Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "TRIETHANOLAMINE STEARATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TEA-Stearate is the triethanolamine (TEA) salt of stearic acid. It is a cream-colored, wax-like solid. In cosmetics and personal care products, TEA-Stearate is used in a variety of baby, bath, eye makeup, fragrance, hair, makeup, nail, personal cleanliness, shaving, skin and suntan preparations.

Anti-moth fabric softener and preparation method

ActiveCN103668964AEasy to preparePromote degradationFibre treatmentPreservativeTRIETHANOLAMINE STEARATE

The invention relates to an anti-moth fabric softener and a preparation method thereof, and belongs to the technical field of daily chemicals. The softener comprises the following components in parts by weight: 12-15 part of triethanolamine stearate quaternary ammonium salt, 6-8 parts of tea saponin, 2-5 parts of cocamidopropyl betaine, 0.1-0.3 part of tagetes ethereal oil, 0.2-0.5 part of a thickening agent, 0.02-0.1 part of a preservative agent, 0.2-0.6 part of an antifoam agent, and 100-120 parts of deionized water. The preparation method is simple. The prepared product has excellent biodegradability, is environment-friendly, integrates the functions of yellowing resistance and sterilization, also has a good anti-moth function and is easy to popularize and apply.

Owner:至诚(广东)高新材料有限公司

Enhanced and toughened plant fiber-polyethylene composite membrane material and preparation method thereof

The invention discloses an enhanced and toughened plant fiber-polyethylene composite membrane material. The material is prepared from, by weight, 50-60 parts of linear low-density polyethylene, 8-15 parts of waxy corn starch, 8-15 parts of plant fiber powder, 3-6 parts of stearic acid triethanolamine ester quaternary, 25-35 parts of degradable calcium carbonate master batch, 10-18 parts of vinyl-terminated silicone oil, 0.3-0.8 part of hydrogen containing silicone oil, a proper amount of sulfuric acid solution, a proper amount of platinum catalyst, 10-16 parts of straw extract fiber and 15-20 parts of towel gourd fiber. After being used, the composite membrane material can be decomposed into water and carbon dioxide under the natural conditions within 6-18 months, is high in biodegradation speed and free of white pollution, and meets the environment protection requirement; the prepared plant fiber-polyethylene composite membrane material has good stretching resistance and tear resistance.

Owner:合肥市智源包装科技有限公司

Reinforced toughened plant fiber composite film and preparation method thereof

The invention discloses a reinforced toughened plant fiber composite film and a preparation method thereof. The composite film is prepared from the following raw materials in parts by weight: 20-45 parts of straw extract fiber, 15-35 parts of towel gourd fiber, 20-40 parts of ramee, 10-30 parts of corn starch, 12-25 parts of chitosan, 6-17 parts of molecular sieve, 5-20 parts of polyvinyl alcohol, 5-15 parts of polycaprolactone, 2-6 parts of potassium tripolyphosphate, 2-7 parts of diethyl phthalate 1-5 parts of triethanolamine stearate quaternary ammonium salt, 2-8 parts of reinforcer, 5-25 parts of clearing agent and 6-20 parts of adhesive. The invention also discloses a preparation method of the composite film. The tensile strength of the plant fiber composite film is 16-25 MPa, the tearing strength is 75-105 MPa, and the plant fiber composite film has favorable stretching resistance and tear resistance. Besides, the preparation method is simple, has the advantages of accessible and common raw materials and lower cost, and is suitable for wide popularization and further expanded application.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Method for performing crease-resistant finishing on cotton fabrics

ActiveCN107034669ANo yellowingGood anti-wrinkle and anti-deformation effectWrinkle resistant fibresVegetal fibresSodium Hypophosphite MonohydrateHazardous substance

The invention relates to a method for performing crease-resistant finishing on cotton fabrics. The method comprises the following steps: 1) putting bleached pure cotton cloth into a mixed solution of malic acid, sodium hypophosphite, stearic acid triethanolamine ester quaternary softening agent and penetrating agent JFC, steeping, rolling and steeping for two times, wherein the residual rate is controlled to be 90-100% and 2) drying, baking, soaping and then drying. The method has the advantages that malic acid is used as a crease-resistant finishing agent, and meanwhile, sodium hypophosphite with a catalytic effect, the nontoxic softening agent and the penetrating agent are added for performing the crease-resistant finishing on the cotton fabrics, so that the crease-resistant effect is guaranteed, the traditional problems of strong crease-resistant finishing capacity and larger abrasive resistance loss are solved and the fabrics are free from yellowing phenomenon; a crease-resistant finishing agent which is prepared at reasonable ratio of malic acid to catalyst to softening agent to penetrating agent is green and environment-friendly, cannot release toxic harmful materials, such as, formaldehyde, and is safe; the production cost is reduced; the method has certain popularization and application values in production.

Owner:WUYI UNIV

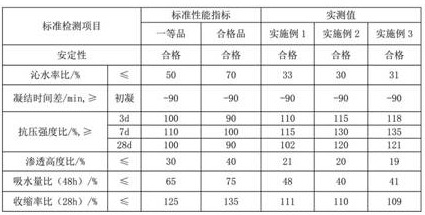

GBL concrete waterproof compacting agent

The invention discloses a GBL concrete waterproof compacting agent. The compacting agent comprises, by weight, 10 to 17 parts of sodium silicate, 20 to 28 parts of aluminum potassium sulfate dodecahydrate, 1 to 4 parts of polyether, 0.05 to 0.5 part of a polyhydroxy compound, 1 to 6 parts of polyethylene glycol, 0.5 to 1.2 parts of n-butyl alcohol, 0.01 to 0.06 part of mineral fiber, 0.2 to 0.4 part of diethanol amine, 2 to 5 parts of lithium carbonate, 0.2 to 0.4 part of triethanolamine stearate, 0.05 to 0.1 part of a surfactant, 0.002 to 0.006 part of an NNO dispersing agent and 40 to 70 parts of water. The invention further discloses a preparation method of the compacting agent. The compacting agent can significantly improve the concrete anti-permeability, reduce the concrete shrinkage, prevent the concrete from cracking after hardening, and effectively prevent water molecule permeation, thereby improving the concrete strength and performance.

