Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Sodium formaldehydesulfoxylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rongalite, also called Rongalit (registered trademark of BASF), is sodium hydroxymethylsulfinate, or Na+HOCH2SO2−. The salt has many names, including also sodium formaldehyde sulfoxylate, and Bruggolite. It is listed in the European Cosmetics Directive as sodium oxymethylene sulfoxylate (INCI).

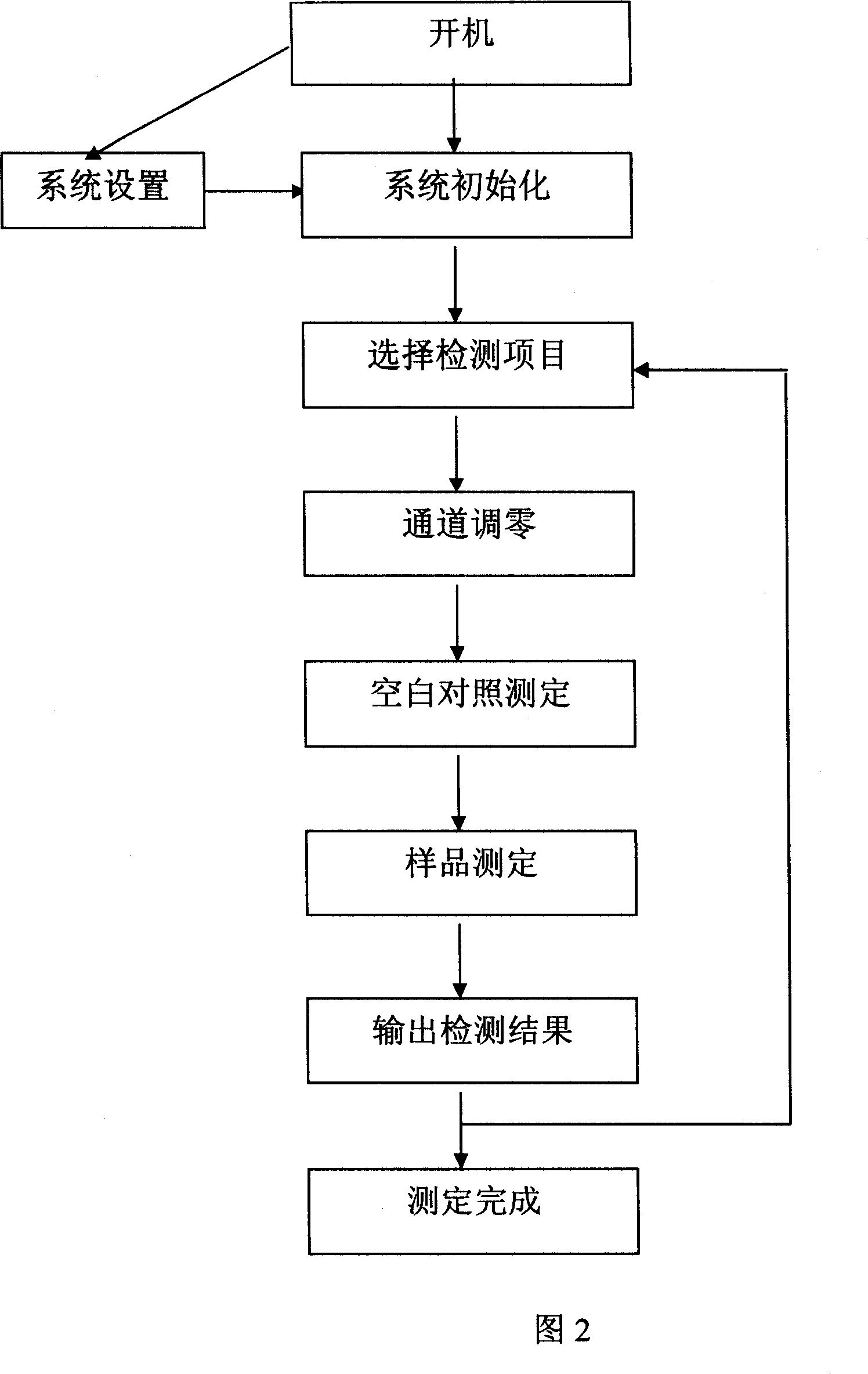

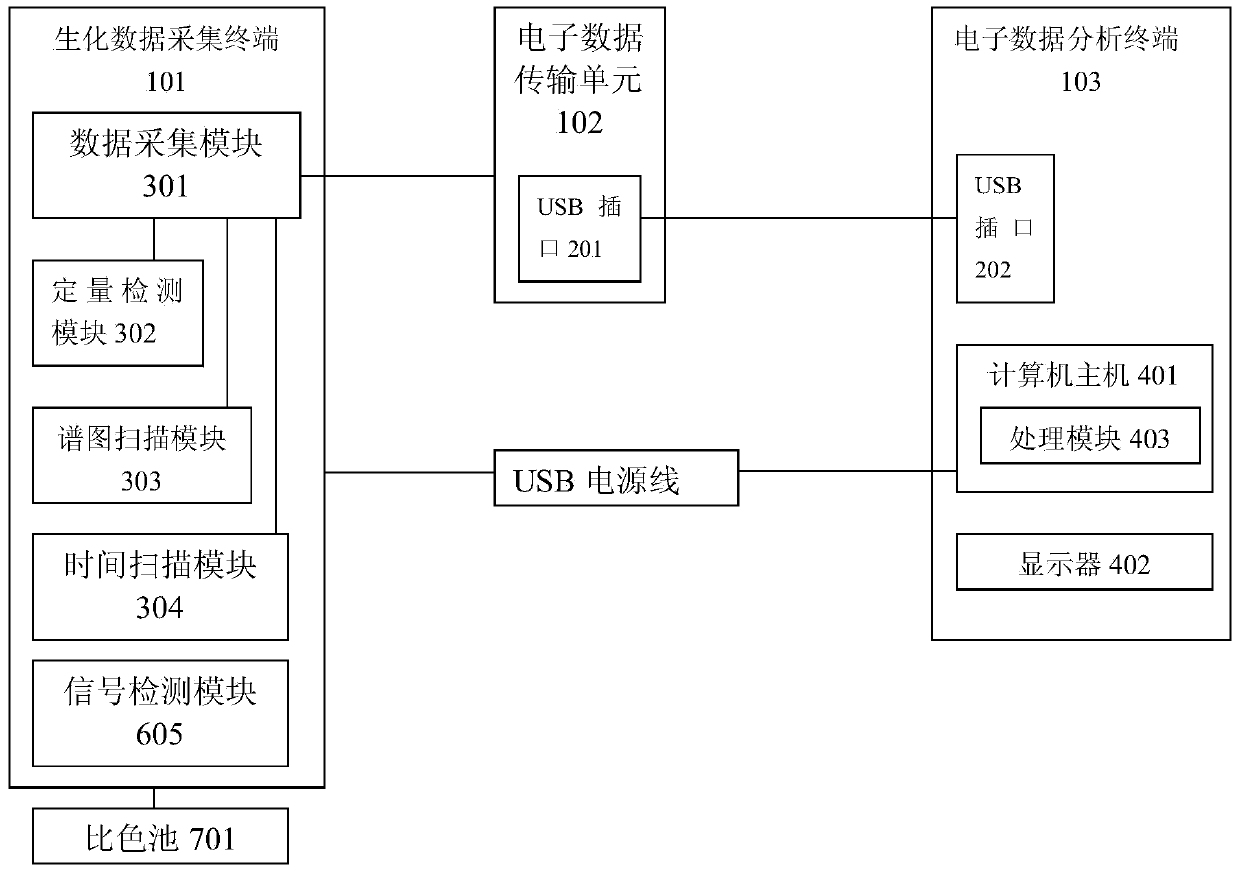

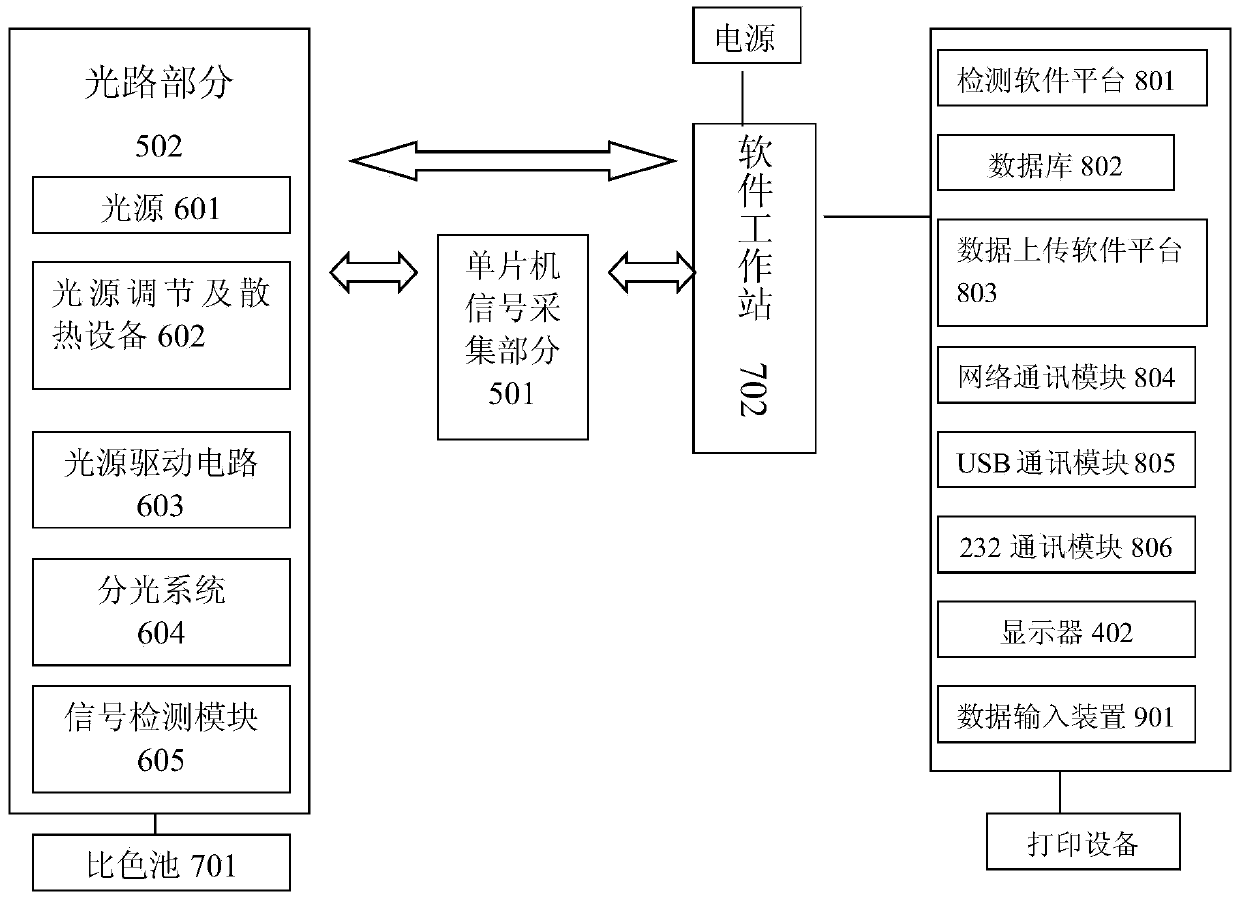

Foodstuff safety multiple item quick detector

InactiveCN101105443AGo digitalEasy to operateColor/spectral properties measurementsMicrocontrollerHuman–machine interface

