Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Lanthanum(III) chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum chloride is the inorganic compound with the formula LaCl₃. It is a common salt of lanthanum which is mainly used in research. It is a white solid that is highly soluble in water and alcohols.

Scintillator compositions, and related processes and articles of manufacture

ActiveUS20060237654A1Enhance various propertyImprove propertiesMaterial analysis by optical meansLuminescent compositionsIodideLanthanide

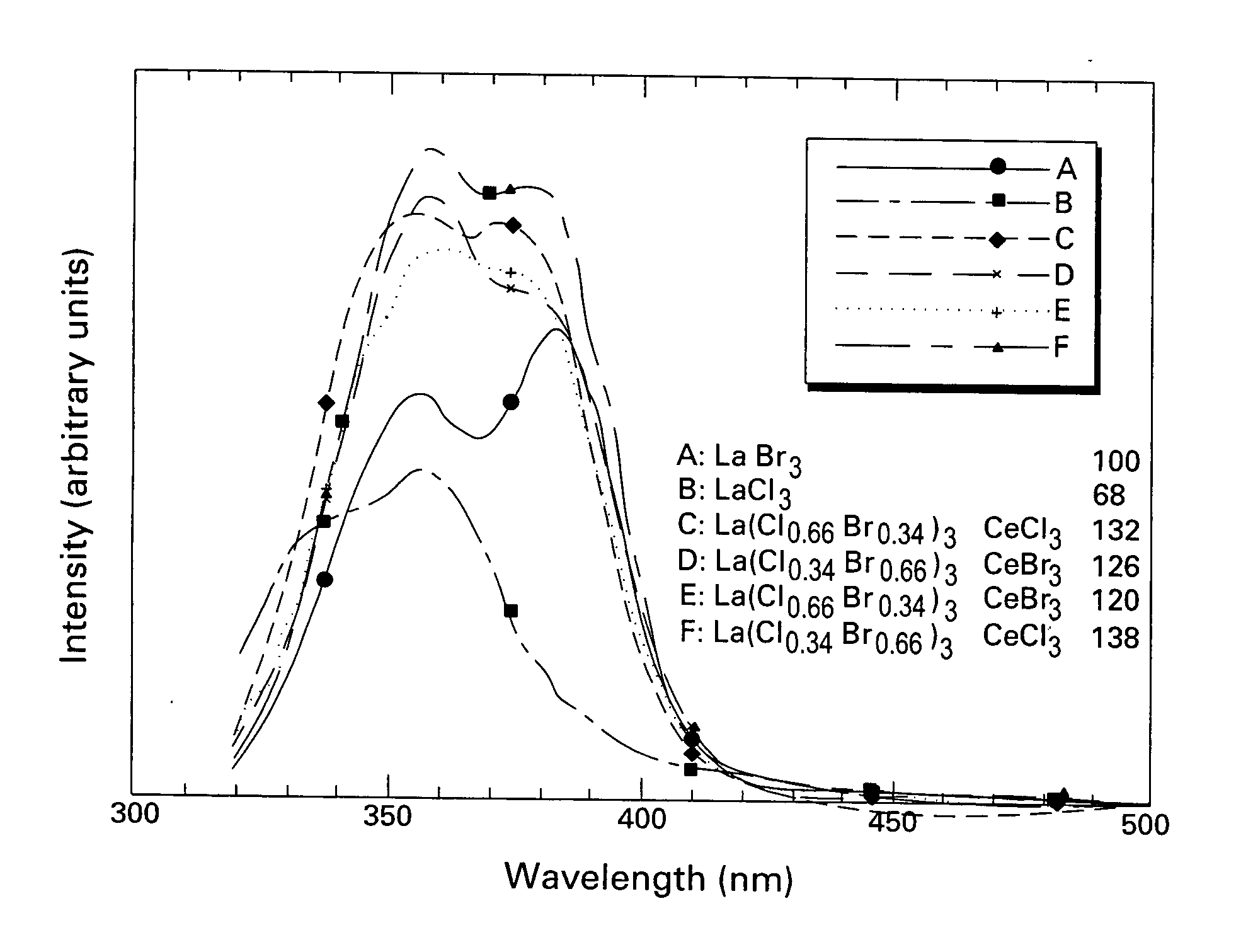

