum pure powder tablets and preparation method thereof

InactiveCN108308613ARetain nutritional valueGood hygroscopicityGaseous food ingredientsFood shapingTabletingSilicon dioxide

The invention belongs to the field of health-care foods, and particularly relates to lycium ruthenicum pure powder tablets and a preparation method thereof. The lycium ruthenicum pure powder tablets consist of 80% by weight or above of lycium ruthenicum pure powder and 20% by weight or below of conventional auxiliary materials. The making method of the lycium ruthenicum pure powder tablets comprises the following steps of firstly, crushing and screening the dried lycium ruthenicum; then uniformly mixing the main materials with the auxiliary materials in formula proportion, performing screening, performing wet granulation, and rapidly drying wet granules; and performing screening, granulation, adding lubricants of talcum powder and / or silicon dioxide, performing uniform mixing to obtain a mixture, and sending the mixture in a tablet press for tabletting. The lycium ruthenicum pure powder is tablettted, so that various nutrient values of the lycium ruthenicum are completely expressed. The making method is unique, the cost is low, the process flow in simple, and the making method is easy and convenient to operate.

Owner:深圳金瑞丰生物科技有限公司

Post-forging heat treatment method for large forgings of hot wall hydrogenation reactor

ActiveCN103849745BShorten the production cycleReduce manufacturing costFurnace typesHeat treatment process controlHeating furnaceWater cooling

The invention discloses a post-forging thermal treatment method for a heavy forging of a hot-wall hydrogenation reactor. The method is used for performing post-forging thermal treatment on the heavy forging, which is made of 12Cr2Mo1 and is 1,500-4,500 millimeters in outer diameter and 100-300 millimeters in wall thickness, of the hot-wall hydrogenation reactor. The post-forging thermal treatment method is characterized by comprising the following steps: I, controlling the final forging temperature, performing air cooling until the surface temperature of a forging is 250-350 DEG C, and feeding the forging into a heating furnace; II, raising the temperature of the heating furnace to 600-700 DEG C at a speed of less than or equal to 80 DEG C per hour, and preserving heat; III, raising the temperature of the heating furnace to 880-930 DEG C at the maximum power of the heating furnace, and preserving heat; IV, discharging a workpiece, and cooling the workpiece in water until the surface temperature of the workpiece is lower than or equal to 80 DEG C; V, feeding the workpiece into the heating furnace for later use, raising the cavity temperature of the heating furnace to 650-720 DEG C at a speed of less than or equal to 80 DEG C per hour, preserving heat, discharging and performing air cooling. By adopting the post-forging thermal treatment method, the performance is preserved in a post-forging thermal treatment process while the quality of the forging is ensured, the production period of the forging of the hot-wall hydrogenation reactor is effectively shortened, and the cost is reduced.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

A protection material and a fabrication method of metal-plastic composite part

InactiveCN102848657AImprove high temperature resistanceGood heat insulationSynthetic resin layered productsLaminationHot meltCeramic materials

The invention provides a protection material, which comprises a high-temperature-resistant protection film and dustless cloth. The high-temperature-resistant protection film is bonded to the dustless cloth. The invention also provides the fabrication method of a metal-plastic composite part, which includes (1) providing a metal part and a plastic part, and pre-pressing hot-melt adhesive between the metal part and the plastic part; (2) placing the metal member above the plastic part which is provided with a region exposed from the metal part, and arranging a protection material on the metal part, wherein the protection material covers the region of the plastic part exposed from the metal part and the protection material adopts the above protection material; and (3) performing hot-melting to the metal part and the plastic part, cooling, and removing the protection material, to obtain the metal-plastic composite part. The inventive protection material has good high temperature resistance and heat-insulating property, can effectively protect the exposed part of the plastic part, to prevent scald, and improves the adhesive melting effect.

