Preparation method of laboratory reagent bottle label protective film

A technology for protective film and reagent bottle, which is applied in the field of preparation of label protective film for laboratory reagent bottles, can solve the problems of mold growth, difficulty in protecting the label from glue and the like, and achieves convenient production, obvious economic and social benefits, and film formation. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

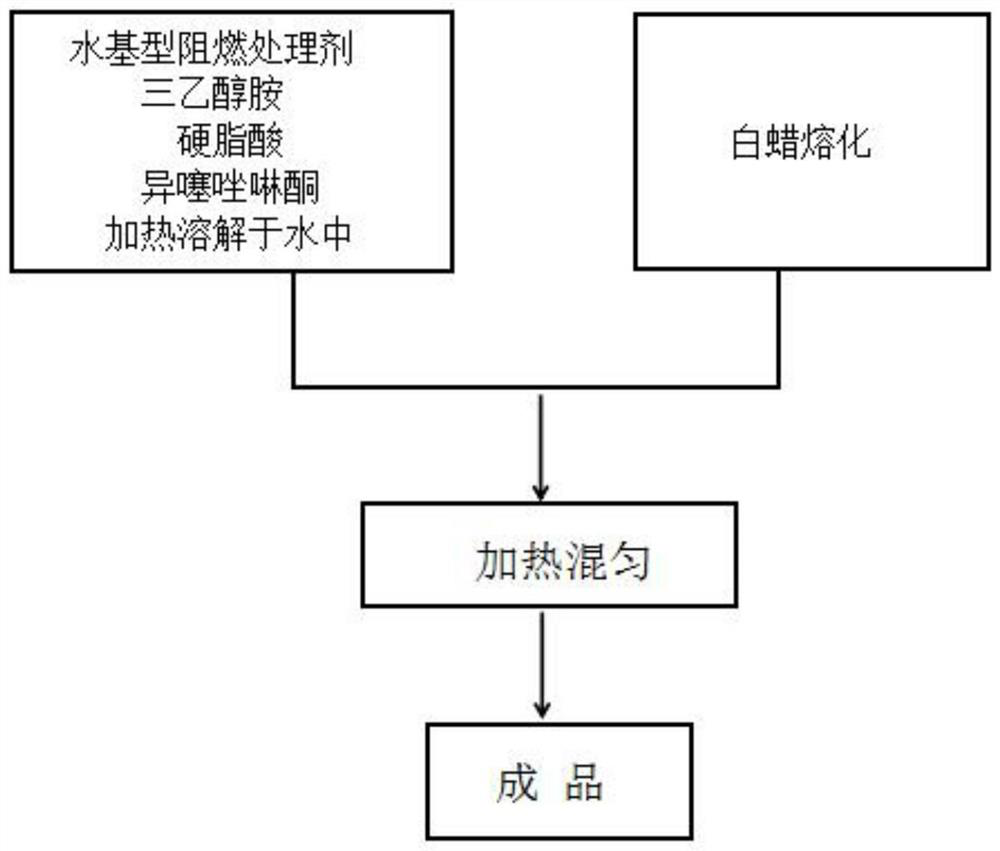

[0017] figure 1 A preparation method of a laboratory reagent bottle label protective film is shown, comprising the following steps:

[0018] S1. Take a 1500ml beaker, add 500g deionized (above grade 2 water standard, total mass is 850g), 100g water-based flame retardant treatment agent (no model limit, preferably transparent). Stir in a water bath at 80°C to dissolve the water-based flame retardant treatment agent (stirring speed 200r / min), then add 14g triethanolamine (analytical grade), 4g stearic acid (analytical grade), 0.1g isothiazolinone (commercial grade) (Sold), water bath at 85°C with stirring, heating and stirring, so that the above substances are completely dissolved under heating and stirring, and this hot solution is solution A.

[0019] S2. Take a 100ml beaker, 20g white candle (commercially available), heat to melt the white wax into a liquid (water bath 82°C, after melting, use tweezers to pick out the residual wax core or remove the wax core in advance), pou...

Embodiment 2

[0022] A preparation method of a laboratory reagent bottle label protective film, comprising the following steps:

[0023] S1. Take a 1500ml beaker, add 500g deionized (above grade 2 water standard, total mass is 900g) and 100g water-based flame retardant treatment agent (BC-1018 transparent). Stir at 82°C in a water bath to dissolve the water-based flame retardant treatment agent (stirring speed 200r / min), then add 14g triethanolamine (analytical grade), 4g stearic acid (analytical grade), 0.1g isothiazolinone (commercial grade) (Sold), stir, heat and stir in a water bath at 85°C, so that the above substances are completely dissolved under heating and stirring, and this hot solution is solution A.

[0024] S2. Take a 100ml beaker, 20g white candle (commercially available), heat to melt the white wax into a liquid (water bath 85°C, use tweezers to remove the residual wax core after melting or remove the wax core in advance), pour solution A while it is still hot, and continue ...

Embodiment 3

[0030] A preparation method of a laboratory reagent bottle label protective film, comprising the following steps:

[0031] S1. Take a 1500ml beaker, add 500g of deionized water (above the standard of secondary water, the total mass is 876g), and 100g of water-based flame retardant treatment agent. Stir at 85°C in a water bath to dissolve the water-based flame retardant treatment agent (stirring speed 200r / min), then add 14g triethanolamine (analytical grade), 4g stearic acid (analytical grade), 0.1g isothiazolinone (commercial grade) (Sold), water bath at 85°C with stirring, heating and stirring, so that the above substances are completely dissolved under heating and stirring, and this hot solution is solution A.

[0032] S2. Take a 100ml beaker, 20g white candle (commercially available), heat to melt the white wax into a liquid (water bath 89°C, use tweezers to remove the residual wax core after melting or remove the wax core in advance), pour solution A while it is still hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com