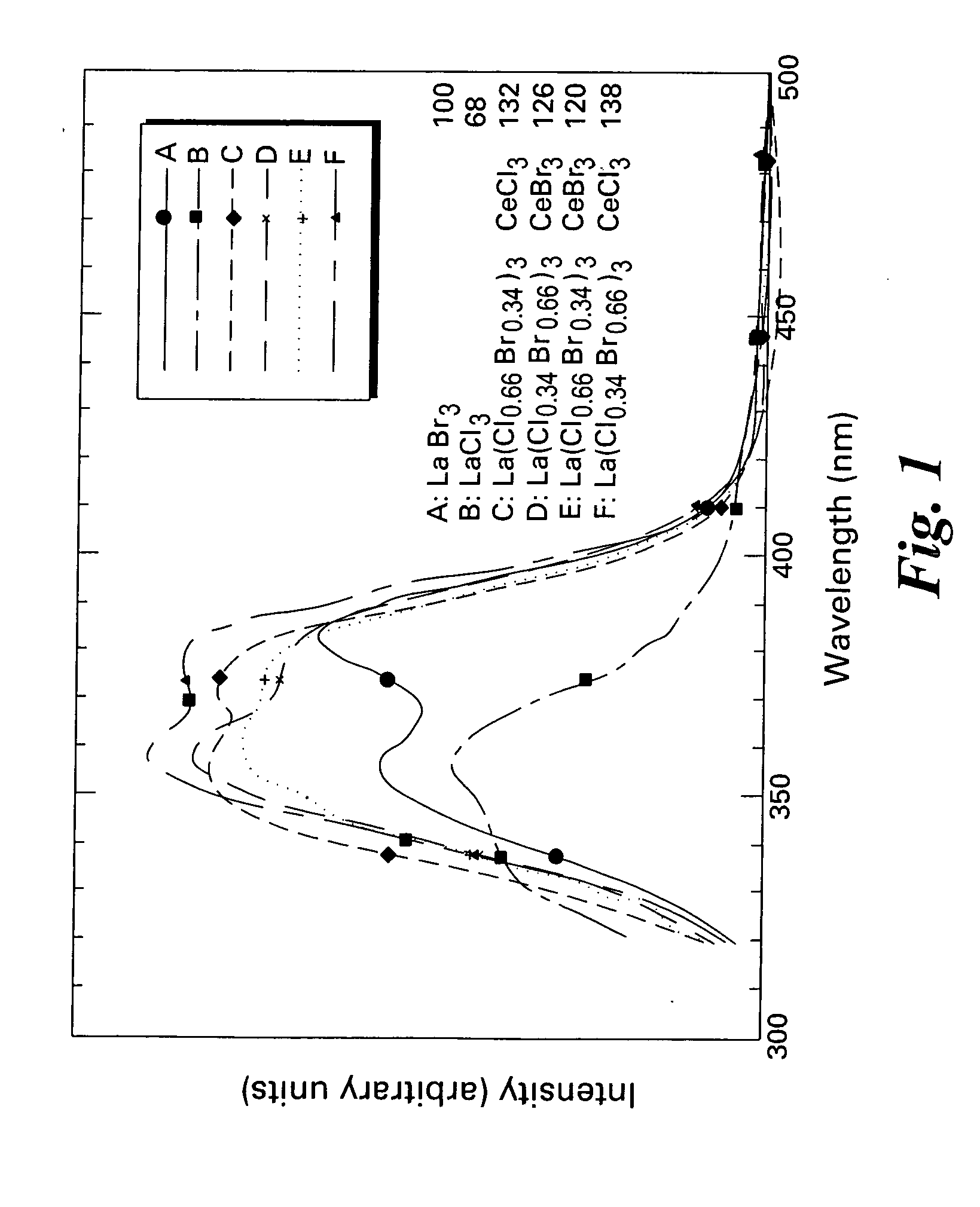

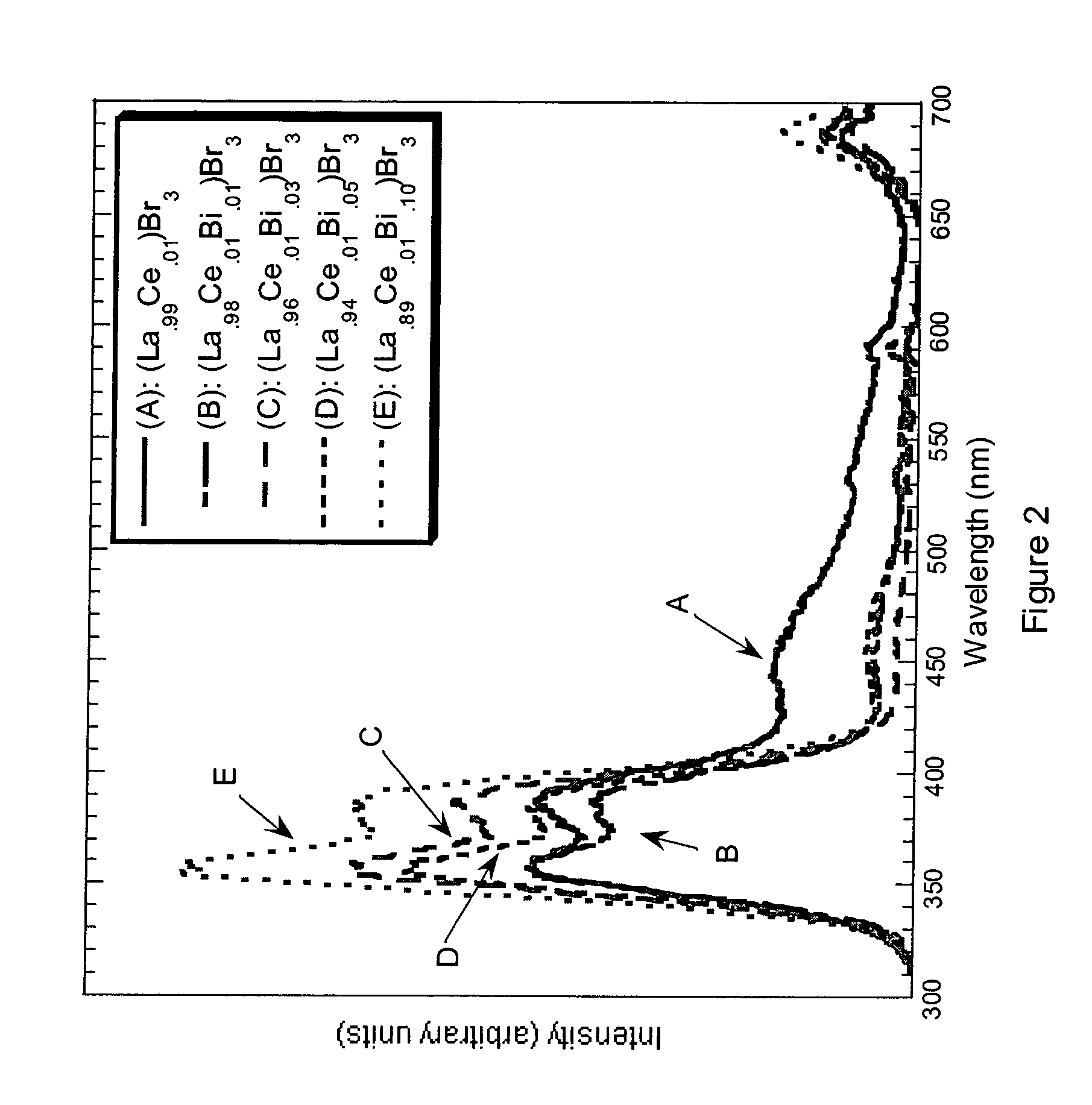

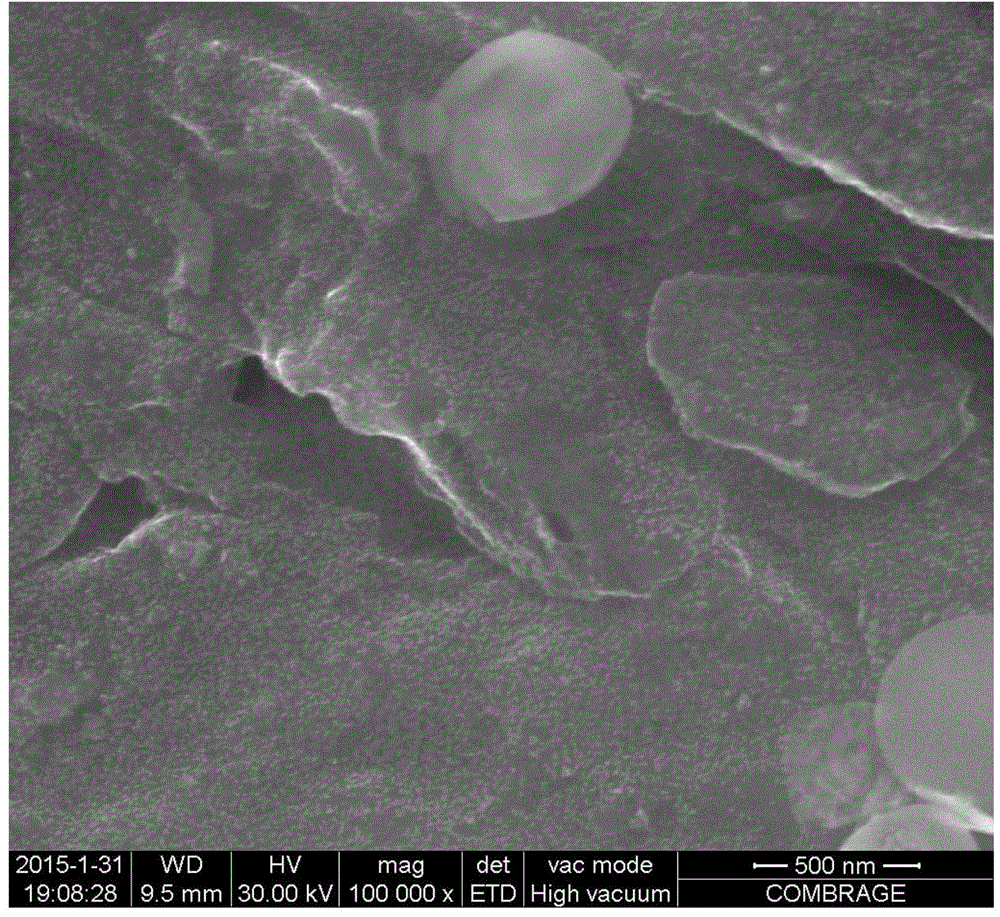

Scintillator materials based on certain types of halide-lanthanide matrix materials are described. In one embodiment, the matrix material contains a mixture of lanthanide halides, i.e., a solid solution of at least two of the halides, such as lanthanum chloride and lanthanum bromide. In another embodiment, the matrix material is based on lanthanum iodide alone, which must be substantially free of lanthanum oxyiodide. The scintillator materials, which can be in monocrystalline or polycrystalline form, also include an activator for the matrix material, e.g., cerium. To further improve the stopping power and the scintillating efficiency of these halide scintillators, the addition of bismuth is disclosed. Radiation detectors that use the scintillators are also described, as are related methods for detecting high-energy radiation.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Gold-containing catalyst for preparing vinyl chloride by using acetylene method as well as preparation method and application of catalyst

