Polymer oil displacement agent and preparation method thereof

An oil displacing agent and polymer technology, which is applied in the field of polymer oil displacing agent and its preparation, can solve problems such as viscosity reduction and the like, and achieve the effects of increased steric hindrance, enhanced salt tolerance, and weakened possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

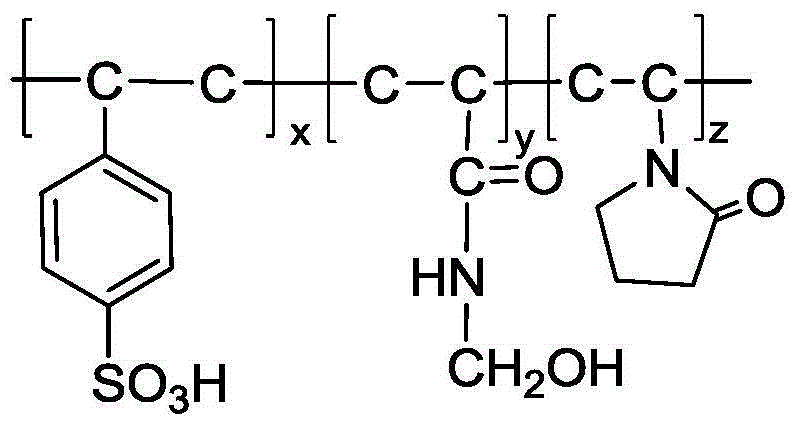

[0026] A polymer oil displacement agent, the oil displacement agent is prepared from three monomers of styrene sulfonic acid, N-methylol acrylamide and N-vinylpyrrolidone, and the proportion of each component is as follows according to weight:

[0027] 40 parts of styrenesulfonic acid

[0028] 35 parts of N-methylolacrylamide

[0029] N-vinylpyrrolidone 25 parts

[0030] A preparation method of polymer oil displacement agent, comprising the following steps:

[0031] a. Take styrene sulfonic acid, N-methylol acrylamide and N-vinylpyrrolidone according to the weight proportion and mix them evenly, add deionized water, and make the monomers with a total mass percentage concentration of 30% aqueous solution;

[0032] b. Cool down the aqueous monomer solution mixed in step a to 0°C, and adjust the pH value to 6-8;

[0033] c. Warm up the aqueous monomer solution in step b to room temperature, and stir with nitrogen gas for 30 minutes;

Embodiment 2

[0037] A polymer oil displacement agent, the oil displacement agent is prepared from three monomers of styrene sulfonic acid, N-methylol acrylamide and N-vinylpyrrolidone, and the proportion of each component is as follows according to weight:

[0038] 30 parts of styrene sulfonic acid

[0039] 40 parts of N-methylolacrylamide

[0040] 30 parts of N-vinylpyrrolidone

[0041] A preparation method of polymer oil displacement agent, comprising the following steps:

[0042] a. Take styrene sulfonic acid, N-methylol acrylamide and N-vinylpyrrolidone according to the weight proportion and mix them evenly, add deionized water, and make the monomers with a total mass percentage concentration of 30% aqueous solution;

[0043] b. Cool down the aqueous monomer solution mixed in step a to 0°C, and adjust the pH value to 6-8;

[0044] c. Warm up the aqueous monomer solution in step b to room temperature, and stir with nitrogen gas for 30 minutes;

[0045] d. Add initiator ammonium sul...

