Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "N-methylolacrylamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforcing agent for papermaking and preparation method thereof

ActiveCN102776802ASmooth responseSimple processReinforcing agents additionPaper/cardboardCelluloseItaconic acid

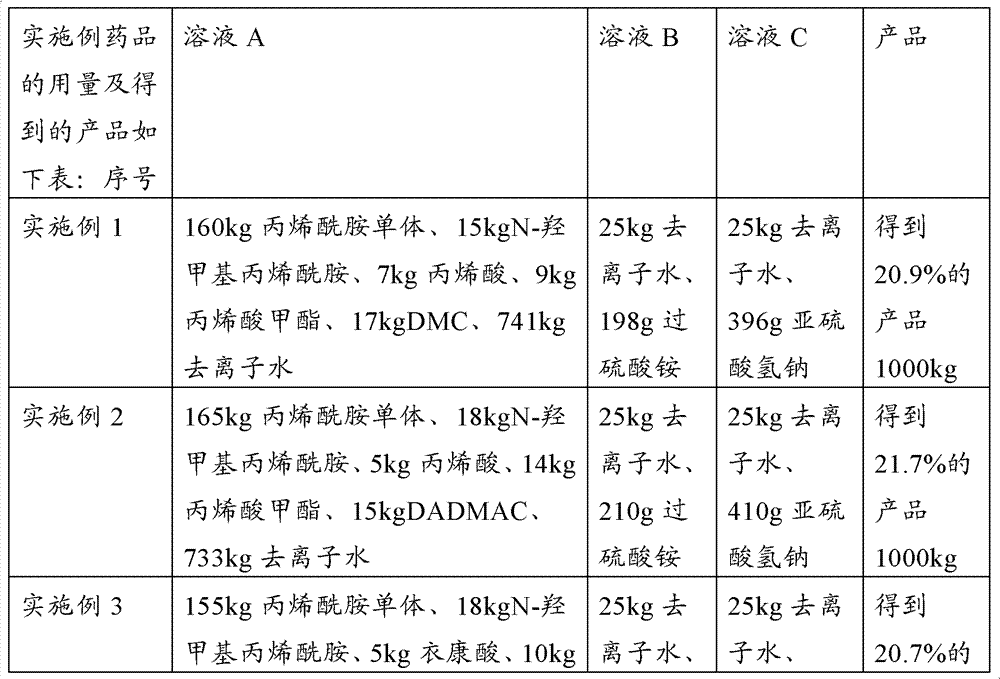

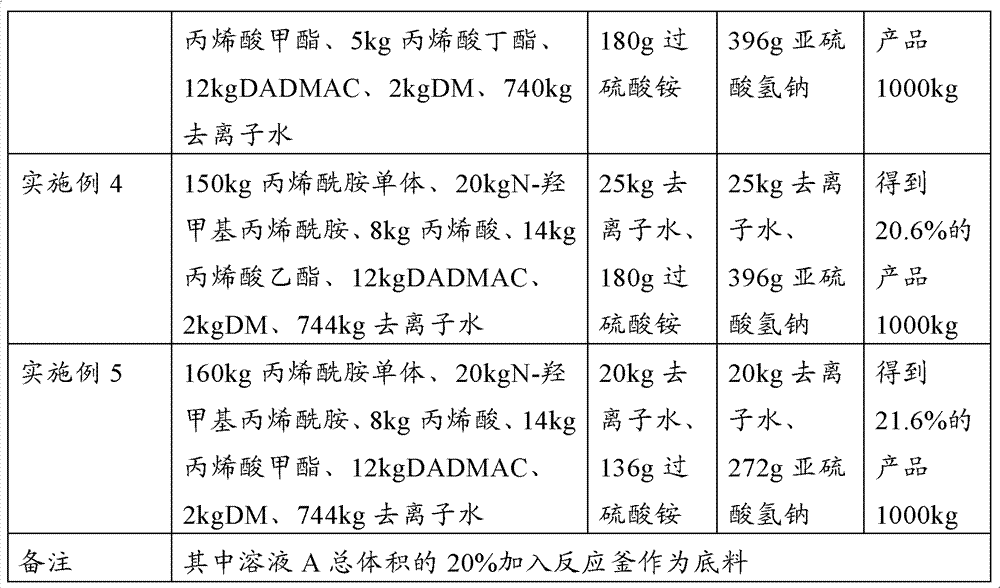

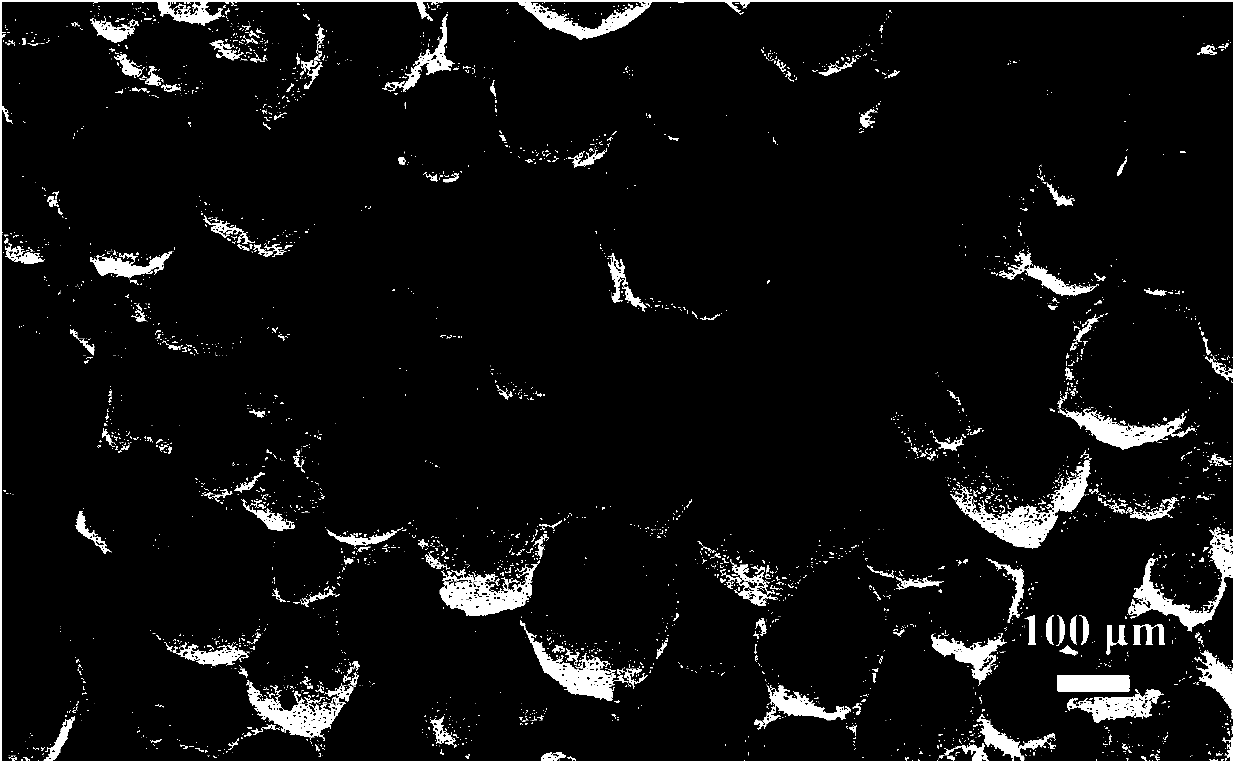

The invention relates to a reinforcing agent for papermaking and a preparation method thereof. The reinforcing agent provided by the invention comprises the following raw materials expressed in mass parts: 15 to 16 parts of acrylamide monomers, 1.4 to 2 parts of N-methylolacrylamide, 1.4 to 2.4 parts of acrylic acid, itaconic acid and acrylate monomers, 1.6 to 2.6 parts of cationic monomers, 75 to 80 parts of water and a redox initiation system accounting for 0.1 to 0.5% of the total amount of the monomers. According to the invention, since N-methylolacrylamide, acrylic acid, itaconic acid and the acrylate monomers are added into the reinforcing agent for papermaking, the reinforcing agent is capable of carrying out self-crosslinking to form a net structure, acting forces among the reinforcing agent and between the reinforcing agent and cellulose are improved, and finally, action effects of the reinforcing agent are enhanced; meanwhile, introduction of the cationic monomers into polymer chains enables the reinforcing agent to have good resistance to interference by hetero-ions and improved adaptability.

Owner:湖北广发纸业有限公司

Manufacture method of high porosity and high strength yttrium-silicon-oxygen porous ceramics

The invention relates to the porous ceramics material field, and concretely relates to a method for manufacturing high porosity and high strength yttrium-silicon-oxygen porous ceramics material through a foaming injection coagution process. According to the method, yttrium oxide and silicon oxide mixed power can be taken as a raw material, water is taken as a disperse medium, polyethyleneimine or ammonium citrate is selected as a dispersant, acrylamide or N-methylolacrylamide is taken as a monomer, a cross-linking agent N,N'-methylene bisacrylamide is added, a foaming agent sodium dodecyl sulfate, a peeling inhibitor polyoxyethylene, a catalyst N, N, N',N'-tetramethyl ethylenediamine and an initiator ammonium persulfate are added after stirring, and then injection mold solidification is carried out, drying is carried out for 24-48 hours at room temperature after demoulding, and then drying is carried out for 24-36 hours under the temperature of 60-90 DEG C, high temperature reaction sintering is carried out for 1.5-2.5 hours under the temperature of 1500-1550 DEG C finally, and the gamma-Y2Si2O7 porous ceramics can be finally manufactured. The manufactured gamma-Y2Si2O7 porous ceramics material having a multi-layer pore structure has controllable porosity with high porosity (75-85%) and high strength (3-8MPa).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

