Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Act as a nucleating agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and preparation method of low-temperature co-fired ceramic material

The invention discloses a low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and a preparation method of the low-temperature co-fired ceramic material. The low-temperature co-fired ceramic material is prepared by sintering the following components in percentage by mass (100% in total): 35%-50% of CaO, 30%-45% of B2O3 and 15%-25% of SiO2. The prepared low-temperature co-fired ceramic material contains a large quantity of microfine crystal grains (CaSiO3) and a small amount of glass and is typical microcrystalline glass ceramic; and the low-temperature co-fired ceramic material is low in dielectric constant and extremely low in loss, good in matching rate with high-temperature conductive silver paste, good in panel flatness and good in comprehensive property, and the dielectric constant and the loss in multiple frequency bands are stable.

Owner:昆明云基新材料有限公司

Nanometer-material-compounded long-glass-fiber-reinforced polypropylene material and preparing method thereof

The invention relates to a nanometer-material-compounded long-glass-fiber-reinforced polypropylene material and a preparing method thereof. The reinforced polypropylene material is prepared from, by weight, 40%-85% of polypropylene, 10%-50% of long glass fibers, 1%-5% of nanometer-material master batches, 1%-5% of compatibilizing agent and 0.2%-1% of antioxidant. According to the preparing method, nanometer materials are prepared to master batches to participate in the molding technology, the nanometer-material particles are evenly dispersed in polypropylene melt, and the performance of the composite material is greatly improved. The nanometer-material-compounded long-glass-fiber-reinforced polypropylene material has the excellent mechanical performance, and meanwhile has the excellent warping resistance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

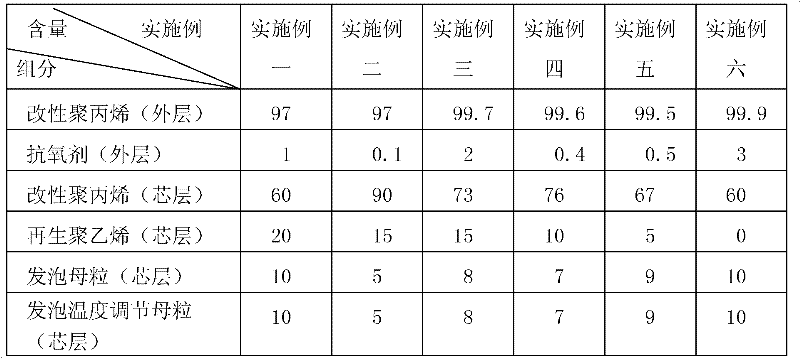

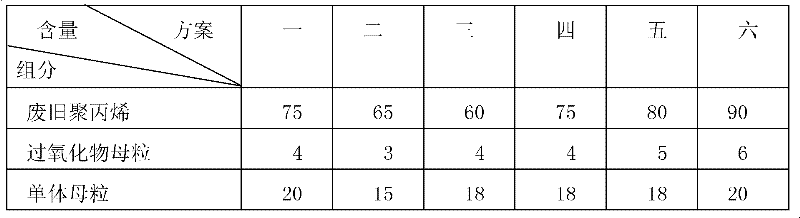

Waste polypropylene-modified foaming plate and manufacturing method thereof

ActiveCN102218879AImprove toughnessHigh strengthSynthetic resin layered productsFlat articlesMasterbatchPolypropylene

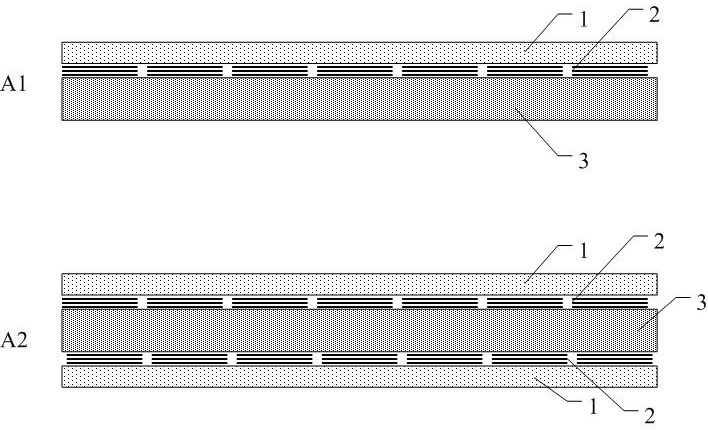

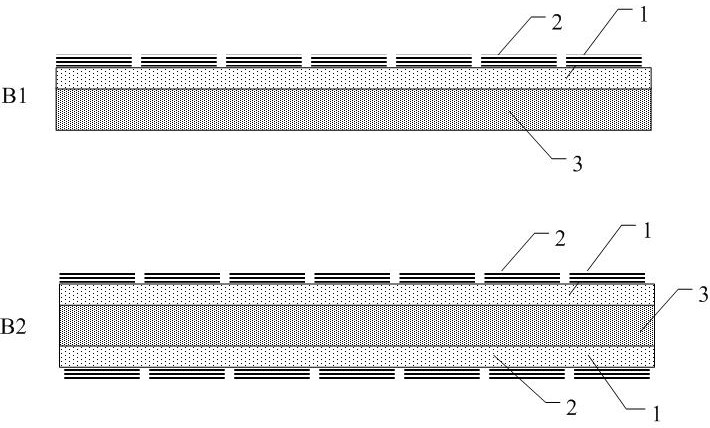

A waste polypropylene-modified foaming plate comprises a core foaming layer and an outer layer covering the upper and the lower surfaces of the core foaming layer; the outer layer is prepared by mixing the following components and performing melt extrusion, wherein the components comprises by weight: 97-99.9 parts of modified polypropylene, 0.1-3 parts of anti-oxidants; the core foaming layer is prepared by mixing the following components and performing melt foaming, wherein the components comprises by weight: 60-90 parts of modified polypropylene, 0-20 parts of regenerated polyethylene, 5-10parts of foaming masterbatches, and 5-10 parts of foaming temperature adjusting masterbatches; the manufacturing method of the foaming plate comprises the following steps: preparing activated inorganic powder, preparing a modified auxiliary agent peroxide masterbatch, preparing a modified auxiliary agent monomer masterbatch, preparing the foaming masterbatch, preparing the foaming temperature adjusting masterbatch, and preparing the core foaming plate. The waste polypropylene-modified foaming plate has high melt strength, and the manufacturing method has the characteristics of low production cost and no environment pollution.

Owner:NANTONG SUDONG NEW EXTERNAL WALL INSULATION BOARDCO

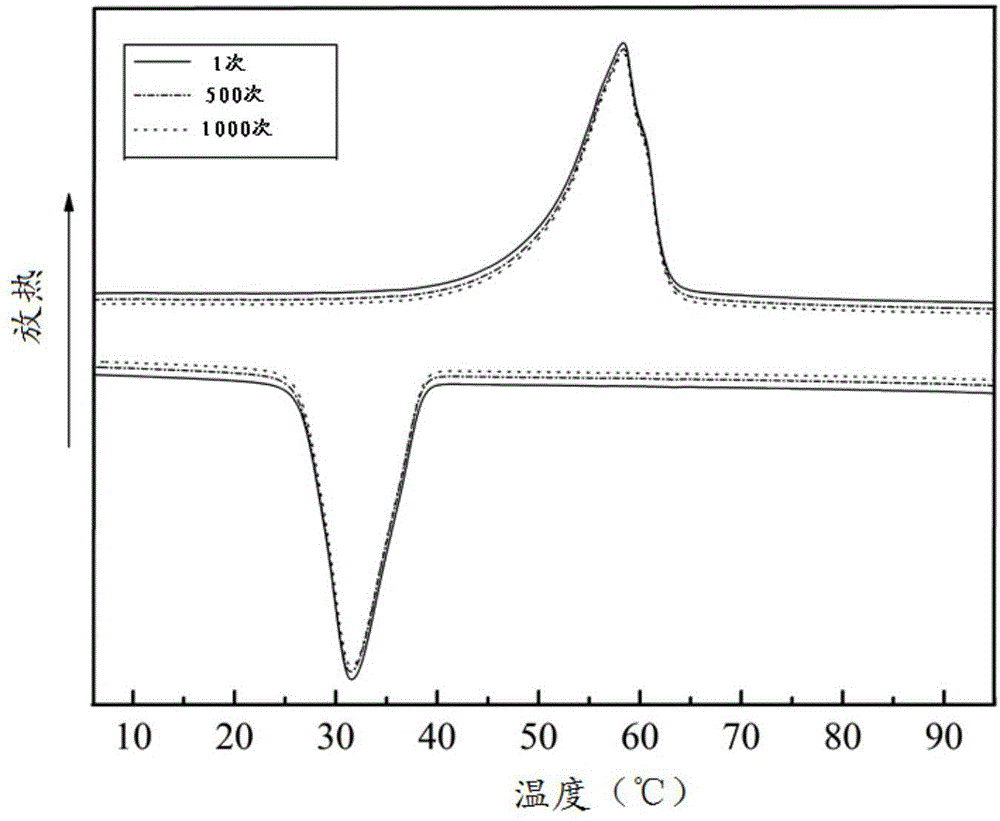

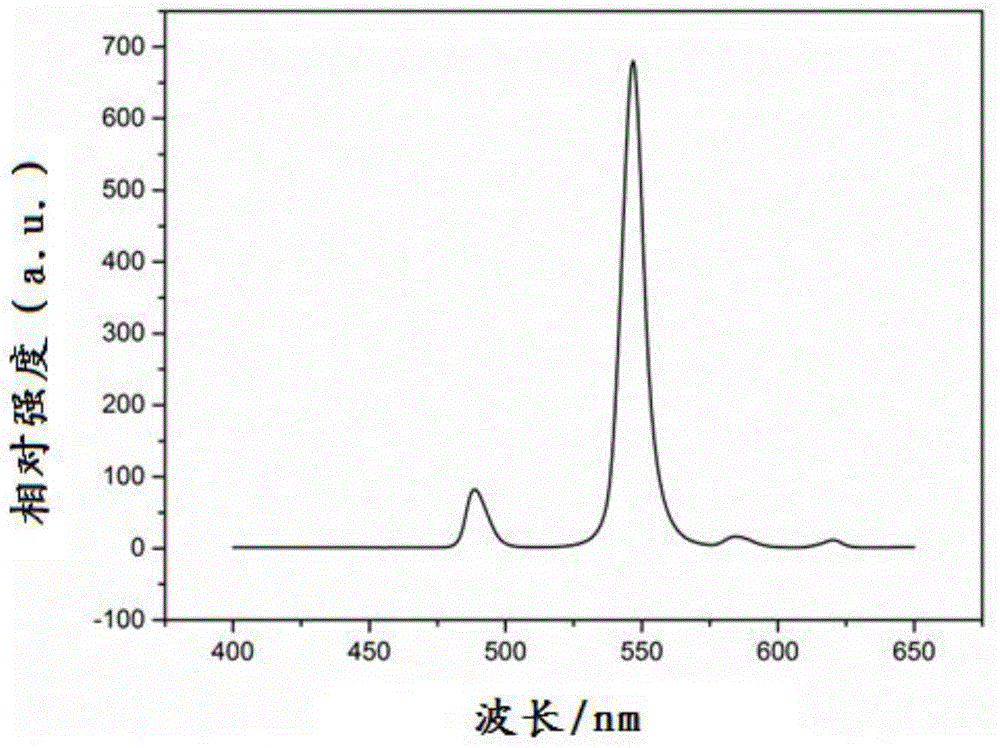

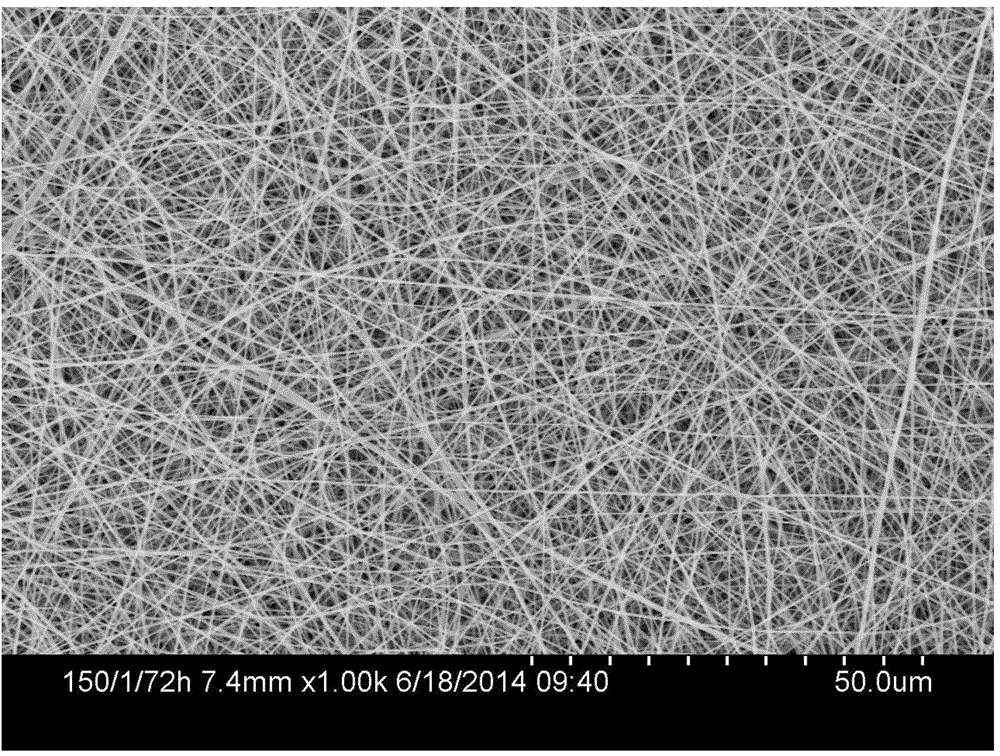

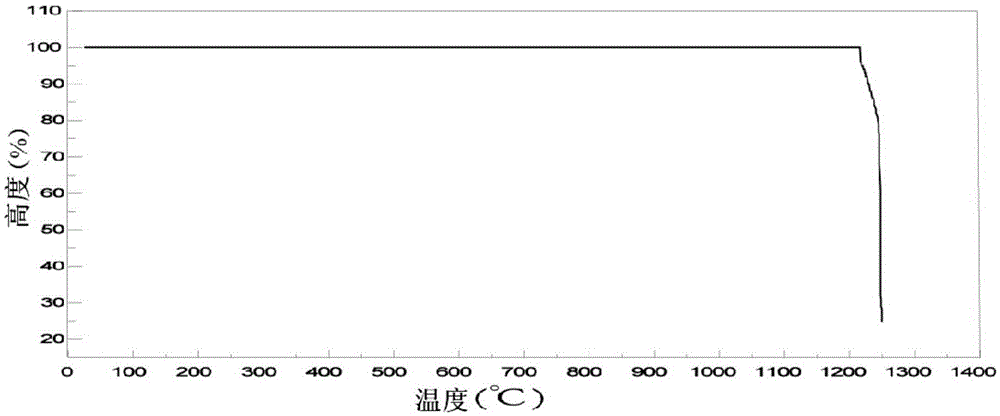

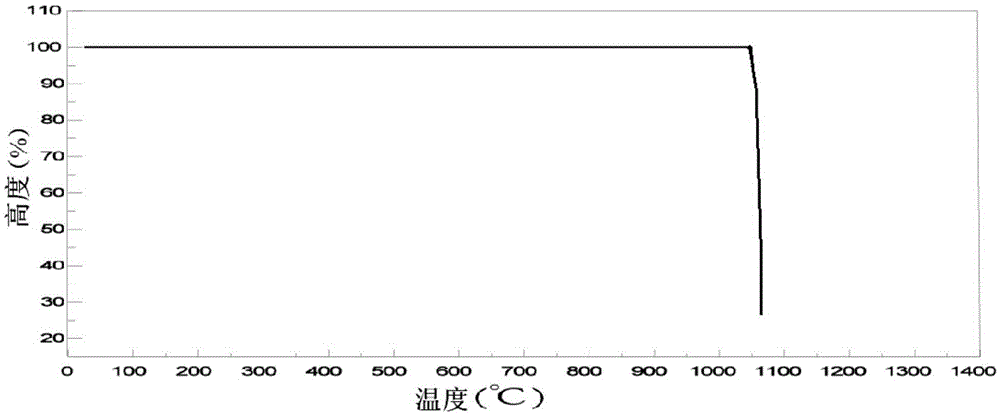

Nano phase change and energy storage luminescent fibers and preparation method thereof