Owner:河南博浪实业有限公司

Mildew-resistant finishing agent for down coats

A disclosed m ildew-resistant finishing agent for down coats is composed of the following raw materials in parts by weight: 10-16 parts of fatty alcohol polyoxyethylene ether, 3-6 parts of chitosan, 5-9 parts of stearic acid triethanolamine ester quaternary ammonium salt, 5-9 parts of marigold, 3-7 parts of didecyl dimethyl ammonium chloride, 5-7 parts of allyl glycidyl ether, 3-5 parts of a cross-linking agent, 15-20 parts of base oil, 4-5 parts of phenyltriethoxysilane, 12-16 parts of natural saponin, 5-8 parts of an emulsifier, 2-4 parts of sodium citrate, 2-7 parts of sodium dodecylbenzenesulphonate, 6-8 parts of polyethylene glycol monooleate, and 100-110 parts of water. The mildew-resistant finishing agent for down coats possesses functions of resisting bacteria, preventing peculiar smell, preventing mildew and the like, does not generate stimulation and anaphylactic reaction on skin, is nontoxic, does not have teratogenicity, does not have potential carcinogenicity and accords with environment protection requirements.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Antibacterial fabric softener

InactiveCN108951143AAnti-yellowingHas the function of sterilization and disinfectionLight resistant fibresBiochemical treatment with enzymes/microorganismsFoaming agentNano sio2

The invention discloses an antibacterial fabric softener. The antibacterial fabric softener comprises following components, by mass, 13 to 15 parts of a stearic acid triethanolamine ester quaternary,0.4 to 1 part of a viscosity reducer, 0.1 to 0.5 part of almondamidopropylamine oxide, 0.6 to 1 part of marine actinomycete, 7 to 20 parts of nanometer TiO2, 7 to 20 parts of nanometer SiO2, 0.3 to 1part of a non-ionic organic fluorine surfactant, 7 to 8 parts of tea saponin, 0.04 to 0.1 part of an antiseptic, and 0.3 to 0.6 part of an anti-foaming agent. The antibacterial fabric softener is capable of preventing yellowing, bacteria, and damage by worms, and sterilizing, is green, is friendly to the environment, and is convenient for popularization and applications.

Owner:苏江

Formula of jewelry cleanser and preparation method

ActiveCN102703234AImprove hydrophilic abilityEasy surface cleaningCationic surface-active compoundsAnionic-cationic-non-ionic surface-active compoundsColloidal silicaTRIETHANOLAMINE STEARATE

The invention discloses a formula of a jewelry cleanser. The formula comprises the following components in parts by weight: 1-10 parts of nanometer colloidal silica dispersant with solid content of 30 percent by weight, 1-20 parts of propylene glycol, 1-20 parts of alkylbenzene sulfonate, 1-20 parts of hydroxymethyl cellulose, 5-30 parts of stearic acid triethanolamine ester quaternary ammonium salt and 100-200 parts of de-ionized water. The invention also discloses a method of preparing the jewelry cleanser. The method comprises the following steps of: (1) adding the propylene glycol and thehydroxymethyl cellulose into the de-ionized water with stirring in sequence and uniformly dispersing the propylene glycol and the hydroxymethyl cellulose, and heating to 50-60 DEG C; (2) adding the alkylbenzene sulfonate and the stearic acid triethanolamine ester quaternary ammonium salt, stirring to fully dissolve the alkylbenzene sulfonate and the stearic acid triethanolamine ester quaternary ammonium salt and cooling to 25 DEG C; and (3) slowly adding the nanometer colloidal silica dispersant with stirring and uniformly dispersing the nanometer colloidal silica dispersant. The various components of the jewelry cleanser are environment-friendly; and the jewelry cleanser has the advantages of extremely high antifouling effect, high stability and capability of polishing the metal. The jewelry cleanser has a good effect of cleaning the surfaces of precious metals and various jewelries.

Owner:GUANGDONG CHJ IND

Pressure sore removing cream prepared from total flavonoids of populus tomentosa leaf and preparation method of pressure sore removing cream

InactiveCN108186779AGood treatment effectNo obvious side effectsAntibacterial agentsAerosol deliveryParaffin waxTreatment effect

The invention belongs to the technical field of traditional Chinese medicine and particularly relates to pressure sore removing cream prepared from total flavonoids of populus tomentosa leaf and a preparation process of the pressure sore removing cream. The flavonoids in the populus tomentosa leaf are subjected to heating reflux extraction with 70% ethanol, further separation and purification areperformed with D101 macroporous resin and polyamide resin, the total flavonoids of the populus tomentosa leaf are obtained, and the cream is prepared from the total flavonoids of the populus tomentosaleaf. The cream is prepared from the total flavonoids of the populus tomentosa leaf and cream base in parts by weight as follows by mixed processing: 0.4-10.0 parts of the total flavonoids of the populus tomentosa leaf, 5.0-45.0 parts of water, 0.42-3.75 parts of glycerin, 0.94-8.43 parts of stearic acid, 0.08-0.75 parts of vaseline, 0.42-3.75 parts of lanolin, 0.44-3.98 parts of liquid paraffin,0.30-2.70 parts of glyceryl monostearate and 0.1-0.9 parts of triethanolamine stearate soap. The cream has good treatment effect on pressure sores.