The invention relates to a multi-project detector for detecting the security of food. The operational power supply separately provides the power to a light path part, a monolithic processor and an auxiliary circuit part. The monolithic processor is separately connected with the light path part, the auxiliary circuit part, an input part and an output part. And the monolithic processor and the auxiliary circuit part are used for calculating and controlling, the input part and the output part are used to input and output the information. The invention can detect the chemical substances which have harm to human body like agricultural chemicals, sulphur dioxide, nitrous acid, rongalite lump, hydrogen peroxide, methyl alcohol, dairy product protein, nitrate and heavy metal, the detecting result is accurate, the detecting speed is quick, the density can be directly showed, the man-machine contact surface is friendly, and the invention has the functions of data storage, inquiry, result printing and GPRS wireless transmission to data server. The invention can be used in real-time, and has the advantages of high detecting efficiency and high automaticity, convenient carrying, practical using, low cost and good effect.

Owner:赵澎涛

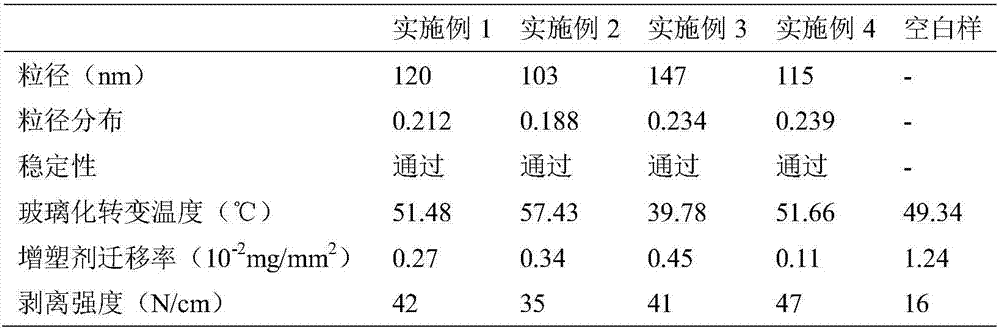

Water-based ink resin for PVC furniture membranes and preparation method of water-based ink resin

The invention provides water-based ink resin for PVC furniture membranes and a preparation method of the water-based ink resin. Raw materials of the water-based ink resin for the PVC furniture membranes comprise an anionic emulsifier, a nonionic emulsifier, a pH buffering agent, an initiator, a chain transfer agent, a methyl methacrylate monomer, a methyl acrylate monomer, a glycidyl methacrylate monomer, tert-butyl hydroperoxide, rongalite, a preservative, and deionized water; based on a design concept of ''polymer welding'', an emulsion-type resin which is well compatible to PVC and of which glass transition temperature is similar to that of the PVC is prepared and designed, wherein the main body of the emulsion-type resin is poly(methyl methacrylate-methyl acrylate), and the high peeling strength of the water-based ink resin and the PVC furniture membranes is guaranteed; and meanwhile, a characteristic that the PVC furniture membranes have a large number of plasticizers is combined, a proper amount of the glycidyl methacrylate monomer with epoxy groups is introduced to a copolymerization monomer system, and therefore the plasticizer migration resistant ability of the water-based ink resin is improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

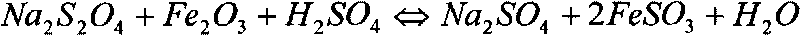

Bleaching production method for washing iron-dyed kaolin

InactiveCN101723391AHigh whitenessNo pollution in the processAluminium silicatesLiquid ratioWastewater

The invention discloses a bleaching production method for washing iron-dyed kaolin, and relates to kaolin. The invention provides a bleaching production method for washing iron-dyed kaolin, which can obtain higher brightness, can realize wastewater recycle and environment-friendly clean production and is suitable for large-scale production. The method definitely gives the process parameters such as the using amount of sodium hydrosulfite, a pH value, solid-liquid ratio, reaction time, adding amount of complexing agent and complexing time, bleaching times, adding amount of sewage treating agent, a pH value of the wastewater and the like to achieve the optimal bleaching effect on the washing iron-dyed kaolin. The natural whiteness of the iron-dyed kaolin can be improved to over 80 percent from about 60 percent, and the sintering whiteness can be improved to over 90 percent from about 87 percent, which meet the whiteness requirements of high-grade daily ceramic raw materials. Meanwhile, the method can treat and recycle the wastewater.

Owner:XIAMEN UNIV

Dye discharging ink for inkjet printing

InactiveUS20080250967A1Avoid corrosionImprove suppression propertiesOther chemical processesDuplicating/marking methodsAlcoholDecomposition

A dye discharging ink for inkjet printing including at least a reducing agent and an amine compound. Embodiments of the dye discharging ink include, as the reducing agent, a sulphur reducing agent such as Rongalite, and, as the amine compound, an alcohol amine compound such as triethanolamine. Embodiments of the dye discharging ink also include a surface active surfactant and / or an antirust agent, and a pH in a range from 9.5 to 11.0. The dye discharging ink for inkjet printing can prevent corrosion of head nozzles due to acidic substances produced by decomposition of a reducing agent, so as to decrease inhibition of linear advancing property of ejected ink, and can prevent decrease in discharging capability due to hydrolysis of the reducing agent.

Owner:MIMAKI ENG

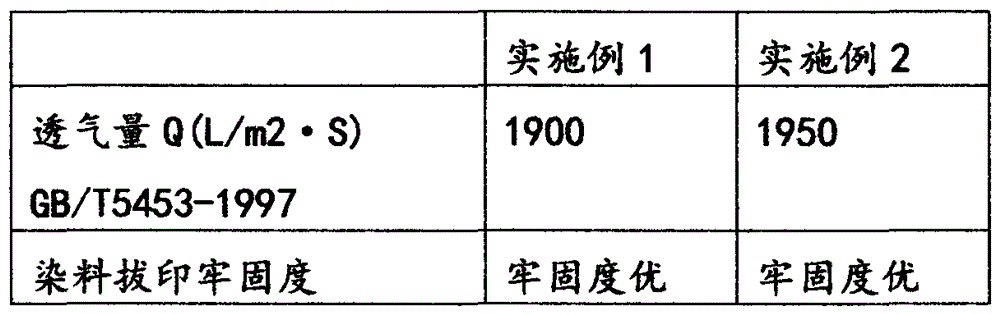

Dyeing and finishing process of viscose woven fabric

InactiveCN107177992AThe texture is clear and firmMeet needsSucessive textile treatmentsDyeing processViscoseOil water

The invention relates to a dyeing and finishing process of viscose woven fabric. The dyeing and finishing process of the viscose woven fabric comprises the steps of dyeing and pretreating a viscose woven fabric semi-finished product: cooking the water-washed viscose woven fabric semi-finished product in a dyeing pretreatment solution, and carrying out discharge print on the sized viscose woven fabric semi-finished product by adopting a mixed dye of vasekine and rongalite, wherein the mass ratio of the rongalite to the vasekine is 1 to 1; adding table salt and sodium carbonate into a rope rinsing machine, wherein the masses of the table salt and the sodium carbonate are equal; placing the dyed viscose woven fabric into a color fixing agent, softening the color-fixed dyed viscose woven fabric by putting into 1g / L of Taigu oil water solution. A discharge print dyeing pattern obtained through the method provided by the invention is high in three-dimensional effect, firm in dye, and good in air permeability.

Owner:SHAOXING SUBO TEXTILE CO LTD

Method for bleaching high-concentration kaolin pulp

InactiveCN101445249AImprove product qualityReduce consumptionSilicon compoundsHigh concentrationKaolin clay

The invention relates to a method for bleaching high-concentration kaolin pulp. The kaolin pulp concentration is 25%-30%. The method comprises the following steps: adding an alkaline agent to water, mixing and adding rongalite to prepare rongalite aqueous solution, wherein, the weight ratio of sodium hydroxide to sodium carbonate in the alkaline agent is 0.33-0.47:10, the weight ratio of the rongalite to the alkaline agents is 100:10.3-10.5, rongalite volume concentration of the rongalite aqueous solution is 10-15% and the pH value of the rongalite aqueous solution is 7.0-8.0; delivering the rongalite aqueous solution and the high-concentration kaolin pulp to a conduit by a pump for mixing, and delivering the mixture to a pulp storage tank, wherein, the added amount of the rongalite aqueous solution is 1.4-2.3% of that of the high-concentration kaolin pulp; and keeping standing and bleaching for 15-20 hours, and adjusting the pH value of the pulp to 2.5-3.0 after bleaching. The method has the advantages of reasonable technical proposal, easy control of operation, stable process, and the bleached high-concentration pulp is beneficial to subsequent filter pressing dehydration processing, which improves the production capacity, reduces the energy consumption and medicament consumption, lowers the production cost and stabilizes quality of kaolin products.