ActiveCN104389046AHigh color purityIncreased fluorescence lifetimeFilament/thread formingMonocomponent synthetic polymer artificial filamentThermal energyFiber

The invention discloses nano phase change and energy storage luminescent fibers. The nano phase change and energy storage luminescent fibers comprise the following components: 50%-100% of a polyurethane solid-solid phase change material and 0%-50% of polymethyl methacrylate; the mass content of the components is 100%; and a benzoic acid ternary rare earth luminescent material accounts for 10%-30% of the total mass based on the total amount of the components. The invention further discloses a preparation method of the nano phase change and energy storage luminescent fibers. The polyurethane solid-solid phase change material is used as a fiber forming polymer and the benzoic acid ternary rare earth luminescent material is used as the luminescent material; ethyl acetate and N,N-dimethylformamide are used as compound solvents; and the phase change and energy storage luminescent fibers with the diameters being 30nm-100nm are prepared by an electrostatic spinning technology. The phase change luminescent fibers have the characteristics of high phase transformation enthalpy value in heat storage and releasing, high phase transformation speed, stable luminescent performance, long fluorescence service life and the like; and the phase change luminescent fibers can be widely applied to the fields of medicine and health, electronic information clothing and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Production method of three-dimensional porous composite bar

The invention discloses a production method of a three-dimensional porous composite bar. The method is characterized by comprising the following steps of: preparing a graphene oxide solution; adding calcium salt and phosphate into the graphene oxide aqueous solution to be uniformly stirred, thus obtaining a graphene oxide / hydroxyapatite precursor solution; and adding konjac glucomannan into the graphene oxide / hydroxyapatite precursor solution under stirring, stirring the solution for 10-120 minutes at 35-60 DEG C, standing, filling the obtained mixed solution into a dialysis bag, soaking the sealed dialysis bag into alkaline solidification liquid, soaking the dialysis bag for 5-15 days at 40-60 DEG C, soaking materials in the dialysis bag in deionized water, cleaning and drying the materials, freezing the materials at a super low temperature and performing vacuum freeze drying on the materials to obtain the three-dimensional porous composite bar. The mechanical property and porosity of the produced composite bar can meet the clinical use requirements of bone repair scaffold materials, and the composite bar can effectively promote bone tissues to quickly and spontaneously repair defects and has a good effect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

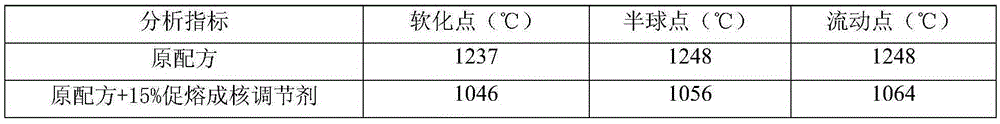

Microcrystalline material fluxing nucleating agent and preparation method thereof

InactiveCN105417950AGuaranteed mutual coordinationLower melting temperatureGlass shaping apparatusSulfurBoron

The invention relates to a microcrystalline material fluxing nucleating agent, which is composed of a base mineral raw material and a regulator mineral raw material. Specifically, the base mineral raw material accounts for 50%-80% of the total mass of the nucleating agent, the regulator mineral raw material accounts for 20%-50% of the total mass of the nucleating agent, and the sum of the two is 100%. The regulator mineral raw material comprises chambersite, manganese boron and sulfur stone, and other mineral raw materials. The composite microcrystalline material fusion promoting nucleating regulating agent prepared by the method provided by the invention can greatly reduce the firing temperature of traditional ceramic glazes, glaze materials or novel microcrystalline ceramics by 100DEG C-200DEG C, and reduce the melting temperature of microcrystalline glass or traditional glass raw materials by 150DEG C-200DEG C.

Owner:HEBEI UNIV OF TECH

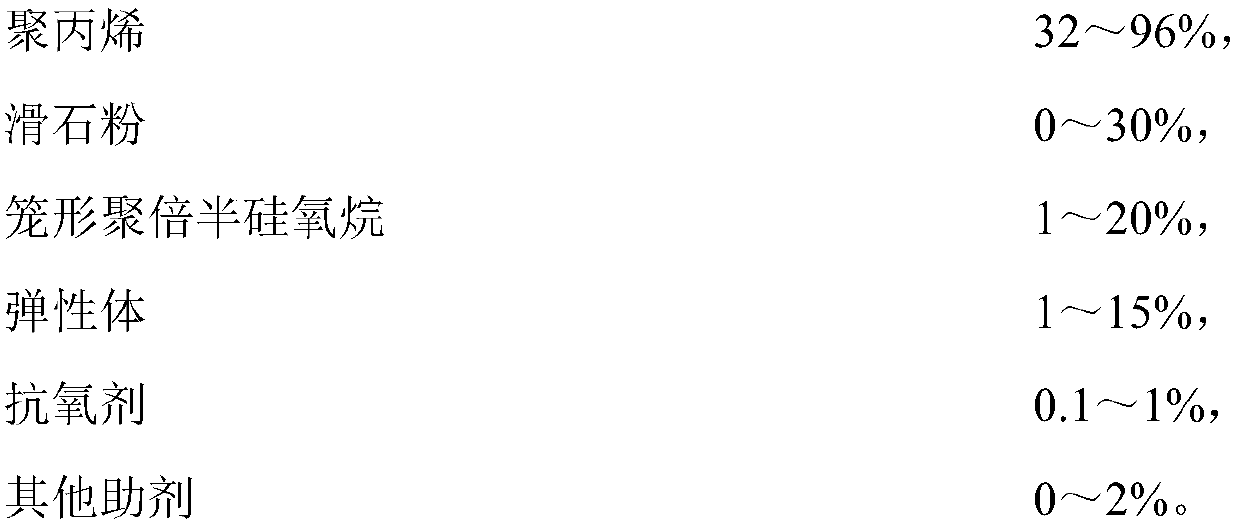

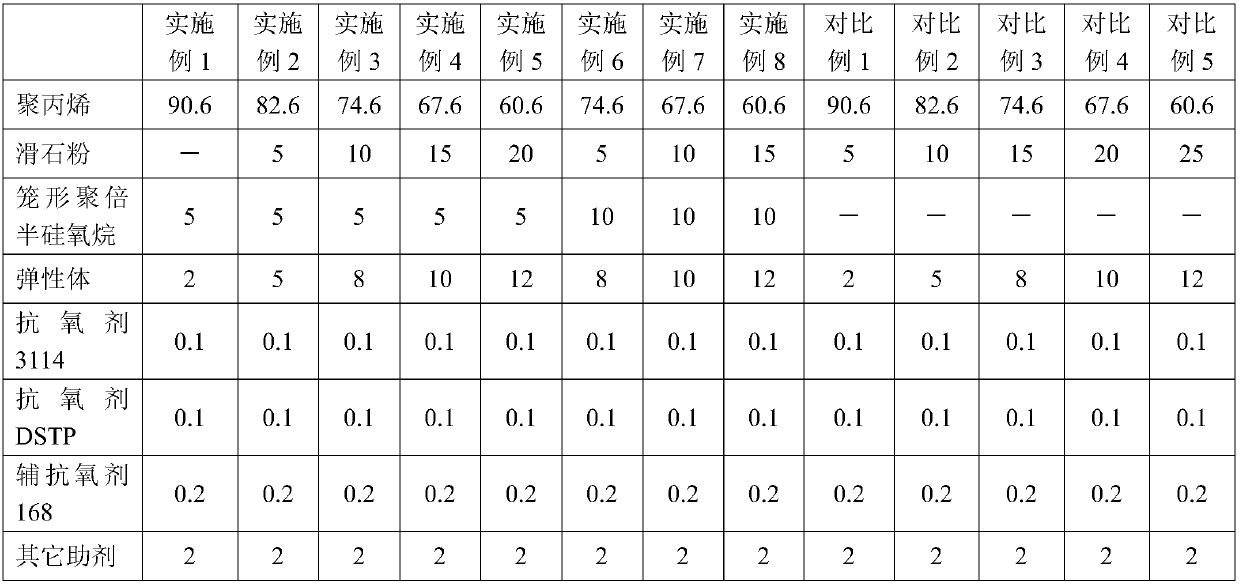

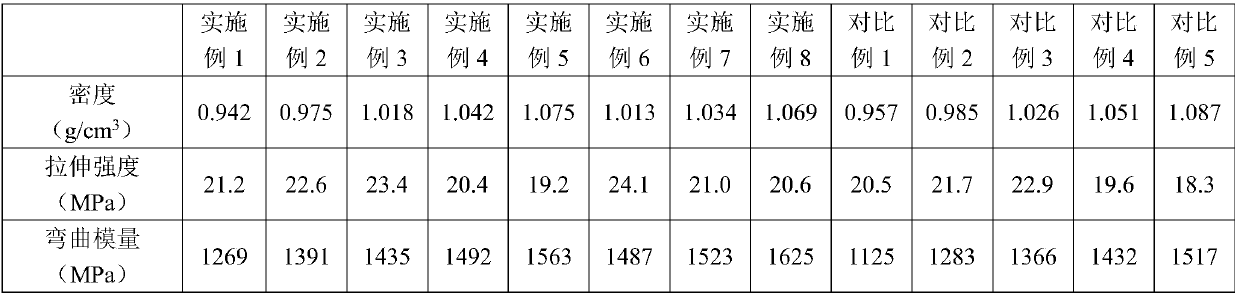

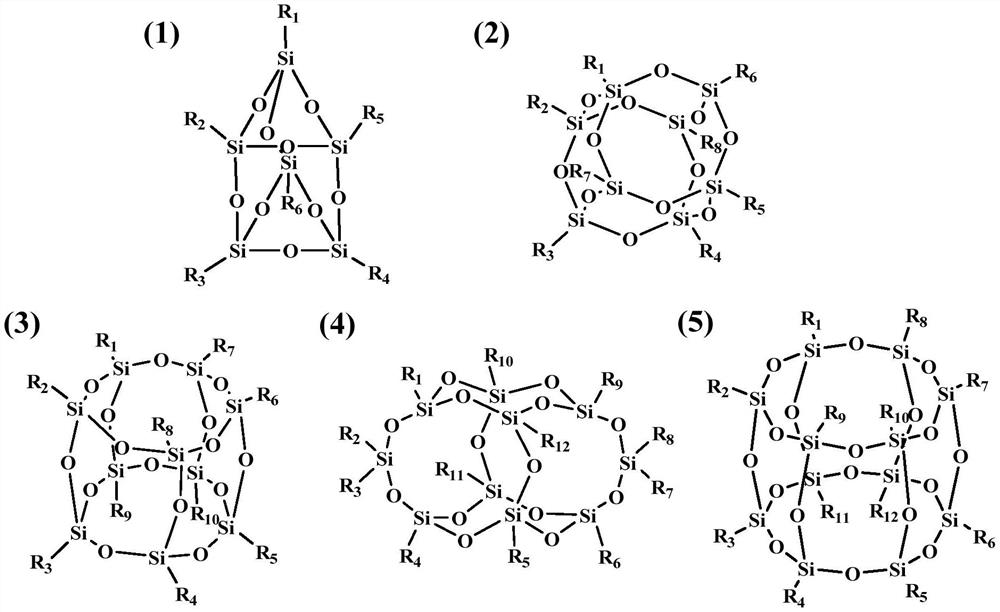

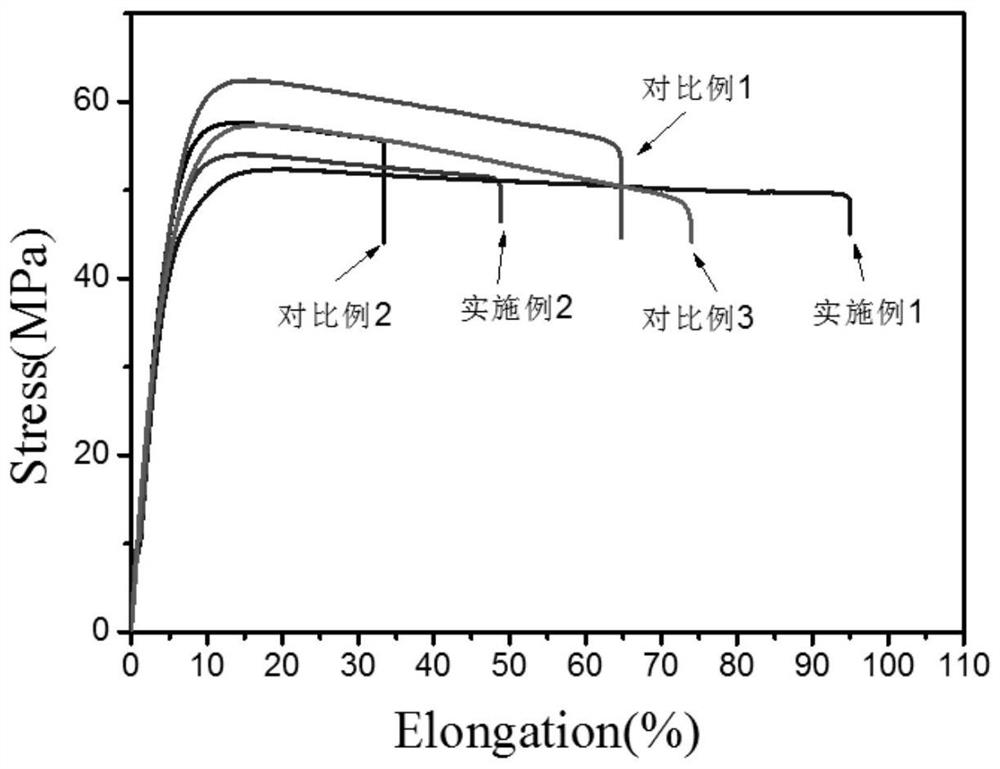

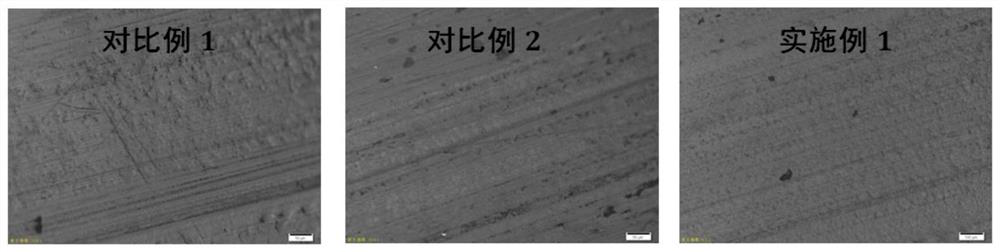

High-rigidity and toughness balance, anti-stress whitening and halogen-free flame retardant polypropylene composite material and preparation method thereof

The invention discloses a high-rigidity and toughness balance, anti-stress whitening and halogen-free flame retardant polypropylene composite material and a preparation method thereof. The composite material consists of the following raw materials in parts by weight: 32-96 parts of polypropylene, 0-30 parts of talcum powder, 1-20 parts of cage-like polysilsesquioxane, 1-15 parts of elastomer, 0.1-1 part of an antioxidant and 0-2 parts of other aids. The high-rigidity and toughness balance, anti-stress whitening and halogen-free flame retardant polypropylene composite material and the preparation method thereof disclosed by the invention have the advantages that through introducing cage-like polysilsesquioxane nanometer particles in a traditional talcum powder reinforced polypropylene baseformula and compounding two different scale systems, the rigidity and the impact resistance of the polypropylene composite material can be significantly improved; meanwhile, the nano-sized cage polysilsesquioxane particles can act as nucleating agents, so that the crystallinity of the polypropylene composite material is improved; in addition, the better carbon formation effect of the cage-like polysilsesquioxane can improve the oxygen index of the polypropylene composite material and solve the problem of easy combustion of the polypropylene composite material, so that the polypropylene composite material can resist stress whitening while having high-rigidity and toughness balance property and is good in flame retardance.