Owner:NINGXIA MEDICAL UNIV

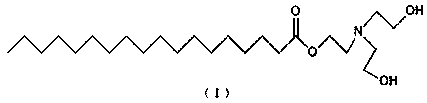

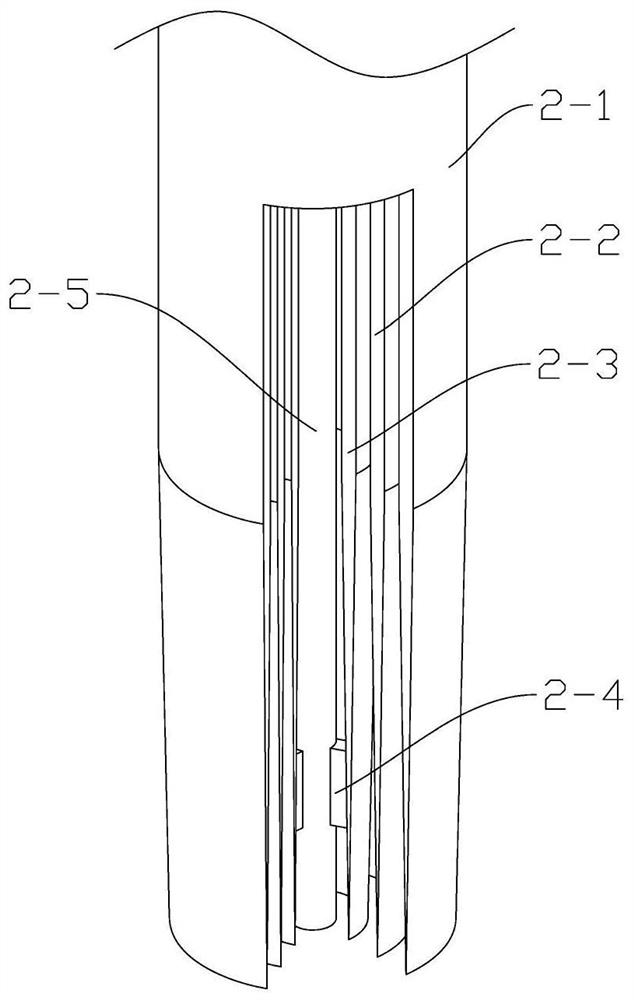

Preparation method of triethanolamine stearate monoester and application of triethanolamine stearate monoester to grinding aiding for talc

InactiveCN111253268AReduce aggregationReduce chanceOther chemical processesOrganic compound preparationChemical synthesisOrganosolv

The invention relates to the technical field of preparation of chemically-synthesized agents, especially to a preparation method of triethanolamine stearate monoester and application of triethanolamine stearate monoester to grinding aiding for talc. The preparation method is characterized in that triethanolamine and stearic acid react for a certain period of time in an inert gas atmosphere under the condition of an organic solvent or no solvent at a certain temperature according to a reaction formula as described in the specification to obtain the triethanolamine stearate monoester which is asolid with a color from colorless to faint yellow and has a structural formula (I) as shown in the specification. Compared with the prior art, the invention has the following beneficial effects: 1) asa grinding aid for talc, the triethanolamine stearate monoester can realize selective adsorption and electrical neutralization on the surface of a material, eliminate an electrostatic effect, improvethe dispersity of a fine powder material and improve the utilization rate of mechanical energy; 2) the p triethanolamine stearate monoester is low in toxicity, efficient and environment-friendly, plays a certain role in inhibiting dust pollution and is beneficial for sustainable development; and 3) the preparation method is simple and easy to control, complex subsequent treatment is not needed, and the production efficiency of modified talc is improved.

Owner:辽宁精华新材料股份有限公司

High-wear-resistance phosphating solution and preparation method thereof

InactiveCN105908177AImprove wear resistanceSimplify the phosphating processMetallic material coating processesXylyleneHydroxylamine

The invention discloses a high-wear-resistance phosphating solution and a preparation method thereof. The high-wear-resistance phosphating solution is prepared from, by weight, 10-15 parts of polyvinylpyrrolidone, 3-8 parts of hexamine, 15-20 parts of lauryl sodium sulfate, 1-3 parts of ammonium peroxydisulfate, 3-6 parts of stearic acid triethanolamine ester quaternary, 2-6 parts of sodium xylene sulfonate, 2-6 parts of sodium fluosilicate, 10-20 parts of hydroxylamine sulphate, 3-6 parts of sodium metanitrobenzene sulfonate, 55-65 parts of deionized water and 5-8 parts of isooctyl palmitate. Compared with an existing phosphating solution and phosphating technology, the high-wear-resistance phosphating solution is adopted for carrying out phosphating treatment on a workpiece, and therefore the phosphating technology is simplified, phosphating efficiency is improved, and phosphating cost is reduced. Meanwhile, a phosphating film formed by the high-wear-resistance phosphating solution is more compact, evener, excellent in bonding force with a workpiece substrate and excellent in wear resisting property, and the preparation method is simple and low in cost.

Owner:WUXI EPIC TECH

Novel alkali-resistant penetrant for leather

The invention discloses a novel alkali-resistant penetrant for leather. The novel alkali-resistant penetrant for leather comprises the following components in parts by weight: 10-15 parts of fatty alcohol polyoxyethylene ether, 3-8 parts of methyltriethoxysilane, 55-65 parts of deionized water, 15-20 parts of octadecylamine polyoxyethylene ether, 1-3 parts of sophorolipid, 8-10 parts of alkylphenol polyoxyethylene, 3-6 parts of stearic acid triethanolamine ester quaternary ammonium salt, 2-6 parts of sodium xylene monosulfonate, 2-6 parts of trioctyl phosphate, 10-20 parts of sodium diethylhexyl sulfosuccinate, 3-6 parts of acrylic acid and 5-8 parts of sucrose ester. The alkali-resistant penetrant for leather has very high permeability and strong alkalinity, and can obviously enhance the permeability of the leather dyes; and the comprehensive properties of the penetrant are effectively enhanced. The alkali-resistant penetrant for leather is economical and practical, has the characteristics of low cost and long use period, can effectively prevent the leather from damage and does not damage the leather.

