Smelting and forging method for high-toughness alloy steel forged piece

An alloy steel, high-toughness technology, applied in the direction of improving process efficiency, can solve the problems of easy generation of white spots, affecting the performance of forgings, etc., and achieve the effect of realizing waste utilization, improving the utilization rate of arc heat, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

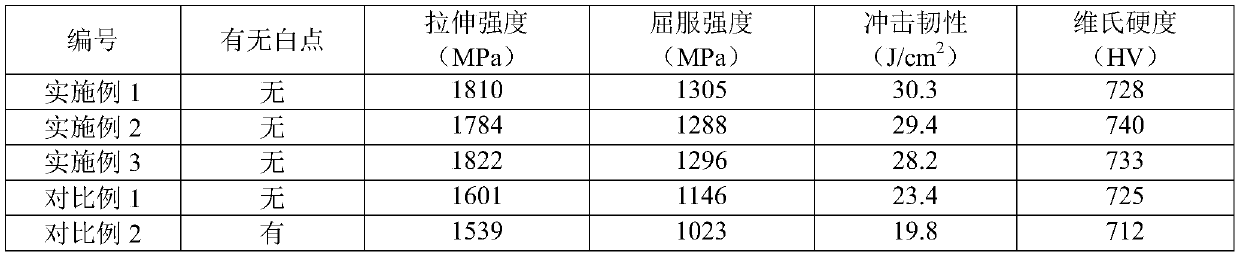

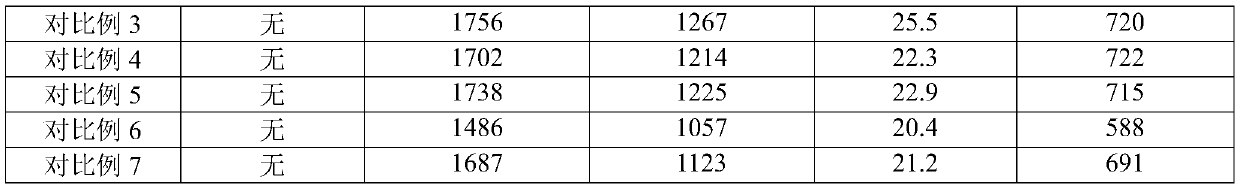

Examples

Embodiment 1

[0045] (1) Put 28.5t of low-sulfur phosphorus scrap steel (with iron content ≥ 98wt%, C content ≤ 0.2wt%, sulfur and phosphorus content ≤ 0.05wt% respectively) into the electric arc furnace, melt at 1500°C with electricity, add carbon Add carbon with agent to make the carbon content reach 0.8%; add 765kg Mo during the melting period;

[0046] (2) After the furnace charge is melted by 90%, add lime and fluorite to cover the furnace charge according to the consumption of 15kg / t molten steel and 5kg / t molten steel;

[0047] (3) After the charge is fully melted, add a slow-release deoxidizer to the slag for pre-deoxidation according to the amount of 3kg / t molten steel. The preparation method of the slow-release deoxidizer is as follows: breaking and processing polyethylene plastic into polyethylene plastic pellets, and then mixing each group according to the ratio of Al 35wt%, lightly burned magnesium powder 10wt%, bauxite 19wt%, and polyethylene plastic pellets 36wt%. Separately...

Embodiment 2

[0055] (1) Add 28.5t of low-sulfur phosphorus scrap steel (with iron content ≥ 98wt%, C content ≤ 0.2wt%, sulfur and phosphorus content ≤ 0.05wt%) into the electric arc furnace, and melt at 1300°C with electricity, adding carbon Add carbon with agent to make the carbon content reach 0.72%; add 615kg Mo during the melting period;

[0056] (2) After the charge is melted by 80%, add lime and fluorite to cover the charge according to the amount of 12kg / t molten steel and 4kg / t molten steel;

[0057] (3) After the charge is fully melted, add a slow-release deoxidizer to the slag for pre-deoxidation at an amount of 2kg / t molten steel. The preparation method of the slow-release deoxidizer is as follows: breaking and processing polyethylene plastic into polyethylene plastic pellets, and then according to the proportion of Al 32wt%, lightly burned magnesium powder 9wt%, bauxite 20wt%, and polyethylene plastic pellets 39wt%. Separately mixed, hot-pressed into pellets with a particle si...

Embodiment 3

[0065] (1) Add 28.5t of low-sulfur phosphorus scrap steel (with iron content ≥ 98wt%, C content ≤ 0.2wt%, sulfur and phosphorus content ≤ 0.05wt%) into the electric arc furnace, melt at 1400°C with electricity, and add carbon Add carbon with agent to make the carbon content reach 0.8%; add 690kg Mo during the melting period;

[0066] (2) After the charge is melted by 90%, add lime and fluorite to cover the charge according to the amount of 10.4kg / t molten steel and 5.6kg / t molten steel;

[0067] (3) After the charge is fully melted, add a slow-release deoxidizer to the slag for pre-deoxidation according to the amount of 4kg / t molten steel. The preparation method of the slow-release deoxidizer is as follows: breaking and processing polyethylene plastic into polyethylene plastic pellets, and then according to the proportion of Al 36wt%, lightly burned magnesium powder 11wt%, bauxite 17wt%, and polyethylene plastic pellets 36wt%. Separately mix, hot press particle size into pell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com