Owner:CHONGQNG PRET NEW MATERIAL +4

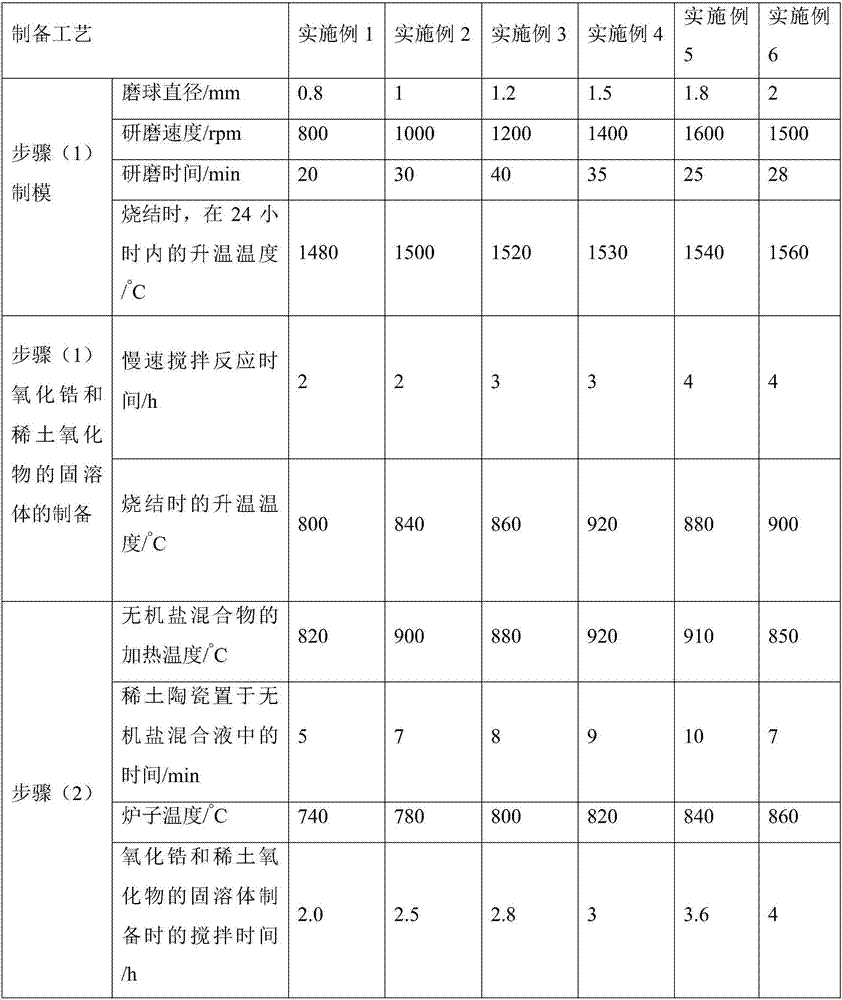

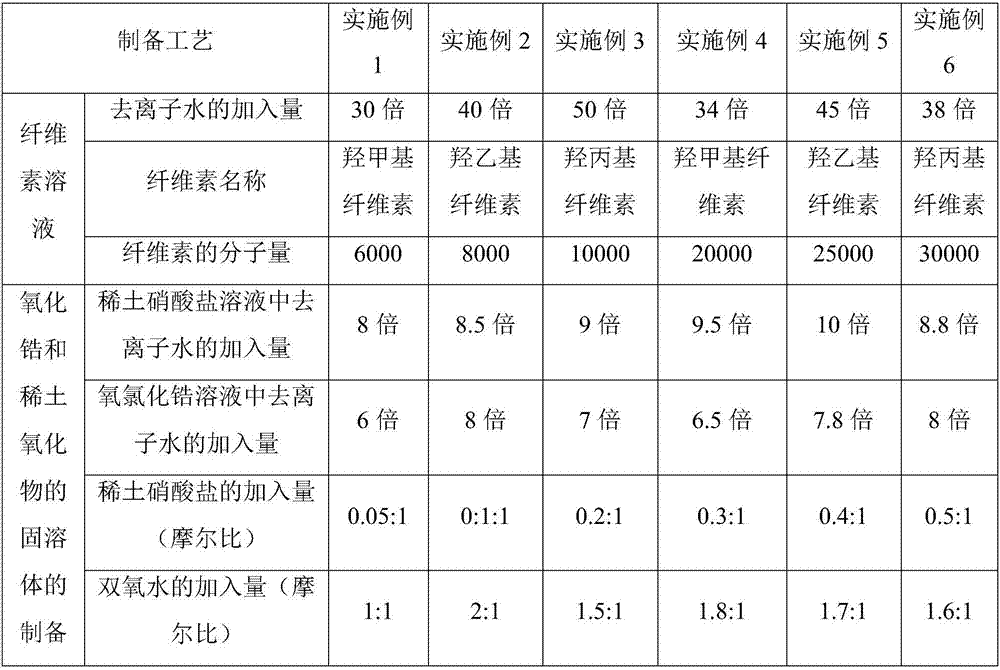

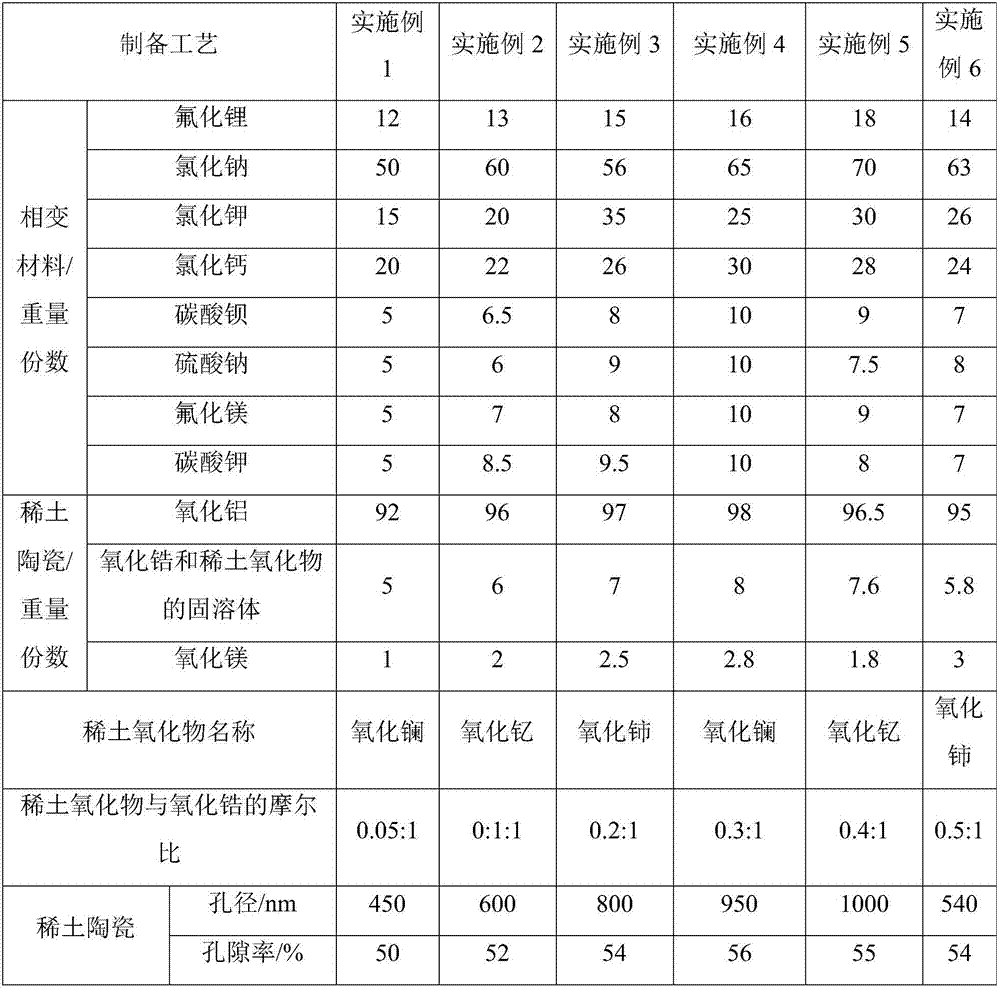

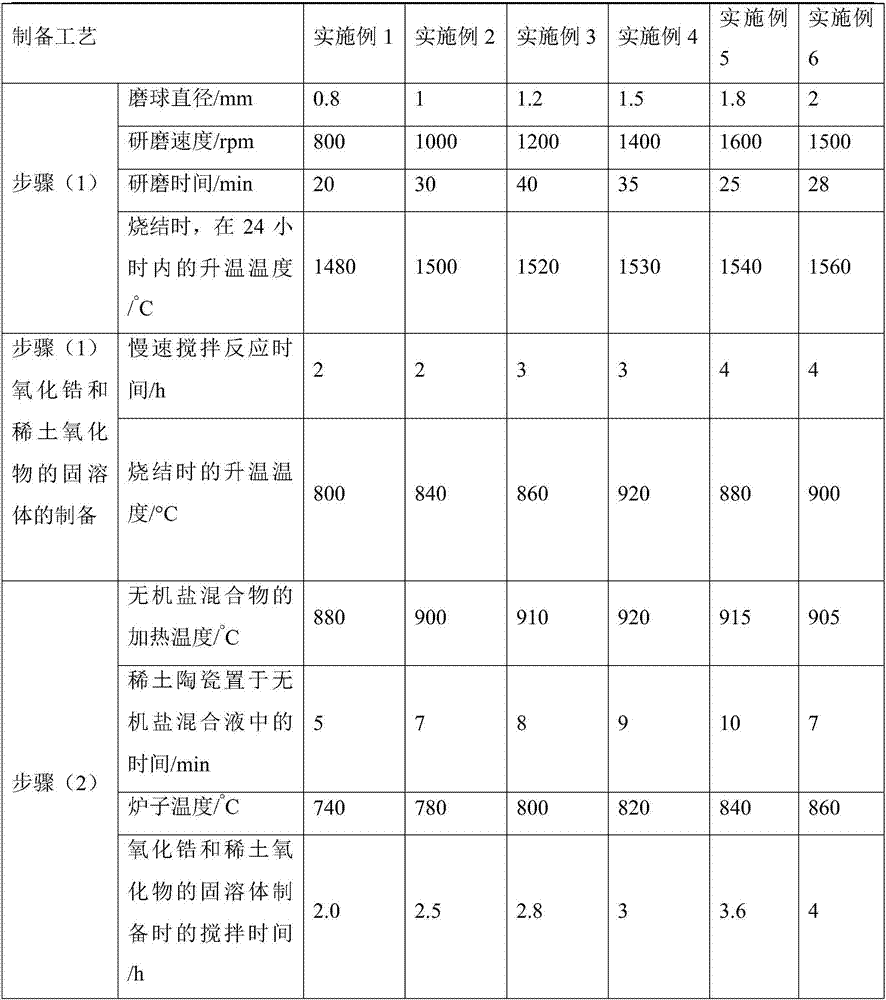

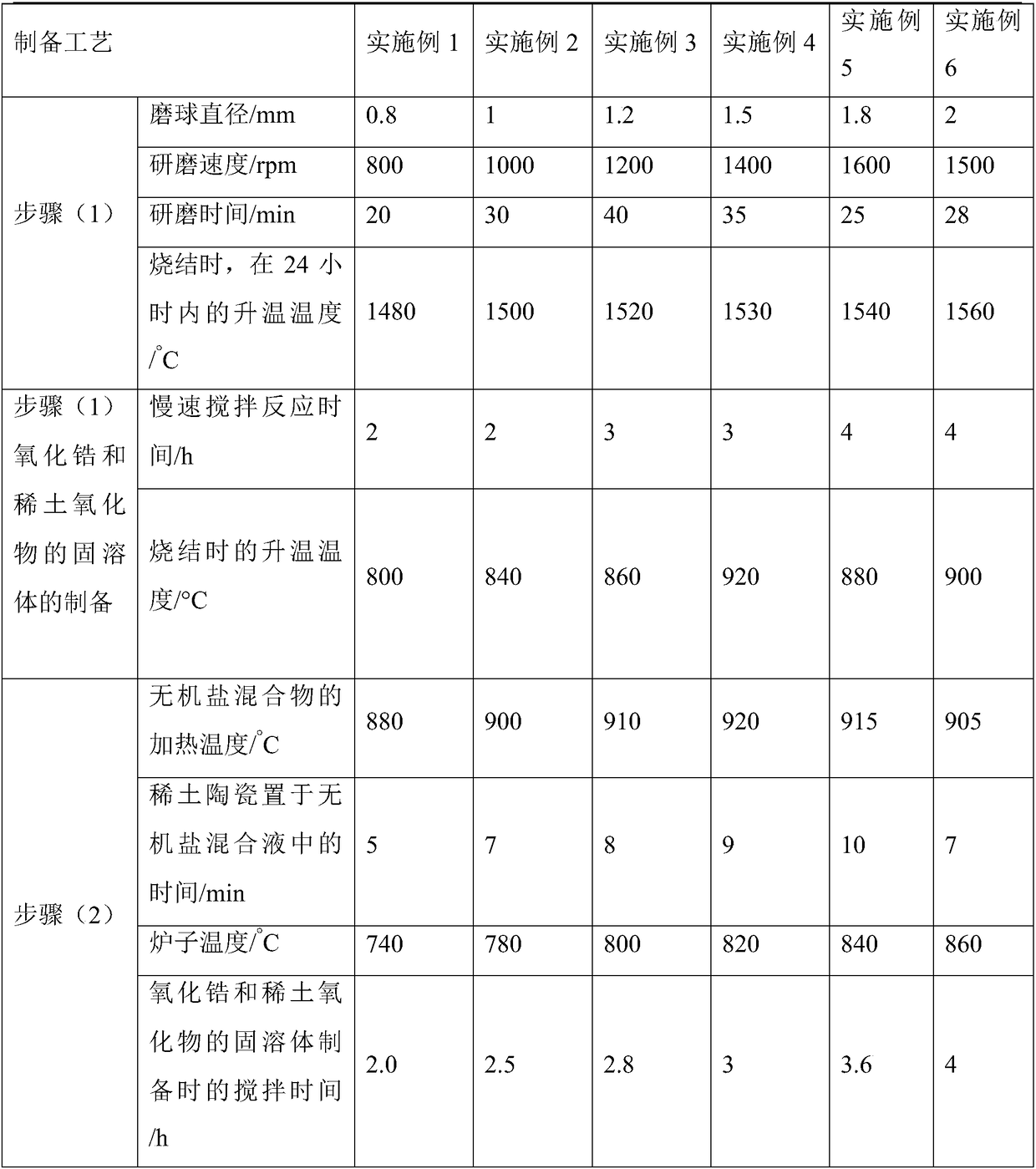

High-temperature phase change energy storage and discharge material of rare earth ceramic and preparation method thereof

ActiveCN107266047ALow melting pointHigh melting pointHeat-exchange elementsCeramicwarePorosityDecomposition

The invention belongs to the field of phase change energy storage and discharge materials, and relates to a high-temperature phase change energy storage and discharge material of rare earth ceramic and a preparation method thereof. The phase change energy storage and discharge material comprises a phase change material and rare earth ceramic, wherein the aperture of the rare earth ceramic is 450-1000nm, and the porosity of the rare earth ceramic is greater than or equal to 50%; the phase change material is evenly embedded in the hole of the rare earth ceramic; the volume of the phase change material occupies 1 / 2-2 / 3 of the volume in the embedded hole; the phase change material is inorganic salt mixture, and a phase change temperature for the inorganic salt mixture to be changed into a liquid state from a solid state is 820-920 DEG C; the rare earth ceramic comprises the solid solution of zirconia and rare earth oxide. The adopted inorganic salt mixture is characterized in that villiaumite with high corrosion, relatively high smelting point and relatively low latent heat is compounded with other inorganic salts, a smelting point in the formed inorganic salt mixture is lowered, meanwhile, the latent heat is increased, a phase change temperature is prevented from being overhigh while energy is stored as much as possible, the villiaumite with the relatively high corrosion is subjected to gasification decomposition, and a ceramic material is corroded.