Owner:董荣琴

Food leavening agent and preparation method thereof

PendingCN107723261AEnsure balancePrevent proliferationBacteriaAlcoholic beverage preparationBiotechnologyTRIETHANOLAMINE STEARATE

The invention discloses a food leavening agent. The agent is prepared from 30-50 parts of lactobacillus plantarum, 15-20 parts of auxiliary lactobacillus casei, 15-20 parts of lactobacillus acidophilus, 3-5 parts of octadecanol stearate and 4-6 pats of stearic acid triethanolamine. The processing technology is simple, and each parameter is easy to control and operate. Lactobacillus acidophilus canadjust the balance of intestinal flora, inhibit propagation of intestinal harmful microbes and have an antagonistic effect on pathogenic microbes.

Owner:江苏中通生物科技有限公司

Solid blocky eyelash black

The invention discloses solid blocky eyelash black which is prepared from the following components in parts by weight: 20-35 parts of stearic acid triethanolamine, 3-8 parts of an inorganic pigment, 2-5 parts of paraffin, 4-12 parts of wool fat, 15-20 parts of candelilla wax and 12-20 parts of bee wax. The invention provides the solid blocky eyelash black; due to addition of substances such as thebee wax and the inorganic pigment, the solid blocky eyelash black is excellent in adhesion property and solid stability and good in ductility, and has effects of moisturizing and freshening eyelash and is free of irritation to skin after being used.

Owner:蔡银中

Anti-rust phosphating solution and preparation method thereof

InactiveCN105951069ASimplify the phosphating processImprove Phosphating EfficiencyMetallic material coating processesTRIETHANOLAMINE STEARATEEthylenediaminetetraacetic acid

The invention discloses an anti-rust phosphating solution and a preparation method thereof. The anti-rust phosphating solution is prepared from the following raw materials in parts by weight: 10-16 parts of polyvinylpyrrolidone, 3-6 parts of sodium 3-nitrobenzene sulfonate, 5-9 parts of stearic acid triethanolamine ester quaternary ammonium salt, 5-9 parts of marigold essential oil, 3-7 parts of ethylenediaminetetraacetic acid, 5-7 parts of allyl glycidyl ether, 3-5 parts of tartaric acid, 15-20 parts of 2-methyl-4-isothiazolin-3-one, 4-5 parts of hexamethylenetetramine, 6-8 parts of sodium lauryl sulfate, 100-110 parts of water and 12-16 parts of zinc dihydrogen phosphate. Compared with a conventional phosphating solution and a conventional phosphating process, the anti-rust phosphating solution and the preparation method disclosed by the invention have the advantages that when the anti-rust phosphating solution is adopted for phosphating treatment of a workpiece, the phosphating process is simplified, the phosphating efficiency is improved and the phosphating cost is reduced; meanwhile, a phosphating film formed by adopting the anti-rust phosphating solution not only is denser and more uniform, but also can be effectively protected from rust; and the preparation method is simple and low in cost.

Owner:WUXI EPIC TECH

Cleaning agent special for aluminum frame dies and preparation method thereof

The invention discloses a cleaning agent special for aluminum frame dies. The cleaning agent comprises the following raw materials by weight: 15-25 parts of isopropanol, 8-14 parts of sodium silicate,6-13 parts of cocamidopropyl betaine, 7-12 parts of alkylbenzene sulfonate, 10-20 parts of stearic acid triethanolamine ester quaternary ammonium salt, 15-30 parts of organic acid, 4-9 parts of fattyamine polyoxyethylene ether, 2-6 parts of silicon dioxide, 7-11 parts of sodium dodecyl sulfate, 3-5 parts of sodium oleate, 8-14 parts of glycerin, 30-40 parts of softened water, 6-12 parts of modified sepiolite powder, 1-2 parts of a defoamer, 2-4 parts of a lubricant, and 1-3 parts of a bactericide. The cleaning agent special for aluminum frame dies provided by the invention can effectively remove impurities and oil stains on aluminum frame surfaces, and greatly improves the cleanliness of aluminum frame dies, thereby improving the quality of the prepared aluminum frames.

Owner:河南颇文商贸有限公司

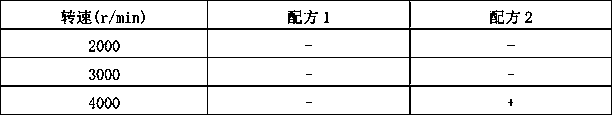

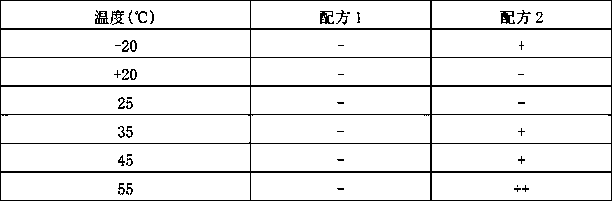

Formula of lubricant for wire drawing and its preparation method

InactiveCN100547062CImprove the lubrication effectReduce manufacturing costAdditivesParaffin waxChemical industry

The invention belongs to the technical field of chemical industry, and relates to a lubricant production formula for wire drawing and a production method thereof. The formula mainly consists of paraffin wax, emulsifier OS, emulsifier OP, polyethylene glycol, stearic acid, triethanolamine and deionized water composed of. The preparation method of the present invention is: firstly add deionized water into the disperser and heat it to 85-90°C, then turn on the disperser, and in the dispersed state, paraffin, emulsifier OS, emulsifier OP, stearic acid 1. Add triethanolamine into the disperser, disperse for 30 minutes, then add polyethylene glycol into the disperser, continue to disperse for 10 minutes, stop the disperser, and when the temperature of the material in the disperser drops to room temperature, the drawn wire can be obtained. Use lubricant. This product is widely used in the drawing lubrication of galvanized products, nickel-plated products, copper-plated and chrome-plated products, and has the characteristics of good lubricating effect, low production cost and bright products.