Owner:梁明

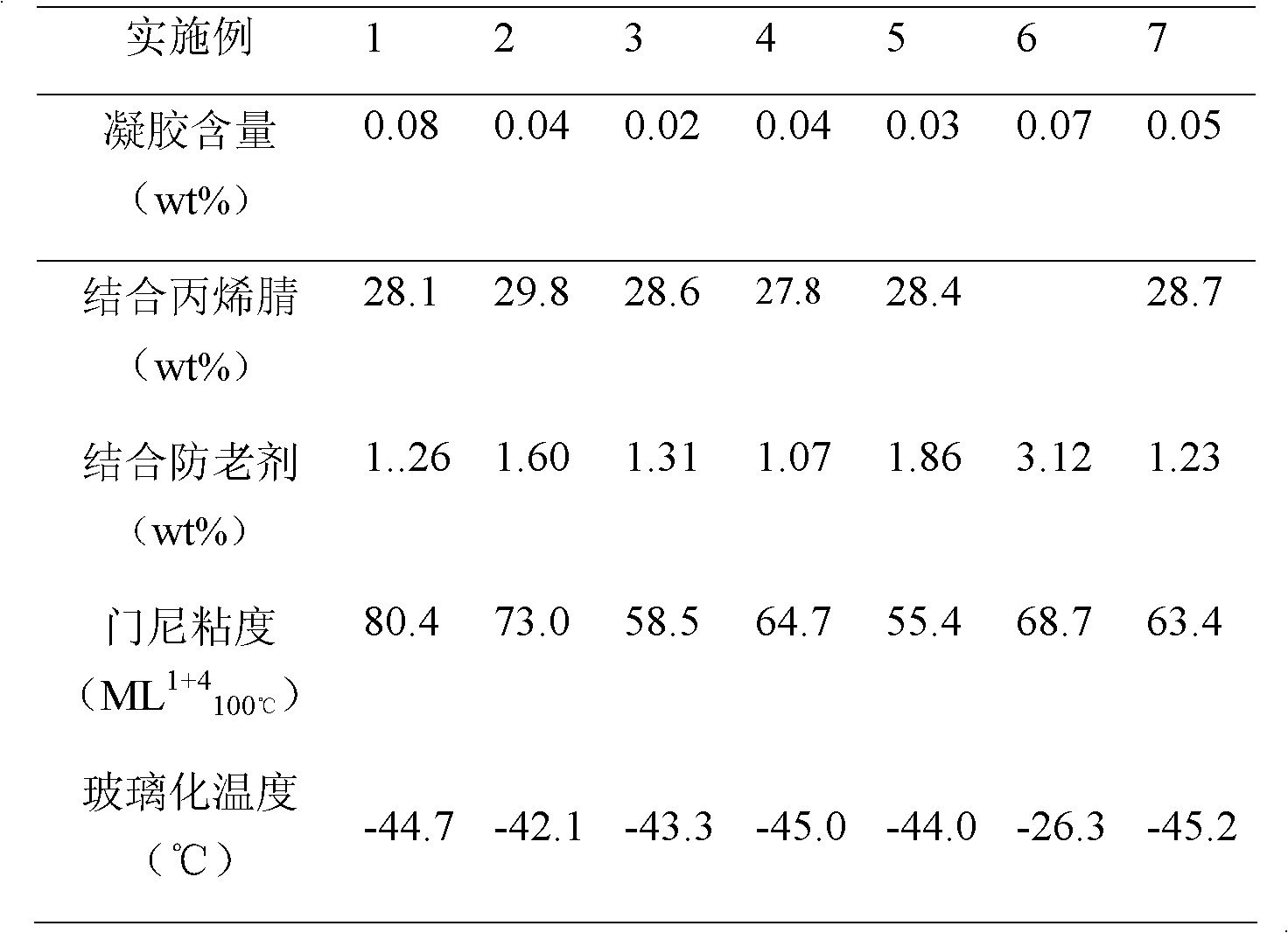

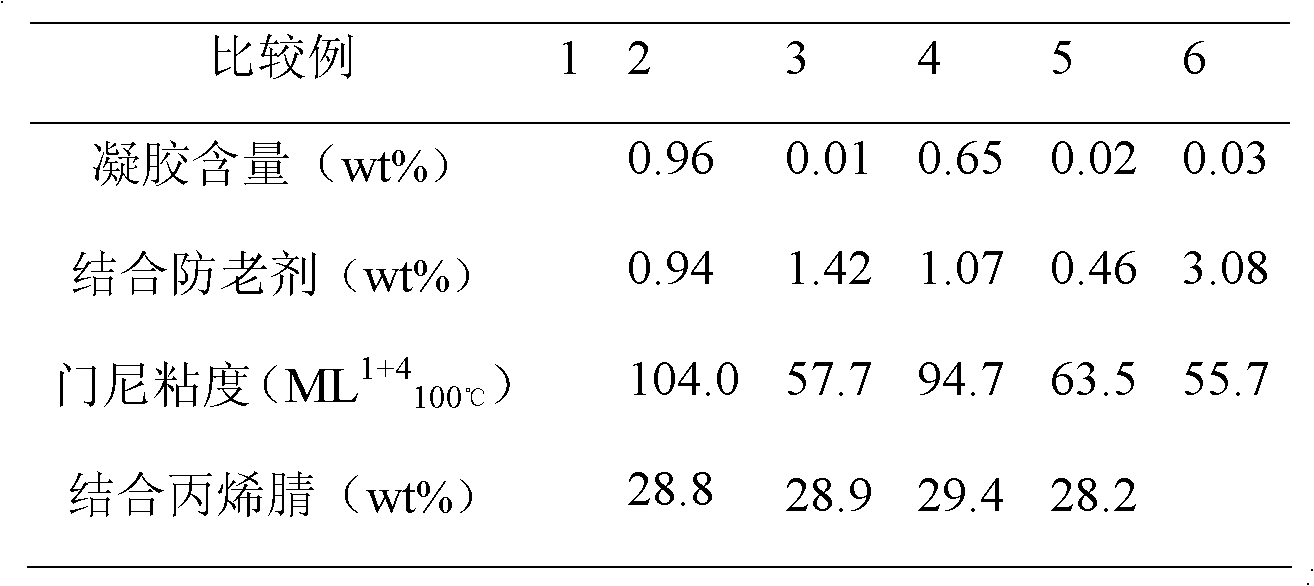

Nitrile rubber and preparation method thereof

Owner:PETROCHINA CO LTD

Top dyeing and post-processing method of flame retardant polyester fiber

InactiveCN101457489ADo not change colorGuaranteed fastnessDry-cleaning apparatus for textilesDyeing processDisperse dyeAcetic acid

The invention relates to wool top dyeing of flame-retardant polyester fibers and a post-treatment method thereof. The method comprises the following steps: the flame-retardant polyester fiber wool top is placed in a wool top dyeing machine and operates for 3-5 min at the temperature of 40-50 min, glacial acetic acid is added and PH Value is adjusted to 5-6, monoammonium phosphate and Yuri Huading DIF are added for operating for 5-10min, disperse dye is added for operating for 5-10 min before the temperature rises, the temperature stops rising until 85 DEG C, then the temperature is maintained for 10-15 min, the temperature rises to 100-120 DEG C for operating for 30-60 min, liquor drainage and flushing are carried out with a bath ratio of 1:20-50; the dyed flame-retardant polyester fiber wool top is put into lotion soap with 2-5% of fiber fabric by weight, the lotion soap is processed for 20-30 min at the temperature of 80-90 DEG C, or, the dyed the flame-retardant polyester fiber wool top is first placed in bath consisting of 0.5-2g / L sodium hudroxide , 0.5-2g / L rongalite and 0.5-1g / L nonionic surface active agent for being processed for 20-30 min at the temperature of 70-80 DEG C and then placed in glacial acetic acid bath with 1-4% of fiber fabric by weight for being processed for 10-15 min at the temperature of 40-45 DEG C; the bath ratio is 1:20-1:50. The wool top dyeing of the invention features good levelling of dyeing and high color fastness of dyeing wool top.

Owner:HEILAN HOME

Kaoline alkaline static bleaching technology

InactiveCN101531372AReduce the rate of hydrolysisAvoid ineffective hydrolysisPigmenting treatmentAluminium silicatesSlurryEngineering

The invention relates to kaoline alkaline static bleaching technology. The technology comprises: evenly mixing classified kaoline ore slurry and rongalite, standing the mixture for a while, adding a regulator into the mixture, controlling the ore slurry pH value to between 3 and 5, and evenly stirring the mixture to obtain the product. The technology has the advantages of simple operation, easy realization in production and obvious effect, can be widely used in kaoline processing enterprises and has great popularization value and application prospect.

Owner:茂名市银华高岭土实业有限公司

Method for preparing anti-bacteria, water-proof and anti-ageing nano propyl-phenyl emulsion

The invention is the antibacterial, waterproofing, anti-aging nanometer benzene-acrylic emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 24.4%, styrene (St) 24%, non-ionic emulsifier (MS-01) 1.8%, nano-ZnO 1.8%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, methylacrylic acid (MAA) 1%, tert-butyl hydroperoxide (TDHP) 0.6%, sodium formaldehydesulfoxylate (SFS) 0.6%, ammonium persulfate (APS) 0.4%, NaHCO3 0.2%, and AMP-95 0.2%. According to the said weight proportions, prepare the emulsion through pre-emulsifying, milling, and polymerizing at high temperature.

Owner:何一军

Method for preparing anti-bacteria, water-roof and anti-ageing purified propyl emulsion

The invention is the antibacterial, waterproofing, anti-aging nano pure-acrylic emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 24%, methyl methacrylate (MMA) 23.6%, non-ionic emulsifier (MS-01) 2%, nano-ZnO 1.8%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, acrylic acid (AA) 0.8%, tert-butyl hydroperoxide (TDHP) 0.6%, sodium formaldehydesulfoxylate (SFS) 0.6%, ammonium persulfate (APS) 0.4%, polymerizable emulsifier (AMPS) 0.4%, NaHCO3 0.2%, and AMP-95 0.2%. According to the said weight proportions, prepare the emulsion through pre-emulsifying, milling, and polymerizing at high temperature.

Owner:何林道

Method for synthesizing nano composite silicon propyl emulsion

The invention is the synthesizing method of nano compound emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 22%, methyl methacrylate (MMA) 22%, organosilicon monomer (ethylene triethoxy silicon hydride A-151) 4.1%, non-ionic emulsifier (OP-10) 1.5%, nano-SiO2 1.5%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, methylacrylic acid (MAA) 1%, polymerizable emulsifier AMPS 0.5%, ammonia 0.5%, tert-butyl hydroperoxide (TDHP) 0.5úÑ, sodium formaldehydesulfoxylate (SFS) 0.5%, ammonium persulfate (APS) 0.4%, and NaHCO3 0.3%. According to the said weight proportions, prepare the emulsion through emulsifying, milling, drop adding and polymerizing at high temperature.

