Flake prevention control method for age hardening type plastic mold steel

A plastic mold steel and control method technology, applied in the field of metal heat treatment, can solve the problems of not being able to completely eliminate white spots, long annealing time, and large energy consumption, so as to avoid white spot defects, save production time, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 10Ni3MnCuAl finished flat steel, the size and shape are 126mm×810mm.

[0035] 1. Smelting: UHP+LF+VD smelting electrodes are used, and the hydrogen content of the steel is 1.8×10 -6 , electroslag furnace electroslag remelting Φ750mm electroslag ingot;

[0036] 2. Forging: One upsetting and one pulling production, forging ratio 7.6, upsetting ratio 2, final forging temperature 870°C;

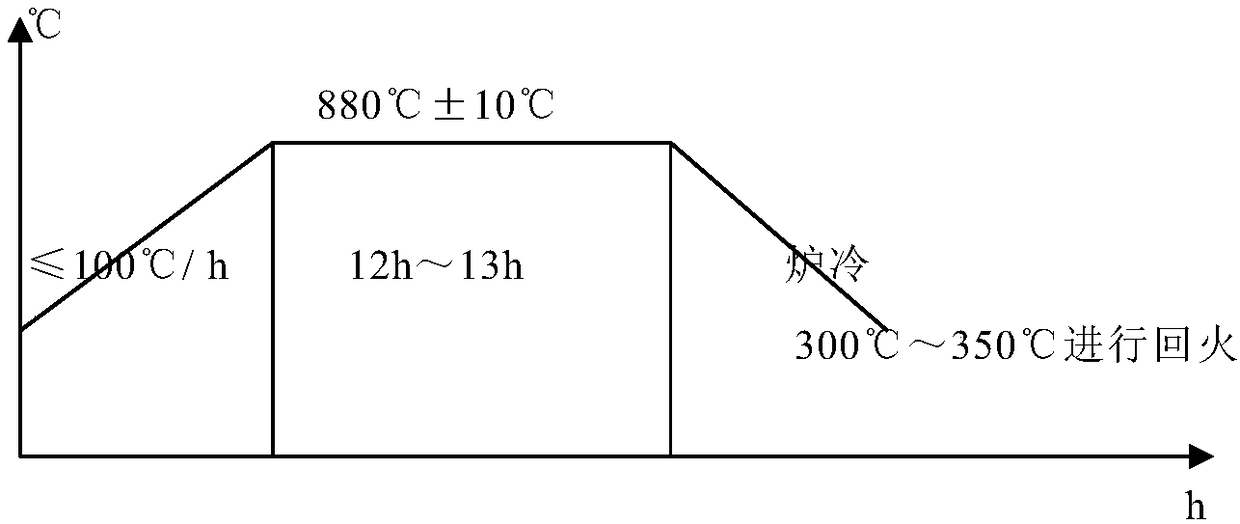

[0037] 3. Heat treatment: After forging, the finished flat steel is sent to heat treatment. The solid solution temperature is 880°C. After solid solution, it is tempered for a period of time. After heat preservation, it is cooled to 200°C with the furnace and released from the furnace.

[0038] 4. Physical and chemical test results

[0039] ① The results of chemical composition analysis of flat steel are shown in Table 1.

[0040] Table 1

[0041]

[0042] ②After heat treatment, the finished material shall be inspected according to SEP1921 ultrasonic flaw detection, and shall meet t...

Embodiment 2

[0045] 10Ni3MnCuAl finished flat steel, the size and shape are 180mm×680mm.

[0046] 1. Smelting: UHP+LF+VD smelting electrodes are used, and the hydrogen content of the steel is 2.0×10 -6 , electroslag furnace electroslag remelting Φ610mm electroslag ingot;

[0047] 2. Forging: Two upsetting and two drawing production, forging ratio 6.3, upsetting ratio 2, final forging temperature 870°C;

[0048] 3. Heat treatment: After forging, the finished flat steel is sent to heat treatment. The solid solution temperature is 880°C. After solid solution, it is tempered for a period of time. After heat preservation, it is cooled to 200°C with the furnace and released from the furnace.

[0049] 4. Physical and chemical test results

[0050] ① See Table 2 for the analysis results of the chemical composition of the flat steel.

[0051] Table 2

[0052]

[0053] ②After heat treatment, the finished material shall be inspected according to SEP1921 ultrasonic flaw detection, and shall mee...

Embodiment 3

[0056] 10Ni3MnCuAl finished flat steel, the size and shape are 280mm×605mm.

[0057] 1. Smelting: UHP+LF+VD smelting electrodes are used, and the hydrogen content of the steel is 1.6×10 -6 , electroslag furnace electroslag remelting Φ750mm electroslag ingot;

[0058]2. Forging: Two upsetting and two drawing production, forging ratio 6.8, upsetting ratio 2, final forging temperature 880°C;

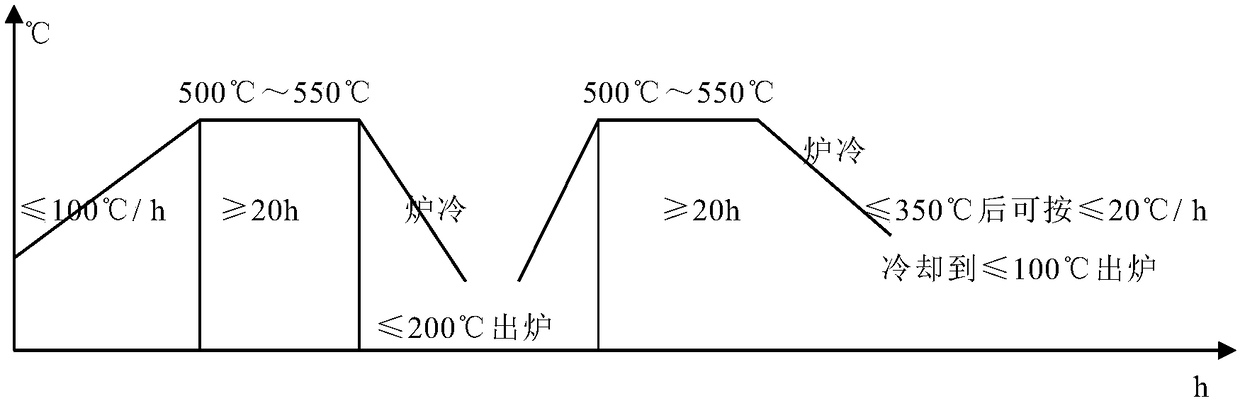

[0059] 3. Heat treatment: After forging, the finished flat steel is sent for heat treatment. The solid solution temperature is 880°C. After solid solution, two-stage tempering treatment is carried out. After heat preservation, it is cooled to 350°C with the furnace and then cooled to 100°C at 20°C / h to be released from the furnace.

[0060] 4. Physical and chemical test results

[0061] ① See Table 3 for the analysis results of the chemical composition of the flat steel.

[0062] table 3

[0063]

[0064] ②After heat treatment, the finished material shall be inspected according to SE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com