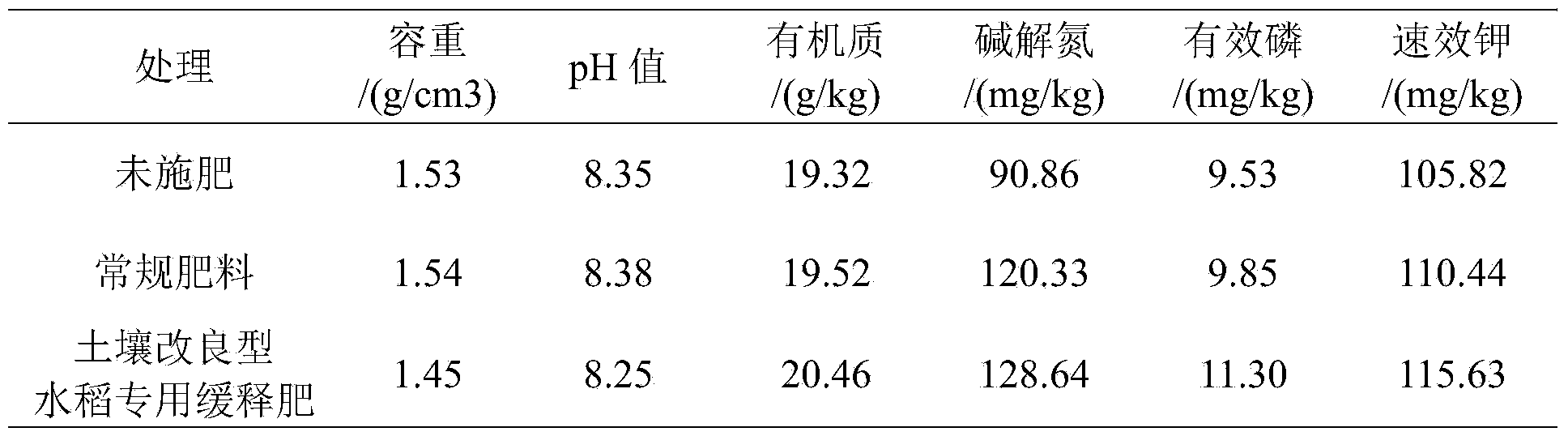

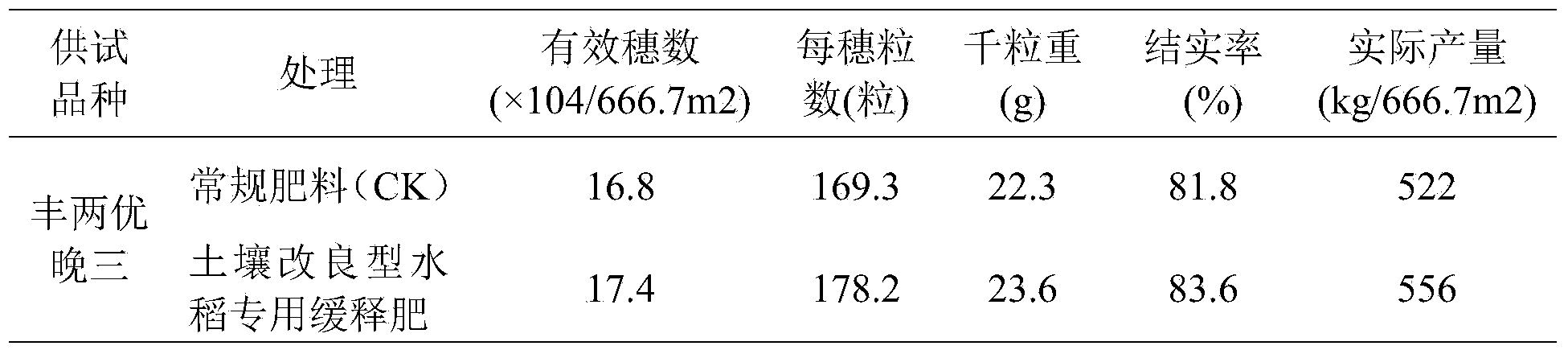

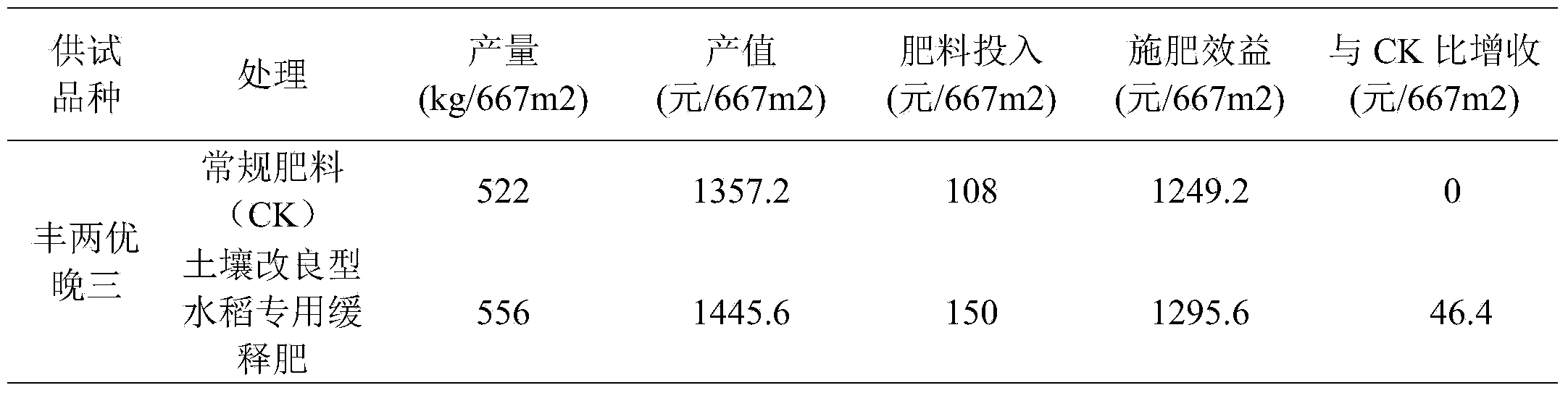

Soil-improvement special slow release fertilizer for rice, and preparation method thereof

ActiveCN103524219AReduce improvementReduce the fertilization effectFertiliser formsFertilizer mixtures2-ButanolUnsaturated polyester

The invention discloses a soil-improvement special slow release fertilizer for rice. The soil-improvement special slow release fertilizer for rice comprises 30-45wt% of powdery urea, 20-40wt% of urea phosphate, 8-15wt% of potassium chloride, 15-30wt% of a potash magnesium sulfate fertilizer, 2-8wt% of zinc humate, 1-6wt% of manganese humate, 1-5wt% of urea iron humate, 0.005-0.02wt% of compound sodium nitrophenolate, 1-5wt% of a slow release agent and 1.99-6wt% of an auxiliary material, wherein the slow release agent contains 5-15wt% of N-methylolacrylamide, 10-30wt% of an unsaturated polyester resin, 4-10wt% of cyclohexanol, 5-13wt% of 2-butanol, 1-5wt% of talcum powder, 1-4wt% of kaolin, 1-6wt% of ethyl cellulose, and the balance distilled water. The invention also discloses a preparation method of the soil-improvement special slow release fertilizer for rice.

Owner:ANHUI SIERTE FERTILIZER IND

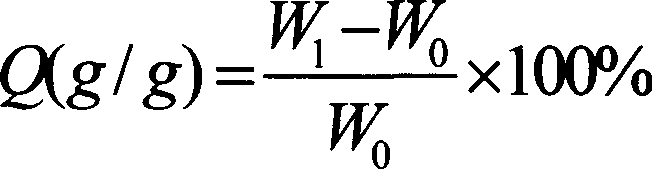

White emulsion with environmental protection and high viscosity and its preparation method

InactiveCN102485820ASimple production processLow costMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePolyvinyl alcohol

Owner:圣象实业(江苏)有限公司

Modified diatomite environmental production antibacterial inner compartment wallpaper

InactiveCN107100038AMeet the standards of green environmental protection and energy savingImprove insulation effectSpecial visual effect coatingsCoatings with pigmentsDecompositionAdipate

The invention discloses a modified diatomite environmental production antibacterial inner compartment wallpaper, which belongs to the field of the wallpaper. The wallpaper is made by base paper by coating a PVC paste on the base paper, heating, embossing and printing the patterns on the base paper, The PVC paste comprises the