Owner:何一军

Novel discharging agent for textile printing and dyeing

InactiveCN104805720AImprove discharge effectOvercome solubilityDyeing processTextile printerSolubility

The invention discloses a novel discharging agent for textile printing and dyeing. The novel discharging agent is prepared by the following components in parts by weight: 3 to 8 parts of fatty alcohol-polyoxyethylene ether, 3 to 6 parts of epichlorohydrin, 3 to 7 parts of boric acid, 5 to 10 parts of polyethylene glycol oil-based ether, 3 to 7 parts of polyvinylpyrrolidone, 2 to 3 parts of N-benyl-2-naphthylamine, 3 to 7 parts of sodium hydroxide, 11 to 12 parts of thiourea dioxide, 3 to 6 parts of rongalite, 7 to 12 parts of linear alkyl benzene sulphonic acid, 3 to 5 parts of ammonium sulfate, 17 to 22 parts of ethylene glycol, and 20 to 30 parts of deionized water. The novel discharging agent has the advantages that a modifying method is simple, the stability of a product is good, and the discharging effect of the thiourea dioxide can be improved; the defects of low solubility because of using the convention thiourea dioxide as the discharging agent for discharging and dyeing and the poorer dispersing uniformity, poorer net permeating property, insufficient playing of discharging function and the like in the discharging liquid are overcome.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

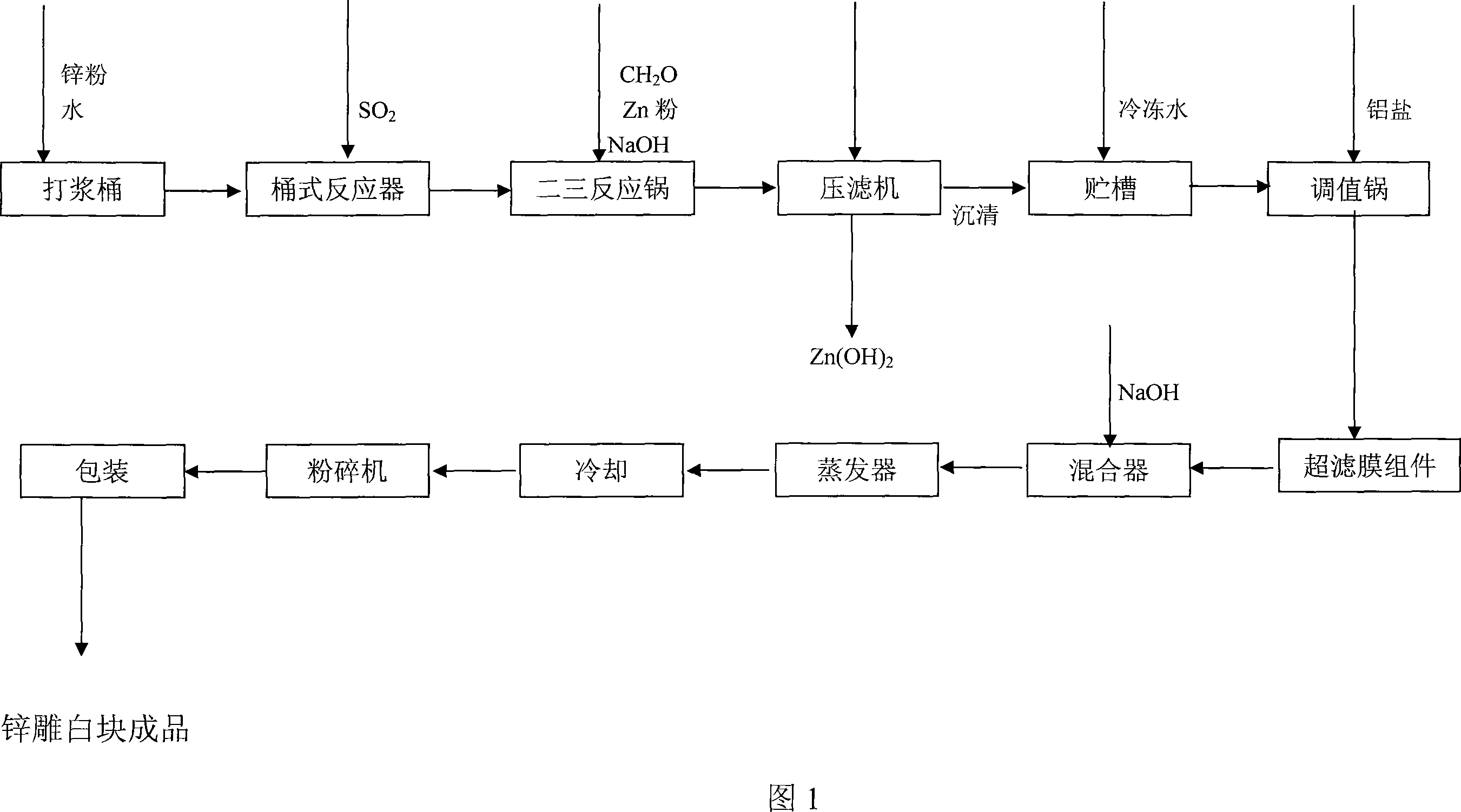

Method for producing rongalite with low zinc

InactiveCN101092422AReduce manufacturing costHigh content of finished productsSodium organic compoundsSodium/potassium compoundsPlastics industryDithionous acid

This invention relates to a method for producing low-zinc rongalite. The method comprises: mixing water and zinc powder, beating, adding SO2, reacting to obtain zinc hydrosulfite, placing in a reaction pot, adding formaldehyde and zinc powder, reacting to obtain alkaline sodium formaldehyde sulfoxylate, precipitating, removing the supernatant, adding NaOH, reacting to obtain sodium formaldehyde sulfoxylate, filtering, standing for settlement, cooling, adjusting the pH value, performing ultrafiltration, mixing, adding NaOH, sending into an evaporator, evaporating to obtain melt of low-zinc sodium formaldehyde sulfoxylate, cooling, solidifying, and pulverizing to obtain the final product. The obtained low-zinc rongalite can satisfy the requirements of pharmaceutical and plastic industries. The zinc content is less than or equal to 50 ppm. The low-zinc rongalite has such advantages as high purity, high stability, low production cost and convenient usage.

