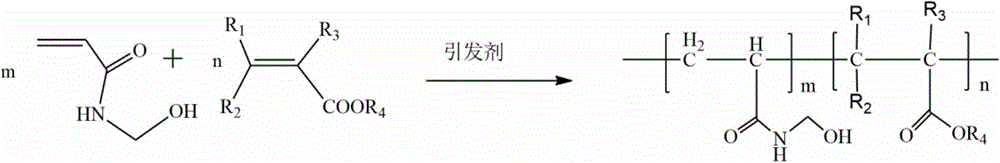

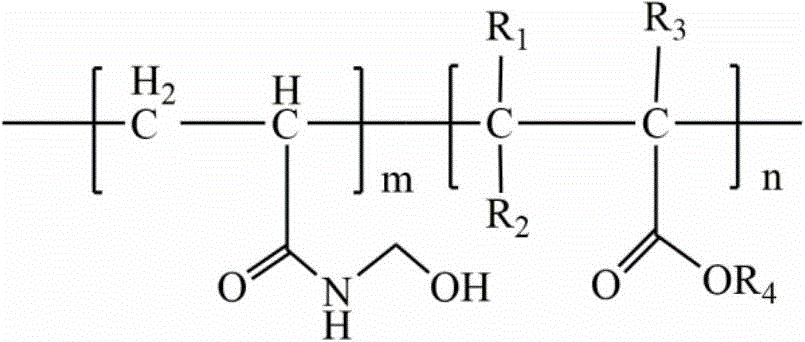

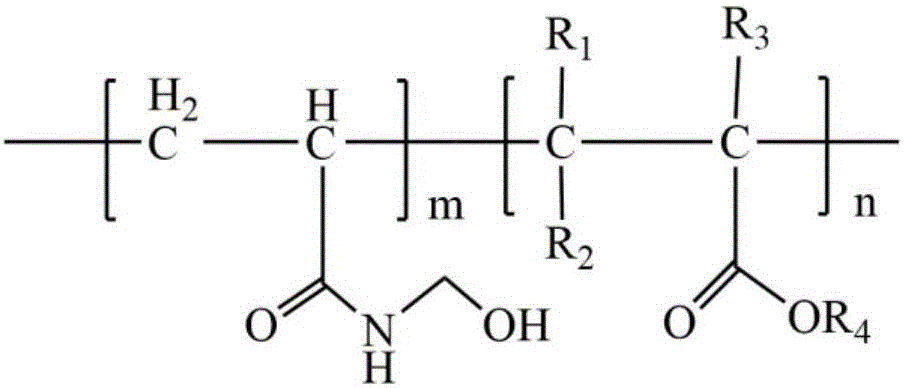

N-Methylolacrylamide modified polycarboxylate ceramic water reducer and normal-temperature preparation method and application thereof

A technology of methylol acrylamide and ceramic water reducing agent is applied in the field of N-methylol acrylamide modified polycarboxylate ceramic water reducing agent and its preparation at room temperature, which can solve the problem of high cost and achieve good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a. Add 100g of N-methylolacrylamide and 100g of water into the reactor at normal temperature and stir and mix to obtain the mixed liquid I;

[0026] b. Add an aqueous solution containing 3g of ammonium persulfate into the above mixed solution I, stir and fully dissolve to obtain mixed solution II;

[0027] c. Add 72g of acrylic acid, 1g of sodium hypophosphite, 5g of mercaptoacetic acid, and 5g of 2-acrylamide-2-methylpropanesulfonic acid mixture dropwise into the mixture II for 2 hours, and react at room temperature after the addition 1h, to obtain mixed solution III;

[0028] d. Add a certain amount of NaOH solution to the mixed solution III until the pH of the mixed solution is 7 to obtain N-methylolacrylamide modified polycarboxylate ceramic water reducer.

[0029] Water-reducing performance of N-methylolacrylamide modified polycarboxylate ceramic water-reducing agent After the ceramic body slurry was left to stand for 0h and 0.5h, the slurry flowed through the fil...

Embodiment 2

[0031] a. Add 100g of N-methylolacrylamide and 100g of water into the reactor at normal temperature and stir and mix to obtain the mixed liquid I;

[0032] b. Add an aqueous solution containing 0.5 g of ammonium persulfate into the above mixed solution I, stir and fully dissolve to obtain mixed solution II;

[0033] c. Add 720g of acrylic acid, 3g of sodium hypophosphite, 1g of mercaptoacetic acid, and 1g of 2-acrylamide-2-methylpropanesulfonic acid mixture dropwise into the mixture II for 4 hours. After the addition, react at room temperature 3h, obtain mixed solution III;

[0034] d. Add a certain amount of NaOH solution to the mixed solution III until the pH of the mixed solution is 9 to obtain N-methylolacrylamide modified polycarboxylate ceramic water reducer.

[0035] Water-reducing performance of N-methylolacrylamide modified polycarboxylate ceramic water-reducing agent After the ceramic body slurry was left to stand for 0h and 0.5h, the slurry flowed through the fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com