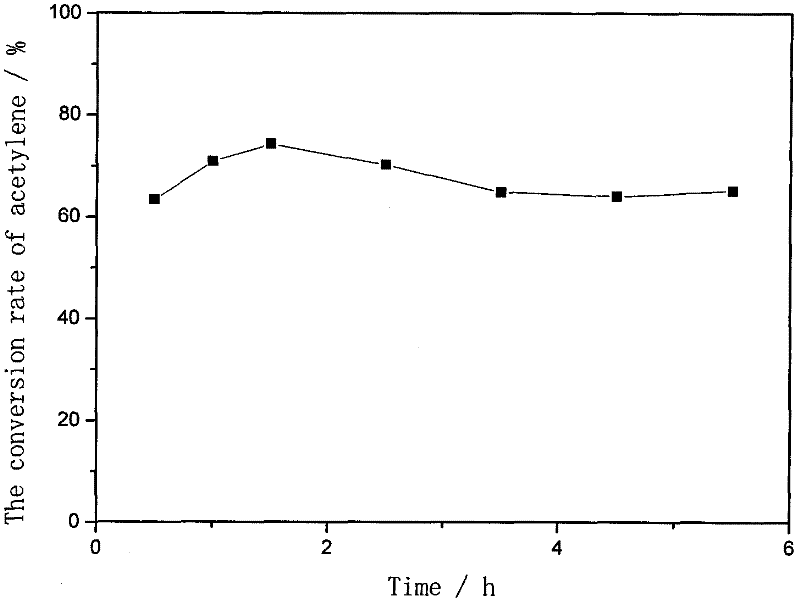

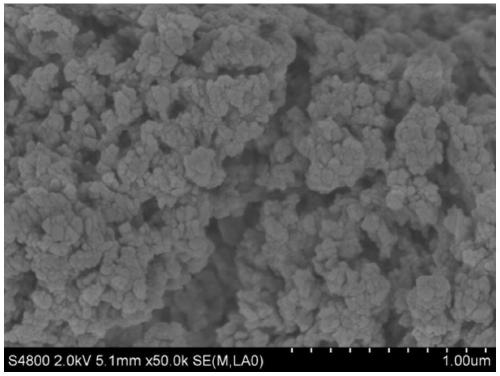

InactiveCN102327777ANo pollution in the processThere will be no deactivationMolecular sieve catalystsPreparation by halogen halide additionMicro structureEthyl Chloride

The invention discloses a gold-containing catalyst for preparing vinyl chloride by using an acetylene method as well as a preparation method and application of the catalyst. The catalyst contains a gold element, a lanthanum element, a cobalt element, a co-catalytic metal element and a carrier with a porous micro-structure. The gold accounts for 0.3%-2% by mass of the catalyst; the gold element in the catalyst comes from gold chlorides or gold nitrates; the cobalt element comes from chlorides of the cobalt or cobalt nitrates; and the lanthanum element comes from lanthanum chlorides or lanthanum nitrates. The catalyst disclosed by the invention in use is free from inactivation phenomenon caused by sublimation of industrial catalyst mercury chloride, has no pollution to the environment, overcomes defects of high toxicity and high pollution of the conventional industrial catalyst mercury chloride, has the characteristics of simple preparation method, high conversion rate of the acetylene and selectivity of the vinyl chloride, long service life up to 1000 hours or more, high temperature resistance, and high intensity and is renewable, and the conversion rate of the acetylene and selectivity of the vinyl chloride approximate to or exceed the technical indexes of the mercury chloride catalyst.