Owner:王崇高

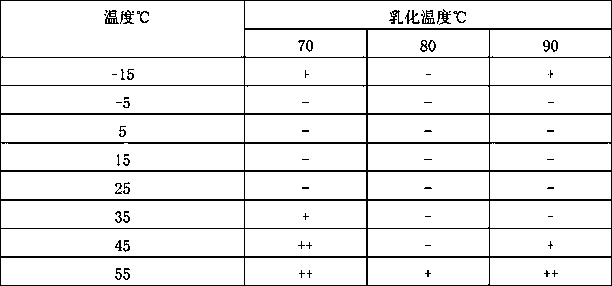

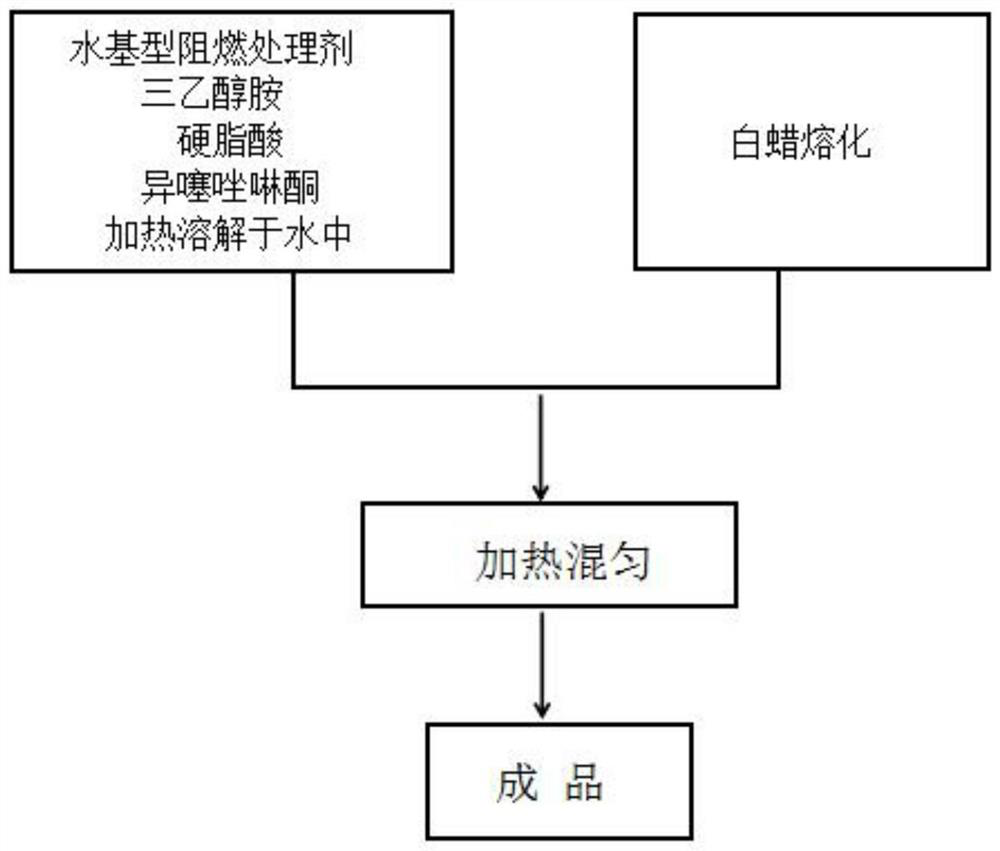

Preparation method of laboratory reagent bottle label protective film

PendingCN114797513AWith anti-mildew effectWith fire performanceLiquid surface applicatorsTransportation and packagingIsothiazolinoneThiazole

The invention discloses a preparation method of a laboratory reagent bottle label protective film, and relates to the technical field of label protective films. Putting the water-based flame-retardant treatment agent into deionized water, and heating in a water bath to fully dissolve the water-based flame-retardant treatment agent; triethanolamine, stearic acid and isothiazolinone are added, and water bath heating and stirring are continued; heating to melt the white wax, and pouring the white wax while hot; and adding boiling deionized water, heating and stirring until the substances are completely dissolved, taking down, standing, naturally cooling to room temperature, covering and storing in a glass container to obtain a prepared finished product. The water-based flame-retardant treating agent is used as a raw material of the label protective film, so that the prepared finished product has good fireproof performance; isothiazolinone is added, so that the prepared protective film has a mildew-proof effect; and stearic acid and triethanolamine are added, so that the raw materials are more fully dissolved and emulsified, and the finished product is more uniform. And the prepared finished product is uniform in film formation, fast in film formation and convenient to manufacture, meets the requirements of green chemistry, and has obvious economic benefits and social benefits.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

A method for anti-wrinkle finishing of cotton fabric

ActiveCN107034669BNo yellowingGood anti-wrinkle and anti-deformation effectWrinkle resistant fibresVegetal fibresPolymer scienceSodium Hypophosphite Monohydrate

A method for non-formaldehyde anti-wrinkle finishing of cotton fabrics, which has the following steps: Step 1: put malic acid, sodium hypophosphite, triethanolamine stearate quaternary ammonium softener into the pure cotton cloth after scouring and bleaching, and penetrate Soaking in the mixed solution of JFC agent, two dipping and two rolling, control the excess rate of 90-100%; Step 2: drying, curing, soaping and drying. The invention has the following advantages: by using malic acid as anti-wrinkle finishing agent, adding sodium hypophosphite with catalytic effect, non-toxic softener and penetrating agent at the same time, it is used for anti-wrinkle finishing of cotton fabrics, while ensuring anti-wrinkle effect At the same time, it improves the previous problem of large loss of strength and wear resistance in anti-wrinkle finishing, and at the same time, the fabric has no yellowing phenomenon; the anti-wrinkle finishing agent is formed by a reasonable ratio of malic acid, catalyst, softener, and penetrating agent, which is green and environmentally friendly. It releases toxic and harmful substances such as formaldehyde, is safe and secure, and reduces production costs, so it has certain popularization and application value in production.