Owner:BYD CO LTD

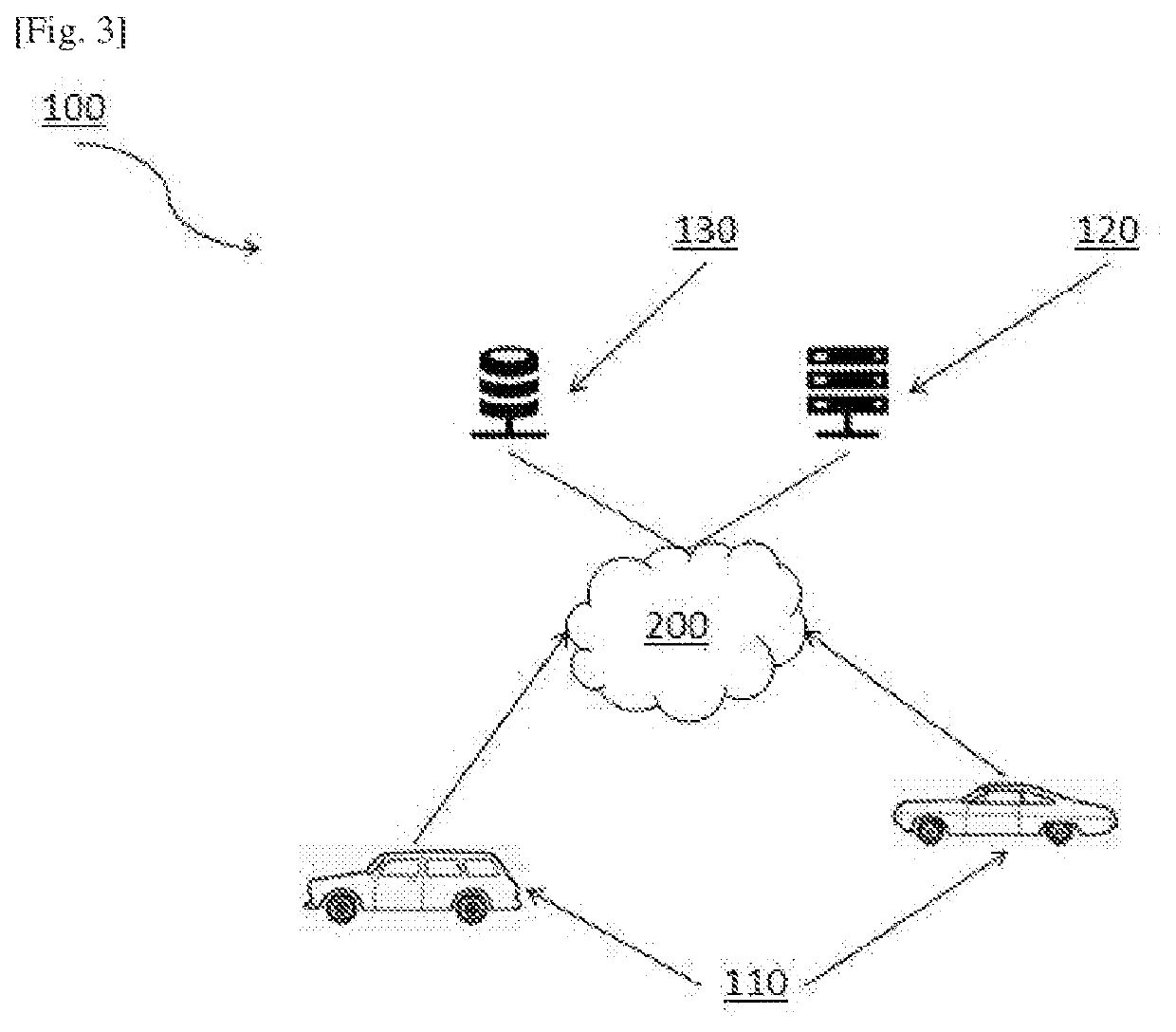

Method for predicting a signal and/or service quality and associated device

PendingUS20220217557A1Quality improvementMaximize service qualityAssess restrictionConnection managementQuality of serviceSignal quality

A method for predicting at least one parameter representative of a signal quality and / or service quality liable to be delivered to a device when it is connected to one radiofrequency antenna among a plurality of antennas that are configured to establish a connection with said device. The method includes: obtaining at least one parameter of decrease in the signal and / or service quality, predicting at least one parameter representative of a signal and / or service quality by applying at least one prediction model configured to predict at least one parameter representative of a signal quality and / or service quality, on the basis of an estimated parameter of decrease in the signal and / or service quality, and of an indication of a moment and of a position of the device for which the prediction must be carried out, the prediction model having been trained beforehand via supervised learning on a training database.