Owner:JIANGSU DONGTAI FINE CHEM

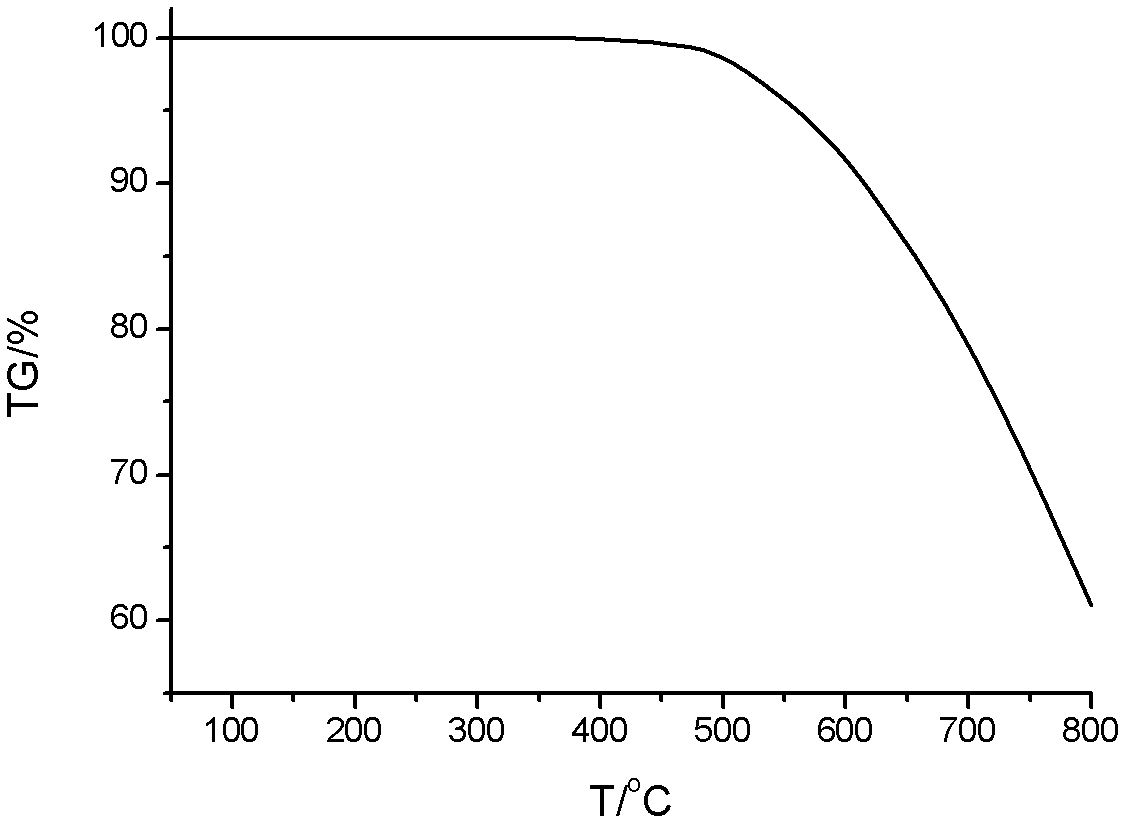

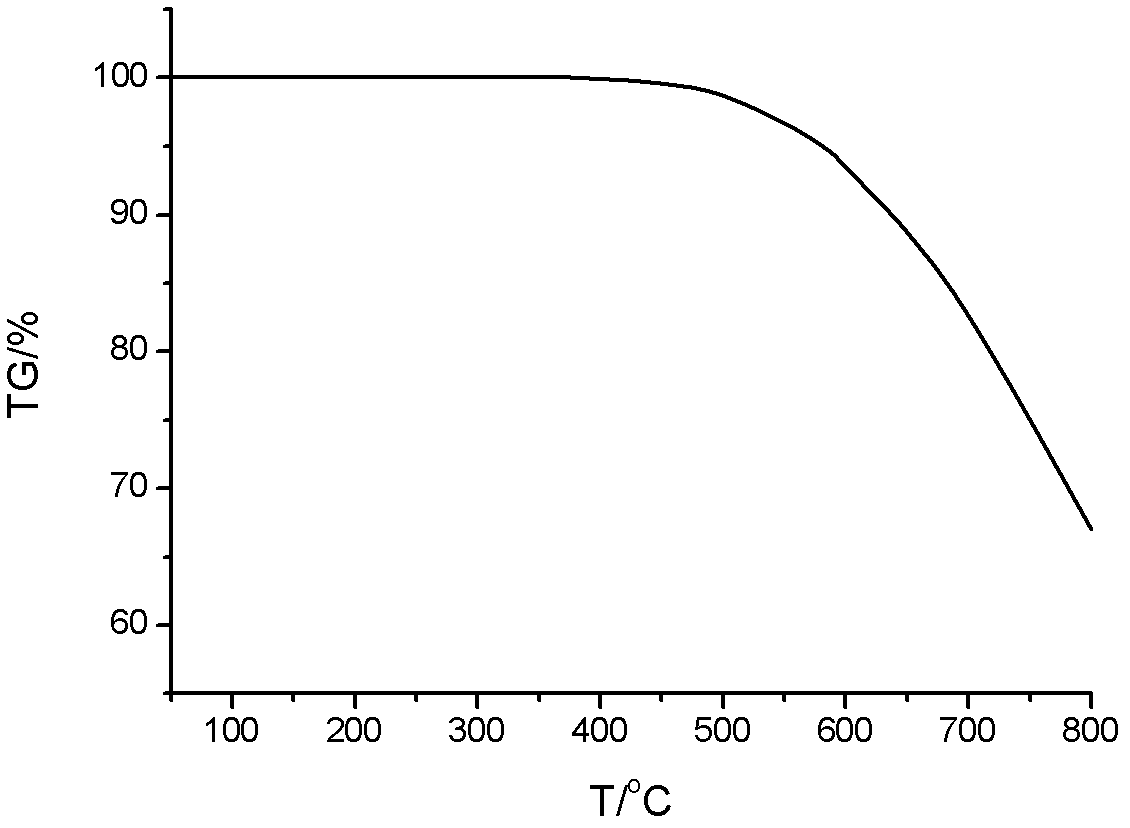

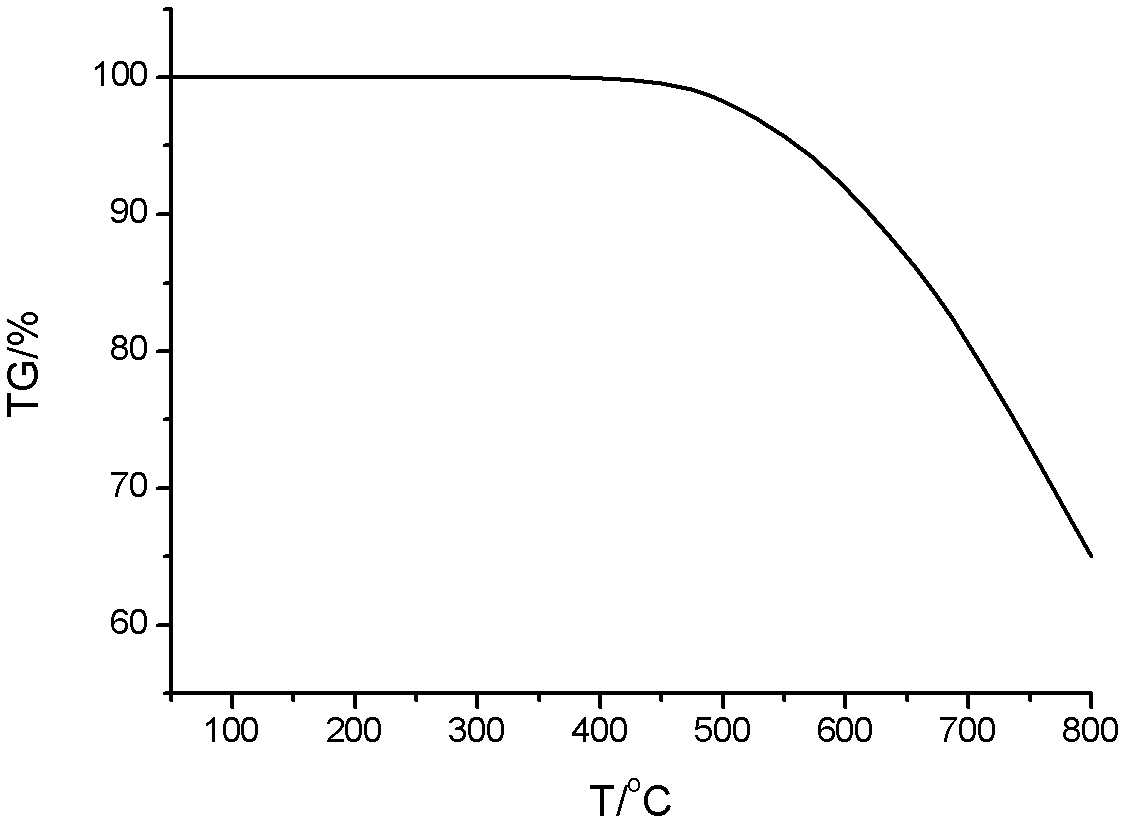

Preparation method of aromatic polybenzimidazole

The invention discloses a preparation method of aromatic polybenzimidazole, comprising the following steps: 1, under the protection of nitrogen, adding aromatic tetramine and diacid monomer with equimolar ratio in a strongly acidic solution to conduct condensation polymerization with the reaction temperature of 100-250 DEG C and the reaction time of 0.5-30h; 2, pouring the product of the step 1 in water and precipitating to obtain a polymer, washing the polymer with water repeatedly, immersing in an alkaline solution to remove residual acid, and then immersing in boiling water containing rongalite for 0.5-6h; and 3, drying the product of the step 2 in a vacuum environment with the temperature of 50-150 DEG C to obtain the aromatic polybenzimidazole. The method has the advantages of high molecular weight, good thermal stability, excellent dissolubility and film forming property, etc.

Owner:SHANGHAI DIAIBI CHEM TECH

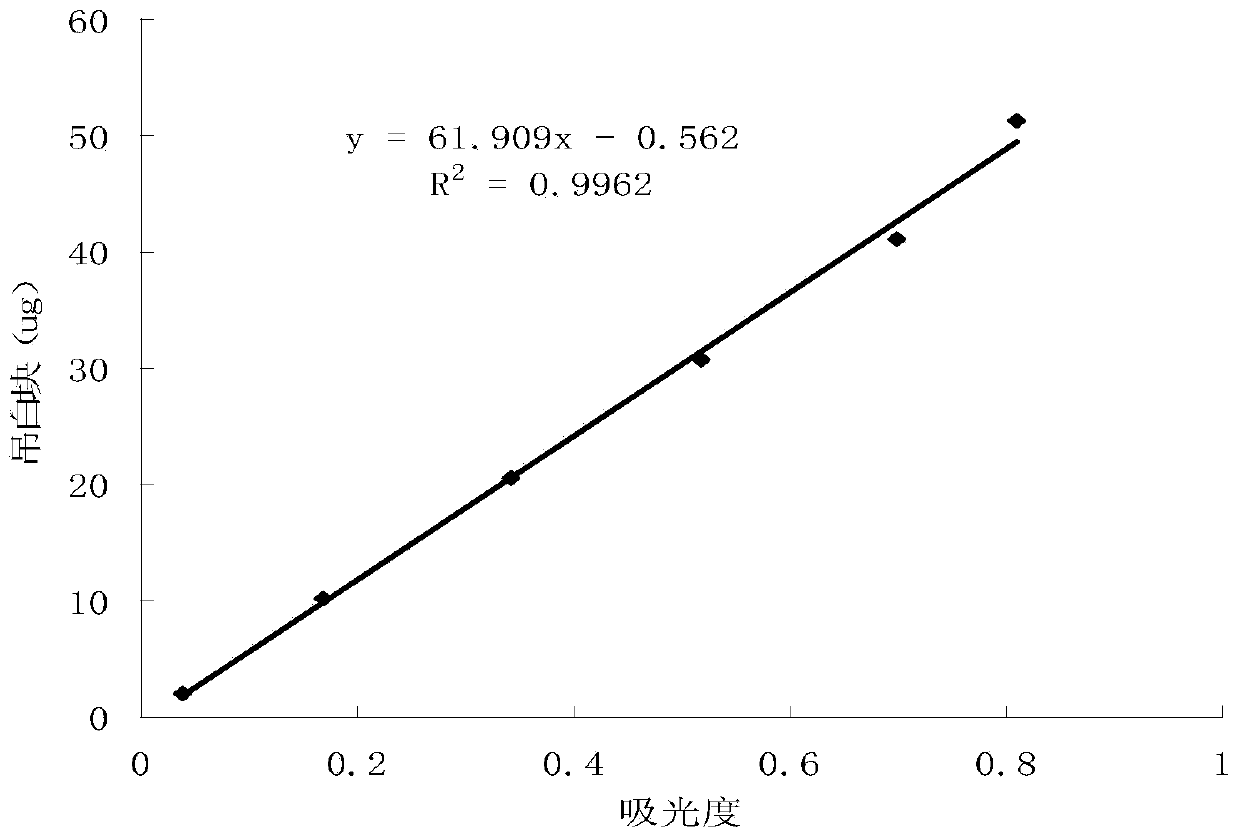

Method for rapidly detecting sodium formaldehydesulfoxylate dihydrate in food

InactiveCN104198413ALow detection limitMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationQuantitative determinationPhysical chemistry

The invention provides a method for rapidly detecting sodium formaldehydesulfoxylate dihydrate in food, which is low in detection limit, accurate, rapid and convenient and can meet the requirements on field rapid detection and laboratory detection. The method comprises the following steps: (1) arranging equivalent samples in two sample tubes, firstly adding an appropriate amount of reagent D in one sample tube to transform sodium formaldehydesulfoxylate dihydrate in the sample of the tube into formaldehyde and retaining the equivalent sodium formaldehydesulfoxylate dihydrate contained in the sample in the other sample tube; (2) adding an appropriate amount of reagent A, reagent B and reagent C into the two sample tubes respectively to realize chromogenic reaction of the samples in the two sample tubes; (3) qualitatively determining whether the sample contains sodium formaldehydesulfoxylate dihydrate through the difference in color development of the samples in the two sample tubes, wherein the color of the sample in which sodium formaldehydesulfoxylate dihydrate is transformed into formaldehyde is deeper than that of the sample with equivalent untransformed sodium formaldehydesulfoxylate dihydrate; and (4) quantitatively determining the content of sodium formaldehydesulfoxylate dihydrate in the sample according to the measured absorbance value of the sample.

Owner:BEIJING ZHIYUNDA TECH CO LTD

Method for preparing weather resistant reinforced acrylate based resin

The present invention relates to a method for preparing a weather resistant reinforced acrylate based resin. More specifically, an activator-free conversion rate improver is included in an acrylate-styrene based graft copolymer, thereby improving the haze value, light transmittance, and yellow index when mixed with an acrylate-styrene based non-graft copolymer, and securing the weather resistance. In particular, according to the present invention, a weather resistant reinforced thermoplastic resin having excellent colors which are close to natural colors can be provided even without using sodium formaldehyde sulfoxylate (SFS) and iron ions.

Owner:LG CHEM LTD

High-rubber ASA resin powder and preparation method thereof

The invention belongs to the field of polymer materials, and relates to a h igh-rubber ASA resin powder and a preparation method thereof. The preparation method of the high-rubber ASA resin powder comprises the following steps: 1) preparation of a seed; 2) preparation of a core; 3) preparation of a shell; and 4) post-treatment, wherein an emulsifier adopted in step 1) to step 3) is a mixture of ananionic surfactant and a nonionic surfactant, and a mass ratio of the anionic surfactant to the nonionic surfactant is (8-9):1; and a reducer solution adopted in the step 1) to step 3) is prepared through dissolving 0.1 g of ferrous sulfate, 1.5 g of sodium formaldehydesulfoxylate and 2 g of ethylenediaminetetraacetic acid in 500 g of deionized water. The preparation method has the advantages oflow temperature in the synthesis process, low energy consumption, easiness in operation, and high conversion rate; the impact strength of the obtained product is greatly improved, is equivalent to that of foreign products, and can basically meet requirements of most application fields; and the autonomous production of the high-rubber ASA resin powder is realized.