Owner:TIANJIN WEIYUAN TECH DEV CO LTD

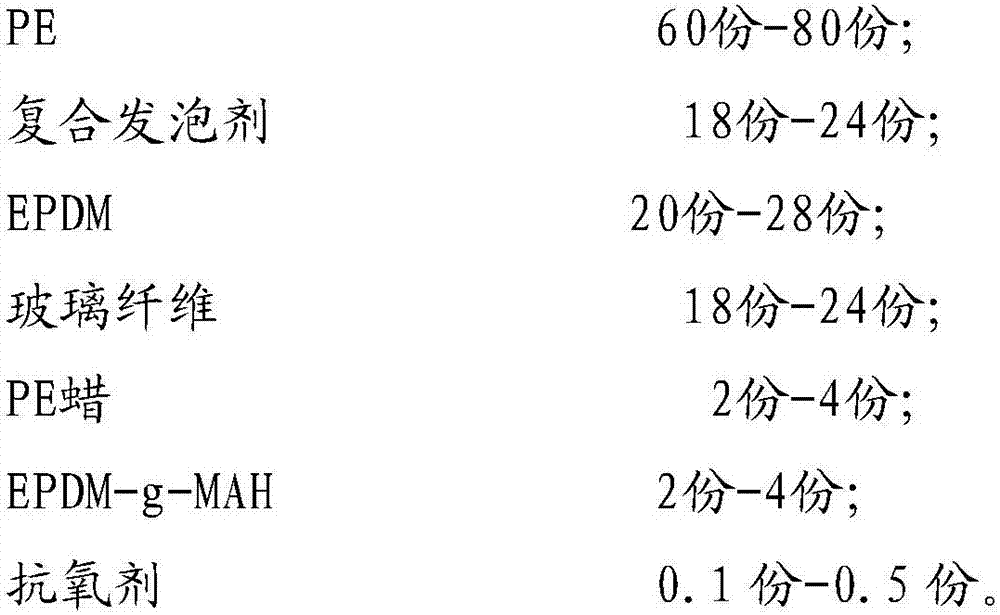

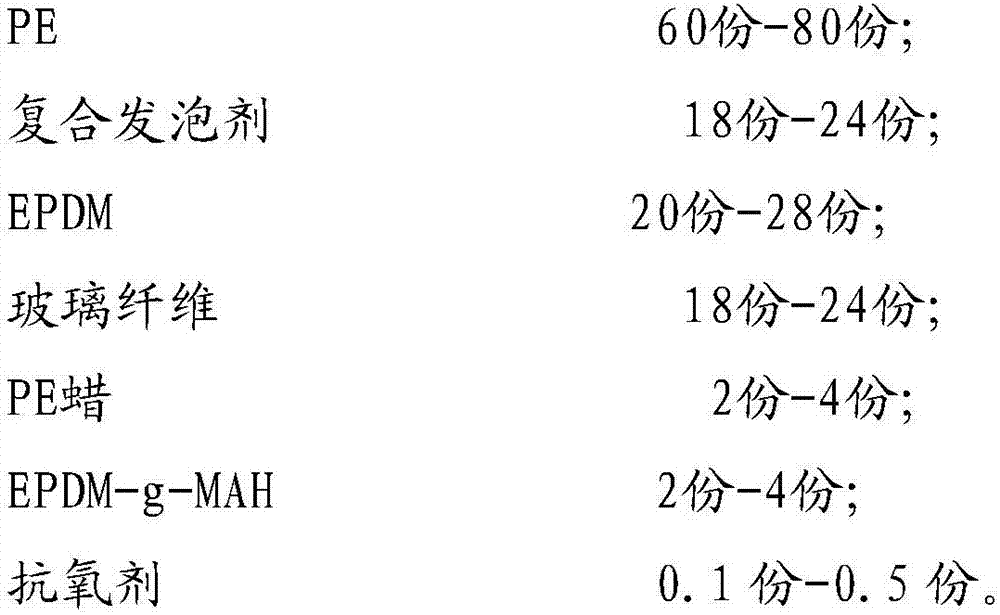

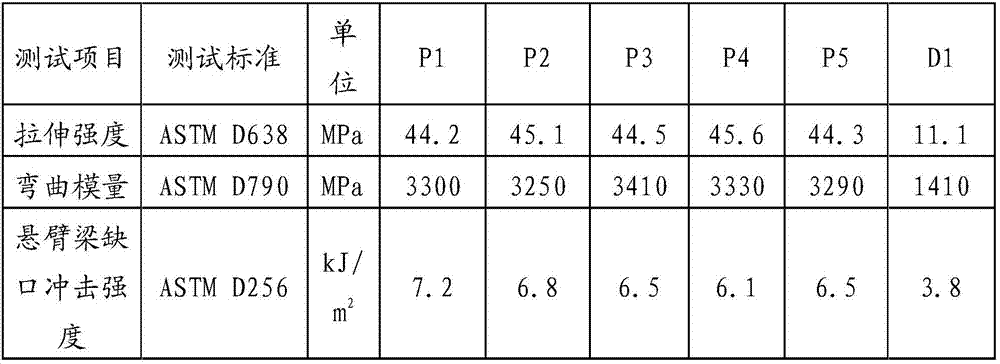

PE (Poly Ethylene) foaming material and preparation method thereof

The invention relates to a PE (Poly Ethylene) foaming material and a preparation method of the PE foaming material. The PE foaming material comprises the following components in parts by weight: 60-80 parts of PE, 18-24 parts of composite foaming agent, 20-28 parts of EPDM (Ethylene-Propylene-Diene Monomer), 18-24 parts of glass fiber, 2-4 parts of PE wax, 2-4 parts of EPDM-g-MAH (Ethylene-Propylene-Diene Monomer grafted Maleic Anhydride) and 0.1-0.5 parts of antioxidant. In the PE foaming material, addition of ZnO can effectively facilitate decomposition of a foaming agent AC (Azodicarbonamide); an N atom of an AC azo group is provided with a lone pair electron and belongs to a lewis base substance, but Zn<2+> of ZnO can receive the lone pair electron and belongs to a lewis acid substance, so that combination of the N atom and Zn<2+> can easily facilitate decomposition of the foaming agent AC; nano CeO2 mainly exerts an effect of a nucleating agent, forms a liquid-solid interface between a melt and gas, and facilitates heterogeneous nucleation of bubbles, so that the activation energy of bubble nucleation and the nucleation number are reduced; and a fine and dense bubble structure with high closed porosity is finally formed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparing method of high-performance polyethylene fiber and carbon nano tube composite fiber

InactiveCN106521676ASolve reunionGood dispersionMonocomponent polyolefin artificial filamentArtifical filament manufactureCarbon nanotubeSynthetic fiber

The invention relates to the technical field of synthetic fiber industry, in particular to a preparing method of high-performance polyethylene fiber and carbon nano tube composite fiber. The preparing method of the high-performance polyethylene fiber and carbon nano tube composite fiber includes the steps that carbon nano tubes are added into concentrated sulfuric acid, the mixed solution is heated under the condition of magnetic stirring, a KMnO4 water solution is added, reflux is carried out for 2-2.5 h at the temperature, and concentrated sulfuric acid is added after cooling to obtain purified carbon nano tubes; the carbon nano tubes are added into ethyl alcohol and ultrasonically treated for 1 h, heating and stirring are carried out under high-speed magnetic stirring, isopropanol liquid is added, filtering and drying are carried out, and the functionalized carbon nano tubes are obtained through Soxhlet extraction; a high-performance polyethylene fiber solution is prepared, the carbon nano tubes and antioxidant are added, and high-performance polyethylene fiber and carbon nano tube gel solution is prepared through ultrasonic treatment and heating; the high-performance polyethylene fiber and carbon nano tube gel solution is added into a double-screw spinning machine to conduct spinning to obtain gel protofilament, and extraction and drying stretch are carried out to obtain the high-performance polyethylene fiber and carbon nano tube composite fiber. The fiber performance is improved.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

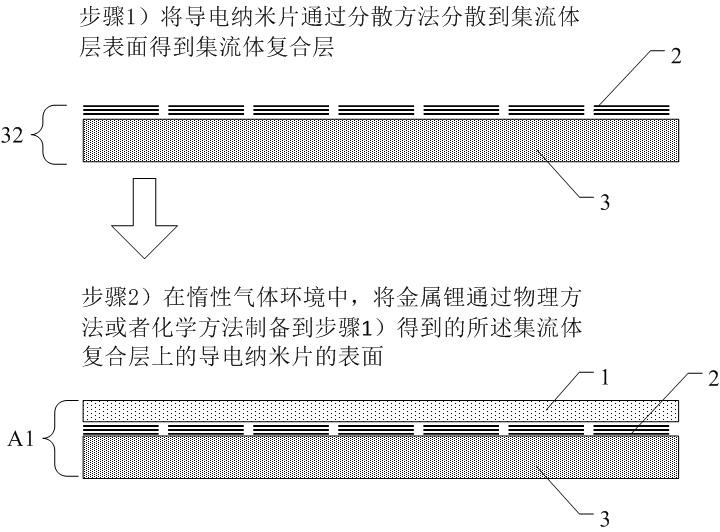

Lithium metal composite electrode with controllable nucleation and growth of lithium metal and preparation method thereof

PendingCN112117437APromote circulationExcellent rate performanceElectrode carriers/collectorsNegative electrodesMetallic lithiumComposite electrode

The invention discloses a lithium metal composite electrode with controllable nucleation and growth of lithium metal and a preparation method thereof. The lithium metal composite electrode comprises acurrent collector layer, a nucleation layer and a lithium metal layer; the nucleation layer is arranged between the metal lithium layer and the current collector layer; or, the metal lithium layer isarranged between the nucleation layer and the current collector layer, and the nucleation layer is composed of conductive nanosheets; and the current collector layer is made of a conductive material.The invention further comprises a preparation method of the lithium metal composite electrode, the preparation method is simple and easy to implement, complex metal lithium microstructure design andpreparation are avoided starting from the thought of metal lithium surface nucleation, the practicability is extremely good, and the obtained lithium metal composite electrode shows excellent cycle performance as a metal lithium-based battery anode; and after multiple times of charging and discharging, the surface is smooth, and no obvious dendritic crystal is formed.