Owner:CONTINENTAL AUTOMOTIVE GMBH

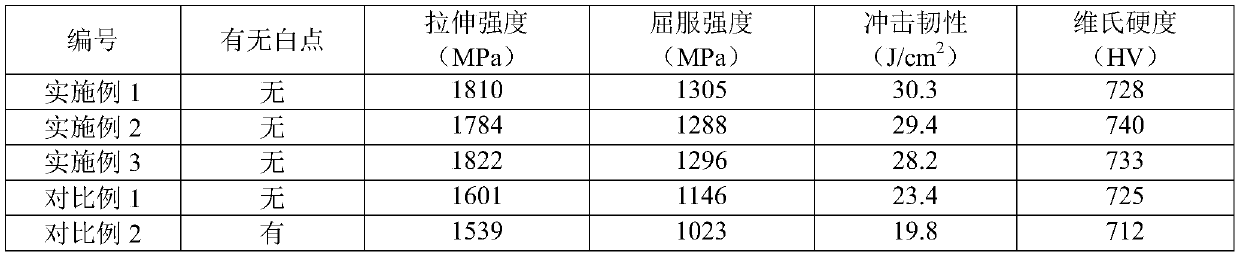

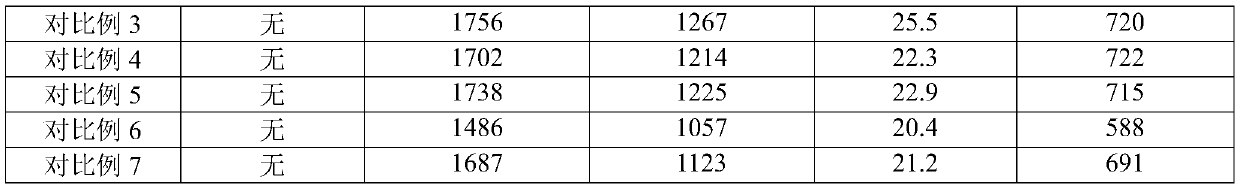

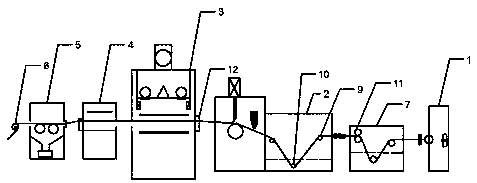

Smelting and forging method for high-toughness alloy steel forged piece

ActiveCN110343811AImprove performanceSave raw materialsProcess efficiency improvementElectric arc furnaceSlag

The invention discloses a smelting and forging method for a high-toughness alloy steel forged piece. The smelting and forging method for the high-toughness alloy steel forged piece comprises the following steps: placing waste steel in an electric-arc furnace and smelting, and adding Mo; smelting 80%-90% of a furnace burden, and adding slag for covering; completely smelting the furnace burden intomolten steel and then adding a slow-release deoxidizer; slagging off, forming new slag and then adding Cr, W and Mn into the molten steel, and adding a precipitation deoxidizer; adding a diffusion deoxidizer into the surface of the slag in batches, meanwhile, blowing an inert gas, stirring and refining, and adding V into the molten steel before the refining is concluded; supplementing Si and Co into the molten steel, and continuing to smelt for 10-15min; adding a final deoxidizer and deoxidizing, then entering a vacuum degassing furnace, blowing argon in a vacuum and carrying out degassing treatment, then tapping and pouring, carrying out die release, and then obtaining a steel ingot; feeding the steel ingot into a heating furnace, and obtaining a finished forged piece through three heating numbers; and filling the finished forged piece into an electric furnace and annealing. According to the smelting and forging method for the high-toughness alloy steel forged piece, the generation ofwhite points in the forged piece is avoided, and high mechanical property of the forged piece is achieved through reasonable smelting, forged piece and annealing processes.

Owner:浙江精瑞工模具有限公司

Front and back penetration printing technology for tabby hand towel made of pure cotton

The invention discloses a front and back penetration printing technology for a tabby hand towel made of pure cotton. A printing paste formula comprises components as follows: 40%-45% of reactive dye, 1.5%-3.0% of sodium bicarbonate, 0.5%-1.0% of reserve salt S, 5%-10% of urea, 30%-35% of seeweed starch, 10%-15% of Acrapon A paste and the balance of water. The Acrapon A paste is added to color paste, uniform paste penetration is facilitated, and the white point phenomenon on the back of printed fabric is avoided; and the fixation rate of the dye is high, the reaction rate is high, diffusibility, permeability and leveldyeing property are good, the front and back penetration printing technology is insensitive to the color fixation condition, colored light is stable, and good detergency is achieved.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