Owner:TIANJIN UNIV +1

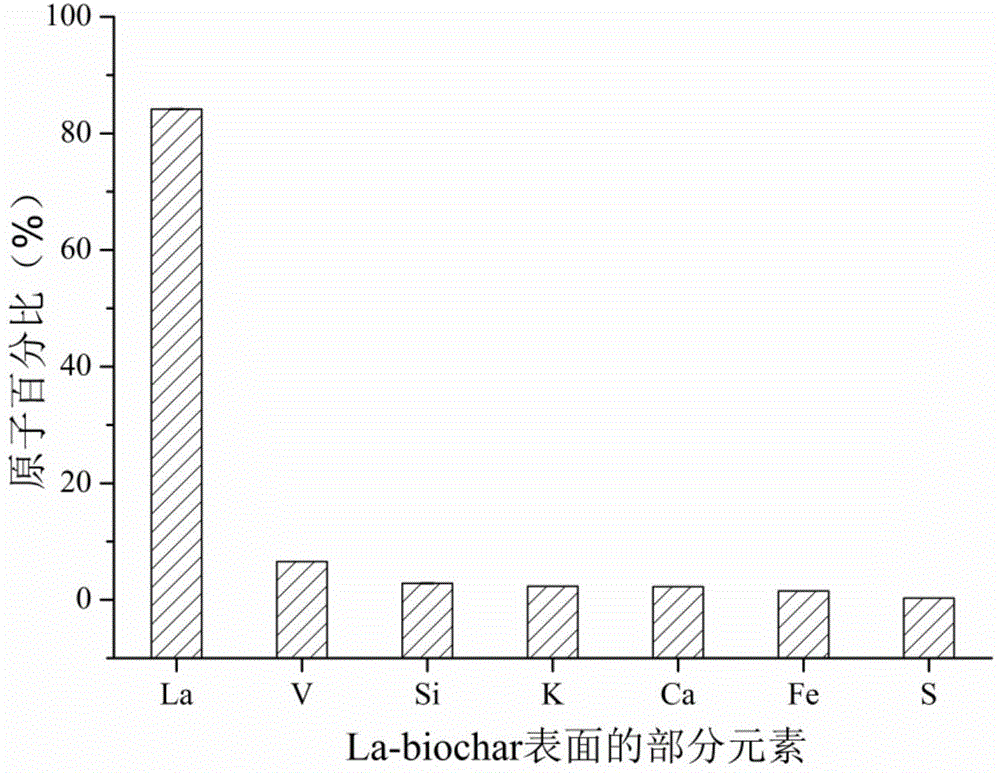

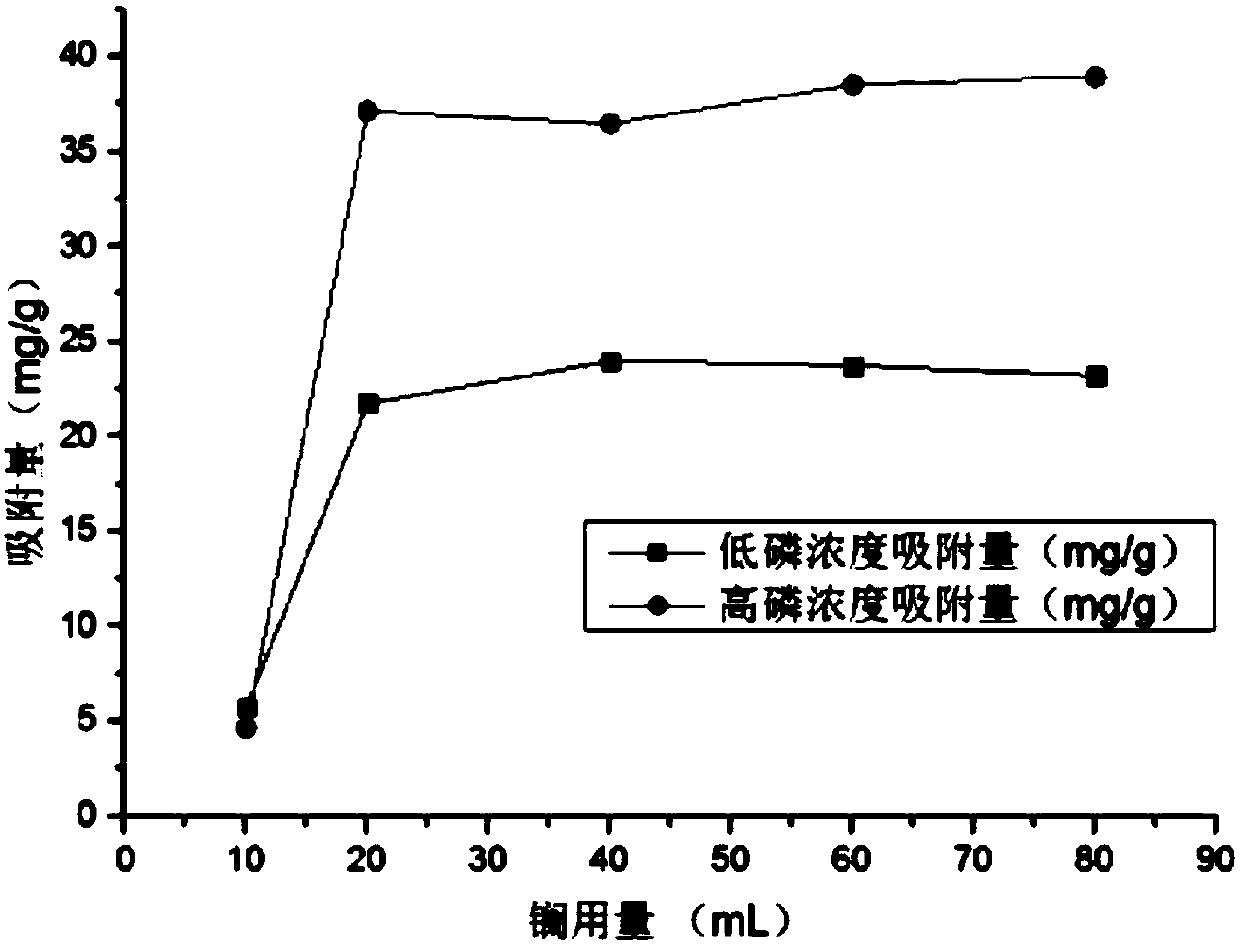

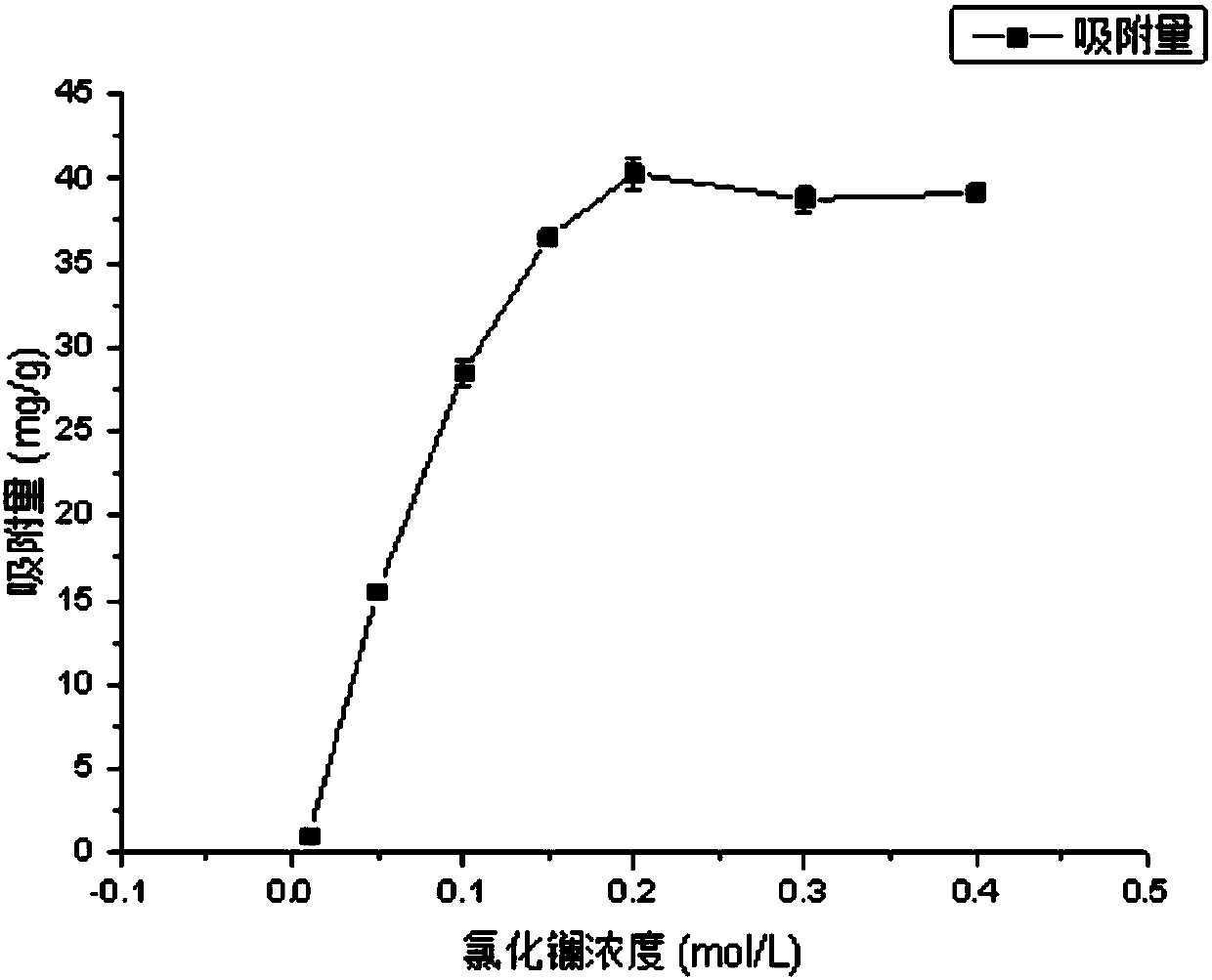

Preparation method and applications of lanthanum-loaded biochar arsenic-removing adsorbent

InactiveCN104815613AThe effect of adsorbing arsenic ions is obviousReduce pollutionOther chemical processesWater/sewage treatment by sorptionSorbentLanthanum

The present invention discloses a preparation method and applications of a lanthanum-loaded biochar arsenic-removing adsorbent. The preparation method mainly comprises: washing corn stalks, remove impurities, carrying out air-drying, crushing, screening, carrying out stirring mixing on the corn stalk powder and a lanthanum chloride solution under a certain condition, adjusting the pH value to the alkaline state, removing excess chlorine ions from the solution, and carrying out anoxybiotic calcination on the mixture for a certain time at a certain temperature so as to prepare the nanometer lanthanum oxide-loaded biochar material. According to the present invention, the prepared lanthanum-loaded biochar can be used for treating pentavalent arsenic ions in wastewater, and has characteristics of simple preparation, low cost, high adsorption efficiency, good application prospect, and the like.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Preparation method and application of lanthanum-loaded modified bentonite dephosphorization material

InactiveCN110038511ASufficient sourceSimple processOther chemical processesWater contaminantsFiltrationChloride