following raw materials: SG-2 PVC powder, modified diatomite, attapulgite powder, nano-level calcium carbonate, anatase titanium dioxide, cellulose, Arabic gum, ethyl acrylate, dimethyl fumarate, palm oil, zinc oxide, aluminium nitride, sodium oleate, isopropyl p-hydroxy-benzoate, ethyltrimethoxysilane, N-methylolacrylamide, poly hexamethylene adipate, a plasticizer, a dispersant, a foaming agent, a foam stabilizer, and a mildew inhibitor. The PVC paste is prepared by stirring the raw materials and grinding the materials. The inner compartment wallpaper has the advantages of green environmental protection, strong adhesion capability, long usage life, good antibiosis, water resistance, mildew resistance, and adsorption and decomposition of toxic gas, and can effectively purify air and improves the indoor environment.

Owner:合肥佳洋电子科技有限公司

Printing and dyeing process of cotton fabric

ActiveCN103938471APromote degradationImprove dyeing effectBiochemical fibre treatmentBleaching apparatusDiphenyl etherSulfonate

The invention discloses a printing and dyeing process of a cotton fabric. The printing and dyeing process comprises the steps of pretreatment of the fabric, and dyeing treatment, wherein the dyeing treatment comprises the steps of soaking the fabric subjected to pretreatment in a dye vat for dyeing, controlling the bath ratio of the dye vat to be 1:(12-15), carrying out dip dyeing for 8-10min at 25-30 DEG C, heating to be at 58-60 DEG C and carrying out dip dyeing for 15-25min. Dye liquid in the dye vat contains dye, N-methylolacrylamide, alpha-olefin sulfonate, methyl diphenyl ether disulfonate, a poly(quaternary ammonium dye-fixing agent, sodium silicate and other components; according to the printing and dyeing process, the operation is convenient, few procedures are needed, the energy consumption is low, the printing and dyeing efficiency is high, and waste liquid caused by printing and dyeing process is easy to treat.

Owner:CHANGXING HONGFENG PRINTING & DYEING

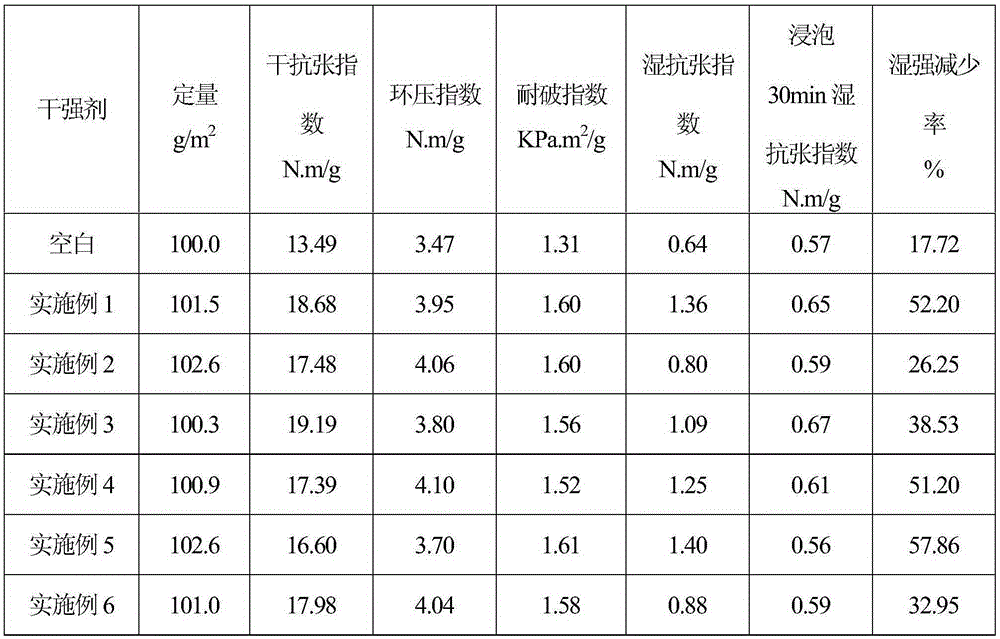

Preparation method for papermaking dry-strength agent with temporary wet-strength improving effect