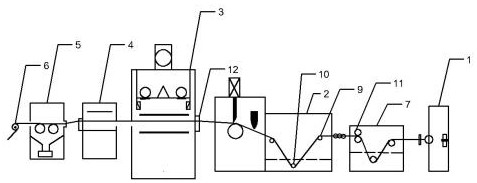

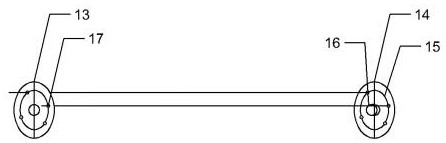

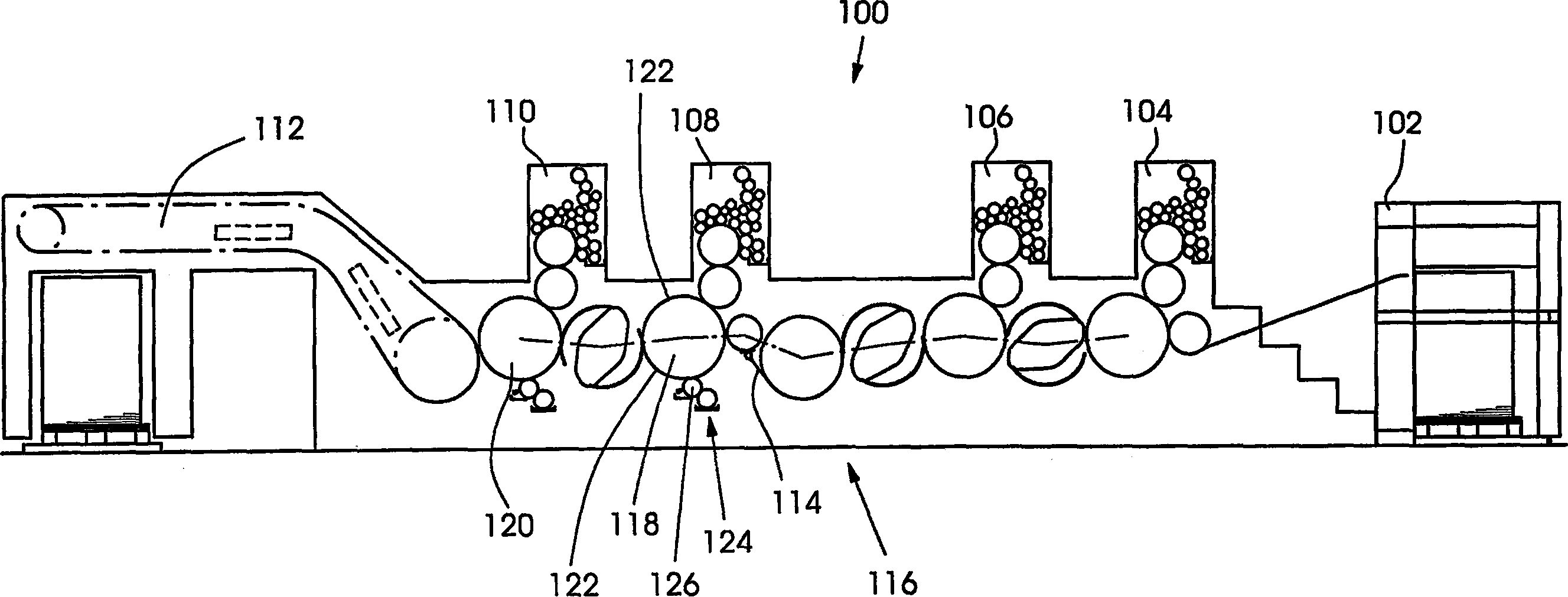

Yarn flocking assembly line process and continuous production equipment

The invention relates to a flocking process and production equipment, in particular to a yarn flocking assembly line process and continuous production equipment. The yarn flocking assembly line process comprises the steps of feeding, pretreatment, gluing, flocking, drying, brushing and winding, and adding a yarn rotating device, so that the circumferential surface of the yarn is adhered uniformlywith relatively dense fluff, wherein in the pretreatment process, the hairiness of the surface of a substrate is cleaned through a decontamination solution, an adhesive can be sprayed uniformly in a later procedure, and a phenomenon of a white point on the flocking product is prevented; and the product prepared by using the yarn flocking process and the production equipment is stable in performance and has relatively high use value.