The invention discloses a preparation method of a lanthanum-loaded modified bentonite dephosphorization material. The preparation method comprises the steps as follows: performing ultrasonic treatmenton a lanthanum chloride solution in an alkaline environment, mixing the treated solution with bentonite, then, performing stirring and ultrasonic treatment, and finally, performing cleaning, filtration, grinding and sieving to obtain the lanthanum-loaded modified bentonite dephosphorization material. Compared with the prior art, the method has the advantages that selected raw materials are sufficient, natural, non-toxic, convenient to use and low in cost, the treatment process is simple, the treatment cost is lower, used raw materials are environment-friendly materials, secondary pollution isavoided, and meanwhile, the preparation time is obviously shortened. The dephosphorization material prepared with the preparation method of the lanthanum-loaded modified bentonite dephosphorization material has the phosphorus removal rate up to 90% or above and has characteristics of high efficiency, controllability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin

InactiveCN102430418AHigh catalytic activitySimple processPhysical/chemical process catalystsPreparation by halogen halide additionMetal chlorideFixed bed

The invention disclose a method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin, which belongs to the field of preparing the hydrochlorination catalyst of acetylene. The catalyst comprises stannic chloride, rare earth chloride, other metal chlorides and carriers, wherein the rare earth chloride is adopted as cerium chloride or lanthanum chloride, and the carriers are cerium-zirconium powder or zirconia. The catalyst is prepared by soaking method, can be applied to fixed-bed reactors, has low cost, has no pollution, and has good catalytic activity and high selection in the process of producing vinyl chloride by hydrochlorination of acetylene.

