Styrene-acrylic emulsion and synthetic method thereof and electrical steel coating

A technology of styrene-acrylic emulsion and synthesis method, which is applied in the direction of coating, etc., can solve the problems affecting the long-term storage and use of electrical steel coatings, and achieve the effect of good surface quality, good resin dispersion and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

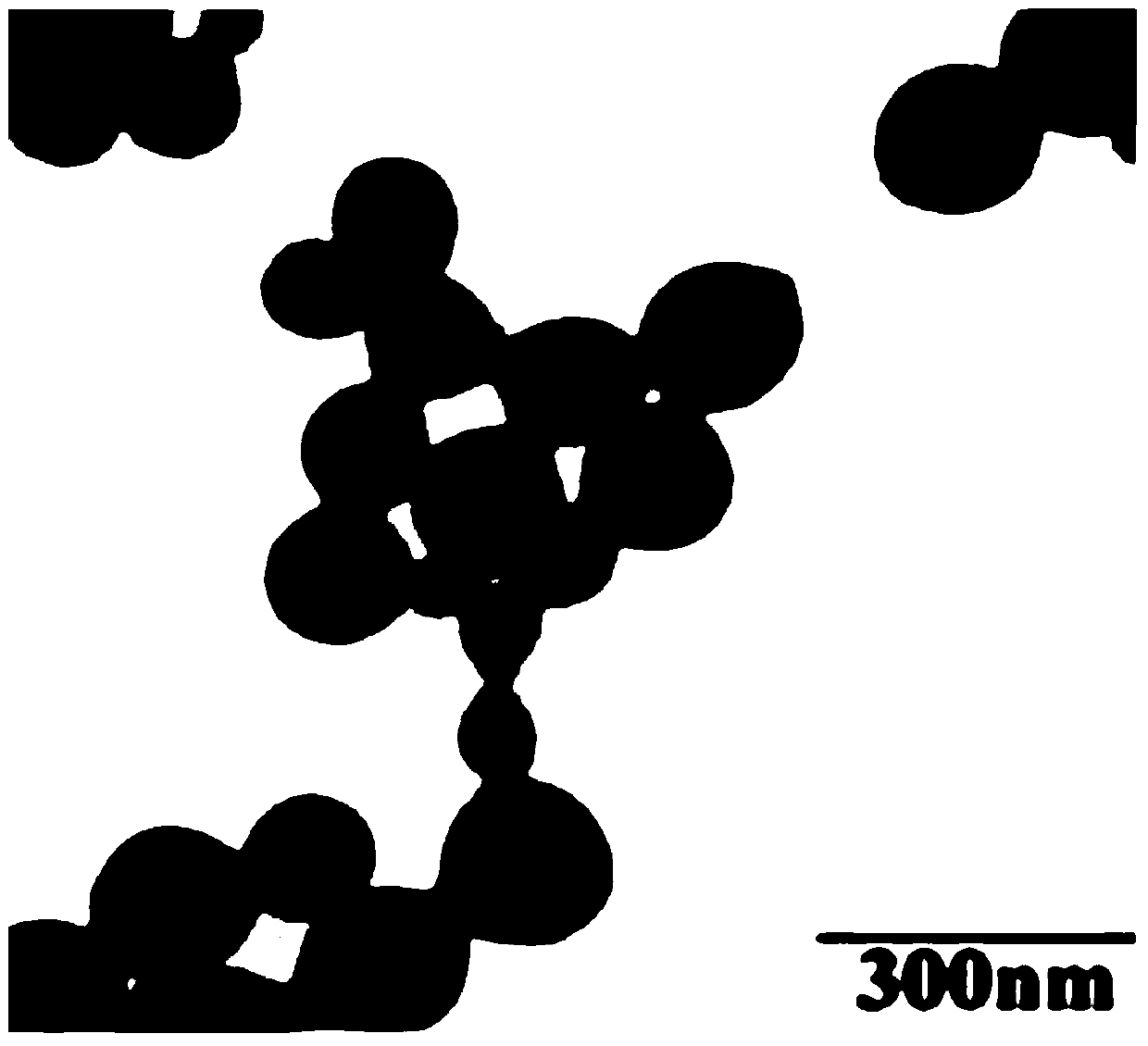

Image

Examples

Embodiment 1

[0028] A kind of styrene-acrylic emulsion, each component accounts for the weight ratio of emulsion total amount:

[0029] 20.0% styrene, 20.0% butyl acrylate, 5.0% isooctyl acrylate, 0.5% methyl methacrylate, 0.5% methacrylic acid, 0.2% alkylphenol polyoxyethylene ether OP-10, 0.8% dodecane Sodium sulfate K12, 0.4% N-methylolacrylamide, 51.8% water, 0.3% sodium bicarbonate and 0.5% ammonium persulfate.

[0030] A kind of synthetic method of styrene-acrylic emulsion:

[0031] A, take each component according to the weight ratio that each component of above-mentioned styrene-acrylic emulsion accounts for the total amount of emulsion;

[0032] B. Styrene, butyl acrylate, isooctyl acrylate, methyl methacrylate, methacrylic acid, alkylphenol polyoxyethylene ether OP-10, sodium lauryl sulfate K12, N-hydroxy Methacrylamide, sodium bicarbonate and part of the water weighed, mixed and stirred; pre-emulsified for 30 minutes to form a "pre-emulsion", and the weight of the part of the ...

Embodiment 2

[0041] A kind of styrene-acrylic emulsion, each component accounts for the weight ratio of emulsion total amount:

[0042] 10.0% styrene, 30.0% butyl acrylate, 2.5% isooctyl acrylate, 2.5% methyl methacrylate, 0.8% methacrylic acid, 0.4% alkylphenol polyoxyethylene ether OP-10, 1.0% dodecane Sodium sulfate K12, 0.6% N-methylolacrylamide, 51.0% water, 0.4% sodium bicarbonate and 0.8% ammonium persulfate;

[0043] A kind of preparation method of styrene-acrylic emulsion:

[0044] A, take each component according to the weight ratio that each component of above-mentioned styrene-acrylic emulsion accounts for the total amount of emulsion;

[0045] B. Styrene, butyl acrylate, isooctyl acrylate, methyl methacrylate, methacrylic acid, alkylphenol polyoxyethylene ether OP-10, sodium lauryl sulfate K12, N-hydroxy Methacrylamide, sodium bicarbonate and part of the water weighed, mixed and stirred; pre-emulsified for 15 minutes to form a "pre-emulsion", and the weight of the part of th...

Embodiment 3

[0054] A kind of styrene-acrylic emulsion, each component accounts for the weight ratio of emulsion total amount:

[0055]30.0% styrene, 10.0% butyl acrylate, 1.0% isooctyl acrylate, 1.5% methyl methacrylate, 0.7% methacrylic acid, 0.3% alkylphenol polyoxyethylene ether OP-10, 1.7% dodecane Sodium sulfate K12, 0.8% N-methylolacrylamide, 54.0% water, 1.0% sodium bicarbonate and 1.2% ammonium persulfate;

[0056] A kind of preparation method of styrene-acrylic emulsion:

[0057] A, take each component according to the weight ratio that each component of above-mentioned styrene-acrylic emulsion accounts for the total amount of emulsion;

[0058] B. Styrene, butyl acrylate, isooctyl acrylate, methyl methacrylate, methacrylic acid, alkylphenol polyoxyethylene ether OP-10, sodium lauryl sulfate K12, N-hydroxy Methacrylamide, sodium bicarbonate and part of the water weighed, mixed and stirred; pre-emulsified for 20 minutes to form a "pre-emulsion", and the weight of the part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com