Owner:浙江久大纺织科技有限公司

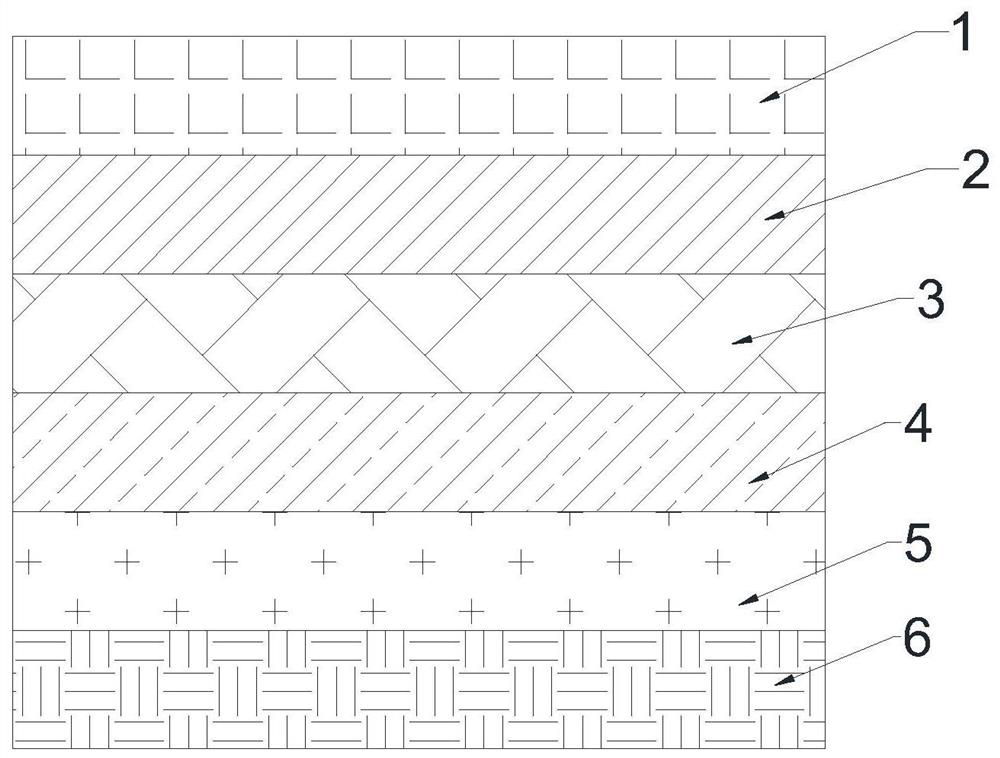

Heat transfer printing hot stamping foil and anti-counterfeit heat transfer printing process

InactiveCN113263847AImprove stabilityUniform tensionDecorative surface effectsPattern printingHot stampingPolyester

The invention discloses a heat transfer printing hot stamping foil and an anti-counterfeit heat transfer printing process. The heat transfer printing hot stamping foil comprises a base film layer and a hot melting adhesive powder layer, and a transparent release layer, a protection layer, an ink layer and a fine aluminum plating layer are sequentially arranged between the base film layer and the hot melting adhesive powder layer. The base film layer is composed of a PET polyester film. Paraffin is adopted as a release agent in the transparent release layer. The protection layer is made of waterborne polyurethane resin. The ink layer is composed of a synthetic resin layer and a dye layer, and the color of the hot stamping foil is formed. The fine aluminum plating layer reflects light, so that the ink layer presents metallic luster. The hot melting adhesive powder layer is made of hot melting plastic. According to the heat transfer printing hot stamping foil, the brightness of the hot stamping foil after hot stamping can be enhanced, the hot stamping foil has a bright effect and a good anti-counterfeiting effect, and the ink layer has the anti-counterfeiting effect of metallic luster. The anti-counterfeit heat transfer printing process is high in working efficiency, interruption of all materials during printing can be effectively prevented, and printed sheets are protected against white dots, dirt and streaks.

Owner:安徽金彩防伪技术有限公司

A kind of forging process of gcr15 roller sleeve

ActiveCN106064221BExtendedIncrease the lengthMetal-working apparatusEngine componentsPunchingMachining process

The invention aims to provide a forging process for a GCr15 roller sleeve. The forging process comprises the steps that firstly, a forge piece is heated; secondly, the roller sleeve is subjected to four-time heating forming forging, specifically, four-time heating forming is adopted as the forging technique of forging of the GCr15 roller sleeve, namely ejection and upsetting, punching, drawing-out and round rolling reshaping; and thirdly, annealing and cooling are conducted. The machining process is improved, so that the length of drawing-out and punching during forging is prolonged, straightening of the forge piece during punching forging is improved, the uniformity of the wall thickness is improved, white dots in the sleeve are prevented, and the performance of the forge piece is improved.