Owner:WUYI UNIV

Formula of jewelry cleanser and preparation method

ActiveCN102703234BImprove stabilityImprove decontamination abilityCationic surface-active compoundsAnionic-cationic-non-ionic surface-active compoundsColloidal silicaTRIETHANOLAMINE STEARATE

The invention discloses a formula of a jewelry cleanser. The formula comprises the following components in parts by weight: 1-10 parts of nanometer colloidal silica dispersant with solid content of 30 percent by weight, 1-20 parts of propylene glycol, 1-20 parts of alkylbenzene sulfonate, 1-20 parts of hydroxymethyl cellulose, 5-30 parts of stearic acid triethanolamine ester quaternary ammonium salt and 100-200 parts of de-ionized water. The invention also discloses a method of preparing the jewelry cleanser. The method comprises the following steps of: (1) adding the propylene glycol and thehydroxymethyl cellulose into the de-ionized water with stirring in sequence and uniformly dispersing the propylene glycol and the hydroxymethyl cellulose, and heating to 50-60 DEG C; (2) adding the alkylbenzene sulfonate and the stearic acid triethanolamine ester quaternary ammonium salt, stirring to fully dissolve the alkylbenzene sulfonate and the stearic acid triethanolamine ester quaternary ammonium salt and cooling to 25 DEG C; and (3) slowly adding the nanometer colloidal silica dispersant with stirring and uniformly dispersing the nanometer colloidal silica dispersant. The various components of the jewelry cleanser are environment-friendly; and the jewelry cleanser has the advantages of extremely high antifouling effect, high stability and capability of polishing the metal. The jewelry cleanser has a good effect of cleaning the surfaces of precious metals and various jewelries.

Owner:GUANGDONG CHJ IND

Circulating heat exchange agent for reactor

InactiveCN105419731AGuaranteed stabilityExtend the production cyclePreparation by halogen halide additionHeat-exchange elementsTetrachloroethaneReaction temperature

The invention discloses a circulating heat exchange agent for a reactor. In the invention, chlorinated hydrocarbons and a heat stabilizing agent are employed, wherein the chlorinated hydrocarbons include at least one selected from trichloroethane, tetrachloroethylene, tetrachloroethane and pentachloroethane, and the heat stabilizing agent is any one selected from hydroquinone, cresol or triethanolamine stearate. The trichloroethane, the tetrachloroethylene, the tetrachloroethane and the pentachloroethane are low in gasification latent heat and are free of corrosion on the reactor, so that reaction temperature is easy to control and a reaction process is relatively stable, thereby ensuring effective production efficiency of the reactor and reducing maintaining cost. The circulating heat exchange agent itself is very stable and is not a flammable and explosive substance, so that the circulating heat exchange agent can be separated out in subsequent process and does not cause influence on product quality even the heat exchange agent leaks in the reactor. The heat exchange agent is suitable for a reaction system of producing chloroethylene through a traditional calcium carbide method with a mercuric chloride catalyst and also can be used for other reaction systems being controllable in reaction temperature, so that the heat exchange agent is excellent in promotion and application value and development prospect.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD

A kind of preparation method of modified polyacrylamide water treatment material

ActiveCN108794690BImprove stabilityImprove safety and environmental protectionScale removal and water softeningCelluloseMeth-

Owner:河北紫金化工产品有限公司

After-finishing process of brushed fabric

InactiveCN106319952AExcellent flame retardantImprove antistatic performanceFibre treatmentArylTRIETHANOLAMINE STEARATE

The invention discloses an after-finishing process of a brushed fabric. The after-finishing process of the brushed fabric comprises the following steps: 1) putting 1 to 2 parts by weight of alkyl dimethyl aryl ammonium chloride, 3.1 parts by weight of dithiocarbamic acid, 4.1 parts by weight of tri(hexadecenol)ester, 1.7 parts by weight of stearic acid triethanolamine ester quaternary ammonium salt and 0.7 part by weight of methylsulfuric acid alkyl trimethylammonium sequentially into 51 parts by weight of deionized water and stirring uniformly; 2) putting 3.1 parts by weight of hydroxyethyl cellulose, 1.2 parts by weight of mahogany petroleum sulfonate, 0.7 part by weight of mannan, 4.2 parts by weight of polypropylene oxide glycol and 0.4 part by weight of pomegranate bark powder sequentially and stirring continuously until the components are mixed completely and uniformly to prepare finishing liquid; 3) performing padding treatment on the fabric in the finishing liquid, taking out the fabric and drying the fabric at constant temperature. The fabric finished by the process has good properties and soft hand feeling.

Owner:常熟市鑫博伟针纺织有限公司

Environment-friendly cleaning agent for down coats

InactiveCN106085640AStrong decontaminationGood color protectionInorganic/elemental detergent compounding agentsCationic surface-active compoundsTRIETHANOLAMINE STEARATECleansing Agents

A disclosed environment-friendly cleaning agent for down coats is composed of the following raw materials in parts by weight: 35-56 parts of deionized water, 6-8 parts of glutamine, 2-7 parts of sodium polystyrenesulfonate, 5-8 parts of ethylenediaminetetraacetic acid, 4-8 parts of stearic acid triethanolamine ester quaternary, 4-5 parts of phenyltriethoxysilane, 4-9 parts of a dispersant, 22-24 parts of butyl acetate, 2-6 parts of sophorolipid, 1-8 parts of sodium dodecyl sulfate, 2-6 parts of an emulsifier, 3-6 parts of methylcyclosiloxane, 6-10 parts of base oil, 2-6 parts of allyl glycidyl ether, 2-7 parts of borax, and 11 parts of zinc acetate. The environment-friendly cleaning agent for down coats is strong in detergency, does not stimulate skin, is friendly to environment, is good in color protection effect and possesses a bactericidal effect.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Highly waterproof antibacterial breathable sleeping bag and preparation method thereof

ActiveCN114224143AImprove antibacterial propertiesWaterproof and breathableSleeping rugBiochemical fibre treatmentPolymer scienceTRIETHANOLAMINE STEARATE

The invention discloses a highly waterproof antibacterial breathable sleeping bag and a preparation method thereof.The waterproof fabric is prepared by compounding bamboo charcoal fiber fabric, a polytetrafluoroethylene film and a hot melt adhesive, due to the existence of the polytetrafluoroethylene film, the fabric is excellent in waterproof and breathable performance, and the bamboo charcoal fiber fabric is good in antibacterial performance; therefore, by taking the waterproof fabric as a raw material, arranging the polytetrafluoroethylene film on the outer side, sewing the core sleeve and then filling the down feather filler into the core sleeve, the prepared sleeping bag is good in heat preservation performance and excellent in waterproof, antibacterial and air-permeable performance. The wool and a small amount of acrylic fibers are added, the fluffy feeling, the soft and comfortable feeling and the moisture resistance are improved, the surfaces of the wool and the acrylic fibers are treated through a stearic acid triethanolamine ester quaternary ammonium salt solution, and due to the charge attraction effect and the intermolecular hydrogen bond effect, the wool and the acrylic fibers are endowed with the high antibacterial property; the finally prepared sleeping bag has excellent antibacterial performance and good waterproof and moisture-proof performance, and is skin-friendly and comfortable.