Owner:四川兴彩高新材料有限公司

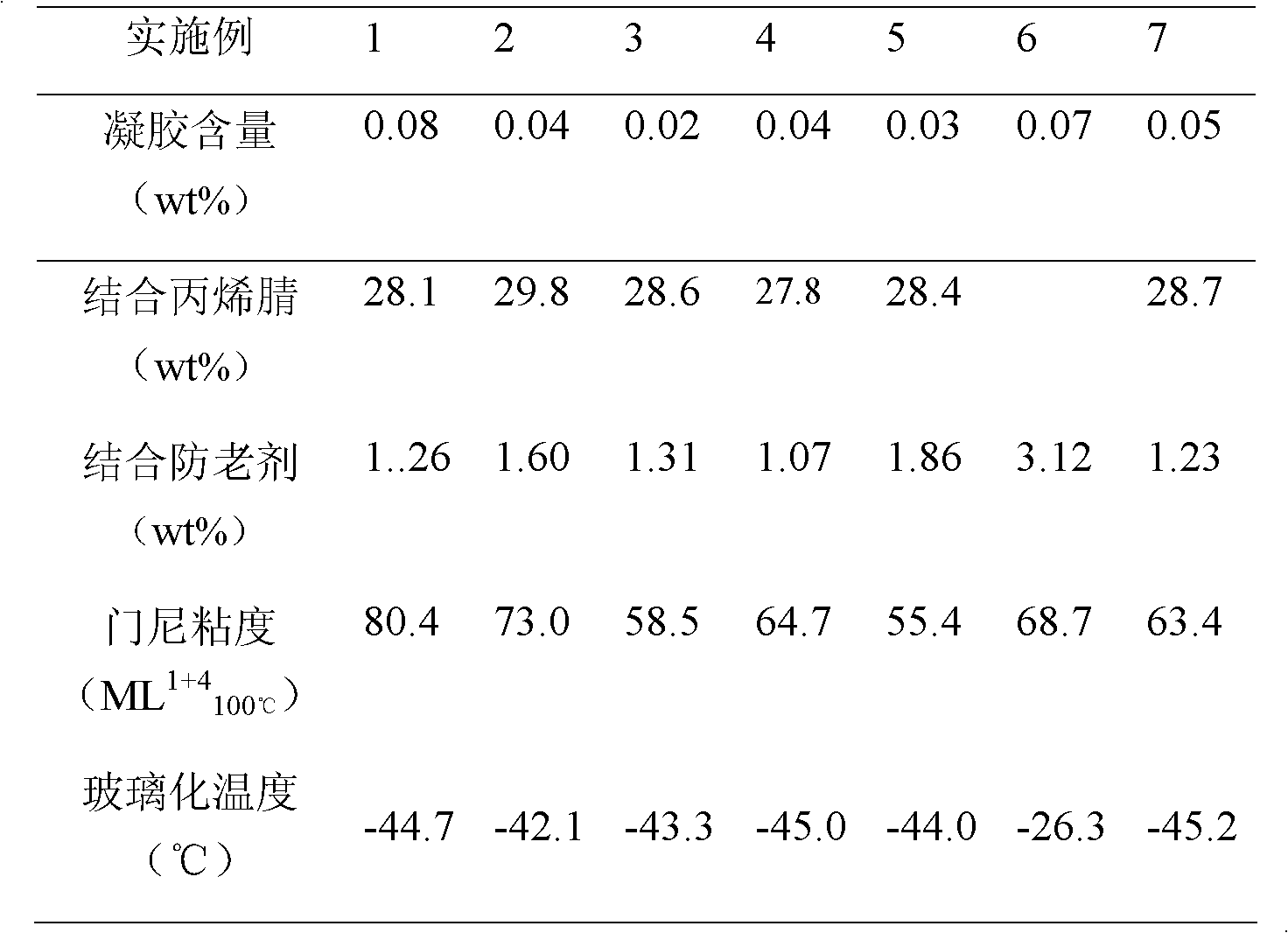

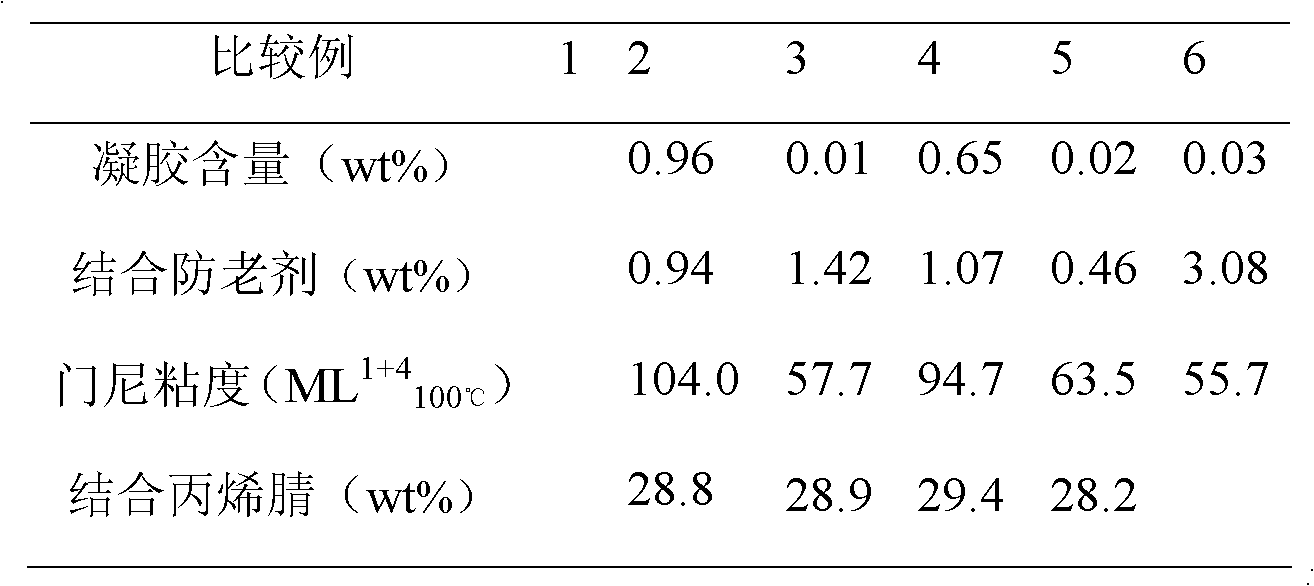

Nitrile rubber and preparation method thereof

The invention relates to a nitrile rubber and a preparation method thereof. The nitrile rubber is prepared from the following polymerization monomers by mass percent: 50-78% of C4-C5 aliphatic conjugate diene monomer, 20-48% of vinyl nitrile monomer and 1.0-5.0% of unsaturated amine or phenolic antioxidant monomer. By adopting a low-temperature polymerization way, an organic peroxide rongalite is used for oxidizing and reducing an initiating system, by increasing the addition of an emulsion system and a molecular weight regulator, the polymerization reaction is carried out smoothly, and molecular parameters of a polymer can be effectively regulated. The preparation method is simple in process and high in polymerization rate, and improves the stability of mucilage in the polymerization process. The content of N-(p-anilino phenyl) unsaturated amide or imide in the polymer is higher, and effective copolymerization of an antiager monomer of the N-(p-anilino phenyl) unsaturated amide or imide and C4-C5 aliphatic conjugate dienes and cyanoethylene is realized.

Owner:PETROCHINA CO LTD

Printing and dyeing process of denim

The invention discloses a printing and dyeing process of denim. The printing and dyeing process comprises the following steps: (1) grey cloth pretreatment; (2) paste mixing and printing: mixing printing paste, cooperatively using pigment printing paste and sulfur dye printing paste, controlling the viscosity at 40000-45000Pa.S, printing by using a flat screen printing machine, and drying at the temperature of 100-105 DEG C, wherein the pigment printing paste is prepared from the following components in parts by mass: 14-16 parts of pigment color paste, 30-35 parts of waterborne polyurethane binder, 45-50 parts of emulsified paste and 7-9 parts of urea; the sulfur dye printing paste is prepared from the following components in parts by mass: 7-8 parts of sulfur dye, 25-30 parts of sodium formaldehydesulfoxylate dehydrate, 30-35 parts of etherified starch paste, 12-14 parts of sodium carbonate, 8-9 parts of glycerin and 16-18 parts of warm water; (3) ageing; (4) oxidant spraying; (5) washing; (6) shaping. The printing and dyeing process is simple in operation, little in environment pollution, rich in design and color and favorable in printing and spraying effects.

Owner:CHANGSHU XIONGFA KNITTING PLUSH

Method for preparing low zinc low iron clarification rongalite

InactiveCN101353354AEasy to controlMeet control requirementsSodium organic compoundsSodium/potassium compoundsChromiumIon

The invention relates to a method for preparing low-zinc low-iron clear rongalite, which comprises the steps that: rongalite solution is used as a raw material and quinoline organic precipitator is used for precipitating zinc and ferrous ions in the solution before concentration; then, sampling and filtering are carried out, ammonia-ammonium chloride with the pH of 10 is used for buffering the solution with Eriochrome black T as a visualization reagent, and the content of the residual zinc ions in filtrate is measured by colorimetry; after the measured value meets the control requirement of 1 to 3mg / L, stirring is stopped, after precipitation and aging are carried out for 2 to 3 hours, precipitates are filtered away and then the filtrate is colorless and transparent; then, cooling for crystallization, crushing and packaging are carried out for obtaining the products of the clear rongalite with zinc and ferrous contents lower than 10PPm after the filtrate is concentrated to the content of over 98 percent at a vacuum level ranging from minus 0.085 to minus 0.095mPa and temperature lower than 75 DEG C. The invention has the advantages that the products prepared by the method have good stability and zinc and ferrous contents of lower than 10PPm, thus meeting special requirements on rongalite products by industries such as medicine and rubber, etc.

Owner:湖南中成化工有限公司

Method for producing salicylic acid by refining salicylic acid solution

InactiveCN101143817AReduce consumptionSimple production processOrganic compound preparationCarboxylic compound preparationActivated carbonSodium Phenolate

The invention relates to a method which utilizes sodium salicylate solution to refine, process and produce salicylic acid. Phenol reacts with liquid alkali, so that sodium phenolate is generated, the dried sodium phenolate reacts with carbon dioxide to generate sodium salicylate, which is then resolved in water, and therefore the sodium salicylate solution is produced. The first step is to regulate the pH value, that is, the sodium salicylate solution with twenty to forty percent of mass concentration is heated until 50 DEG C to 75 DEG C, and the pH value is regulated to four to six; the second step is to preserve heat, that is, the sodium salicylate solution is added with activated carbon and thermally insulated for two to four hours under the condition of temperature between 50 DEG C and 75 DEG C; the third step is filtration, the sodium salicylate solution is filtered, the filtrate is added with rongalite when filtrate is clean, and after five to twenty minutes, the filtrate is filtered into an acid eduction pot; in the fourth step, the salicylic acid is separated out from the acid eduction pot by utilizing vitriol to regulate the pH valve to one to two point five, and a pure product with more than ninety nine point three percent of content is produced after temperature reduction, filtration, washing and drying of the salicylic acid. The production technique of the invention has the advantages of simple process, convenient operation, little pollution, low material consumption and high purity of products, and meanwhile, the invention is convenient for industrialized production.