Owner:INNER MONGOLIA UNIVERSITY

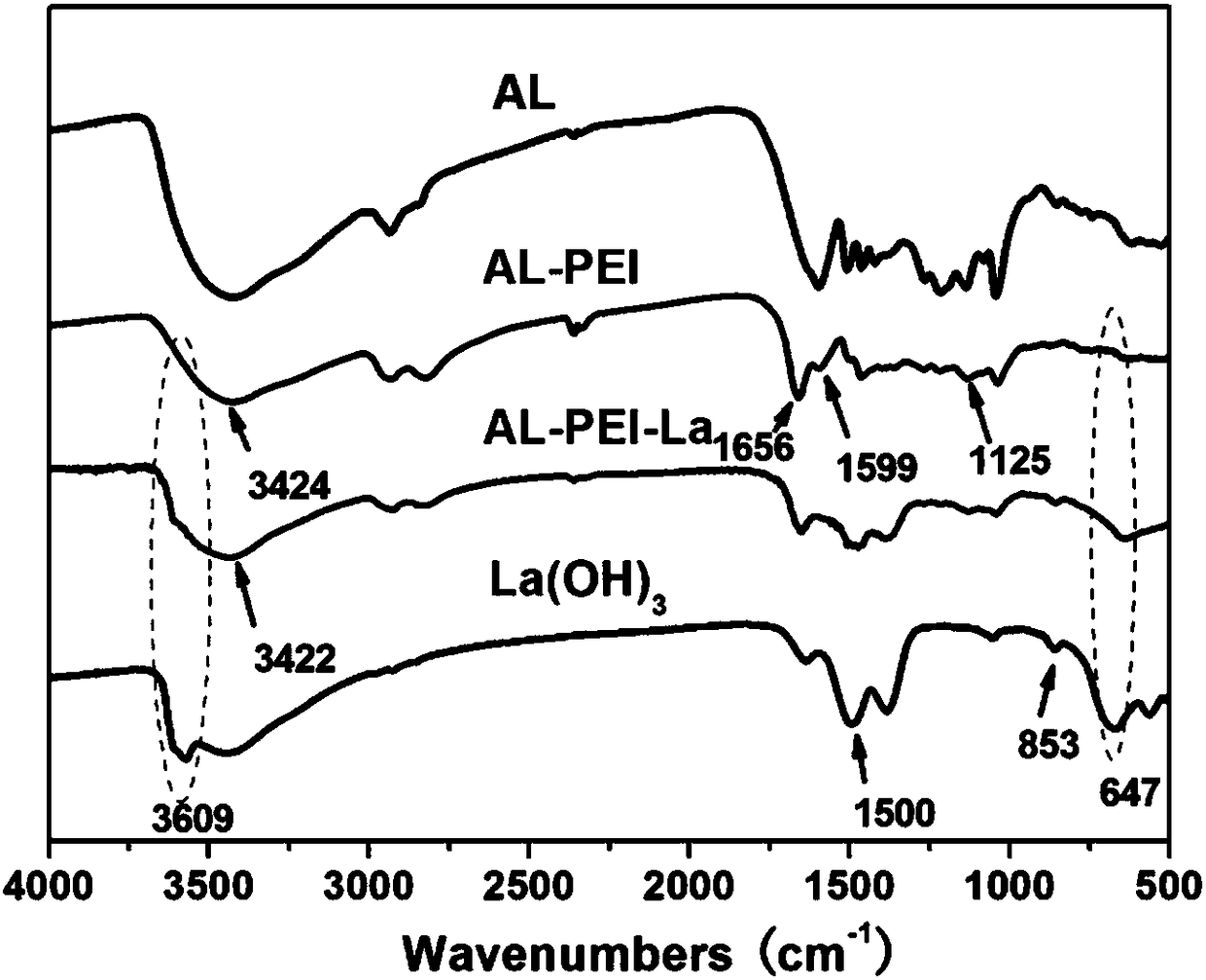

Nano-lanthanum hydroxide modified lignin porous carbon as well as preparation method and application thereof

ActiveCN109433153AExcellent adsorption capacityImprove removal efficiencyOther chemical processesWater contaminantsPorous carbonLanthanum hydroxide

The invention discloses nano-lanthanum hydroxide modified lignin porous carbon as well as a preparation method and application thereof. The preparation method comprises the following steps: preparingacetic acid lignin porous carbon: dissolving acetic acid lignin into a strong alkaline solution according to the ratio of 1 g to 5 mL, uniformly mixing and then drying to constant weight; carbonizinga dried solid mixture in an inert atmosphere, cooling to room temperature and then washing to neutral; carrying out vacuum drying to constant weight to obtain the acetic acid lignin porous carbon; preparing the nano-lanthanum hydroxide modified lignin porous carbon: adding the acetic acid lignin porous carbon into an ethanol aqueous solution of lanthanum chloride heptahydrate for uniformly mixing,adjusting a pH value of the solution, raising the temperature, fully reacting, sufficiently washing a reaction product and carrying out vacuum drying to constant weight to obtain the nano-lanthanum hydroxide modified lignin porous carbon. Highly-dispersed lanthanum hydroxide nanoparticles retain on the surface of the lanthanum hydroxide modified lignin porous carbon prepared by the preparation method disclosed by the invention; the absorption experiment shows that the modified acetic acid lignin porous carbon has a remarkable adsorbing effect on phosphorus, which is remarkably improved as compared with unmodified acetic acid lignin porous carbon.

Owner:ZHEJIANG FORESTRY UNIVERSITY

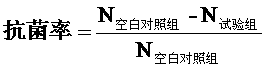

Antibacterial property resin composite material and preparation method thereof

The invention provides an antibacterial property resin composite material, which is prepared by 100 parts of matrix resin and 5-10 parts of lanthanum / magnesium oxide antibacterial agent prepared by nanometer magnesia and lanthanum chloride. According to the material, the composite material of lanthanum (La3+) and magnesium oxide (MgO) is taken as the antibacterial agent, then the antibacterial agent and plastic materials are mixed uniformly according to different proportions, the antibacterial property resin composite material is treated through conventional plastic preparation technology, the technology is simple, the original technology is not changed, the prepared composite material has good antibacterial activity, the antibacterial activity for various bacterium can reach above 88%, and other mechanical properties of the plastics are not damaged.

