On-line detection method of dye liquor components of bundle dyeing machine based on boards

A detection method and dyeing machine technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of large influence on the detection results of dyeing components, defective fabrics, long time intervals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

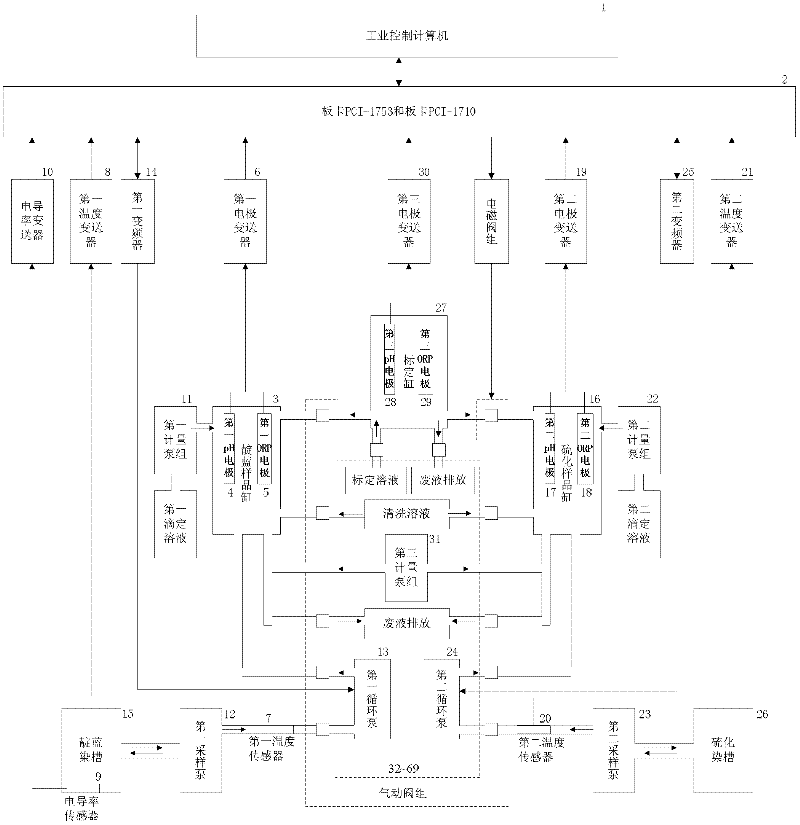

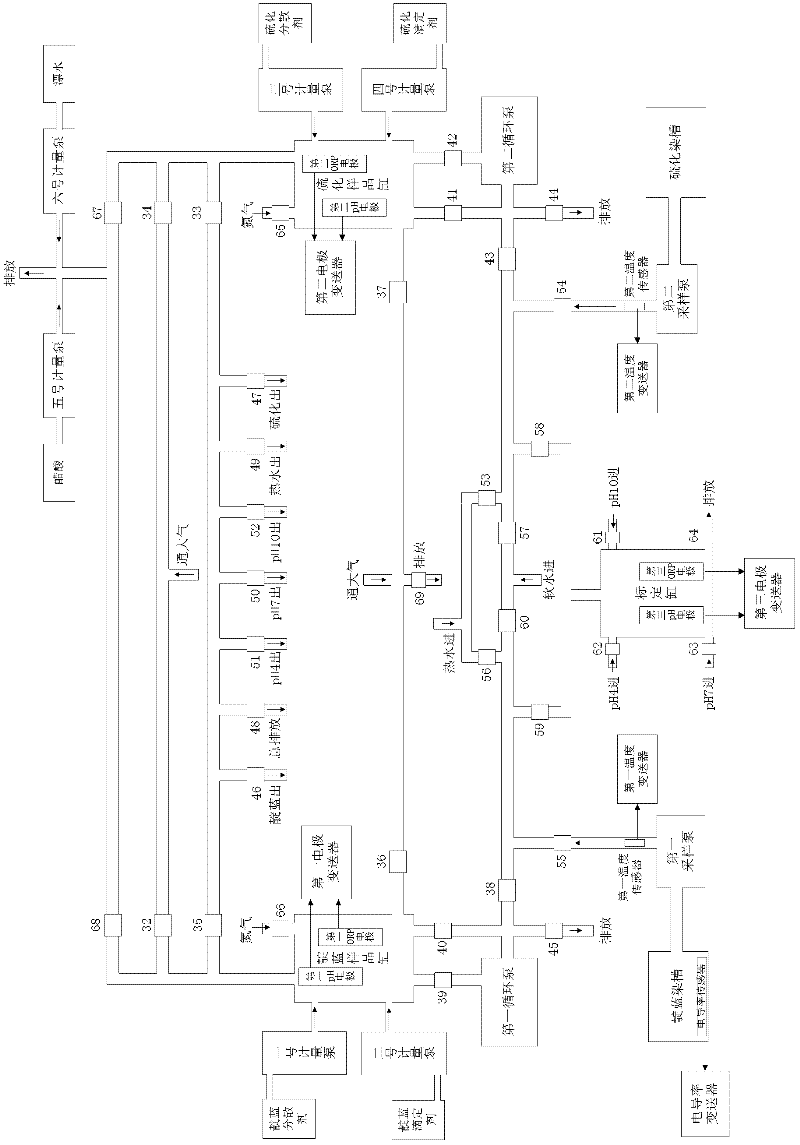

[0023] see figure 1 , a method for on-line detection of dye solution components of a board-based beam dyeing machine, comprising the steps of:

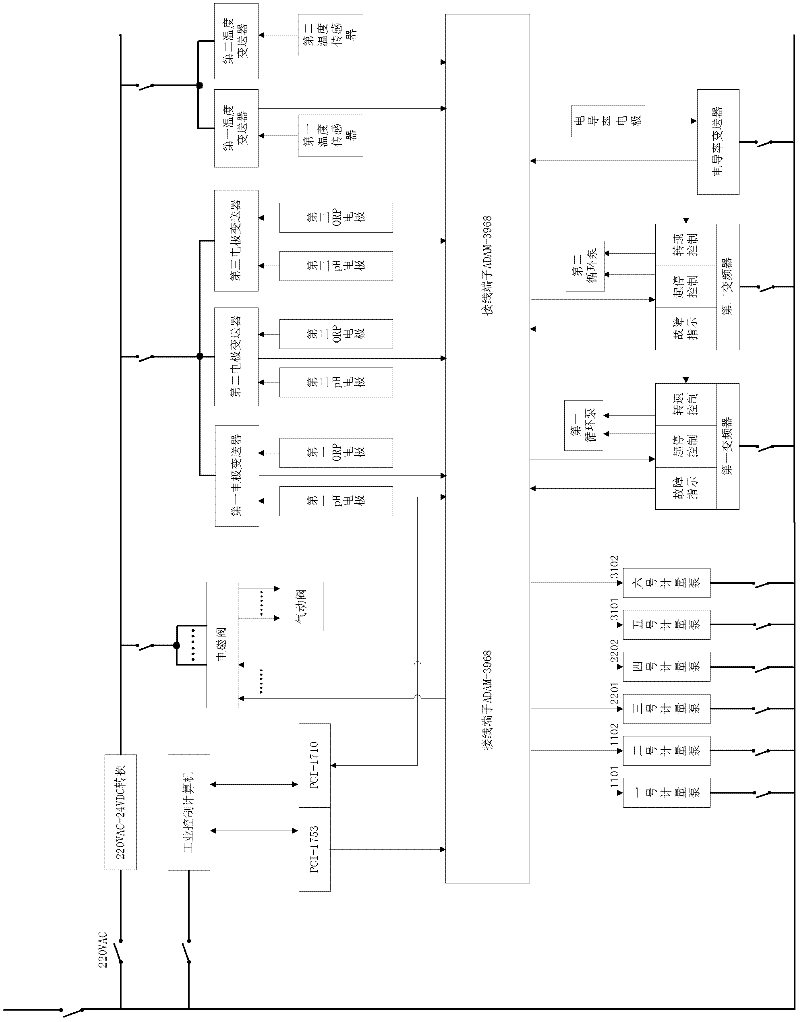

[0024] ① Set up an online detection system, which includes an industrial control computer 1 and the actuators and detection equipment controlled by the industrial control computer. Data exchange is performed between them through the board card 2. 1753. The board PCI-1710 has 16 single-ended analog inputs, 2 analog outputs, 16 digital inputs and 16 digital outputs, the board PCI-1753 has 96 digital inputs / outputs; industrial control computer It is only connected to the board, and the detection data is collected and the actuator is controlled through the board; the detection equipment includes pH electrodes, ORP electrodes and their transmitters, temperature sensors and Temperature transmitter, conductivity sensor and conductivity transmitter in indigo dyeing liquor online detection device; actuator includes metering pump, sampling pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com