Owner:仪征龙兴塑胶有限公司

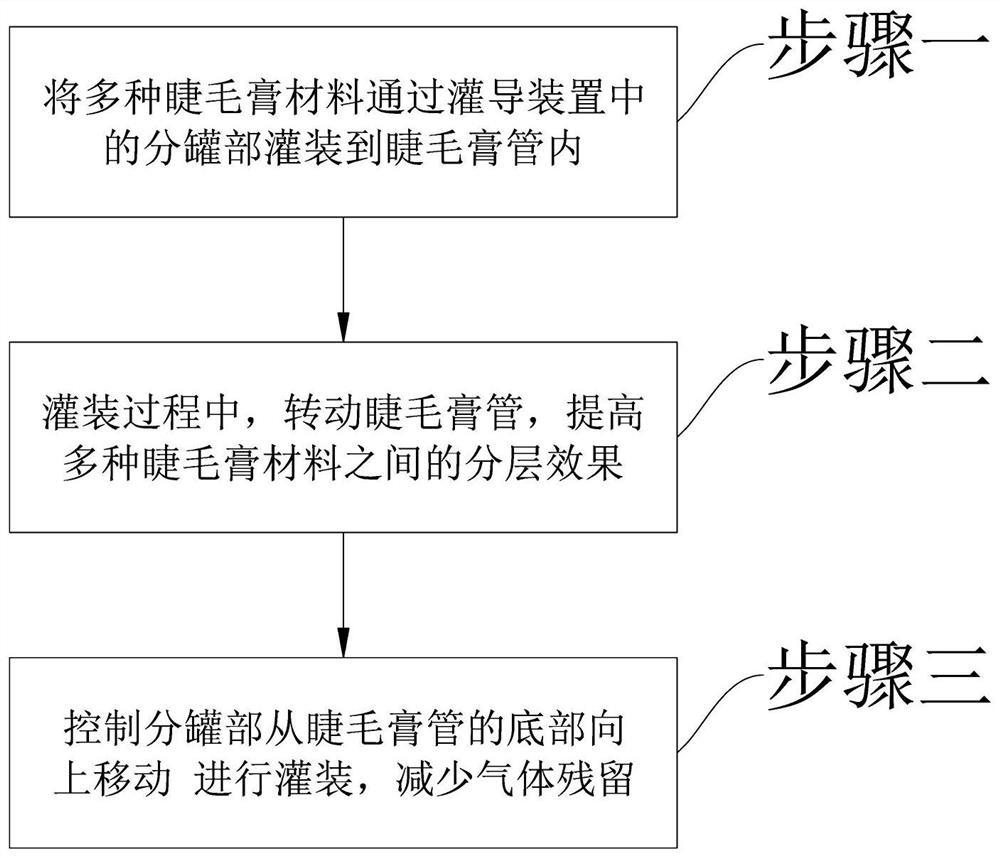

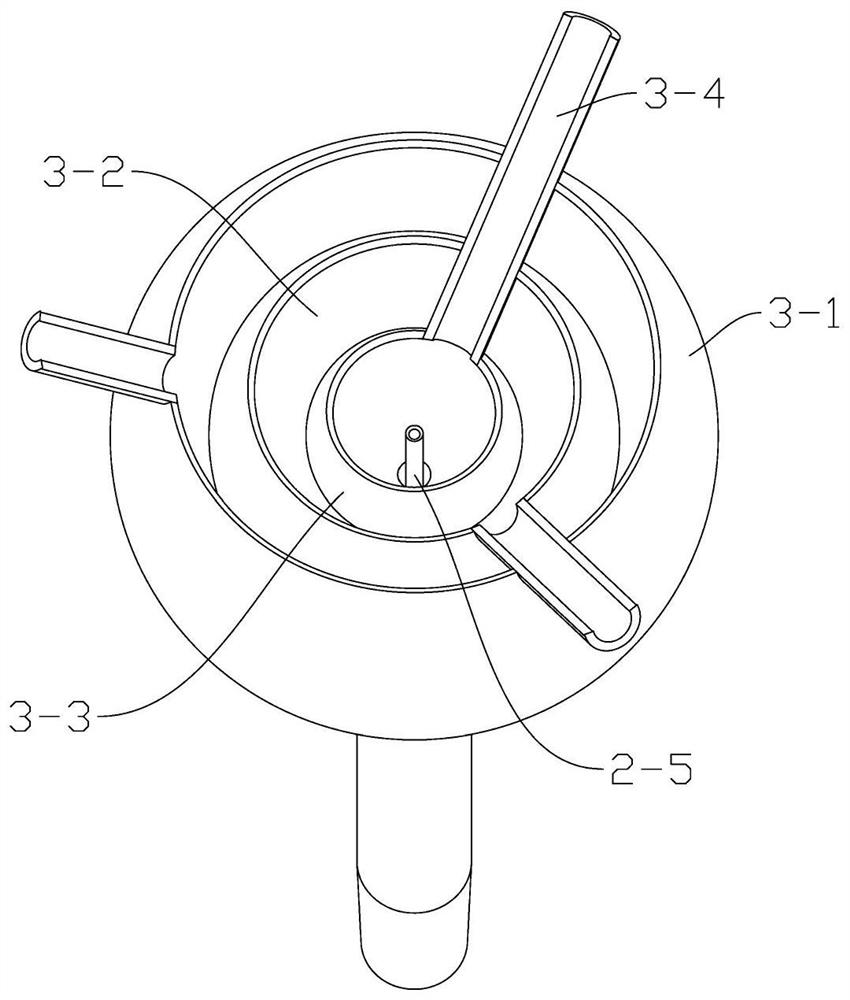

Mascara cream and preparation process thereof

PendingCN113460383AExpand the scope of processingImprove the convenience of color matchingCosmetic preparationsMake-upPolymer scienceEngineering

