A protection material and a fabrication method of metal-plastic composite part

A technology for protecting materials and production methods, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of deformation of plastic parts, scald plastic parts, etc., to prevent burns, good protection, and good prevention Effects of electrostatic performance and dust removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

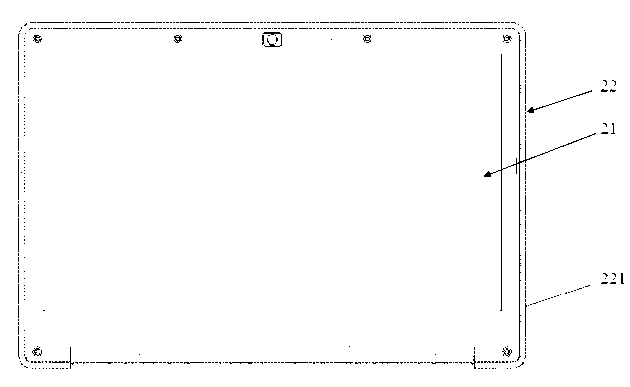

[0038] This embodiment 1 is used to make such as figure 1 As shown in the metal-plastic composite, the metal-plastic composite includes a metal panel 21 and a plastic shell 22, and the manufacturing method of the metal-plastic composite includes the following steps:

[0039] 1) Provide the metal panel 21 and the plastic shell 22. Put the metal panel 21 on the pre-pressing machine to pre-press the hot melt adhesive. for 3M 725;

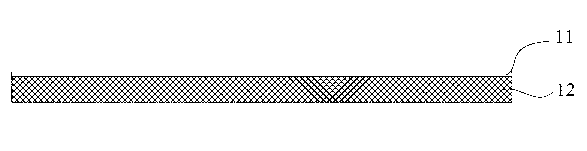

[0040] 2) Install protective materials: fix the plastic shell 22 and the metal panel 21 on the lower mold, place the metal panel 21 above the plastic shell 22, the peripheral edge 221 of the plastic shell 22 exposes the metal panel 1, and the metal panel 21 Set the protective material on, such as figure 2 As shown, the protective material includes a dust-free cloth 12 and a high-temperature-resistant protective film 11 bonded to the dust-free cloth 12, so that the protective material completely covers the area where the plastic shell 22 exposes the ...

Embodiment 2

[0059] This embodiment 2 is used to make a metal-plastic composite, the structure of the metal-plastic composite is basically the same as the metal-plastic composite in embodiment 1, including a metal panel and a plastic shell, and the manufacturing method of the metal-plastic composite includes the following The above steps:

[0060] 1) Provide a metal panel and a plastic shell. Put the metal panel on the pre-pressing machine to pre-press the hot melt adhesive. Set the pre-pressing pressure to 0.6 Mpa, the temperature to 70°C, the pre-pressing time to 10S, and the hot-melt adhesive to be Sika Pa H192;

[0061] 2) Install protective material: fix the plastic shell and metal panel on the lower mold, place the metal panel above the plastic shell, and the periphery of the plastic shell exposes the metal panel; set protective material on the metal panel, the protective The material includes a dust-free cloth and a high-temperature-resistant protective film bonded to the dust-free...

Embodiment 3

[0066] This embodiment is used to make a metal-plastic composite, the metal-plastic composite has basically the same structure as the metal-plastic composite in Example 1, including a metal panel and a plastic shell, and the manufacturing method of the metal-plastic composite includes the following step:

[0067] 1) Provide a metal panel and a plastic shell, put the metal panel on the pre-pressing machine to pre-press the hot melt adhesive, set the pre-pressing pressure to 0.3Mpa, the temperature to 100°C, the pre-pressing time to 5S, and the hot-melt adhesive to TESA8475;

[0068]2) Install protective material: fix the plastic shell and metal panel on the lower mold, place the metal panel above the plastic shell, and the periphery of the plastic shell exposes the metal panel; set protective material on the metal panel, the protective The material includes a dust-free cloth and a high-temperature-resistant protective film bonded to the dust-free cloth, so that the protective m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com