InactiveCN105384870AEasy to enhance performanceHigh dry strength performanceReinforcing agents additionGlyoxalWet strength

The invention discloses a preparation method for a papermaking dry-strength agent with temporary wet-strength improving effect. Conventional hydroformylated polyacrylamide dry-strength agents are normally prepared by preparing cationic polyacrylamide at first and then carrying out hydroformylation by using glyoxal, wherein the process of hydroformylation is difficult to control, and gelation occurs if control is improper. The preparation method provided by the invention employs N-methylolacrylamide as a main monomer and subjects N-methylolacrylamide, acrylamide, cationic monomer and anionic monomer to free radical solution copolymerization so as to prepare the papermaking dry-strength agent with a macromolecular chain containing a great number of active hydroxymethyl groups. The papermaking dry-strength agent prepared in the invention has the advantages of easiness in adherence and adsorption, effective resistance to interference by anionic garbage, high dry-strength improving effect on paper and certain temporary wet-strength improving effect on the paper. The papermaking dry-strength agent is simple to synthesize, does not contain organochlorine, is friendly to environment and has good storage stability.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Method for preparing copolymerized acrylonitrile high water-absorption fiber

InactiveCN1743517AControllable water absorption ratioEasy to produceFibre treatmentMonocomponent synthetic polymer artificial filamentWater bathsFiber

This invention relates to a preparation method for copoly acrylonitrile high water-absorption fibers including: 1, preparing copoly-acrylonitrile fiber with the following formal of the material massratio: 100% acrylonitrile, methyl acrylate monomers and potential crosslinker, initiator 0.3-0.8% of the gross mass of the monomer s and the cross linker, the acrylonitrile: 75%-85%, the methyl acrylate: 5-15% and the potential crosslinker: one or many of a N-methylolacrylamide, methacrylic acid beta-hdyroxyl ethyl, ethyl hydroxyl acrylate and propy1 hydroxy1 acylate in 0.3~0.8%. The materials are mixed and dissolved in DMSO to be added with the initiator and protected by N to be copolymerized for 6-10h under 60-80degC to get the acrylonitrile solution to be defoamed and stretched by wet spin to get copoly acrylonitrile fibers to be processed with boiling-water bath, hot-crosslinked under 130-180deg.C for 5-15min to be hydrolyzed, cleaned with weak acid, de watered and dried to get the fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vinyl acetate/ethylene and vinyl chloride polymer blends as binders for nonwoven products

ActiveUS7247586B2Improve waterproof performanceEliminate security concernsSynthetic resin layered productsWoven fabricsCelluloseWet strength

This invention is directed to an improvement in binders particularly suited for use in preparing nonwoven products and to the nonwoven products. The improved binders comprise a blend of a vinyl chloride (VCl) polymer emulsion and a self crosslinkable vinyl acetate-ethylene-N-methylolacrylamide (VAE-NMA) polymer emulsion. The blend of the VCl polymer emulsion and the VAE-NMA polymer emulsion can be applied to cellulose and cellulose / synthetic nonwoven substrates and cured in the absence of an acid catalyst to provide a self-sustaining web having excellent wet strength performance.

Owner:WACKER CHEM CORP

Aqueous polyurethane waterproof paint and preparation method thereof

ActiveCN104774551AAvoiding Amine ProblemsAvoid amine problems like MOCA problemsAnti-corrosive paintsPolyurea/polyurethane coatingsCross-linkPlasticizer

The invention provides an aqueous polyurethane waterproof paint and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A is composed of polyurethane performed polymer, N-methylolacrylamide and citric acid, and the component B is composed of an inorganic filling material, a plasticizer, a cross-linking agent, an emulsifier, an antifoaming agent, a catalyst, pigment and water. The preparation method comprises the following steps: successively adding N-methylolacrylamide and citric acid according to desired weight parts, carrying out stirring and heating, adding the polyurethane performed polymer in one shot before temperature rises to 62 DEG C, then carrying out heating to 82 DEG C, carrying out a reaction at a constant temperature of 83 to 85 DEG C for 2 to 3 h and then carrying out cooling to 52 to 54 DEG C so as to obtain the component A; successively adding raw materials of the component B into a reaction vessel stirrer according to desired weight parts, carrying out uniform mixing through stirring and grinding the mixed materials to a fineness of 51 to 55 [mu]m in a three-roller machine so as to obtain the component B; and uniformly mixing the component A with the component B according to a weight ratio of 1: 2 so as to obtain the aqueous polyurethane waterproof paint. The aqueous polyurethane waterproof paint has the characteristics of high temperature resistance, good weatherability, good waterproof performance, etc.

Owner:北京奥克兰防水工程有限责任公司

N-methylol acrylamide and preparation thereof

InactiveCN101462978ANo emissionsNo pollution in the processOrganic compound preparationCarboxylic acid amides preparationHydroquinone CompoundSolvent

The invention relates to a N-methylolacrylamide and a preparation method thereof, belonging to the fine chemistry industry field. Acrylamide and paraformaldehyde are used as raw materials, and the N-methylolacrylamide is prepared by reaction in the presence of a catalyst and solvent; wherein, one or several of parahydroxyben-zaldehyde, hydroquinone and phenothiazine are added in a reaction system. The invention optimizes the reaction environment required by the production, has fewer byproducts and improves the product quality and the yield correspondingly, and the invention has simple technology and convenient use and is safe and environment-friendly.

Owner:TIANJIN CHEM REAGENT RES INST

High-strength paper packaging adhesive formula

InactiveCN104804654AHigh-quality high-strength performanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCarboxymethyl celluloseAdhesive

The invention discloses a high-strength paper packaging adhesive formula. The high-strength paper packaging adhesive in the formula includes the following raw materials in parts by mass: 63.0-70.0 parts of water, 8.0-8.5 parts of polyvinyl alcohol, 0.2-0.4 part of 40% hydrochloric acid, 1.3-1.7 parts of glyoxal, 6.5-7.2 parts of styrene, 16.0-16.8 parts of kaolin, 4.0-5.5 parts of butyl acrylate, 0.3-0.6 part of N-methylolacrylamide, 1-2 parts of borax, 0.4-0.5 part of an emulsifier OP-10, 0.3-0.8 part of carboxymethyl cellulose, 0.2-1.4 parts of an initiator, and 0.3-1.1 parts of other additives. The formula is simple and easy to realize mass production, and is especially suitable for paper packaging.

