All-black solar photovoltaic module and manufacturing method thereof

A technology of solar photovoltaic and manufacturing method, applied in the field of all-black solar photovoltaic modules and their manufacturing, can solve the problems of expanding the scope of white spot glue deficiency, failing to reach full blackness, hidden quality problems, etc., to achieve optimal product performance and improve quality , the effect of large output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

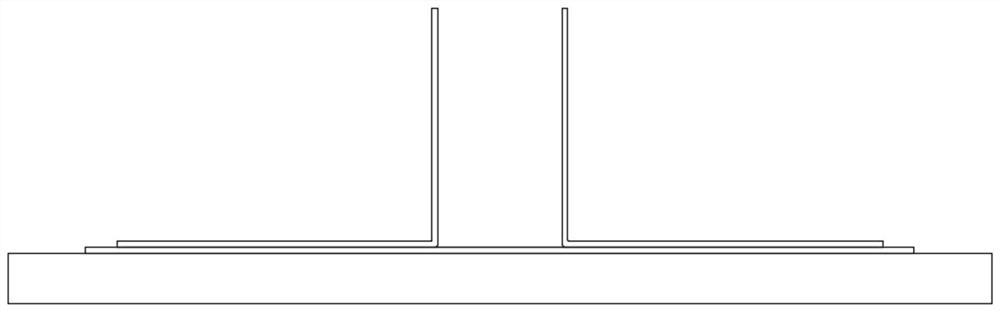

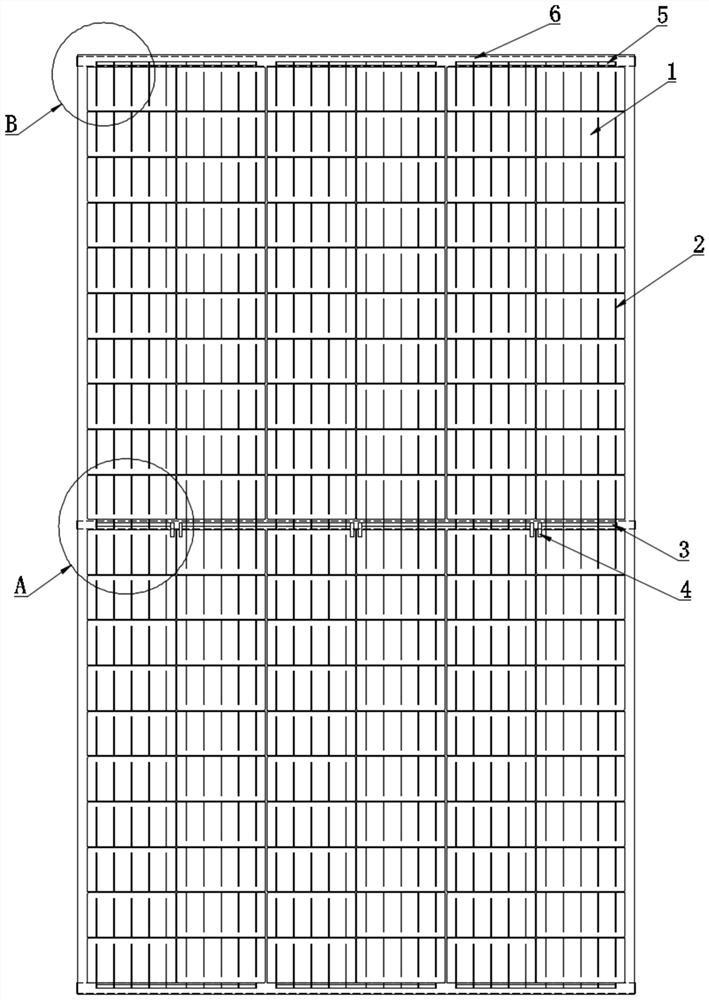

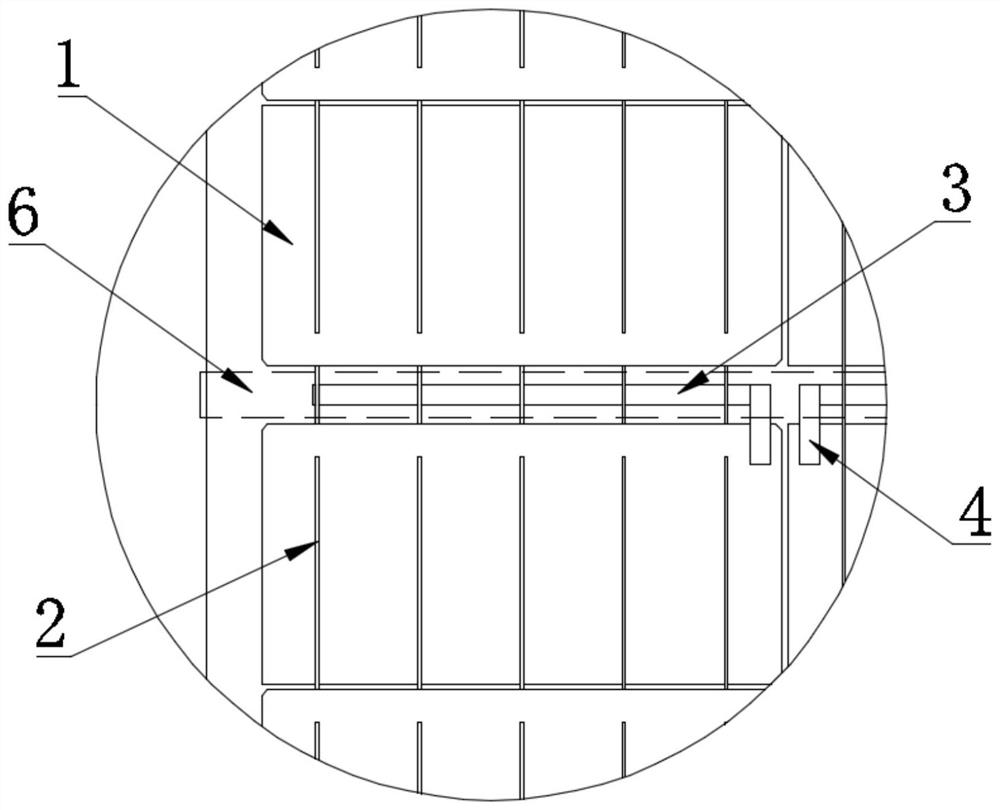

[0065] The all-black solar photovoltaic module of this embodiment includes, from top to bottom, a light-transmitting layer, a first EVA film layer, a cell array, a second EVA film layer, and a back sheet. See Figure 2 to Figure 4 , the battery square array includes a plurality of battery slices 1 arranged in a matrix, and each column of battery slices 1 is sequentially connected by interconnecting strips 2 to form a battery string. There are six battery strings in the battery square array. There is a gap between the two battery sheets 1 in the middle of each battery string. The interconnection strips 2 in the gap are connected by the first bus bar 3, and the first bus bar 3 is connected with the second bus bar 4 perpendicular to the first bus bar 3 in the horizontal direction and penetrating the backplane. The interconnection strips 2 at both ends of the battery strings are connected through the third bus bar 5 . In order to obtain the maximum output power and optimize the...

Embodiment 2

[0078] This embodiment is basically the same as Embodiment 1, except that the angle between the end of the second bus bar 4 inclined to the back plate and the back plate is 14°.

Embodiment 3

[0080] This embodiment is basically the same as Embodiment 1, except that the angle between the end of the second bus bar 4 inclined to the backplane and the backplane is 16°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com