Owner:BEIHANG UNIV

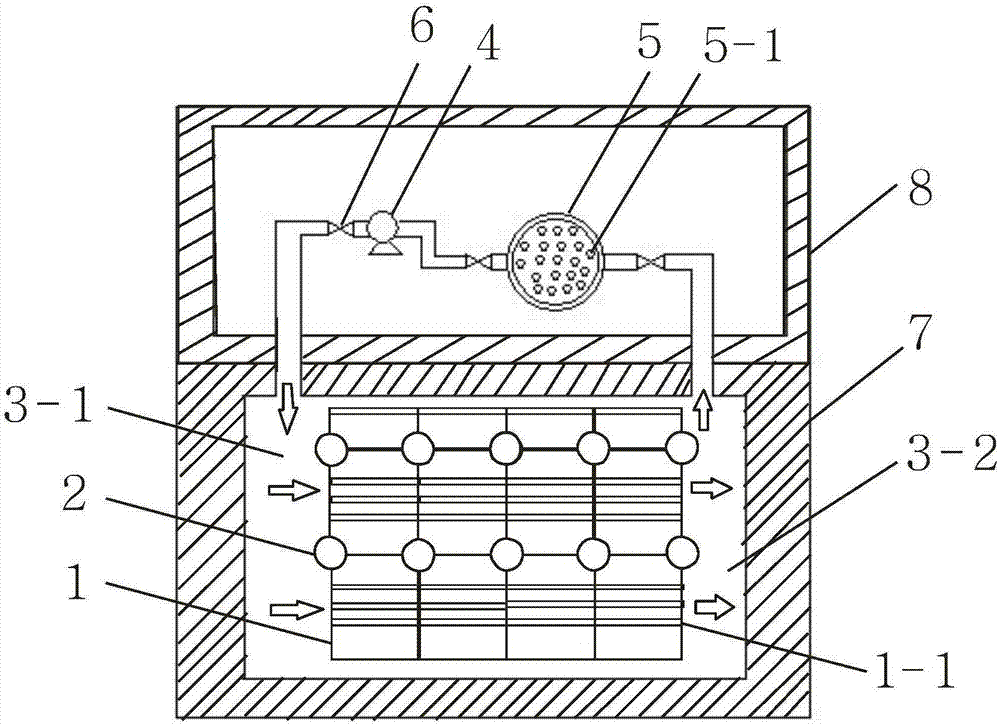

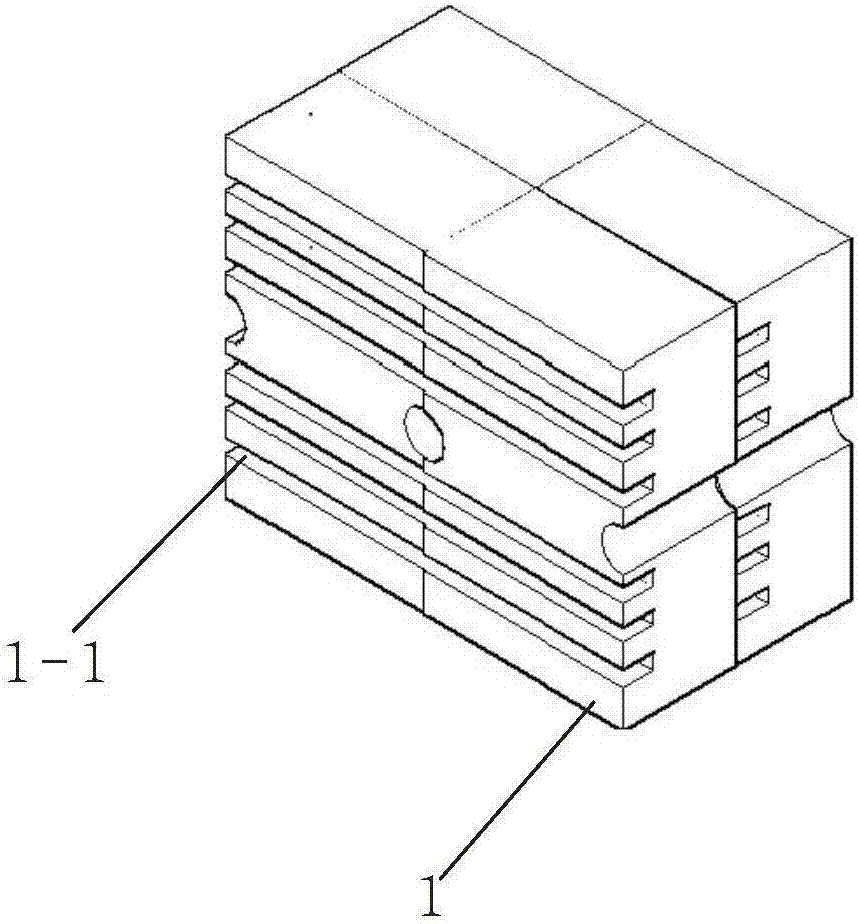

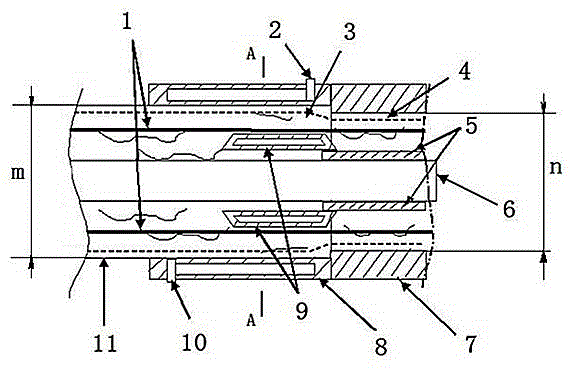

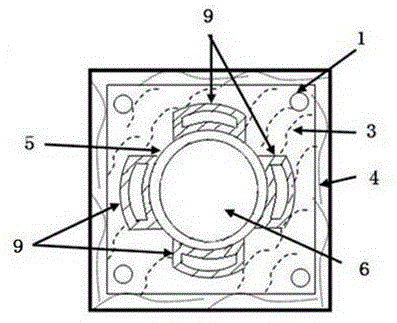

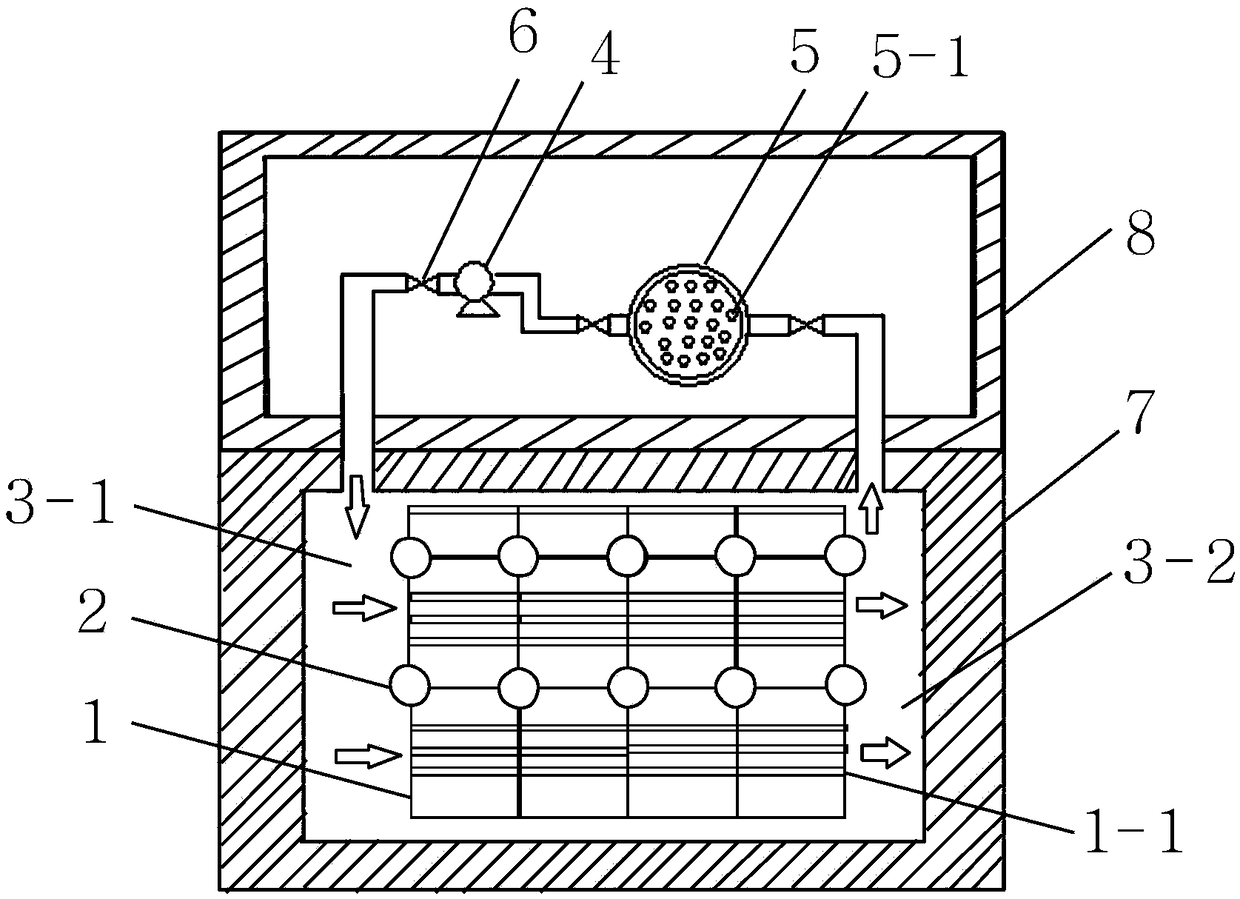

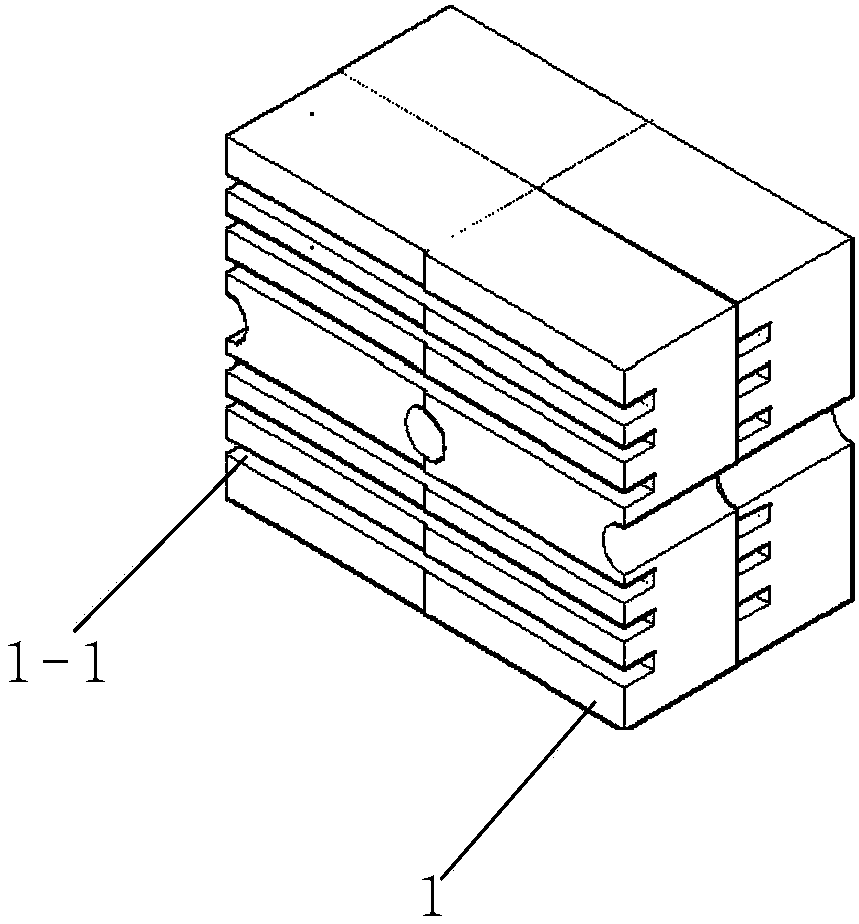

Energy-storage heat exchange device

ActiveCN107167013ARealize the purpose of energy storage and heat exchangeLow melting pointHeat storage plantsCold airElectricity

The invention relates to an energy-storage heat exchange device. The energy-storage heat exchange device comprises an energy storage pile, a heat exchanger, a heating tube and a fan, wherein a thermal insulation layer A is arranged at the periphery of the energy storage pile; a gap between the energy storage pile and the thermal insulation layer A is taken as an air flue; a ventilating groove is formed in the energy storage pile; the fan is connected with the heat exchanger through a pipeline; the other end of the fan is accessed into the air flue A through a pipeline; the other end of the heat exchanger is accessed into an air flue B through a pipeline; the air flue A and the air flue B refer to air flues formed between opposite two ends in the energy storage pile and the thermal insulation layer A; an electric heating tube is arranged in the energy storage pile in a penetrating mode for heating the energy storage pile; under driving of the fan, air flow enters the energy storage pile through the air flue A; and air flow is heated by the energy storage pile. The energy-storage heat exchange device utilizes off-peak electricity to heat the energy storage pile, and utilizes the energy storage pile to slowly release heat for heating air flow to form hot air; and after entering the heat exchanger to exchange heat, hot air is changed into cold air for being blown into the fan, and re-enters the air flue A under driving of the fan in a circulating mode, so that the energy-storage heat exchange purpose is realized.

Owner:天津朗华科技发展有限公司

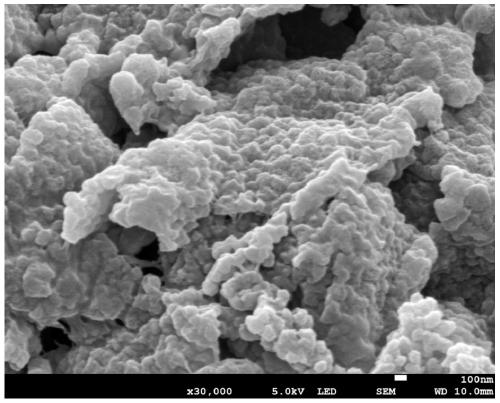

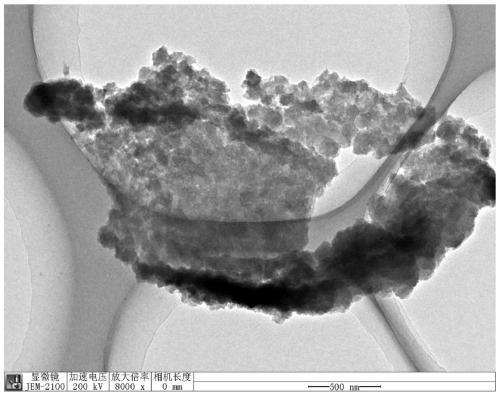

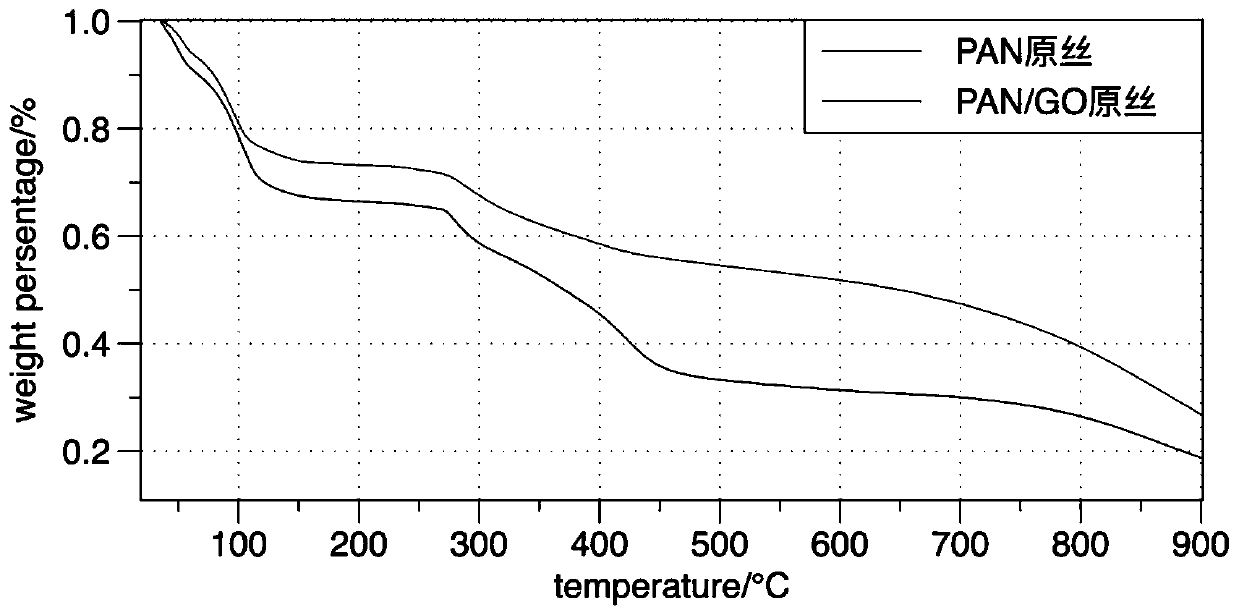

Polyacrylonitrile-coated graphene composite material as well as preparation method and application thereof

ActiveCN111285949AAchieve tight wrappingIsolated interactionArtifical filament manufactureCarbon fibersSpinning

The invention discloses a polyacrylonitrile-coated graphene composite material as well as a preparation method and application thereof. A basic unit of the polyacrylonitrile-coated graphene compositematerial is of a core-shell structure, an inner core is a carbon material, an outer shell is a polyacrylonitrile layer, the polyacrylonitrile layer is a single layer or multiple layers, and the carbonmaterial is a carbon material with a graphite lattice structure. According to the polyacrylonitrile-coated graphene oxide composite material, graphene is uniformly introduced into a spinning system,meanwhile, a polymer tightly coats the graphene, polyacrylonitrile isolates the interaction between the graphene, the accumulation tendency of the graphene is reduced, the time required for uniform mixing of the graphene and the polyacrylonitrile is greatly shortened, and the production efficiency is improved. Moreover, the introduced graphene can play roles of a nucleating agent and a template agent in the pre-oxidation and carbonization processes, so that a graphite lattice structure with more complete carbon fibers is obtained, and various properties of the carbon fibers are improved.