Owner:ANHUI RUIJIE FORGING

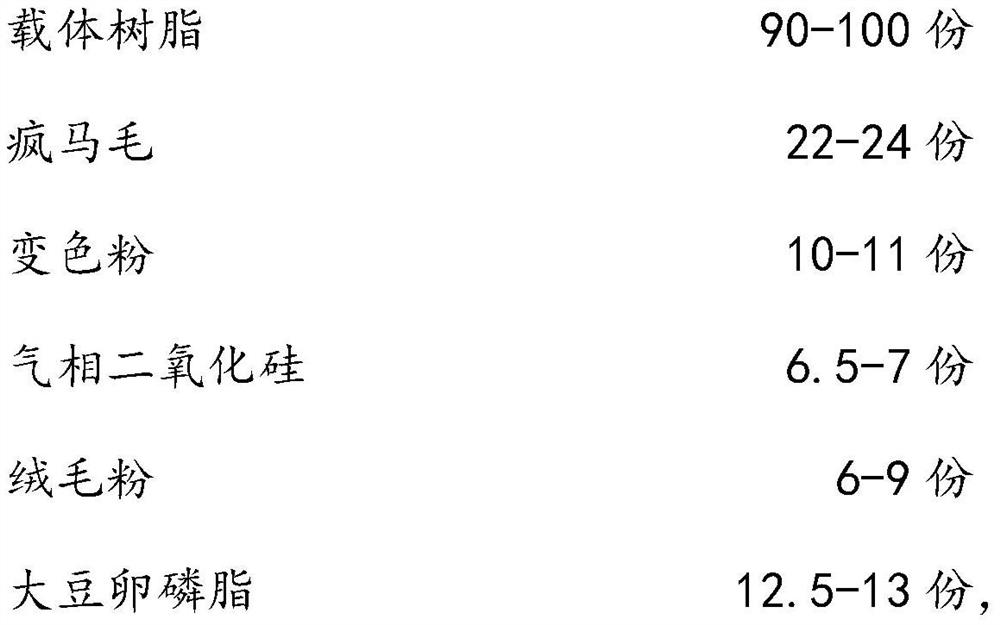

Color-developing PU leather crazy horse resin and preparation method thereof

The invention relates to color-developing PU leather crazy horse resin and a preparation method thereof. The color-developing PU leather crazy horse resin comprises a strong solvent, a weak solvent, carrier resin, crazy horse hairs, color-changing powder, fumed silica, fluff powder and soybean lecithin, and a resin carrier comprises 30-modulus resin, 50-modulus resin and 80-modulus resin. The preparation method comprises the following steps of: (1) preparing slurry: uniformly stirring a strong solvent, a weak solvent and carrier resin to obtain the slurry; (2) preparing a semi-finished product: stirring and mixing color-changing powder, fumed silica, fluff powder and the slurry, grinding by a grinder and filtering to obtain the semi-finished product; and (3) preparing the crazy horse resin: adding soybean lecithin and crazy horse hairs into the semi-finished product in proportion to obtain the crazy horse resin. The obtained crazy horse resin has stronger color development property andstronger velvet feeling.

Owner:QINGYUAN BANGTAI NEW MATERIAL CO LTD

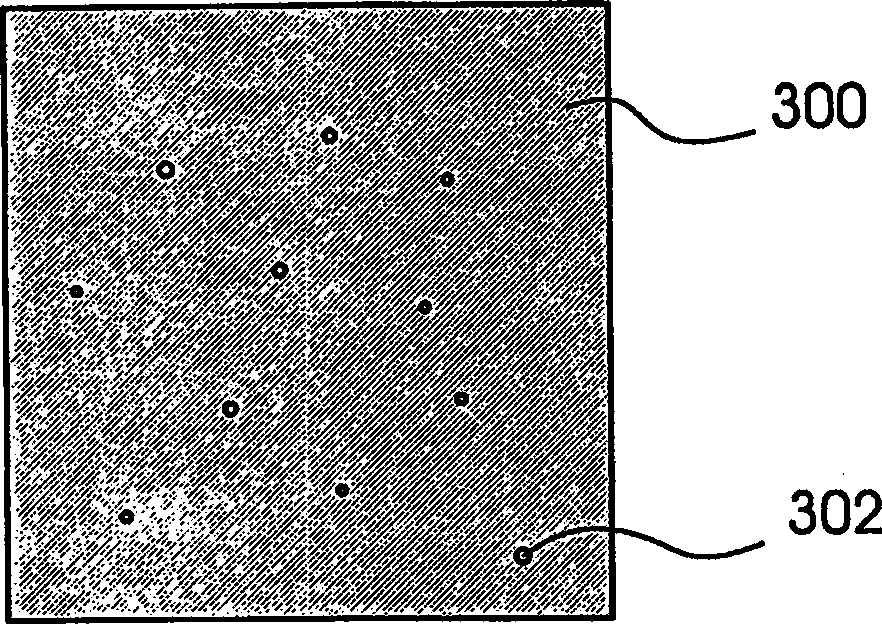

Preparation method of textured structure of crystalline silicon solar cell

ActiveCN106340550BAdvantages of Photoelectric Conversion EfficiencyImprove conversion efficiencyPolycrystalline material growthAfter-treatment detailsPorous layerPre treatment

The invention discloses a preparation method for texture structure of crystalline silicon solar cell, comprising the following steps: 1) placing a silicon wafer into an alkaline solution and removing the damage layer on the silicon wafer surface; 2) placing the silicon wafer in an acidic solution and reducing the structural differences between the different crystal grains; 3) forming a porous layer structure on the surface of the silicon wafer obtained from step 2; and 4) conducting surface etching with a first chemical etching solution for the texture structure of crystalline silicon solar cell. According to the method of the invention, the surface of the silicon wafer undergoes a pretreatment first, that is, the removal of the damage layer in alkali solution, and then proceeds to the homogeneous corrosion in the acid solution. The cooperated use of the two finally forms the surface structure suitable for preparing the nanometer texture, which is obviously advantageous in terms of photoelectric conversion efficiency.

Owner:CSI CELLS CO LTD

A yarn flocking flow process and continuous production equipment

The invention relates to a flocking process and production equipment, in particular to a yarn flocking flow process and continuous production equipment. The yarn flocking flow process includes the steps of feeding, pretreatment, gluing, flocking, drying, brushing and winding, and adding a yarn rotating device to make the circumferential surface of the yarn adhere evenly and densely. In the process, the hairiness on the surface of the substrate is cleaned by the decontamination solution, which facilitates the uniform spraying of the adhesive in the subsequent process and prevents white spots on the flocking products; the products prepared by using the yarn flocking process and production equipment have stable performance and relatively high High use value.