Owner:JURONG DINGSHENG CARTON PACKING

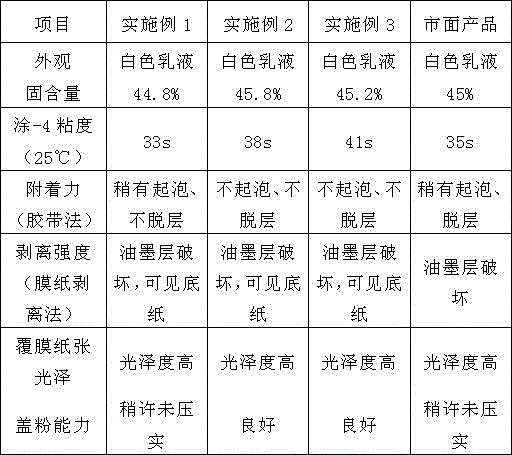

Acrylic ester water-emulsion ink adhesive and preparation method thereof

InactiveCN101585985AImprove performanceComprehensive performance (excellent rubbing resistanceInksEster polymer adhesivesWater basedSocial benefits

The invention provides an acrylic ester water-emulsion ink adhesive and a preparation method thereof, and belongs to the field of water-based ink. The invention aims to solve the problems of poor anti stripping property and poor water resistance of the prior ink adhesive. The adhesive of the invention is prepared by copolymerization of a free radical seeded emulsion, and is prepared from the following compositions in proportion: 150 portions of water, 0 to 60 portions of styrene, 40 to 100 portions of (methyl) acrylic ester, 0 to 3 portions of (methyl) acrylic acid, 0 to 1.5 portions of maleic anhydride, 0.5 to 2 portions of (methyl) acrylamide, 0.1 to 1 portion of N-methylolacrylamide, 0.5 to 3 portions of acrylic acid 2-hydroxyethyl ester and 0.5 portion of NaHCO3. The adhesive has stable performance, excellent comprehensive performance, low price, and innocuity; and the preparation method is simple and convenient, easy to operate, and suitable for industrial production, and has economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Bicomponent adhesive with improved heat resistance and extended pot life

InactiveUS20050215700A1Monocarboxylic acid ester polymer adhesivesOrganic dyesCross-linkPolymer science

A stable, heat resistant colloid stabilized waterbased bicomponent wood adhesive based on vinyl acetate and N-methylolacrylamide as a cross-linking agent and also including an aromatic and / or cyclo aliphatic monomer, such as 2-phenoxy ethyl acrylate and / or isobornyl methacrylate, and methyl methacrylate. The colloid system contains a high molecular weight partially hydrolyzed polyvinylalcohol and one or more intermediate hydrolyzed polyvinyl alcohols.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Method for preparing anti-bacteria, water-roof and anti-ageing purified propyl emulsion

The invention is the antibacterial, waterproofing, anti-aging nano pure-acrylic emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 24%, methyl methacrylate (MMA) 23.6%, non-ionic emulsifier (MS-01) 2%, nano-ZnO 1.8%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, acrylic acid (AA) 0.8%, tert-butyl hydroperoxide (TDHP) 0.6%, sodium formaldehydesulfoxylate (SFS) 0.6%, ammonium persulfate (APS) 0.4%, polymerizable emulsifier (AMPS) 0.4%, NaHCO3 0.2%, and AMP-95 0.2%. According to the said weight proportions, prepare the emulsion through pre-emulsifying, milling, and polymerizing at high temperature.