Owner:SHANDONG UNIV

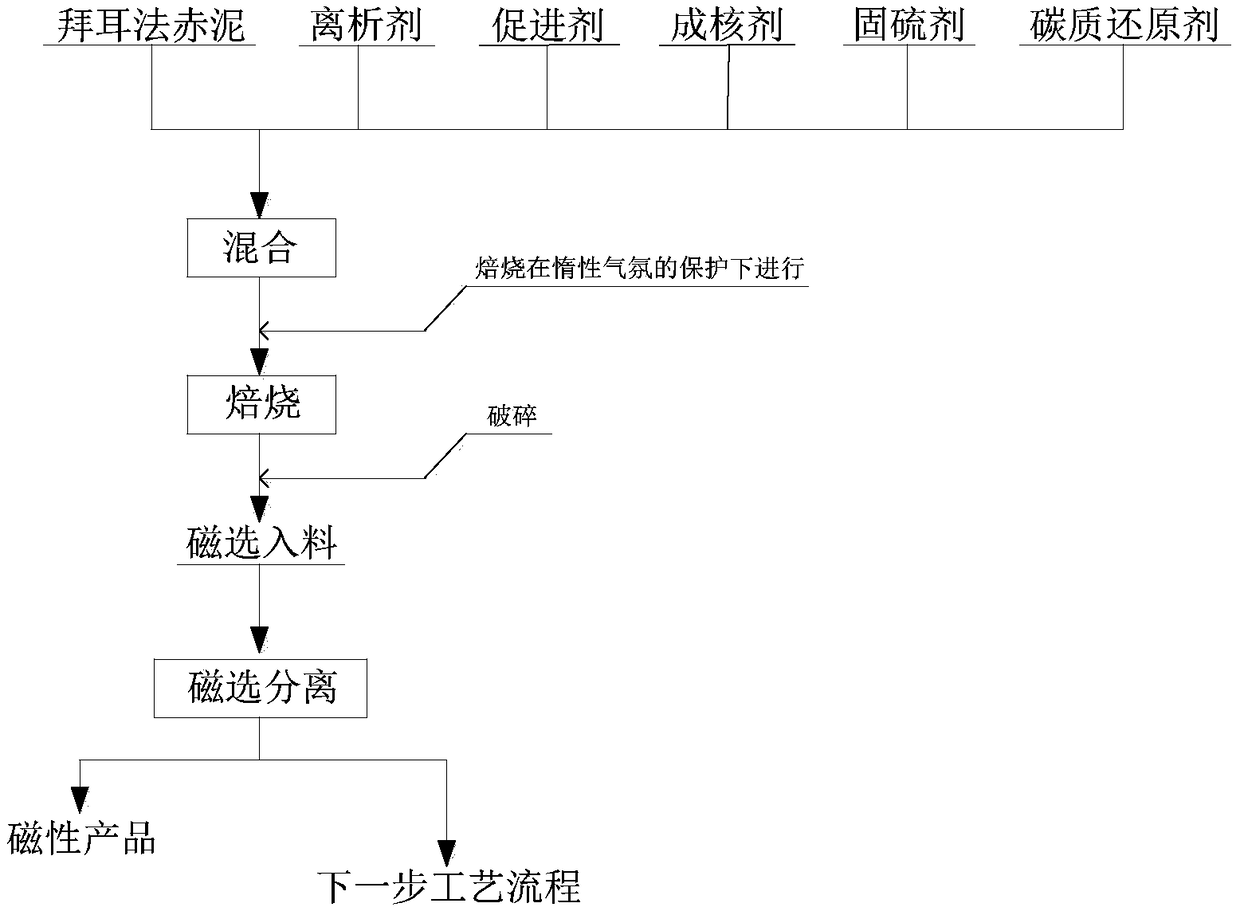

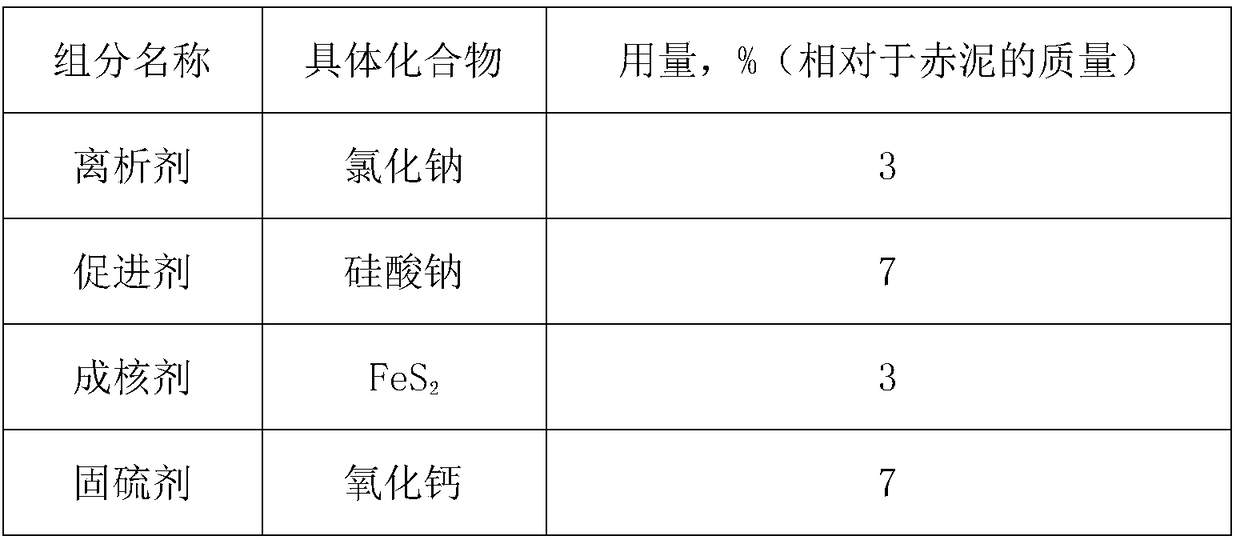

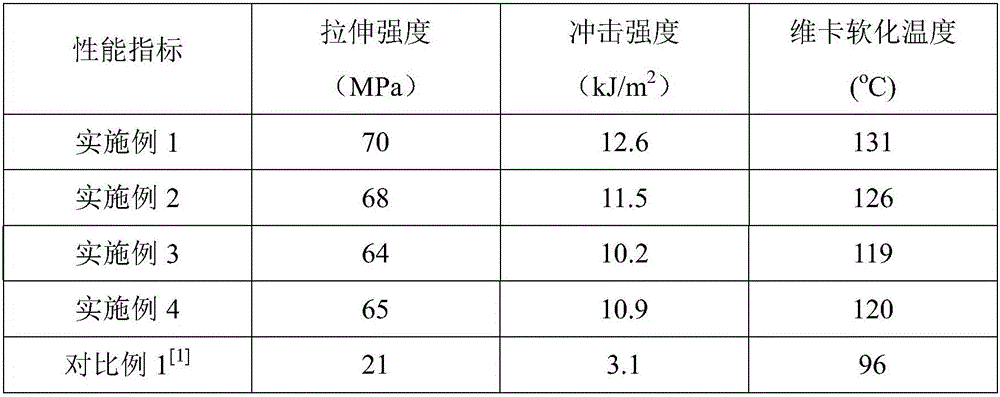

Method for extracting iron through reducing roasting red mud in bayer process

ActiveCN108950180APromote metallizationImprove and increase recoveryMagnetic separationProcess efficiency improvementMass ratioRed mud

The invention discloses a method for extracting iron through reducing roasting a red mud in a bayer process. A chloride-containing compound used as a segregation agent, a sodium-containing compound used as an accelerant, an iron-containing compound used as a nucleating agent, a calcium-containing compound used as a sulphur-fixing agent, and a carbonaceous reducing agent are added into the red mud;and according to the mass ratio of the red mud, the adding dosage of the chloride-containing compound is 3 to 10 percent by weight, the adding dosage of the sodium-containing compound is 5 to 15 percent, the adding dosage of the iron-containing compound is 3 to 8 percent, the adding dosage of the calcium-containing compound is 5 to 12 percent, and the adding dosage of the carbonaceous reducing agent is 5 to 15 percent. According to the method provided by the invention, a method for reducing roasting the red mud is adopted, so that iron in the red mud is reduced into low-price magnetic matterswhich are gathered together under the action of a nucleating agent so as to form large-grained crystal grains and be sorted through weak magnetism. According to the method, the metal conversion rateand a segregation effect in red mud reducing roasting can be remarkably improved, so that an effect on improving the iron recovery rate or the grade is achieved.

Owner:CENT SOUTH UNIV

Preparation method of low-cost heat-resistant food grade polylactic acid material

InactiveCN105936742ASmall molecular weightRaise the crystallization temperatureHeat resistanceCrystallinity

The invention discloses a preparation method of a low-cost heat-resistant food grade polylactic acid material. The method includes: adopting D-lactic acid as the raw material to synthesize oligomeric PDLA with a molecular weight of 2500-20000, conducting purification filtering to obtain pure PDLA, subjecting dried PDLA and industrial grade PLA in certain proportion to melt blending to prepare the low-cost heat-resistant polylactic acid material. The invention utilizes the characteristics of low cost, numerous molecular chains and good fluidity of oligomeric PDLA, which can form stereocomplex crystals in situ with a PLLA molecular chain in industrial grade PLA, and the stereocomplex crystals themselves have the effect of a nucleating agent, can promote the formation of the PLLA molecular chain into homogeneous crystals, and improve the crystallization rate and crystallinity of industrial grade PLA, thus improving the heat resistance of the polylactic acid material.

Owner:CHANGZHOU UNIV

Phase-change cold storage compound and preparation method thereof

InactiveCN111320969AHigh thermal conductivityPrevent phase separationHeat-exchange elementsPhysical chemistryCarbon nanomaterials

The invention relates to a phase-change cold storage compound and a preparation method thereof. The phase-change cold storage compound comprises sodium sulfate decahydrate, a nucleating agent, a thickening agent and a temperature regulator. Wherein based on 100 parts by mass of the sodium sulfate decahydrate, the mass parts of the nucleating agent, the thickening agent and the temperature regulator are respectively 0.5-5 parts, 0.5-5 parts and 10-20 parts; wherein the phase-change cold storage compound further comprises a carbon nano material, and based on 100 parts by mass of the sodium sulfate decahydrate, the mass part of the carbon nano material is 1-5 parts. By optimizing the formula design of the phase-change cold storage composite material, the composite material has the characteristics of safety, no toxicity, low production cost, small degree of supercooling, high cold storage density and good material stability, and can be applied to use scenes needing 4-8 DEG C, such as a phase-change cold storage system of an air conditioner.

Owner:内蒙古信敏惠纳米科技有限公司

Nano particle strengthened polyurethane foam plastic and preparation method thereof

InactiveCN104974498AExpand advantage performanceExtend advantageous properties such as weather resistanceCoatingsPotassium persulfateCarbamate

The invention discloses a nano particle strengthened polyurethane foam plastic and a preparation method thereof, and belongs to the technical field of materials. The foam plastic is composed of the following raw materials in parts by weight: 70 to 90 parts of polyurethane emulsion, 1 to 3 parts of nano nickel powder, 5 to 10 parts of nano calcium carbonate, 3 to 8 parts of potassium persulfate, 2 to 6 parts of nano zinc oxide, 5 to 10 parts of ethyl orthosilicate, and 2 to 6 parts of vulcanized zinc carbamate. The preparation method comprises the following steps: (1) weighing; (2) putting the raw materials into an injection moulding machine; (3) cooling and moulding. The advantages of polyurethane foam plastic are further enhanced by the nano particles, and the physical properties and high temperature resistant performance are improved at the same time.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

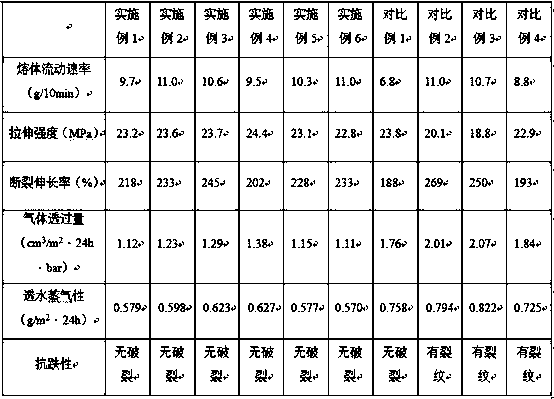

Composite raw material for preparing polyamide film and preparation method of composite raw material

The invention discloses a composite raw material for preparing a polyamide film and a preparation method of the composite raw material. The composite raw material is prepared in steps as follows: a composite particle additive consisting of two inorganic articles with different particle sizes is added in a polyamide polymerization process, after polymerization, obtained polyamide is subjected to granulation, extraction and drying, the obtained material is mixed with bisamide compounds, and the composite raw material for the polyamide film is obtained. Processing master batch is not required tobe used additionally when the composite raw material is used for preparing the film, and the prepared polyamide film has ideal mechanical performance, transparency, stretchability, blocking resistanceand the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Large-section foamed plastic product extruding machine head

ActiveCN104827644ASmall form factorGuaranteed large cross-sectional areaCoatingsInterior spaceSurface layer

The invention discloses a large-section foamed plastic product extruding machine head, which comprises a machine head and a guide sleeve. The large-section foamed plastic product extruding machine head is characterized in that a setting sleeve is arranged at the rear end of the machine head; a plurality of choke flow devices are arranged on the rear part of the guide sleeve; the front end of each choke flow device is fastened on the rear part of the guide sleeve; the sectional area of all choke flow devices occupies 20%-45% of the sectional area enclosed by the inner surface of the setting sleeve; molten plastic is always kept at enough machine head pressure before completely penetrating through the choke flow devices; and a material foams to fully fill an internal space of an inner filling layer, so as to meet the requirements of a foaming process. According to the large-section foamed plastic product extruding machine head, the problem that the pressure provided by virtue of an extrusion screw rod is not enough in a conventional plastic extruding machine head is solved; a large-section plastic product is produced; a composite extrusion foaming process is realized; the external surface layer of the product is uniform in thickness; the inner filling layer is even to foam; the elastic modulus required by the product and the maximal bending stress are reached; and meanwhile, the problem that the inside of the large-section plastic product is relatively difficult to rapidly cool and set is also solved.

Owner:沈阳新永成塑胶有限公司

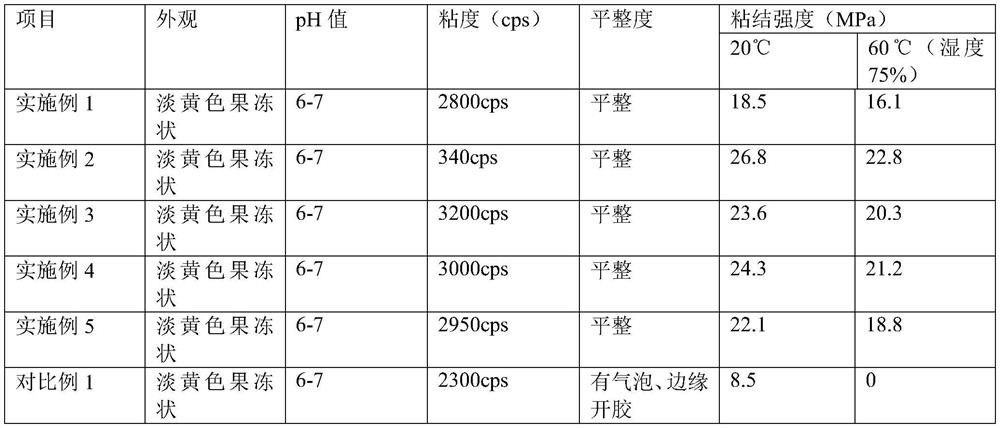

Modified paper-plastic composite adhesive and preparation method thereof

ActiveCN113004858AIncrease stickinessViscous lossNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceAdhesive

The invention relates to the field of binder materials, in particular to a modified paper-plastic composite adhesive and a preparation method thereof. The modified paper-plastic composite adhesive comprises the following components in parts by weight: 40-60 parts of animal glue, 15-30 parts of maltose, 10-25 parts of superfine talcum powder, 0.1-0.5 part of glutamine transaminase, 0.1-0.5 part of collagenase, 30-40 parts of water and 0-5 parts of auxiliaries. According to the invention, the modified paper-plastic composite adhesive overcomes the defects of poor environmental protection property and high cost of chemical paper-plastic composite adhesive and the undesirable phenomena of glue failure and foaming of a plastic film on the surface of a paper-plastic folder caused by poor bonding effect of animal glue and the plastic film in the prior art; the crosslinking density in the adhesive is effectively improved, so that the viscosity of the animal glue can be greatly improved, and the modified animal glue cannot become liquid and lose the viscosity after being heated.