Owner:浙江久大纺织科技有限公司

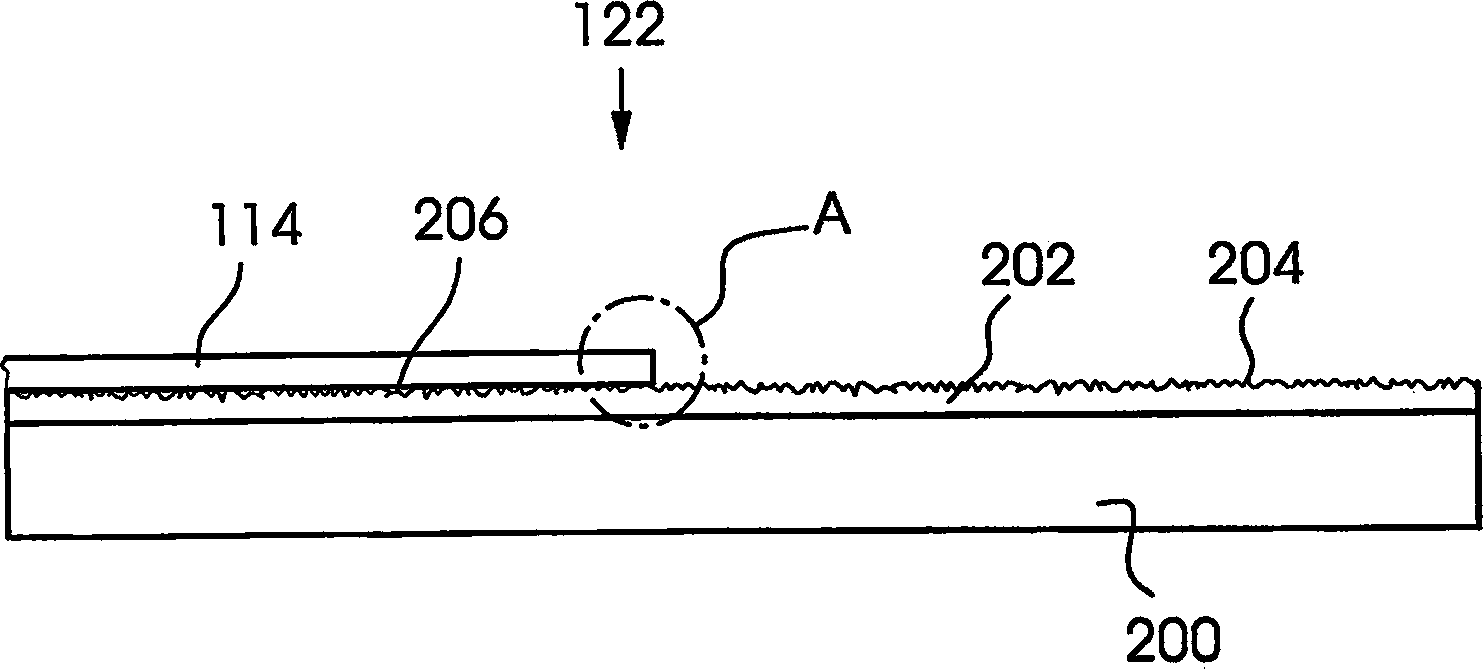

Surface of guiding printed substrate with micro-protuberance

InactiveCN1872543AImproved print image qualityAvoid "white spots"Cylinder pressesPlaten pressesPrinting inkEngineering

A printing-material-carrying surface, having micro-elevations which make contact with a printing material provided with printing ink, and having a guide printing is at least partly provided, preferably substantially only at peaks of the micro-elevations, with a fluid additive to improve print quality, in particular in recto and verso printing. The fluid additive, in particular a liquid additive diluting the printing ink and / or delaying and / or slowing the drying of the printing ink, is at least partly transferred to the printing material by the surface.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Anti-H2S stress corrosion high pressure resistant forgings and method for manufacturing same