Owner:何林道

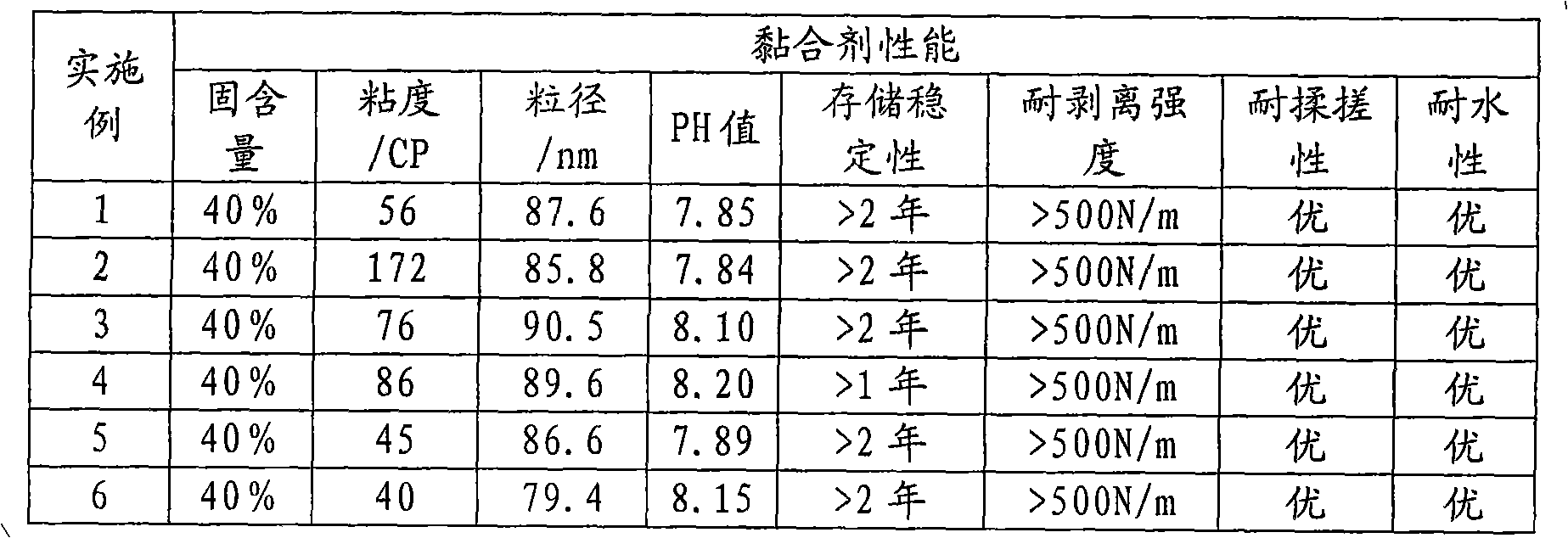

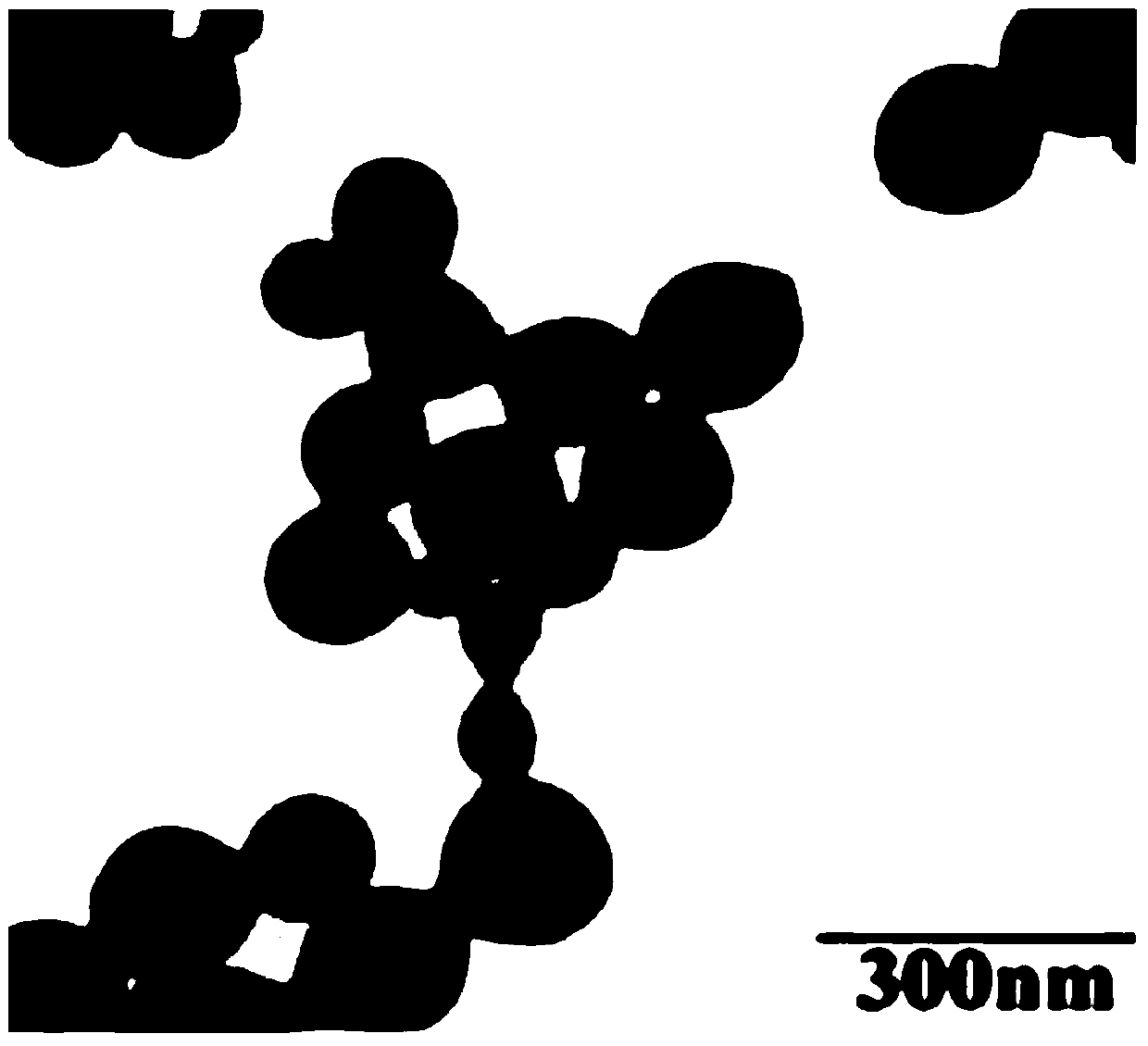

Aqueous dry lamination adhesive and preparation method thereof

ActiveCN105482745AFully bondedImprove adhesionEster polymer adhesivesRosin adhesivesSodium bicarbonateIsooctyl acrylate

The invention discloses an aqueous dry lamination adhesive and a preparation method thereof. Raw materials of the aqueous dry lamination adhesive comprise styrene, butyl acrylate, isooctyl acrylate, acrylonitrile, N-methylolacrylamide, hydroxyethyl acrylate, acrylic acid, rosin, potassium persulfate, sodium dodecylbenzene sulfonate, isooctyl phenol polyoxyethylene ether, sodium bicarbonate, deionized water, ammonia water, a wetting agent and antifoaming agent. Aqueous latex with a core-shell structure is prepared through a segmented polymerization technology, so functional groups make a substrate and a plastic film be fully bonded, and polymer molecular chains are self-crosslinked, thereby the adhesion and the peeling strength of the substrate are improved, the adhesive has excellent initial adhesion, pressure sensitivity and covering ability, the excellent leveling property and the dynamic wetability of the adhesive make a laminated product have brilliant gloss, and the adhesive can be widely used in paper plastic lamination.

Owner:常德市雄鹰科技有限责任公司

Bicomponent adhesive with improved heat resistance and extended pot life

InactiveCN1680505AMonocarboxylic acid ester polymer adhesivesUnsaturated alcohol polymer adhesivesCross-linkPolymer science

A stable, heat resistant colloid stabilized waterbased bicomponent wood adhesive based on vinyl acetate and N-methylolacrylamide as a cross-linking agent and also including an aromatic and / or cyclo aliphatic monomer, such as 2-phenoxy ethyl acrylate and / or isobornyl methacrylate, and methyl methacrylate. The colloid system contains a high molecular weight partially hydrolyzed polyvinylalcohol and one or more intermediate hydrolyzed polyvinyl alcohols.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Styrene-acrylic emulsion and synthetic method thereof and electrical steel coating

InactiveCN103626907ANarrow particle size distributionLarge particle sizeCoatingsIsooctyl acrylateAcrylic resin

The invention discloses a styrene-acrylic emulsion and a synthetic method thereof and an electrical steel coating. The styrene-acrylic emulsion comprises the following components in percentage by weight: 10.0-30.0% of styrene, 10.0-30.0% of butyl acrylate, 1.0-5.0% of 2-ethylhexyl acrylate, 0.5-2.5% of methyl methacrylate, 0.3-1.0% of methacrylic acid, 0.1-1.5% of alkyl phenol polyoxyethylene ether OP-10, 0.1-2.0% of sodium dodecyl sulfate K12, 0.1-1.0% of N-methylolacrylamide, 40.0-70.0% of water, 0.2-2.0% of sodium bicarbonate, and 0.2-2.0% of ammonia persulfate. A preparation method comprises the steps of firstly preparing pre-emulsion and initiator water solution, and mixing and emulsifying the pre-emulsion and initiator water solution in batches. The styrene-acrylic emulsion is narrow in particle size distribution, and fine in particle size; the prepared electrical steel coating is good in resin dispersibility, long in painting liquid shelf life, and suitable for high-speed roller painting.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

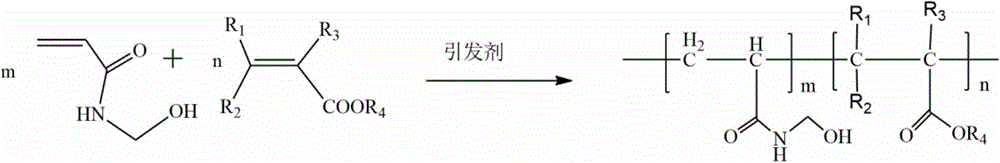

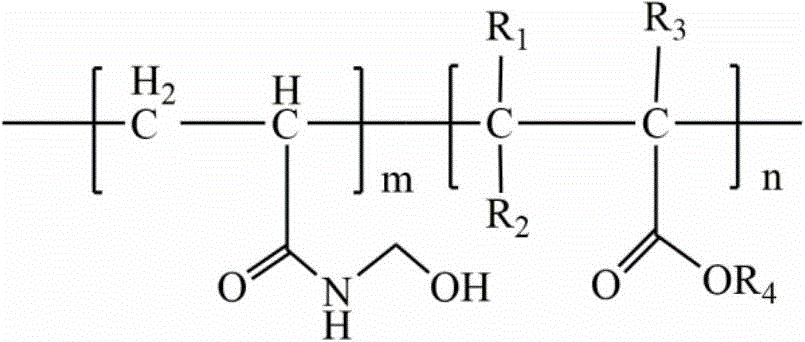

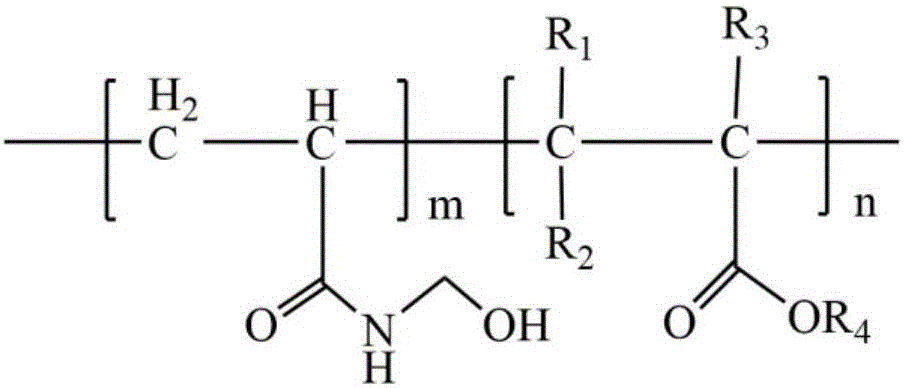

N-Methylolacrylamide modified polycarboxylate ceramic water reducer and normal-temperature preparation method and application thereof

