White emulsion with environmental protection and high viscosity and its preparation method

A high-viscosity, white latex technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, etc., can solve the limitations of ethyl acetate emulsion application, white latex can not meet environmental protection standards, and comprehensive performance is not good No problems such as improvement, to achieve good social benefits, low cost, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

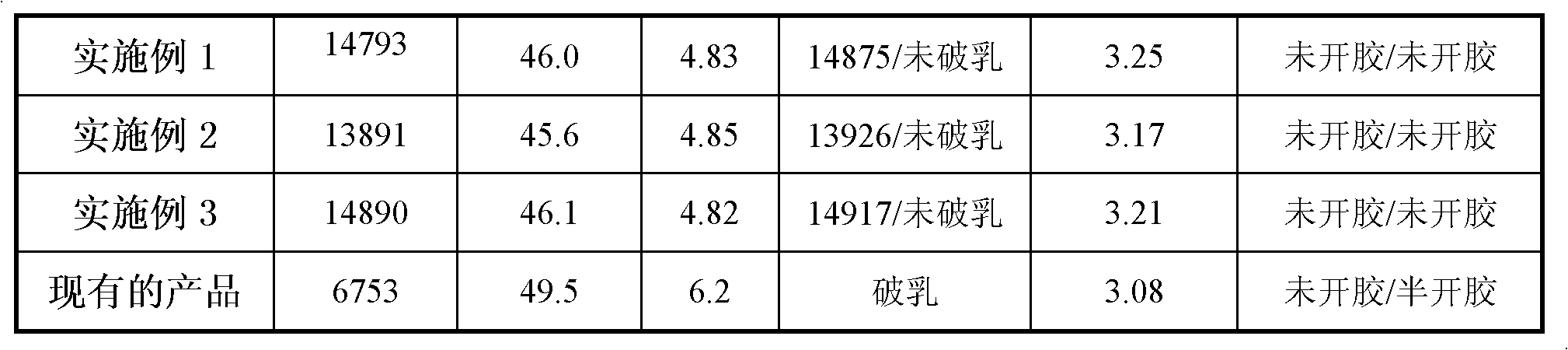

Embodiment 1

[0037] White latex, wherein the weight composition of each component in the raw material is as follows: 250 grams of vinyl acetate; 8 grams of polyvinyl alcohol 1788 type, 13 grams of 1799 type; Initiator: mass concentration is 11 grams of 10% ammonium persulfate solution; 4 grams of phenol polyoxyethylene ether (OP-10); 20 grams of dibutyl phthalate (DBP); 2.8 grams of N-methylolacrylamide (NMA); 10 grams of 95% ethanol; 3 0.6 grams; 1 gram of sodium benzoate; 305 grams of distilled water; 5 grams of methyl silicone oil. Prepare as follows:

[0038] (1) Add distilled water and polyvinyl alcohol in the reaction kettle (four-necked flask) according to the above ratio, and stir at an appropriate speed at a constant speed;

[0039] (2) The temperature of the entire reaction system is raised to 90±2°C to completely dissolve the polyvinyl alcohol;

[0040] (3) Cool down the entire reaction system to 60°C, add all the emulsifier, octylphenol polyoxyethylene ether (OP-10) and antif...

Embodiment 2

[0046] The weight composition of each component in the raw material of white latex is as follows: vinyl acetate 200 grams; Polyvinyl alcohol 1788 type 6 grams, 1799 type 9 grams; Initiator: mass concentration is 6 grams of 10% ammonium persulfate solution; Octylphenol Polyoxyethylene ether (OP-10) 3 grams; Dibutyl phthalate (DBP) 15 grams; N-methylolacrylamide (NMA) 2 grams; 95% ethanol 5 grams; NaHCO 3 0.5 grams; 0.5 grams of sodium benzoate; 250 grams of distilled water; 5 grams of methyl silicone oil. Prepare as follows:

[0047] (1) Add distilled water and polyvinyl alcohol in the reaction kettle (four-necked flask) according to the above ratio, and stir at an appropriate speed at a constant speed;

[0048] (2) The temperature of the entire reaction system is raised to 90±2°C to completely dissolve the polyvinyl alcohol;

[0049](3) Cool down the entire reaction system to 60°C, add all the emulsifier, octylphenol polyoxyethylene ether (OP-10) and antifoaming agent, methy...

Embodiment 3

[0055] The weight composition of each component in the raw material of white latex is as follows: vinyl acetate 300 grams; Polyvinyl alcohol 1788 type 13 grams, 1799 type 17 grams; Initiator: mass concentration is 16 grams of 10% ammonium persulfate solution; Octylphenol Polyoxyethylene ether (OP-10) 8 grams; Dibutyl phthalate (DBP) 20 grams; N-methylolacrylamide (NMA) 4 grams; 95% ethanol 15 grams; NaHCO 3 1 gram; 1 gram of sodium benzoate; 400 grams of distilled water; 5.5 grams of methyl silicone oil. Prepare as follows:

[0056] (1) Add distilled water and polyvinyl alcohol in the reaction kettle (four-necked flask) according to the above ratio, and stir at an appropriate speed at a constant speed;

[0057] (2) The temperature of the entire reaction system is raised to 90±2°C to completely dissolve the polyvinyl alcohol;

[0058] (3) Cool down the entire reaction system to 60°C, add all the emulsifier, octylphenol polyoxyethylene ether (OP-10) and antifoaming agent, meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com