Embodiment 3

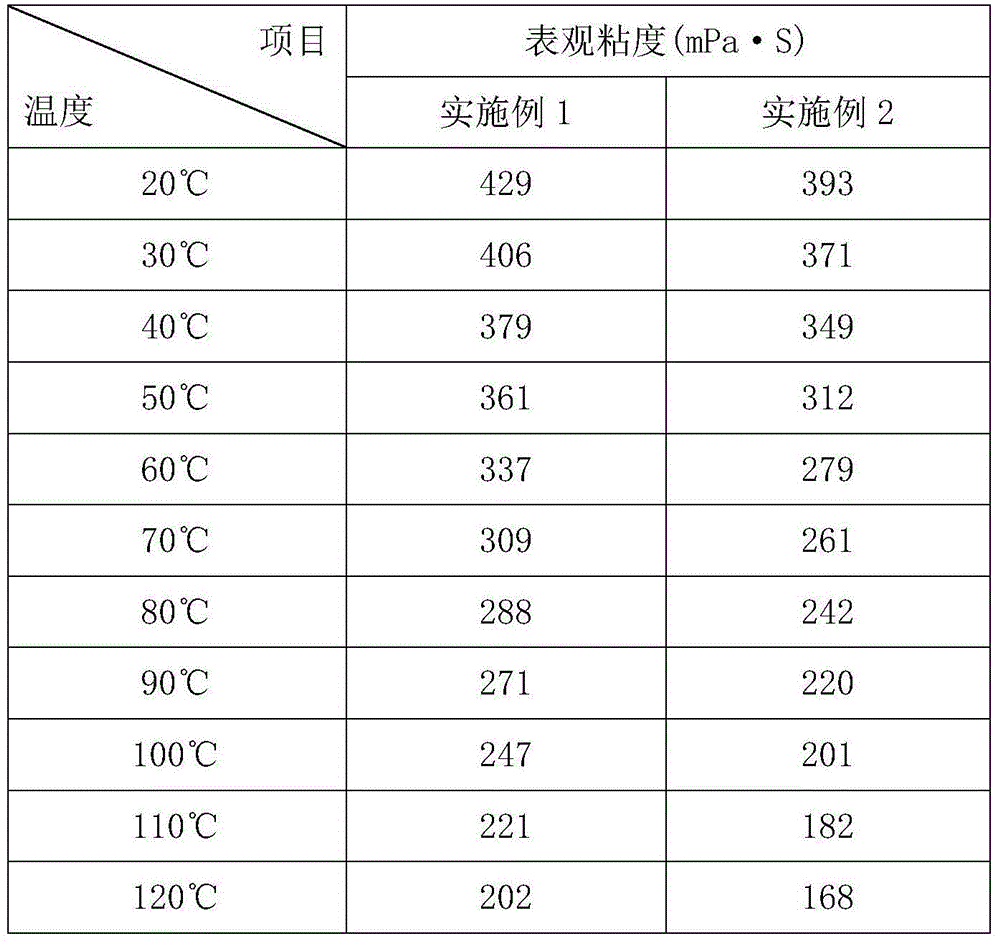

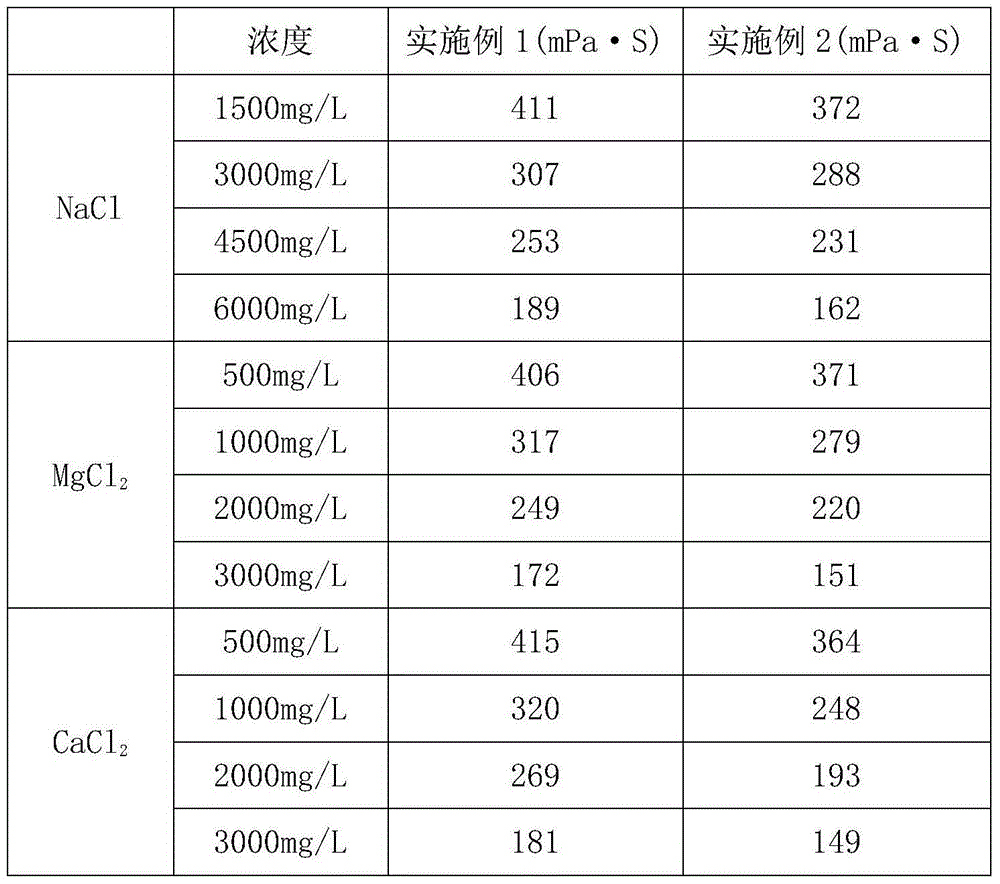

[0047] The temperature resistance investigation of embodiment 3 polymer oil displacement agent

[0048] The polymer oil displacing agent that embodiment 1 and embodiment 2 are made into the aqueous solution of 1500mg / L respectively, put into constant temperature water bath, the temperature of constant temperature water bath is between 20-120 ℃, selects the R / S Plus viscometer with a shear rate of 9.25S -1 , Determination of the apparent viscosity of polymer oil displacement agent aqueous solution with the change of temperature, the data are shown in Table 1.

[0049] Table 1 Apparent Viscosity Variation Results with Temperature

[0050]

[0051] The branching degree of the molecular structure of the oil displacement agent is obviously improved, so the steric hindrance increases, and the benzene ring and five-membered heterocyclic ring on the branched molecular chain increase the rigidity of the molecular main chain and weaken the possibility of chain curling properties, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas permeability | aaaaa | aaaaa |

| Viscosity retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com