Owner:宝武特种冶金有限公司

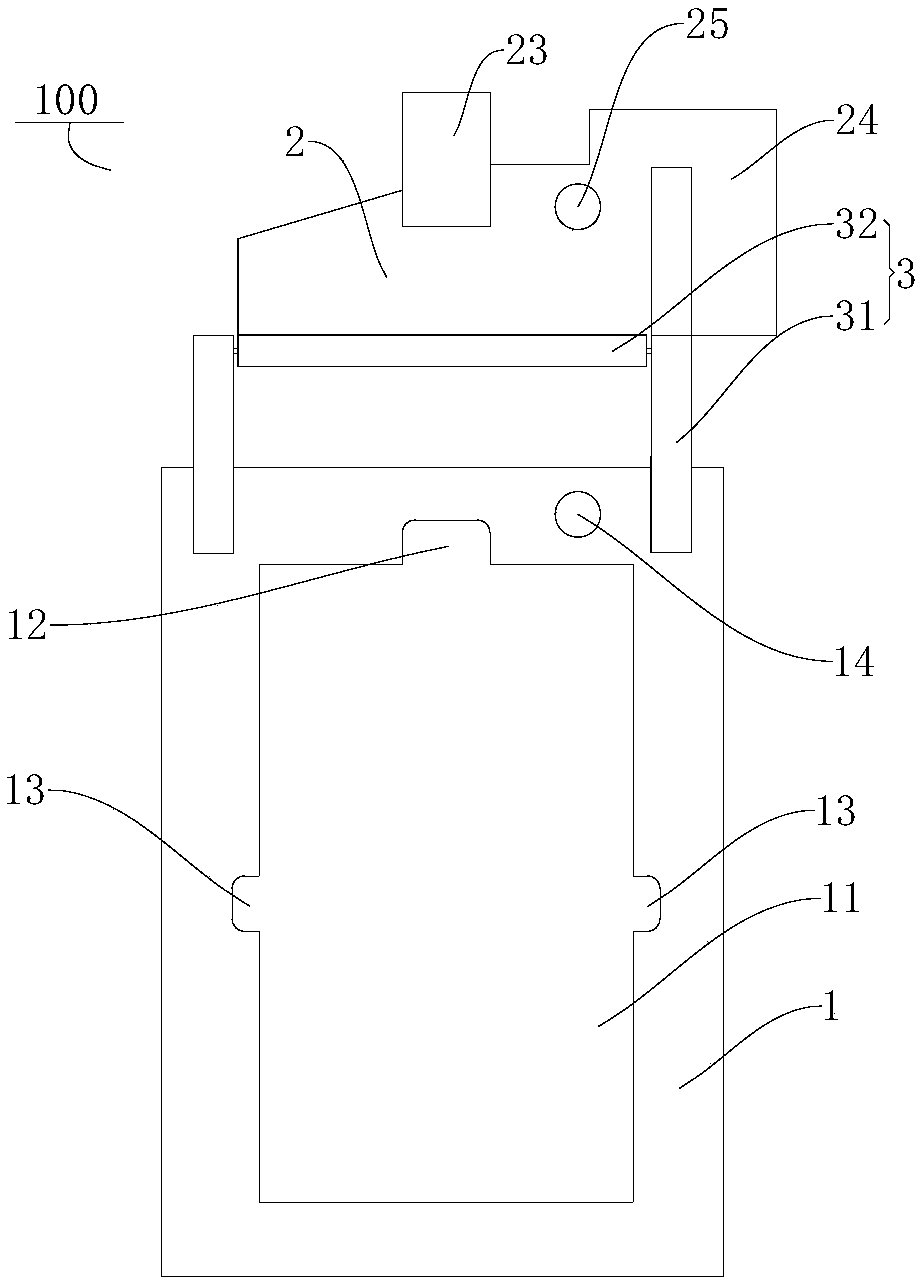

Activating jig for screen of electronic device

ActiveCN109064887AAvoid white spotsAvoid problemsWork holdersIdentification meansPulp and paper industryOpen hole

The invention discloses an activating jig for a screen of an electronic device. An open hole is formed in the screen of the electronic device, and release paper is arranged on the inner surface of thescreen, and covers the open hole; the activating jig comprises a lower mold and a cover plate, wherein a containing groove for containing the screen is formed in the lower mold; the cover plate is movably arranged on the lower mold, the cover plate can move between a first position shielding a part of the containing groove and a second position exposing out of the containing groove, and when thecover plate is located at the first position, the cover plate covers the release paper. According to the activating jig, the cover plate is arranged on the lower mold, and can move between the first position shielding a part of the containing groove and the second position exposing out of the containing groove, when the cover plate is located at the first position, the cover plate covers the release paper, and when the activating jig is used for activating, the cover plate is located at the first position, and the cover plate covers the release paper on the screen; it is avoided that the release paper is blown during activating, and white points, broken filaments, squalidity and the like appear at the open hole of the screen.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

coms image sensor and its manufacturing method

ActiveCN106449683BAvoid white spotsQuality improvementSolid-state devicesDiodePartial thicknessPhotoresist

The invention provides a COMS image sensor and a manufacturing method thereof. When N-type or P-type source-drain injection is carried out on a logic region, a first photoresist firstly coats a semiconductor substrate; a source-drain region which needs to be subjected to source-drain injection is exposed through exposure and development; and a partial-thickness dielectric layer is etched and N-type or P-type source-drain injection is carried out. The dielectric layer in a protective pixel region of the first photoresist is not etched, and the dielectric layer prevents ion injection from damaging the semiconductor substrate on the surface of a photosensitive diode when the ion injection is carried out in a photosensitive diode region in the pixel region, so that white dots, caused by a semiconductor damage, of the COMS image sensor are avoided; the quality of the COMS image sensor is improved; the method is simple and convenient to operate; and the performance of the COMS image sensor is not affected.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com