Acrylic ester water-emulsion ink adhesive and preparation method thereof

A technology of acrylates and acrylates, which is applied in the direction of ester copolymer adhesives, inks, adhesive types, etc., can solve the problems of poor peeling resistance and poor water resistance of emulsions, and is suitable for industrial production. High peel strength and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

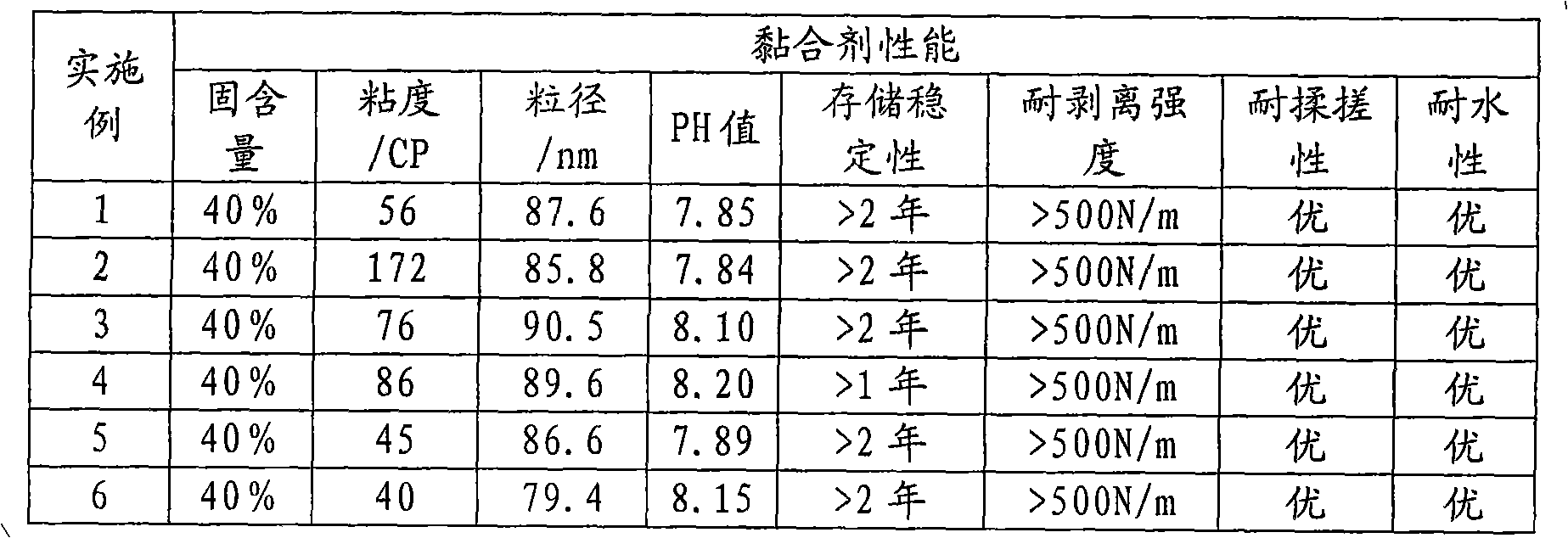

Examples

Embodiment 1

[0055] 1) Mix 5 parts of NaHCO 3 , 964 parts of DI water, 11 parts of 45% DSB aqueous solution and 40 parts of 25% mass fraction of SE10-N DI aqueous solution were added to the reactor, and stirred for 5 minutes at a stirring rate of 500r / min;

[0056] 2) Add 30 parts of MMA, 30 parts of St, 20.7 parts of BA, 15 parts of EHA, 1 part of AA, 1 part of MAA and 0.1 part of -SH into the reactor of step 1) at one time, and continue stirring for 5 minutes , heated to 80°C;

[0057] 3) Add 102.5 parts of APS DI aqueous solution with a mass fraction of 2.44% to the reactor of step 2) at one time, until the color of the liquid mixture in the reactor turns blue, the temperature rises to 85°C, and the stirring rate is reduced to 300r / min ;

[0058] 4) When the temperature drops to 80°C, add dropwise 270 parts of MMA, 270 parts of St, 186.3 parts of BA, 135 parts of EHA, 9 parts of AA, 9 parts of MAA and 0.9 parts of -SH mixture, and dropwise add 3 parts of NAM, The mixed solution of 20...

Embodiment 2

[0061] 1) Mix 5 parts of NaHCO 3 , 964 parts of DI water, 11 parts of 45% by mass fraction of DSB aqueous solution and 40 parts of 25% by mass fraction of SE10-N DI aqueous solution were added to the reactor, and stirred for 5 minutes at a stirring rate of 500r / min;

[0062] 2) Add 30 parts of MMA, 30 parts of St, 20 parts of BA, 15 parts of EHA, 1 part of AA, 1 part of MAA, 1 part of HEA and 0.08 parts of -SH mixture into the reactor of step 1) at one time, and continue stirring After 5 minutes, heat to 80°C;

[0063] 3) Add 102.5 parts of APS DI aqueous solution with a mass fraction of 2.44% to the reactor of step 2) at one time, until the color of the liquid mixture in the reactor turns blue, the temperature rises to 86°C, and the stirring rate is reduced to 300r / min ;

[0064] 4) When the temperature drops to 80°C, add 270 parts of MMA, 270 parts of St, 180 parts of BA, 135 parts of EHA, 9 parts of AA, 9 parts of MAA, 9 parts of HEA and 0.72 parts of -SH mixture dropwise...

Embodiment 3

[0067] 1) Mix 5 parts of NaHCO 3 , 964 parts of DI water, 11 parts of 45% by mass fraction of DSB aqueous solution and 40 parts of 25% by mass fraction of SE10-N DI aqueous solution were added to the reactor, and stirred for 5 minutes at a stirring rate of 500r / min;

[0068] 2) Add 20 parts of MMA, 40 parts of St, 15 parts of BA, 20 parts of EHA, 1 part of MALI and 0.1 part of -SH mixture into the reactor of step 1) at one time, continue to stir for 5 minutes, and then heat to 80°C ;

[0069] 3) Add 102.5 parts of APS DI aqueous solution with a mass fraction of 2.44% to the reactor of step 2) at one time, until the color of the liquid mixture in the reactor turns blue, the temperature rises to 86°C, and the stirring rate is reduced to 300r / min ;

[0070] 4) When the temperature drops to 80°C, add dropwise 180 parts of MMA, 360 parts of St, 135 parts of BA, 180 parts of EHA, 9 parts of MALI, 0.9 parts of -SH mixed solution, and dropwise add 3 parts of NAM, 20 parts of AM and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com