Owner:SHANDONG XINHUA LONGXIN CHEM

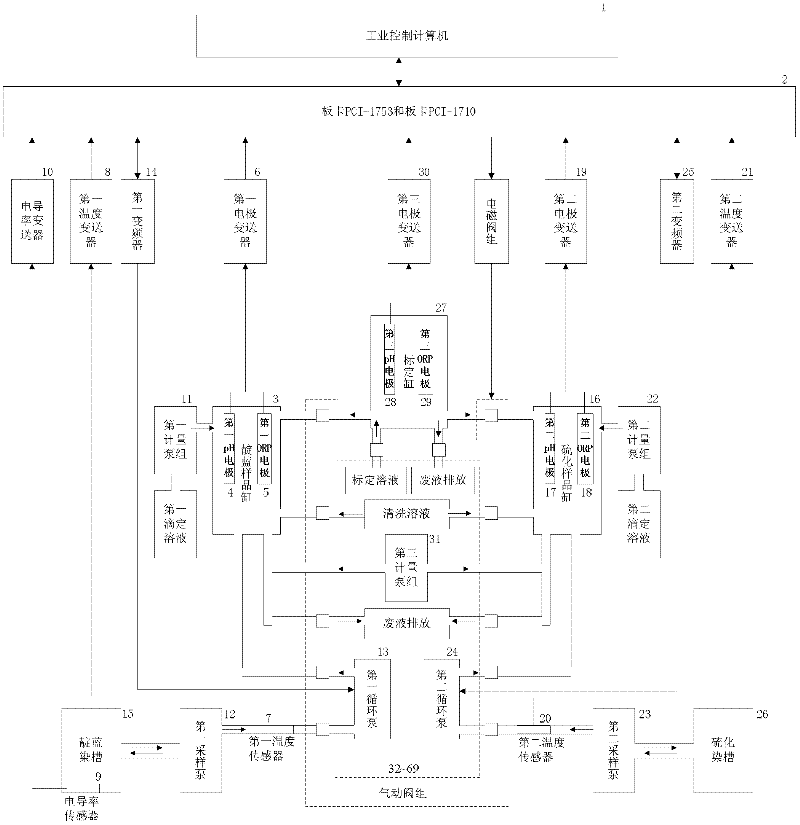

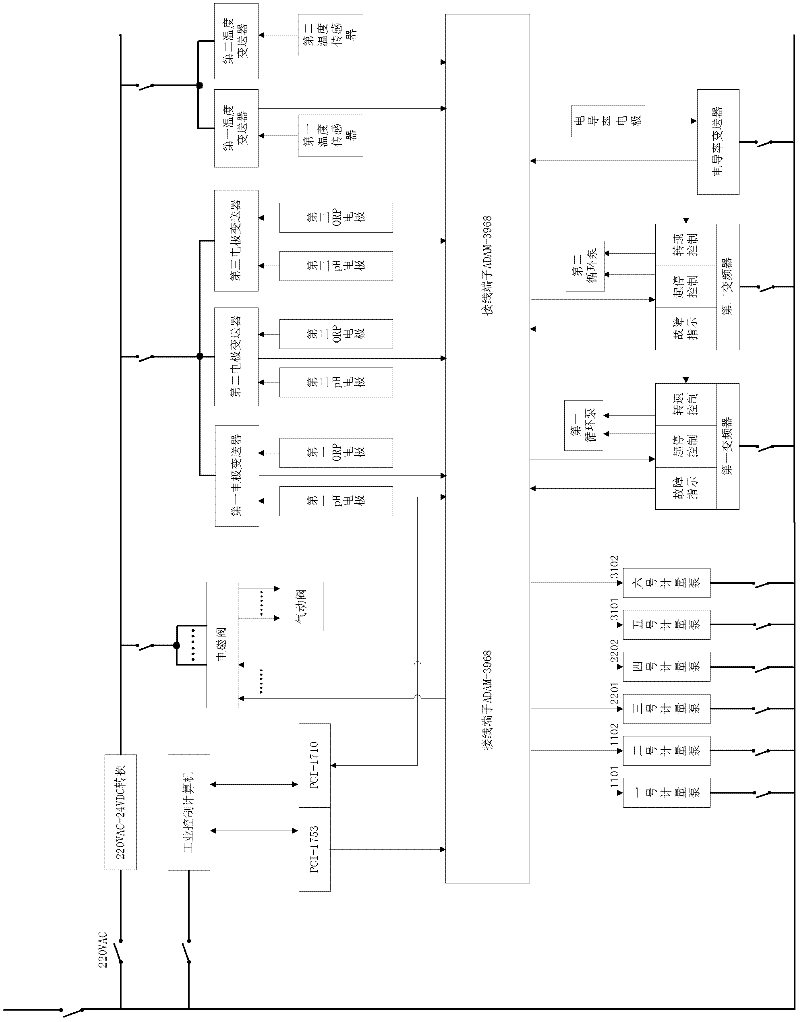

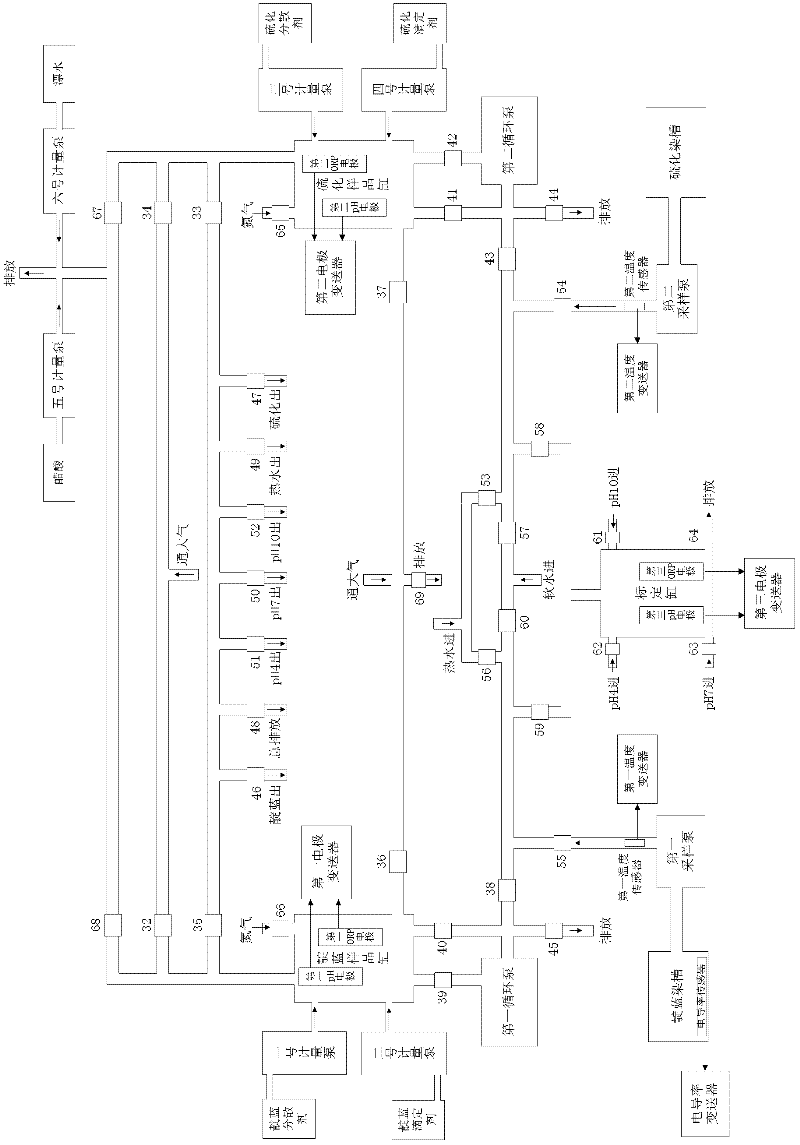

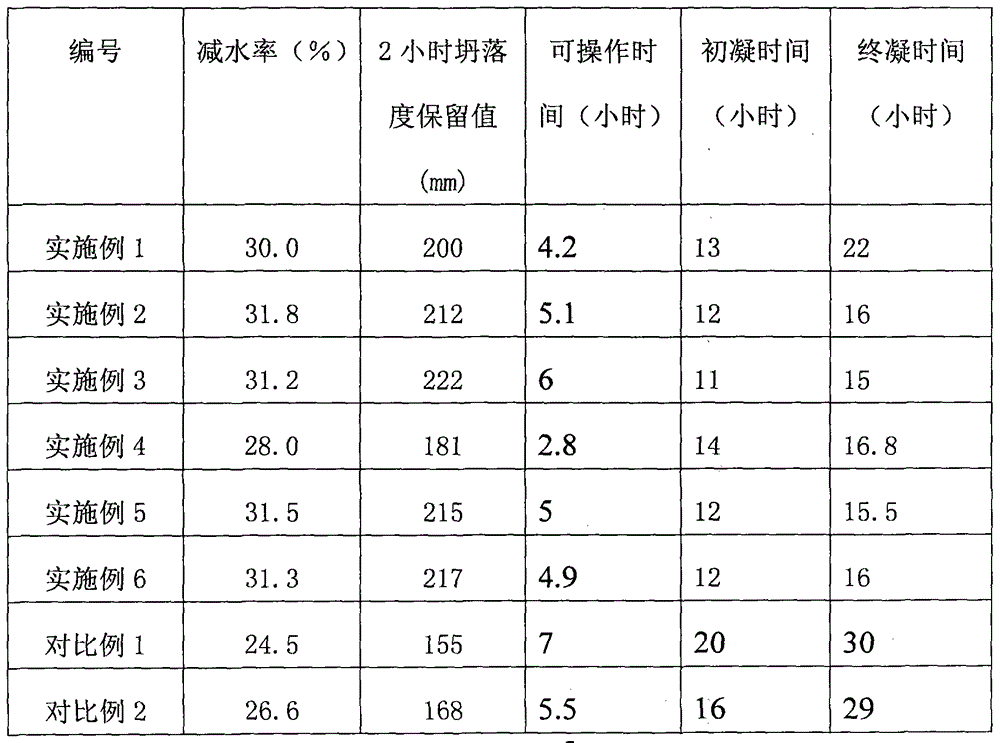

On-line detection method of dye liquor components of bundle dyeing machine based on boards

InactiveCN102520199AGuaranteed accuracyGuarantee the quality of dyeingMaterial analysisSystems designOn board

The invention discloses an on-line detection method of dye liquor components (rongalite, indigo and sodium hydroxide) of a bundle dyeing machine based on YanHua boards. An on-line detection system designed by the method comprises an indigo dye liquor on-line detection unit, a sulfuration dye liquor on-line detection unit, a calibration unit, boards, and an industrial control computer. According to the invention, a dye liquor sample in a dye vat of the dyeing machine is on-line detected in real time, the industrial control computer and the boards are used as a core are used, the concentration of the corresponding components of the dye liquor is on-line detected in real time by using potentiometric titration method, and the pH value and temperature of the dye liquor are on-line detected in real time, and pipelines are cleaned by the system after every detection completes. The method further can calibrate the indigo or sulfuration dye liquor on-line detection unit according to requirements to guarantee the accuracy of the detection results. The method can guarantee the detection precision of the dye liquor components, so as to raise the dyeing quality of dyed fabrics, thus the production cost is reduced, and the labor intensity of technical workers is reduced.