The invention belongs to the technical field of mascara cream processing, and particularly relates to mascara cream and a preparation process thereof. The invention provides the preparation process of the mascara cream. The preparation process comprises the following steps: 1, various mascara cream materials are filled into a mascara cream tube through a separate filling part in a filling and guiding device; 2, in the filling process, the mascara cream tube is rotated, and the layering effect among the various mascara cream materials is improved; and 3, the separate filling part is controlled to move upwards from the bottom of the mascara tube for filling so as to reduce gas residues. According to the preparation process of the mascara cream, mascara cream products with various layered colors can be conveniently processed. The mascara cream comprises, by mass, 30 parts of paraffin, 10 parts of beewax, 10 parts of wool fat, 33 parts of stearic acid triethanolamine and 15 parts of inorganic pigment.

Owner:周学凤

Environment-friendly water-soluble softening agent

InactiveCN106521944ANo adverse effectsMeet environmental protection requirementsGrip property fibresBetainePhosphate

The present invention discloses an environment-friendly water-soluble softening agent, which is prepared from the following components by weight: 33-52 parts of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), 8-22 parts of alpha-{3-[2-hydroxy-3-(N-methyl-N-hydroxyethylamino)propoxy]-propyl}-omega-n-butylpolydimethylsiloxane, 28-47 parts of 3-methyl cyclic ethylene phosphate diester, 47-65 parts of triethanolamine stearate betaine, and 23-35 parts of N-beta-aminoethyl-gamma-aminopropylmethyldimethoxysilane. With the technical scheme of the present invention, the environment-friendly water-soluble softening agent has characteristics of safety, no toxicity, no adverse effect after the contact of human skin, and meeting of environmental protection requirements.

Owner:无锡市华誉日用品厂

Environment-friendly oil removal phosphating solution and preparation method thereof

InactiveCN106065469ASimplify degreasing processImprove Phosphating EfficiencyMetallic material coating processesTRIETHANOLAMINE STEARATEZinc nitrate

The invention discloses an environment-friendly oil removal phosphating solution and a preparation method thereof. The environment-friendly oil removal phosphating solution is prepared from, by weight, 10-20 parts of methyl acrylate, 2-6 parts of hexamine, 6-9 parts of hydroxylamine sulphate, 2-6 parts of polyvinylpyrrolidone, 4-5 parts of ammonium peroxydisulfate, 2-6 parts of starch ether, 12-16 parts of zinc nitrate, 2-6 parts of polyethylene benzyl trimethyl quaternary ammonium salt, 2-6 parts of stearic acid triethanolamine ester quaternary, 100-120 parts of water, and 7-9 parts of sodium fluosilicate. A phosphating film prepared through the environment-friendly oil removal phosphating solution is compact and uniform; the oil removal procedure in the phosphating process is simplified, and the phosphating efficiency is improved; and the preparation method is simple and low in cost.

Owner:WUXI EPIC TECH

Antelope horn sunscreen stick

InactiveCN109419763AMoisturizes and sunscreensHave the effect of improving eyesight and clearing away heatCosmetic preparationsToilet preparationsGallic acid esterScreening effect

The invention belongs to the field of sunscreen products and particularly relates to an antelope horn sunscreen stick, characterized by comprising, by weight, 4 parts of fatty alcohol acetoacetate, 8parts of glycerol, 8 parts of gallic acid oleyl alcohol ester, 10 parts of cyclomethicone, 2 parts of colloidal magnesium aluminum silicate, 20 parts of white oil, 3 parts of triethanolamine stearate,4 parts of Vaseline, 1 part of orchid essence, and 40 parts of refined water. The antelope horn sunscreen stick also includes 3 parts of antelope horn powder. The antelope horn sunscreen stick provided herein can form a waterproof protective film on the surface of skin to arrive at moisturizing and sun-screening effects; the antelope horn powder added herein can improve eyesight and clear heat.

Owner:黄妙珊

High-corrosion-resistance phosphating solution and preparation method thereof

InactiveCN105951071APrevent rustSimplify the phosphating processMetallic material coating processesDodecaneMetallurgy

The invention discloses a high-corrosion-resistance phosphating solution and a preparation method thereof. The high-corrosion-resistance phosphating solution is prepared from raw materials including, by weight, 35-56 parts of deionized water, 6-8 parts of hexamethylene tetramine, 2-7 parts of sodium fluoborate, 5-8 parts of hydroxylamine sulfate, 4-8 parts of stearic acid triethanolamine ester quaternary ammonium salt, 4-5 parts of phenyltriethoxysilane, 4-9 parts of tartaric acid, 22-24 parts of acetic acid butanol, 2-6 parts of sodium dodecyl sulfate, 1-8 parts of sodium lauryl sulfate, 2-6 parts of ethylenediamine tetraacetic acid, 3-6 parts of dimethylcydosiloxane and 6-10 parts of glycerin. Compared with existing phosphating solutions and phosphating technologies, workpieces are subjected to phosphating treatment through the high-corrosion-resistance phosphating solution, the phosphating process is simplified, the phosphating efficiency is improved, and the phosphating cost is reduced; and meanwhile, a phosphating film formed by means of the high-corrosion-resistance phosphating solution is more compact and more uniform, the workpieces can be protected against corrosion effectively, the preparation method is simple and convenient, and the cost is low.

Owner:WUXI EPIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com