The invention relates to N-methylolacrylamide modified polycarboxylate ceramic water reducer, molecularly structurally comprising: an anchor chain segment and a solvation chain segment.The anchor chain segment is composed of N-methylolacrylamide copolymer; the copolymer ceramic water reducer is 3000-20000 in number-average relative molecular weight; the invention also provides a normal-temperature preparation method of the N-methylolacrylamide modified polycarboxylate ceramic water reducer.Owing to the presence of amino and carboxyl groups capable of chelating with anions, the N-methylolacrylamide modified polycarboxylate ceramic water reducer can well release water absorbed by hydrated anions from slurry, thus the slurry has good mobility with low water content.The copolymer ceramic water reducer prepared herein is widely applicable to grinding, pulping and forming processes of ceramic blanks.

Owner:深圳市名轩建材科技有限公司

Vinyl acetate/ethylene and ethylene/vinyl chloride blends as binders for nonwoven products

ActiveUS7153791B2Improve performanceEasy curingSynthetic resin layered productsWoven fabricsCelluloseEmulsion

This invention is directed to an improvement in binders particularly suited for use in preparing nonwoven products and to the nonwoven products. The improved binders comprise a blend of emulsion polymerized ethylene-vinyl chloride (EVCl) polymer and an emulsion polymerized self crosslinkable vinyl acetate-ethylene-N-methylolacrylamide (VAE-NMA) polymer. The blends of the EVCl polymer emulsion and the VAE-NMA polymer emulsion can be applied to cellulose and cellulose / synthetic nonwoven substrates and cured in the absence of an acid catalyst to provide a self-sustaining web having excellent wet strength performance. The blends of EVCl and VAE-NMA polymers do not require an acid catalyst to facilitate cure.

Owner:WACKER CHEM CORP

Water-absorbing resin dry glue powder and application thereof in demulsification of oil-water emulsion

InactiveCN102492069AEasy to separate and recycleEasy to makeNon-miscible liquid separationPolymer scienceSulfite salt

The invention discloses water-absorbing resin dry glue powder and application thereof in demulsification of oil-water emulsion. The dry glue powder is prepared from the following raw materials in percentage by weight: 10-40% of acrylic acid, 5-20% of sodium hydroxide, 0.5-8% of N-methylolacrylamide, 0.5-5% of ammonium peroxydisulfate, 0.5-2% of sodium sulfite and the balance being water; all the raw materials, except acrylic acid, are prepared into a water solution, a sodium hydroxide water solution reacts with acrylic acid, the neutralization degree is controlled to be 60-85%, then the solution of N-methylolacrylamide, ammonium peroxydisulfate and sodium sulfite is added to react at the temperature of 50-80 DEG C to produce hydrogel; and the hydrogel is cut into small pieces and dried ina drying oven, and the dried hydrogel pieces are smashed into the water-absorbing resin dry glue powder. The water-absorbing resin dry glue powder is added in emulsion and can spontaneously absorb water to expand through mechanical stirring so as to dehydrate the emulsion and realize demulsification. The water-absorbing resin dry glue powder is simple to prepare and easy for industrial production; dehydration and demulsification operations are convenient to implement and have low equipment requirement; and a water-absorbing material has high dehydration capability and is easy to separate and recycle, and can be recycled.

Owner:JIANGSU UNIV +1

Preparation method for N-methylolacrylamide

InactiveCN102304057AHigh yieldImprove qualityOrganic compound preparationCarboxylic acid amides preparationEthyl acetateAlkaline catalyst

The present invention discloses a preparation method for N-methylolacrylamide. The method comprises the following steps: firstly adding acrylamide crystal to acetic ether; then heating to a temperature of 38-42 DEG C; then adding a composite polymerization inhibitor and trioxymethylene, wherein the composite polymerization inhibitor comprises hydroquinone and diphenylamine; adopting an alkaline catalyst of triethanolamine to adjust the pH value of the reaction solution to 9.5-9.6; carrying out the reaction for 1.5-2.5 hours at the temperature of 38-42 DEG C after completing the material adding; carrying out filtering while the solution is hot after completing the reaction; adopting dilute sulfuric acid to adjust the pH value of the filtrate to the neutral pH value; carrying out cooling and crystallization for the neutral filtrate to obtain the crude N-methylolacrylamide product. According to the present invention, the product having the content more than 97% and the yield more than 98% can be obtained; compared to the prior art, the product yield and the product quality are effectively improved through the method provided by the present invention.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

Preparation method of paper handle agent

ActiveCN106317323AHigh viscosityComplete copolymerizationNon-fibrous pulp additionPaper/cardboardGlycidyl methacrylateNitrogen

A preparation method of a paper handle agent comprises: (1) taking, by molar percentage, 70-80% of acrylamide, 20-30% of N-methylolacrylamide, 8-15% of glycidyl methacrylate, 0.01-5% of a crosslinking agent and 0.05-5% of a chain transfer agent, and adding them in water while stirring to obtain mixed aqueous solution; introducing nitrogen, adding an initiator and a catalyst, heating to 60-90 DEG C, and polymerizing for 30-90 min to obtain polyacrylamide copolymer; (2) adding suitable organic amine in the product of step (1), carrying out aminomethylation condensation at 60-90 DEG C; cooling the reaction product to 50 DEG C and below, and adding an acid to adjust pH of polymer solution to 6-9; the paper handle agent has the advantages that by adding the handle agent into pulp, finished paper is better in toughness and stiffness and has improved bulkiness and texture.