Owner:浙江金仕文化用品有限公司

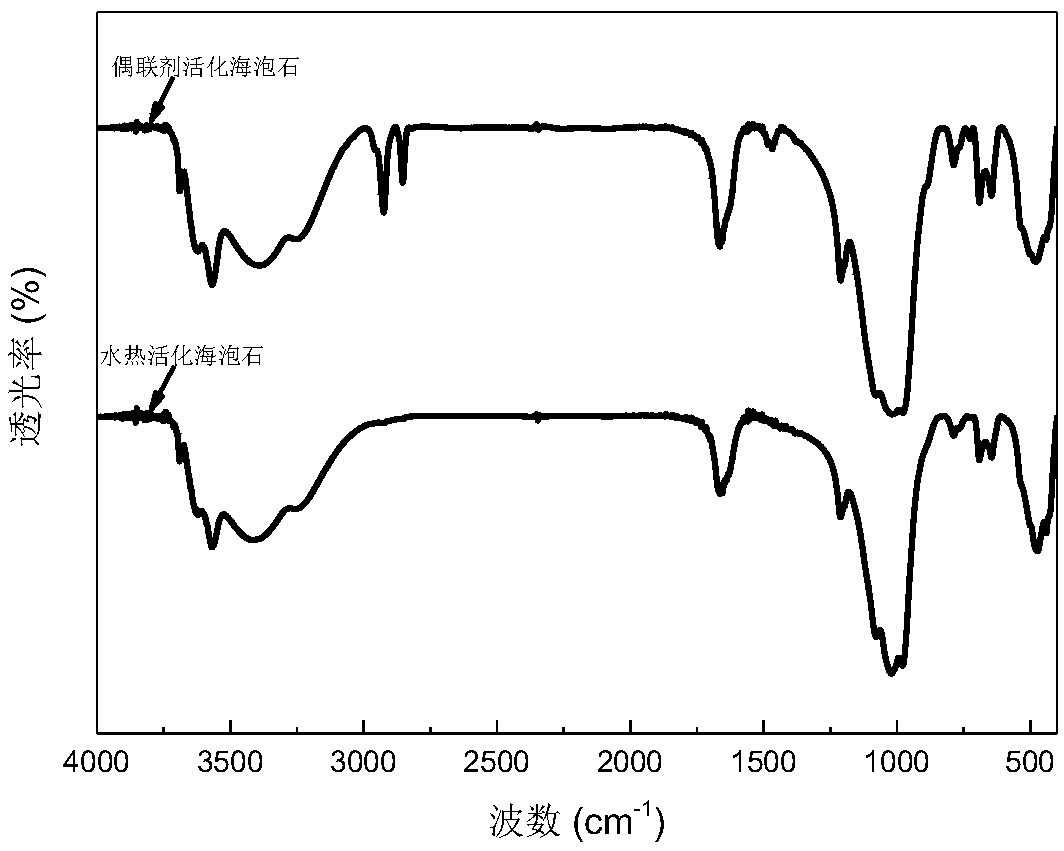

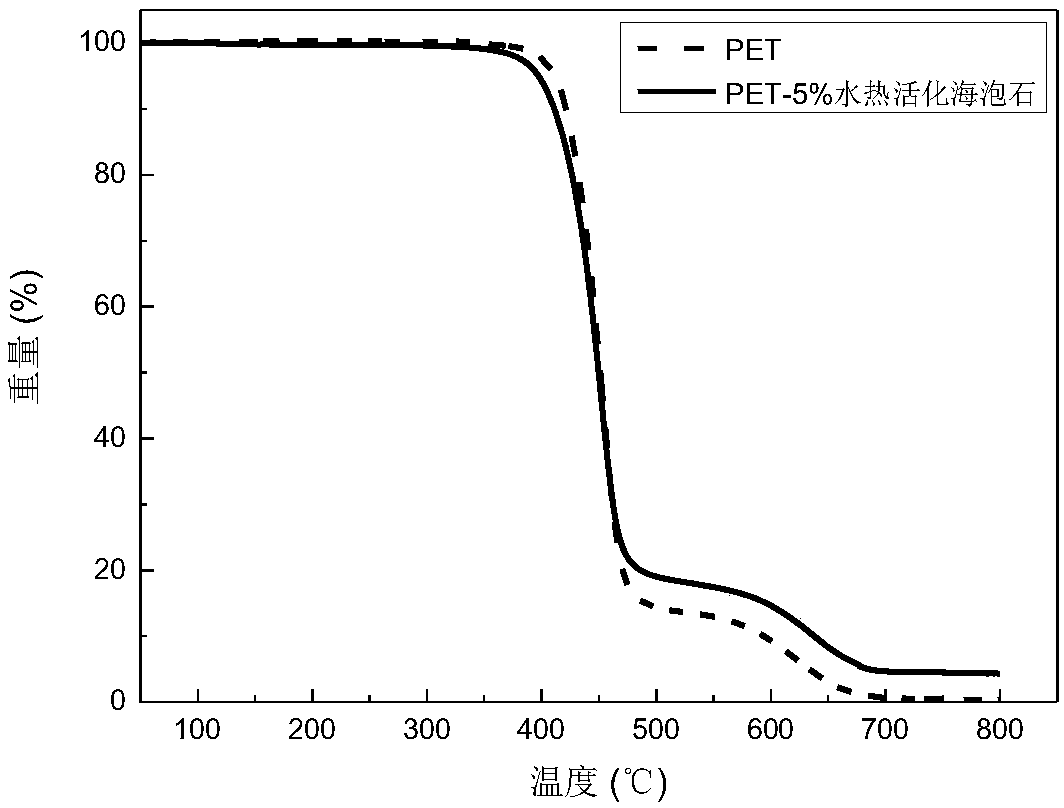

Method for increasing crystallization temperature and crystallization rate of polymer

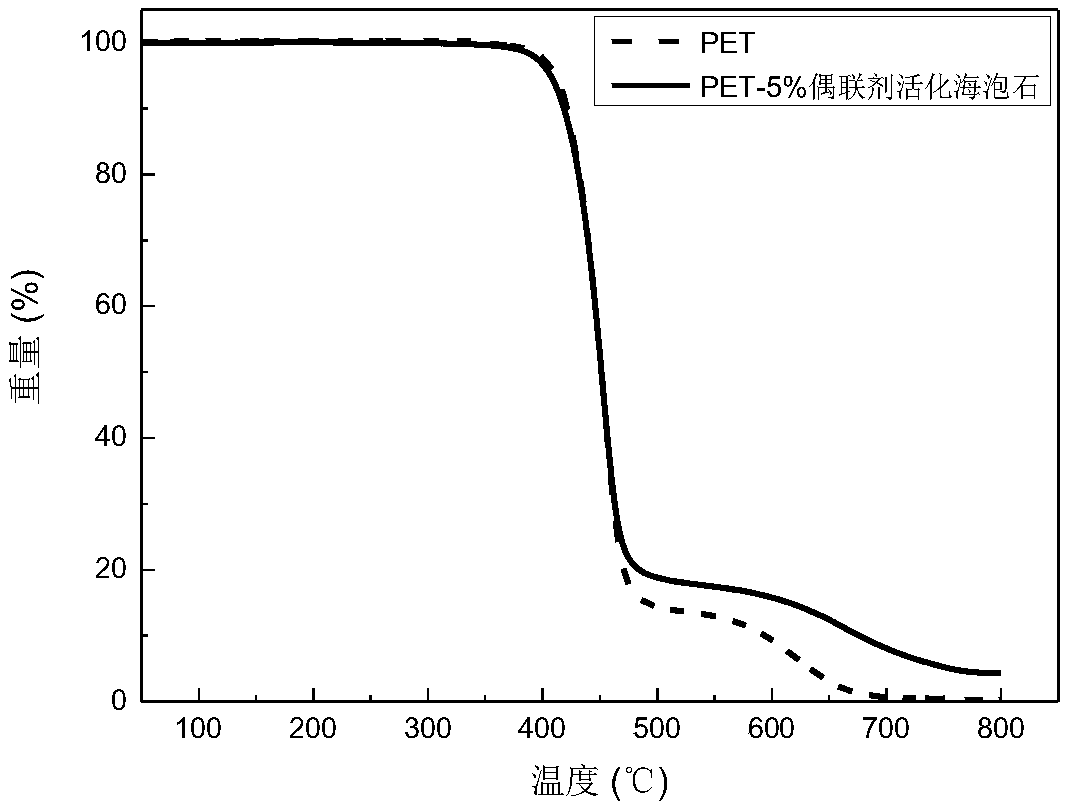

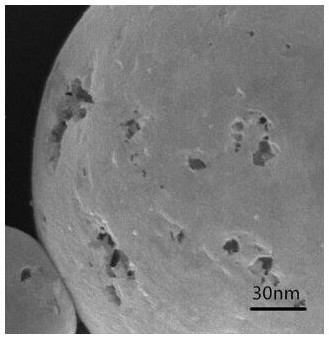

InactiveCN109438932AIncrease the rate of crystallizationAct as a nucleating agentPolymer scienceCrystallization temperature

The invention belongs to the technical field of polymer materials, in particular to a method for increasing the crystallization temperature and the crystallization rate of a polymer. According to themethod, sepiolite is adopted as a nucleating agent for the polymer, and a polymer / sepiolite composite is obtained by mixing, so that the crystallization temperature of the polymer is increased and thecrystallization of the polymer is accelerated. Sepiolite, especially the activated sepiolite, has a high specific surface area and can be well dispersed in the polymer body to promote the crystallization of the polymer. The method provided by the invention is simple, easy to operate and suitable for industrial production.

Owner:FUDAN UNIV

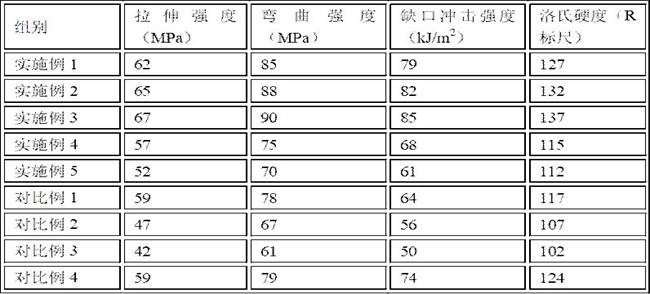

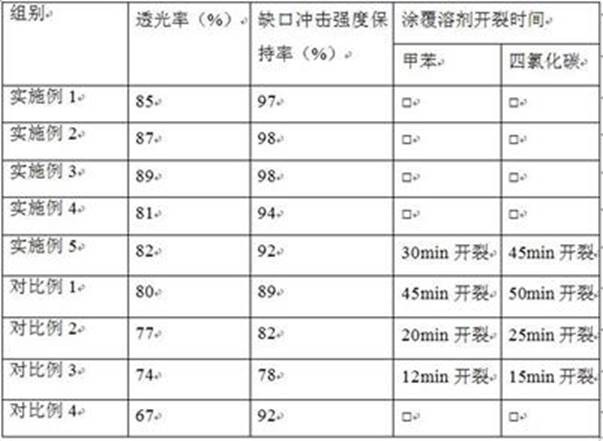

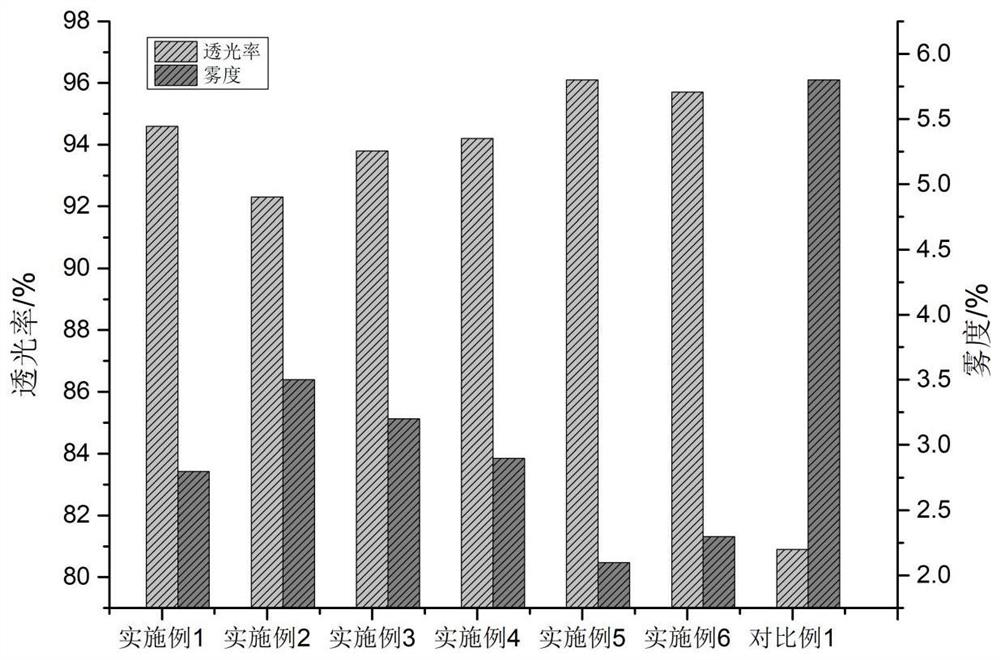

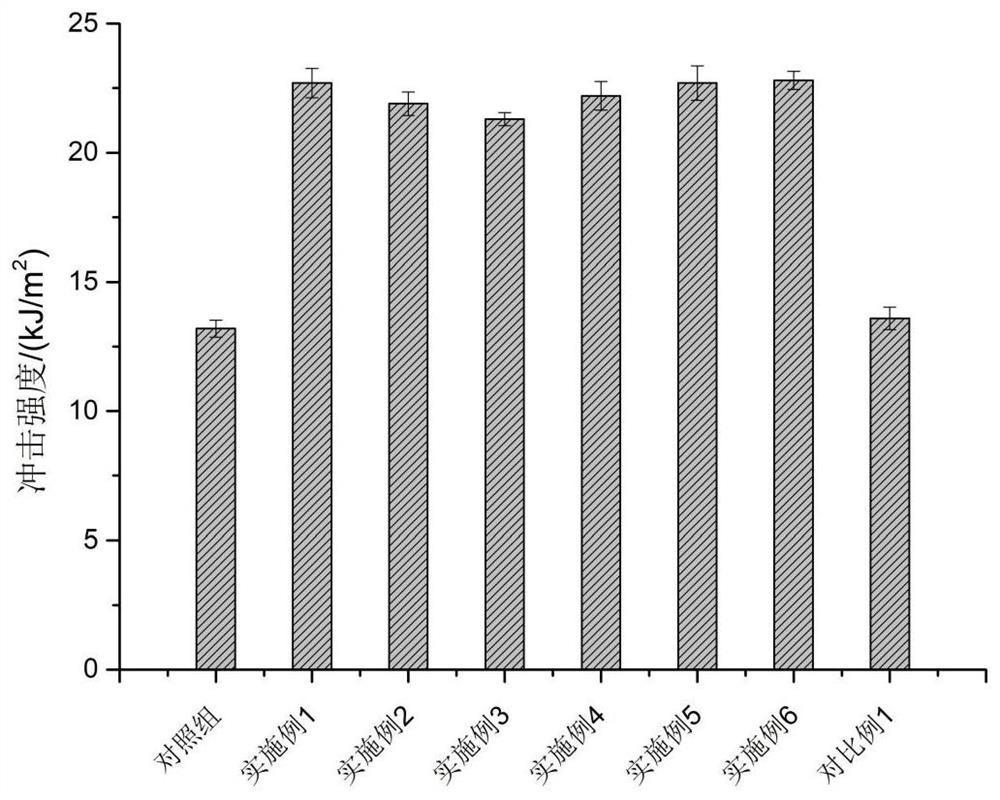

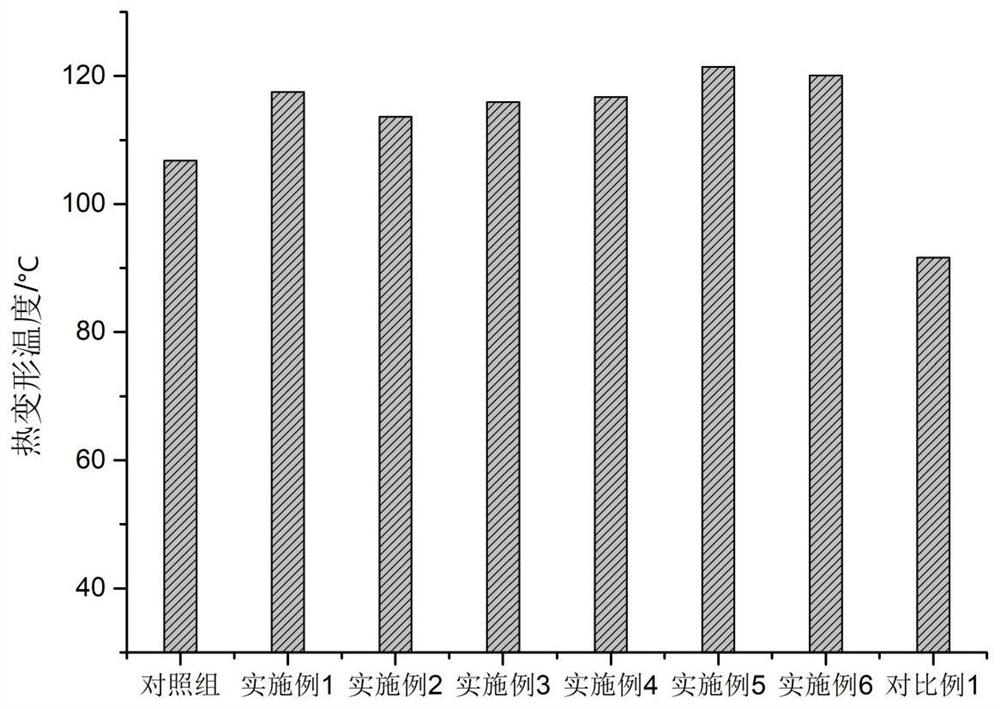

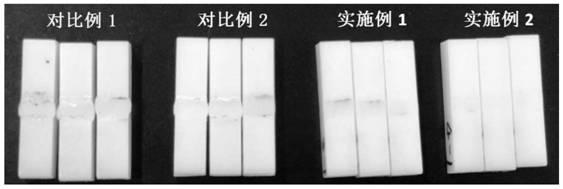

Modified nano-microsphere, PC/PET composite material and preparation method of modified nano-microsphere and PC/PET composite material

The invention provides a modified nano microsphere, a PC / PET composite material and a preparation method thereof, and belongs to the technical field of nano materials and high polymer materials, the modified nano microsphere, the PC / PET composite material is prepared from the following raw materials by weight: 60-80 parts of PC, 12-32 parts of PET, 0.5-2 parts of a composite compatibilizer, 0.1-0.3 part of a transparent agent, and 0-0.5 part of an antioxidant; the composite compatilizer comprises modified silicon dioxide / polydopamine / polystyrene porous hollow nano microspheres and maleic anhydride grafted polyethylene, and the mass ratio of the modified silicon dioxide / polydopamine / polystyrene porous hollow nano microspheres to the maleic anhydride grafted polyethylene is (3-5): 7. The PC / PET composite material provided by the invention has high transparency, high mechanical properties, better oil resistance, solvent resistance, heat resistance and the like, and has a wide application prospect.