Owner:QINGDAO UNIV +1

Method for detecting rongalite in food

InactiveCN103063666AHigh precisionHigh speedMaterial analysis by observing effect on chemical indicatorDistilled waterRongalite

The invention disclosed a method for detecting rongalite in food. The method is characterized by comprising the following steps of 1, solution preparation: preparing a solution A, a solution B, a solution C and a solution D; 2, sample treatment: weighing 1-5 g of a cutout sample in a triangular flask, adding distilled water to 20-80 mL, ultrasonic extracting for 1 - 6 min, and filtering, with the filtrate for use; 3, operation method: taking two 5-30 mL colorimetric tubes (numbered as tube A and tube B with a marker), adding 0.5-5 mL of a sample liquid to each tube, dropping 1-6 drops of the D solution in the A tube, waiting for 0.5-2 min, adding 2-10 drops of the solution A and 2-10 drops of the solution B into the two tubes respectively, shaking uniformly, standing for 5-20 min, shaking for 3-10 times during the standing process, adding 0.05-0.2 mL of the solution C, shaking for 10-40 seconds, standing for 1-10 min, adding the distilled water to a scale mark of 2-8 mL. The method for detecting the rongalite has very high efficiency and wide market prospects.

Owner:BEIJING ZHIYUNDA TECH CO LTD

Super-permeable pressure sensitive adhesive and preparation method thereof

InactiveCN102140319ACompatibility is reasonableLow hazeFilm/foil adhesivesEster polymer adhesivesPolymer scienceEmulsion

The invention discloses super-permeable pressure sensitive adhesive and a preparation method thereof, and belongs to the technical field of adhesive. The super-permeable pressure sensitive adhesive comprises main materials, deionized water, emulsifying agent, ammonium hydrogen carbonate, ammonium persulfate, tertiary butyl, rongalite, defoaming agent and thickening agent. The preparation method comprises the following steps of: preparing emulsion; adding the ammonium hydrogen carbonate, the ammonium persulfate and the emulsion at a heating stage; and adding the tertiary butyl, the rongalite, the defoaming agent and the thickening agent at a cooling state, and mixing the materials uniformly to obtain the super-permeable pressure sensitive adhesive. Compared with the conventional pressure sensitive adhesive, the super-permeable pressure sensitive adhesive has the advantages that: the haze of the super-permeable pressure sensitive adhesive is reduced by over 50 percent, the initial viscosity and the enduring viscosity of the super-permeable pressure sensitive adhesive are improved by over 20 percent, and the super-permeable pressure sensitive adhesive has transparent color, has no mixed color and is suitable to be combined with a film to prepare an adhesive tape. The preparation method for the super-permeable pressure sensitive adhesive has simple process, is convenient for operation, and is suitable for large-scale industrialized production.

Owner:浙江杭宝集团有限公司

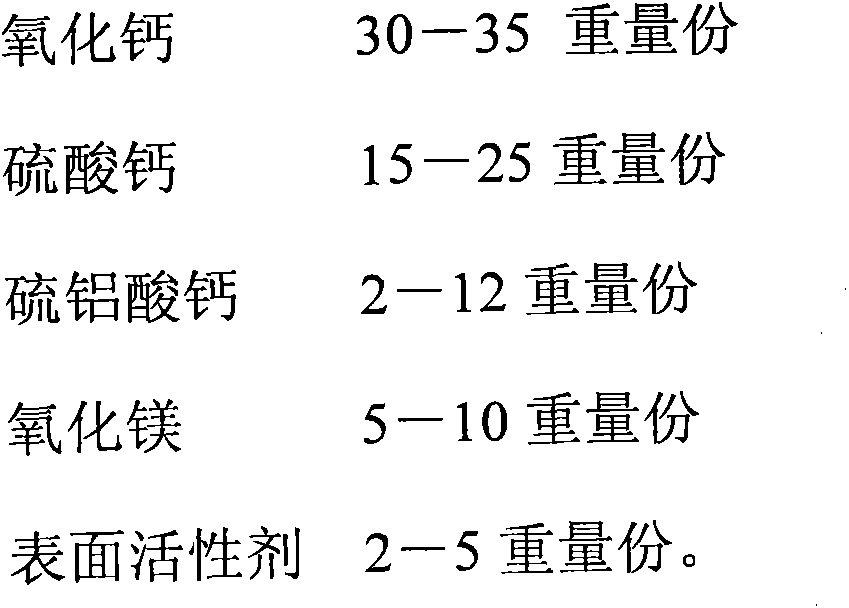

Concrete with improved construction performance and preparation method thereof

The invention provides concrete with improved construction performance. The concrete comprises, in parts by weight, 400-500 parts of cement clinker, 10-20 parts of an expanding agent, 80-120 parts of gypsum, 1-2 parts of a pH value adjusting agent, 8-10 parts of a water reducer, 300-400 parts of quartz sand, and 50-100 parts of furnace slag. The water reducer comprises methyl vinyl polyoxyethylene ether, water, acrylic acid, an oxidant, an amine promoter, a chain transfer agent, formaldehydehydrosulfite (also named as rongalite) and an alkali. The concrete is high in strength and good in construction performance.

Owner:福建科胜加固材料有限公司

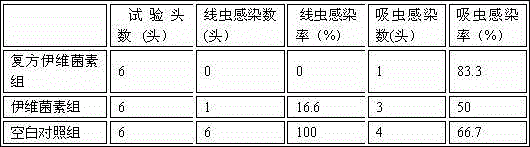

Compound ivermectin injection and preparation method thereof

InactiveCN104306388AGood insect resistanceBroad spectrum insect resistanceOrganic active ingredientsPharmaceutical delivery mechanismSulfite saltPyrrolidinones

The present invention discloses a composing prescription of a compound ivermectin injection and a preparation method of the compound ivermectin injection, and belongs to the veterinary medicine technology. The compound ivermectin injection comprises main drugs, a solvent and an antioxidant so as to prepare the stable high-concentration compound ivermectin injection. The injection has characteristics of advanced technology, good stability, broad spectrum, high efficiency, low irritation on the injected site, easy use, and clinical efficiency superior to the single-formula injection. According to the present invention, the raw materials comprise 0.5-5.0% of ivermectin, 2-20.0% of mebendazole, 0.5-5.0% of levamisole hydrochloride, 0.1-1% of the antioxidant, and the balance of the solvent, wherein the antioxidant is one or a mixture selected from thiourea, L-cysteamine hydrochloride, vitamin C, ethylenediamine, sodium hydrogen sulfite, anhydrous sodium sulfite, sodium formaldehydesulfoxylate dihydrate, sodium metabisulfite and the like, and the solvent is one or a mixture selected from propylene glycol, ethanol, glycerol, glycerol formal, dimethylformamide, dimethylacetamide, 2-pyrrolidone and the like.

Owner:JIANGXI NUCLEAR IND TIANDIHE PHARMA

Simulated digital discharge printing process

InactiveCN107217511APromote environmental protectionFine patternDyeing processOther printing apparatusPulp and paper industryRongalite

The invention discloses a simulated digital discharge printing process, which comprises the following steps of 1, dyeing; 2, pattern printing (pattern printing paste in the pattern printing step includes rongalite, sodium carbonate and glycerin); 3, steaming; 4, water washing (the water washing steps comprise once normal temperature water jar water washing and three times of hot water jar water washing); 5, paste removal shaping. The cloth is subjected to simulated digital discharge printing on the cloth; the characteristics of good environment-friendly effect, fine patterns and operation simplicity are realized. The process can be applicable to the simulated digital discharge printing process of artificial cotton, full cotton and terylene fabrics.

Owner:SHAOXING GAOFENG PRINTING & DYEING CO LTD

Preparation method for vulcanized reactive dye

The invention discloses a preparation method for vulcanized reactive dye, which comprises the following steps: under the condition that 2,4-dinitrochlorobenzene and sodium hydroxide solution are near boiling, hydrolyzing to prepare the dinitrophenol sodium solution; then, heating and boiling the dinitrophenol sodium solution with sodium polysulfide aqueous solution at a certain molecular ratio; under the condition of pressurization or non pressurization, reducing and carrying out sulphureting reaction to prepare; after sulphureting reaction is finished, drying directly by a roller drier to obtain raw dye; and splicing and mixing to obtain commodity dye. The preparation method for the vulcanized reactive dye has the beneficial effect that sodium sulfide or sodium hydrosulfite is used for reducing into a water-soluble leuco body when the vulcanized dye is used, and the water-soluble leuco body is adsorbed by a dyed object to be changed into the original insoluble colored object by the oxidation or other actions to fix the dye on the dyed object.

Owner:苏州贵族公子服饰有限公司

High-strength friction-resistant material for blowers

The invention relates to a high-strength friction-resistant material for blowers. The high-strength friction-resistant material for blowers comprises a friction-resistant material matrix and a high-strength system, wherein the high-strength system accounts for 17-19 wt% of the friction-resistant material matrix. The friction-resistant material matrix comprises the following components in parts by weight: 21-23 parts of polyetheretherketone, 9.2-9.4 parts of carbon fiber, 132-134 parts of anhydrous ethanol, 6.1-6.3 parts of magnesium oxide, 7.2-7.4 parts of magnesium chloride, 1.7-1.9 parts of lecithin, 6.5-6.7 parts of sodium bicarbonate, 6.4-6.6 parts of sodium sulfoxylate formaldehyde, 1.7-1.9 parts of butyl rubber and 6.5-6.7 parts of ethylene-vinyl acetate copolymer. The impact strength, mechanical properties, friction factor, high temperature resistance and antistatic property of the friction-resistant material can be enhanced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com