Owner:GUANGDONG PAPER IND RES INST

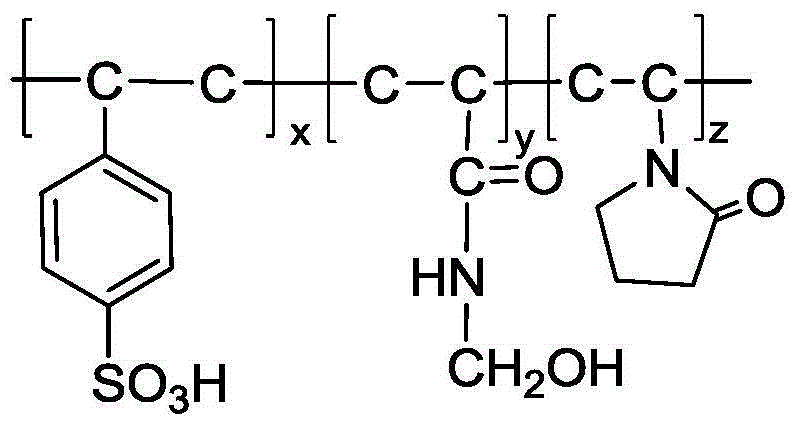

Polymer oil displacement agent and preparation method thereof

InactiveCN104974733APossibility of weakening curlsImprove rigidityDrilling compositionPolymer scienceMonomer

The present invention discloses a polymer oil displacement agent and a preparation method thereof. The polymer oil displacement agent is characterized by being prepared from three monomers by weight: 30-40 parts of styrene sulfonic acid, 25-40 parts of N-methylolacrylamide and 20-30 parts of N-vinyl pyrrolidone. The preparation method of the oil displacement agent is simple and feasible; the prepared oil displacement agent has excellent temperature resistance and high salt tolerance; the molecular structure of the oil displacement agent has significantly improved extent of collateralization, thus increasing the steric hindrance; and coupled with the benzene ring and pentabasic heterocyclic ring on the molecular branched chain, the rigidity of molecular backbone is enhanced, so as to weaken the possibility of curl chain, increase tackability and enhance salt tolerance.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Slightly-viscous emulsion pressure-sensitive adhesive and preparation method thereof

ActiveCN105315924AReduce pollutionSave glue dispensing processEster polymer adhesivesCross-linkViscous pressure

The invention discloses a slightly-viscous emulsion pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from 2-ethylhexyl acrylate, butyl acrylate, acrylic acid, N-Methylolacrylamide and a cross-linking monomer by employing a pre-emulsification semi-continuous polymerization technology for polymerization. The safety and environment friendliness problems of a slightly-viscous pressure-sensitive adhesive because of contained organic solvents in the prior art are solved. An adhesive tape prepared from the slightly-viscous emulsion pressure-sensitive adhesive possesses the peeling strength less than 0.15 N / 25 mm at 180 DEG C, the slightly-viscous emulsion pressure-sensitive adhesive is safe and environment-friendly, and is capable of replacing a part of solvent type slightly-viscous emulsion pressure-sensitive adhesives and being applied to corresponding fields.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Novel agricultural fertilizer and preparation method thereof

InactiveCN106146138APromote degradationIncrease profitOrganic fertilisersSolid/semi-solid fertilisersBoraxChemistry

The invention provides novel agricultural fertilizer and a preparation method thereof. Urea entrapped attapulgite and a sodium alginate substrate are taken as inner cores of the fertilizer, a carboxymethyl modified wheat straw / sodium alginate blend containing urea and borax is taken as an inner coating material, poly(acrylic acid-co-N-methylolacrylamide) attapulgite composited super absorbent resin is taken as an outer coating material, and the fertilizer has a core-shell structure and contains 23.3% of nitrogen and 0.65% of boron. The crop wheat straw is introduced and N-methylolacrylamide is taken as a crosslinking agent. The novel agricultural fertilizer has the beneficial effects as follows: with introduction of the crop wheat straw and application of N-methylolacrylamide as the crosslinking agent, the degradation property of the super absorbent resin can be improved; double layers of the coating materials of the fertilizer both select the crop straw, so that the production cost of the slow release fertilizer can be reduced greatly, the fertilizer is environment-friendly, and one way is provided for utilization of crop resources.

Owner:韩立

Glossy ink-jet recording sheet

InactiveUS20090068442A1Good ink absorptionImprove uniformityDuplicating/marking methodsSynthetic resin layered productsMeth-Polymer science

The present invention provides a glossy ink-jet recording sheet comprising: a paper support; a solvent-absorbing layer comprising a pigment and an adhesive; and an ink-fixing layer comprising a pigment and an adhesive, the ink-fixing layer having a mirror-finished surface; or a glossy ink-jet recording sheet comprising: a paper support; a solvent-absorbing layer comprising a pigment and an adhesive; an ink-fixing layer comprising a pigment and an adhesive; and a glossy layer having a mirror-finished surface; characterized in that the adhesive of the solvent-absorbing layer comprises a ternary copolymer consisting of an alkyl(meth)acrylate, a N-methylolacrylamide, and a styrene.

Owner:OJI PAPER CO LTD

Acrylic resin for melamine board and preparation method thereof

The invention relates to the technical field of paint, in particular to acrylic resin for a melamine board, and aims at solving the technical problems to provide waterborne melamine board paint with the advantages of superstrong adhesive force, high solid content, low viscosity, pollution resistance, ageing resistance, high drying speed, good fullness, safety and environment-friendly effect. The acrylic resin has the technical scheme that the acrylic resin is prepared from the following raw materials in parts by weight: 10 to 20 parts of methacrylic acid, 15 to 25 parts of ethyl methacrylate,20 to 30 parts of n-butyl methacrylate, 15 to 25 parts of isobornyl methacrylate, 1 to 5 parts of N-methylolacrylamide, 15 to 25 parts of aliphatic polyacrylate, 0.5 to 2 parts of initiating agents, 3.75 to 28 parts of silane coupling agents and 7.5 to 15 parts of prepolymers.

Owner:LINFEN TIE HUAN PAINT IND

Waterborne environment-friendly high-adhesion sealing adhesive

InactiveCN106833452AStrong initial adhesionImprove permeabilityMacromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateAdhesive

The invention relates to waterborne environment-friendly high-adhesion sealing adhesive, prepared by combining sealing adhesive stock solution, Tacolyn 3509 emulsion tackifying resin, waterborne rosin, organic wax and deionized water according to a weight ratio of 5:3:1:0.5:0.5, wherein the sealing adhesive stock solution is made by polymerizing, at a weight ratio, deionized water, an emulsifier, styrene, methyl methacrylate, butyl acrylate, 2-ethylhexyl acrylate, acrylic acid, ethyl acrylate, N-methylolacrylamide, diacetoneacrylamide, a molecular control agent, a PH buffer agent, an initiator, a PH regulator and a functional aid. The invention also relates to a preparation method of the waterborne environment-friendly high-adhesion sealing adhesive. Compared with the prior art, the waterborne environment-friendly high-adhesion sealing adhesive has high initial adhesion and high permeability, can dry fast from surface in 20 s, and has peel strength of greater than 2 N / cm when it is dry.

Owner:韩志龙

Vinyl acetate/ethylene and ethylene/vinyl chloride blends as binders for nonwoven products

ActiveUS20060052017A1Stable shelf life viscosityHigh viscositySynthetic resin layered productsWoven fabricsCelluloseEmulsion

This invention is directed to an improvement in binders particularly suited for use in preparing nonwoven products and to the nonwoven products. The improved binders comprise a blend of emulsion polymerized ethylene-vinyl chloride (EVCl) polymer and an emulsion polymerized self crosslinkable vinyl acetate-ethylene-N-methylolacrylamide (VAE-NMA) polymer. The blends of the EVCl polymer emulsion and the VAE-NMA polymer emulsion can be applied to cellulose and cellulose / synthetic nonwoven substrates and cured in the absence of an acid catalyst to provide a self-sustaining web having excellent wet strength performance. The blends of EVCl and VAE-NMA polymers do not require an acid catalyst to facilitate cure.

Owner:WACKER CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com