Method for preparing copolymerized acrylonitrile high water-absorption fiber

A technology of copolymerized polyacrylonitrile fiber and copolymerized polyacrylonitrile, which is applied in the field of preparation of functional synthetic polymer materials, can solve the problems of poor shape retention, high cost, loss of physical-mechanical properties of fibers, etc., and is convenient for industrialization promotion and implementation. , The production process is simple, and the water absorption rate is controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of the copolymerized acrylonitrile superabsorbent fiber of the present invention (hereinafter referred to as the preparation method) mainly includes two steps: firstly, the copolymerized acrylonitrile fiber is prepared, and then the obtained copolymerized acrylonitrile fiber is partially hydrolyzed to prepare the copolymerized acrylonitrile superabsorbent fiber. Described preparation method specifically comprises:

[0012] (1) prepare copolymerized acrylonitrile fiber, the mass ratio formula of its feeding intake is: acrylonitrile and methyl methacrylate monomer and latent crosslinking agent 100%; 0.8%, the acrylonitrile accounts for 75-85% of the total mass of monomers and latent cross-linking agents, and methyl methacrylate accounts for 5-15% of the total mass of monomers and latent cross-linking agents; The linking agent is one or more of N-methylolacrylamide, β-hydroxyethyl methacrylate, hydroxyethyl acrylate and hydroxypropyl acrylate, and th...

Embodiment 1

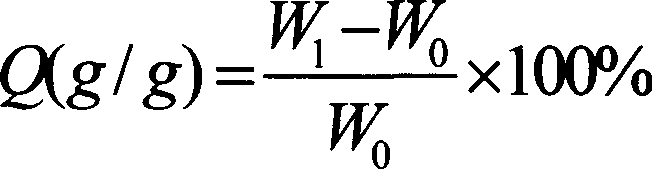

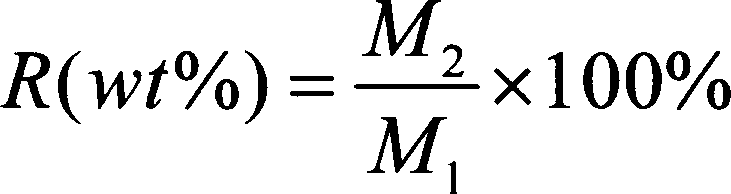

[0023] Acrylonitrile and methyl methacrylate are used as monomers, N-methylolacrylamide is used as latent crosslinking agent, and the content of N-methylolacrylamide is controlled at 5%, 7%, and 10% of the monomer and its total mass , 15%, with azobisisobutyronitrile as the initiator, the dosage is 0.5% of the total mass of the monomer and latent crosslinking agent, in dimethyl sulfoxide, under nitrogen protection, heating at 68-70°C and stirring Solution polymerization, wherein the monomer and latent crosslinking agent are 20% of the total mass of the system except the initiator, and the reaction time is 8h. After vacuum defoaming the obtained copolymer solution, use 40% dimethyl sulfoxide aqueous solution as the coagulation bath Wet spinning, 5-fold stretching in a boiling water bath, relaxation and heat setting in a boiling water bath to obtain copolymerized acrylonitrile fibers, then thermal crosslinking at 170°C for 10 minutes, hydrolysis with 20% NaOH solution for 3 minut...

Embodiment 2

[0036] The content of N-methylolacrylamide is designed to be 10% of the sum of the monomer and its mass, and the content of the initiator azobisisobutyronitrile is respectively 0.3%, 0.5%, and 0.3% of the total mass of the monomer and N-methylolacrylamide. 0.7%, 0.8%, the rest are the same as in Example 1, and four kinds of superabsorbent fibers can be obtained. The saturated water absorption rates of the four fibers tested were 52.0g / g, 54.5g / g, 45.5g / g, and 42.5g / g; the water retention rates were 85.5%, 87.5%, 80.0%, and 78.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Saturated water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com