Owner:上海科进生物技术有限公司

An energy storage heat exchange device

ActiveCN107167013BRealize the purpose of energy storage and heat exchangeLow melting pointHeat storage plantsCold airInsulation layer

The invention relates to an energy-storage heat exchange device. The energy-storage heat exchange device comprises an energy storage pile, a heat exchanger, a heating tube and a fan, wherein a thermal insulation layer A is arranged at the periphery of the energy storage pile; a gap between the energy storage pile and the thermal insulation layer A is taken as an air flue; a ventilating groove is formed in the energy storage pile; the fan is connected with the heat exchanger through a pipeline; the other end of the fan is accessed into the air flue A through a pipeline; the other end of the heat exchanger is accessed into an air flue B through a pipeline; the air flue A and the air flue B refer to air flues formed between opposite two ends in the energy storage pile and the thermal insulation layer A; an electric heating tube is arranged in the energy storage pile in a penetrating mode for heating the energy storage pile; under driving of the fan, air flow enters the energy storage pile through the air flue A; and air flow is heated by the energy storage pile. The energy-storage heat exchange device utilizes off-peak electricity to heat the energy storage pile, and utilizes the energy storage pile to slowly release heat for heating air flow to form hot air; and after entering the heat exchanger to exchange heat, hot air is changed into cold air for being blown into the fan, and re-enters the air flue A under driving of the fan in a circulating mode, so that the energy-storage heat exchange purpose is realized.

Owner:天津朗华科技发展有限公司

Method for preparing conductive polymer/silsesquioxane composite electrode material

InactiveCN102010594BLarge specific surface areaImprove void structureElectrolytic capacitorsIn situ polymerizationConductive polymer

The invention relates to a method for preparing a conductive polymer / silsesquioxane composite electrode material, which comprises two reactions that: silsesquioxane with end benzene ring and sulfonating agent undergo sulfonation reaction to form a phenyl sulfonic acid group, silsesquioxane with end mercapto and oxidant undergo oxidation reaction to form a sulfonic acid group, and the silsesquioxane and an intrinsic conductive polymer monomer undergo in situ polymerization to form the composite electrode material. The method has simple process and low cost; the prepared conductive polymer nanocomposite material has good electric conductivity (more than 5S / m) and large specific surface area; and a super capacitor prepared from the electrode material has the characteristics of high specificpower, high specific energy, good recyclability and the like, and has good application prospect.

Owner:DONGHUA UNIV

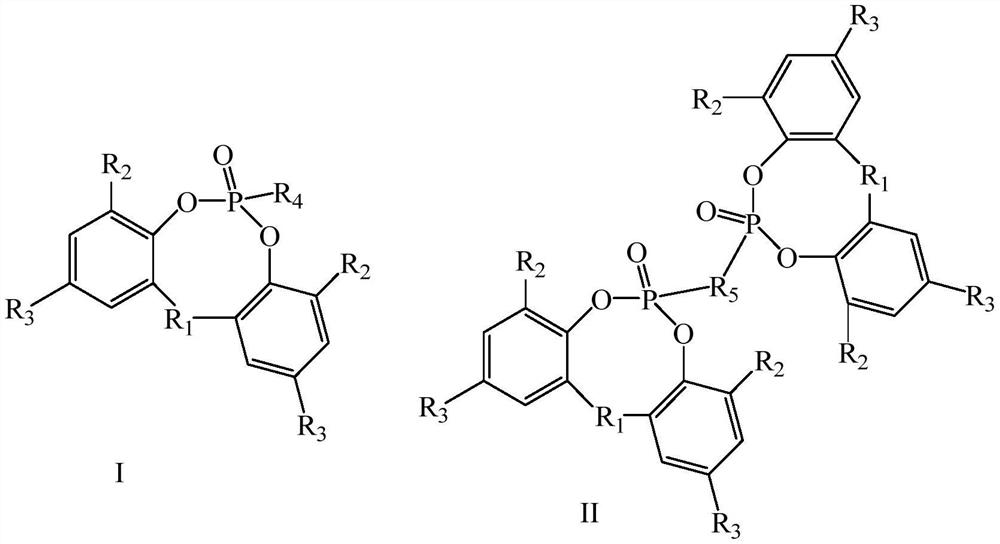

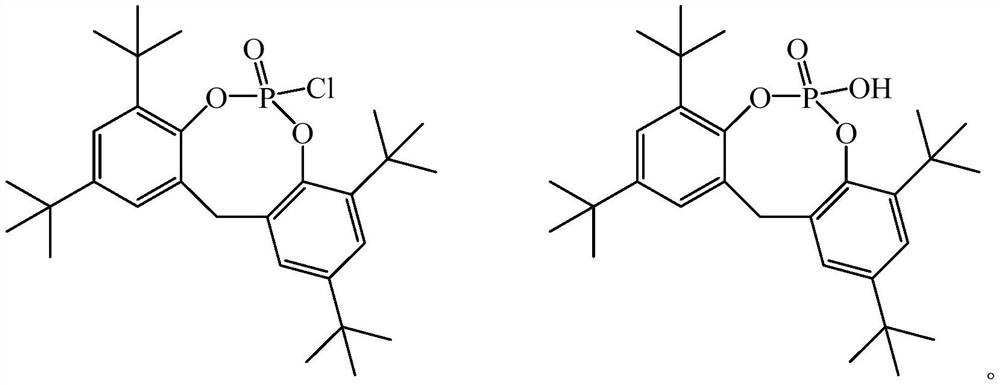

Polyhedral oligomeric silsesquioxane phosphate nucleating agent as well as preparation method and application thereof

InactiveCN112080008AHigh nucleation efficiencyIncrease the rate of crystallizationPolypropyleneSiloxane

The invention discloses a polyhedral oligomeric silsesquioxane phosphate nucleating agent. The polyhedral oligomeric silsesquioxane phosphate nucleating agent is prepared from polyhedral oligomeric silsesquioxane and phosphate in a molar ratio of 1: (0.1-12). The polyhedral oligomeric silsesquioxane phosphate nucleating agent disclosed by the invention is added into a polypropylene matrix, so thatthe substance can well promote crystallization of polypropylene, plays a role of the nucleating agent and accelerates the crystallization rate of polypropylene.

Owner:EAST CHINA UNIV OF SCI & TECH +1

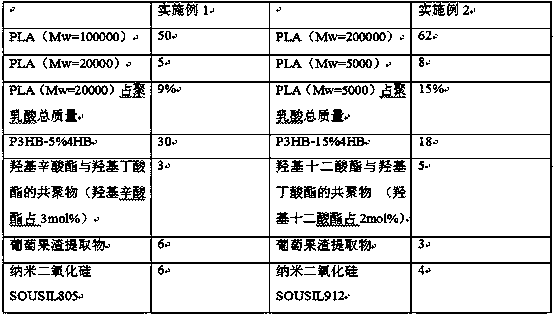

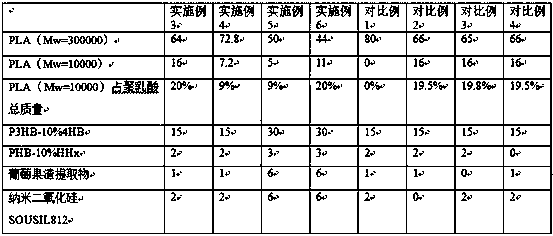

A biodegradable high-barrier plastic product and its preparation method

The invention discloses a biodegradable high-barrier type plastic product and a preparation method of the biodegradable high-barrier type plastic product. The plastic product is prepared from the following raw materials in percentage by weight: 55 percent to 80 percent of polylactic acid, 15 percent to 30 percent of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), 2 percent to 5 percent of polyhydroxyalkanoate containing middle and long chains, 1 percent to 6 percent of grape fruit residue extract and 2 percent to 6 percent of hydrophobic nano silicon dioxide. According to the biodegradable high-barrier type plastic product, the poly(3-hydroxybutyrate-co-4-hydroxybutyrate) is used for toughening the polylactic acid; meanwhile, the low-molecular-weight polylactic acid is added to increase the compatibility of high-molecular-weight polylactic acid and the poly(3-hydroxybutyrate-co-4-hydroxybutyrate); the grape fruit residue extract is used for improving the thermal stability and machinability of the polyhydroxyalkanoate. The biodegradable high-barrier type plastic product provided by the invention has good mechanical strength, anti-falling property and water resistance and air resistance; a machining process is easy to control and the defective rate is low; the biodegradable high-barrier type plastic product can be applied to fields including food packages, cosmetic packages, medicine packages and the like.

Owner:江苏南方包装有限公司 +1

Biodegradable agricultural film preparation method

The invention discloses a biodegradable agricultural film preparation method and belongs to the field of agricultural films. The preparation method disclosed by the invention comprises the steps: taking absolute ethyl alcohol, distilled water, nano titanium dioxide and a silane coupling agent, putting the nano titanium dioxide and the silane coupling agent into a container, adding the absolute ethyl alcohol and the distilled water, evenly stirring, adjusting a pH value, magnetically stirring, filtering to obtain filter cake, using the absolute ethyl alcohol to wash the filter cake and then drying to obtain dried matter; mixing extractive with water, evenly stirring, adding the dried matter, oscillating away from light, centrifuging, taking precipitate, using deionized water to wash the precipitate, vacuum freeze drying and grinding to obtain ground matter; mixing wrapping matter, distilled water and a hydrochloric acid solution, evenly stirring, adjusting a pH and ultrasonically dispersing to obtain dispersed matter; mixing the dispersed matter with absolute ethyl alcohol, ball milling to obtain ball milled liquid, ultrasonically dispersing azodiisobutyronitrile, polyethylene resin, acetone and ball milled liquid, recycling the acetone and pressing on a plate vulcanizing machine to obtain the biodegradable agricultural film.

Owner:方建波

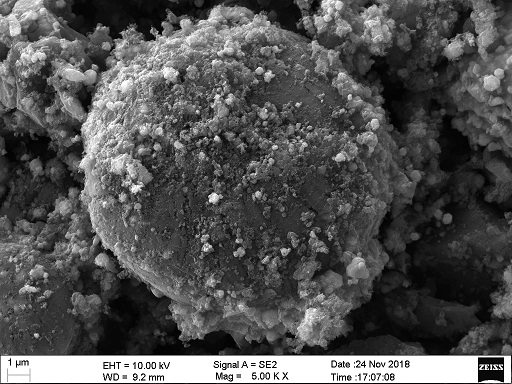

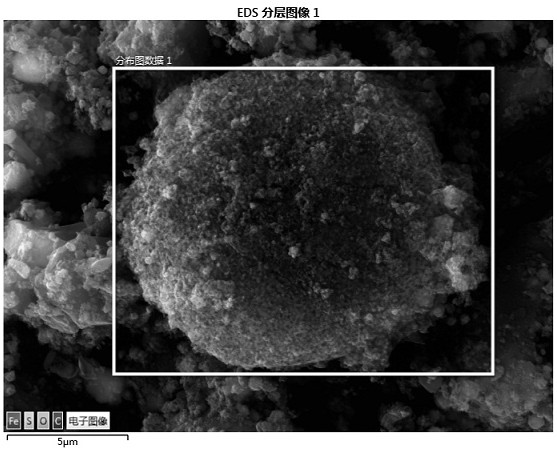

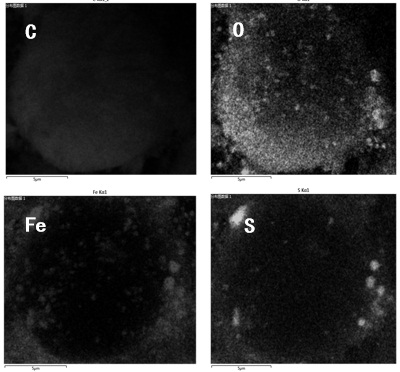

A kind of nano-iron compound/mesophase carbon microsphere composite material and preparation method thereof

ActiveCN109817915BThe synthesis steps are simpleEasy to operateCell electrodesSecondary cellsElectrical batteryMicrosphere

The invention discloses a nano-iron compound / intermediate-phase carbon microsphere composite material and a preparation method thereof, in the composite material, a nano-iron compound is uniformly dispersed, coated or embedded in intermediate-phase carbon microspheres, and the mass fraction of the nano-iron compound is 0.1%-10%. The preparation method comprises the following steps: uniformly dispersing an oil-soluble iron precursor and a sulfur additive in asphalt, carrying out a thermal polymerization reaction under the conditions of proper temperature, pressure and inert atmosphere protection, separating a product to obtain a composite material precursor, and further carbonizing to prepare the nano iron compound / mesophase carbon microsphere composite material. The preparation method hasthe advantages that the oil-soluble iron precursor forms uniformly dispersed nanoparticles in situ, so that the formation of a high-quality mesophase carbon microsphere composite material is promoted,and the product yield and particle size can be regulated and controlled. The lithium ion battery negative electrode material prepared from the composite material has good electrochemical characteristics.

Owner:郑州中科新兴产业技术研究院

High toughness transparent resin and preparation method thereof

ActiveCN113956470BImprove toughnessHigh light transmittanceCarbamic acid derivatives preparationOrganic compound preparationAcetic acidPolymer science

Owner:东阳市福雕文化创意有限公司

A kind of antistatic, friction-resistant and wear-resistant polyoxymethylene material and preparation method thereof

ActiveCN109796723BImprove antistatic performanceImprove friction and wear propertiesPolyoxymethylenePolymer science

The invention discloses an antistatic, friction-resistant and wear-resistant polyoxymethylene material and a preparation method thereof. The polyoxymethylene material is a mixture of polyoxymethylene, ionic liquid and polytetrafluoroethylene. Its preparation method is to vacuum-dry polyoxymethylene, ionic liquid and polytetrafluoroethylene at 80-120°C for 24-48 hours respectively; dry the polyoxymethylene, ionic liquid and polytetrafluoroethylene according to the mass ratio of 100:0.1-2 : 1-20, put into melt extrusion equipment and carry out melt extrusion at 170-200 DEG C to obtain a mixture; discharge the mixture from the melt extrusion equipment and lower to normal temperature to obtain a polyoxymethylene material. The polyoxymethylene material in the present invention has excellent antistatic performance and friction and wear resistance, and its preparation method only needs to use common melting extrusion equipment, and the industrial preparation is simple.

Owner:安徽贺赢新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com