Owner:HEFEI GENIUS NEW MATERIALS

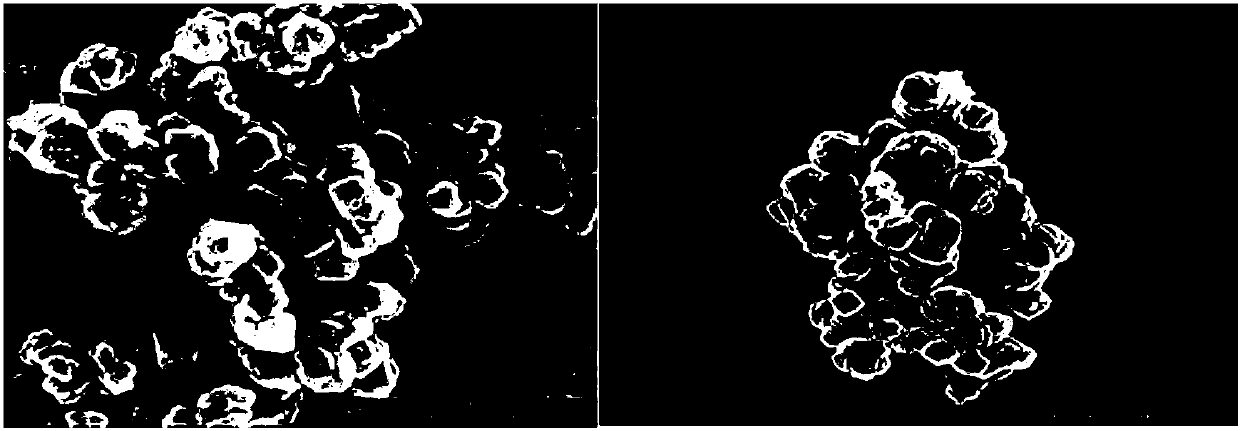

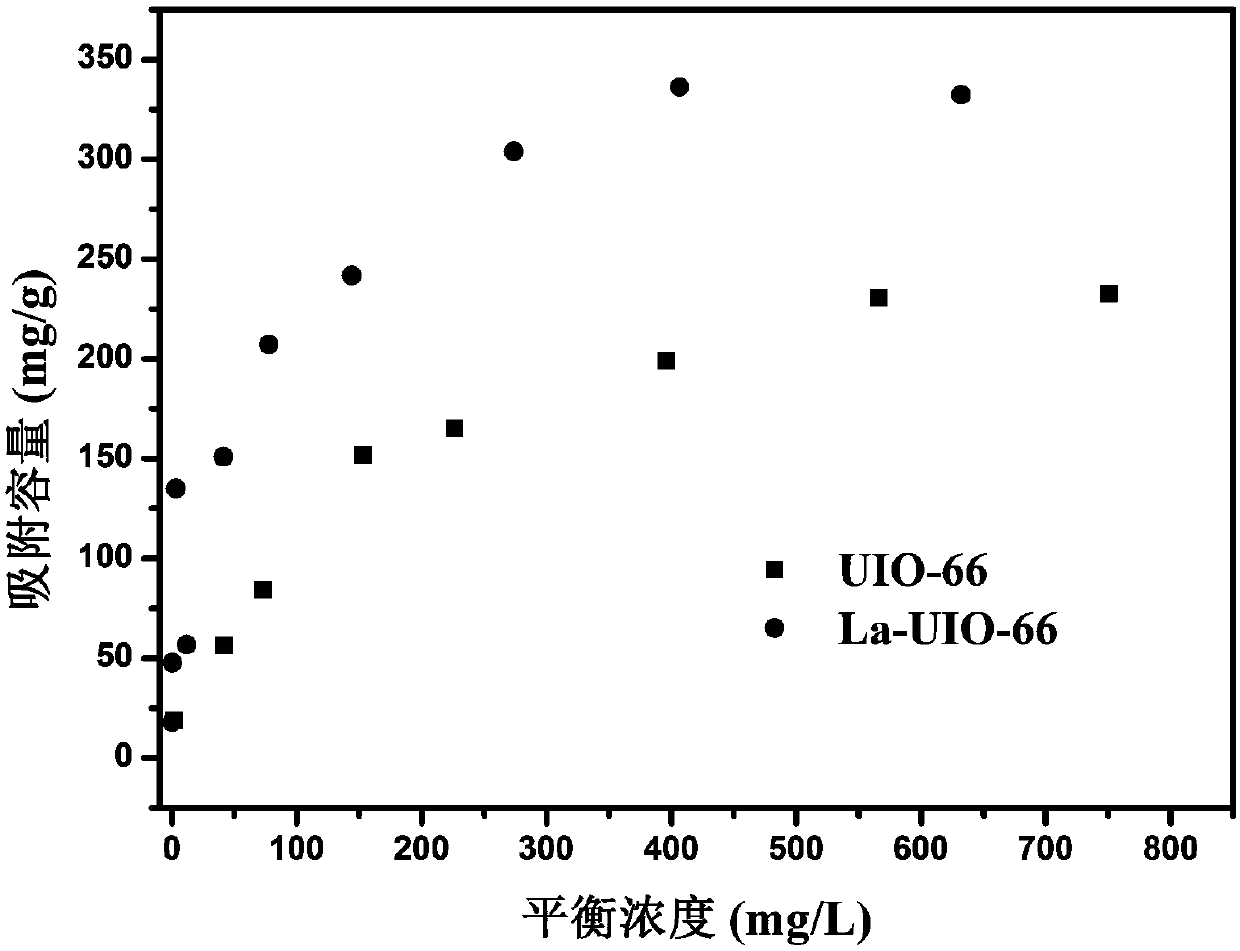

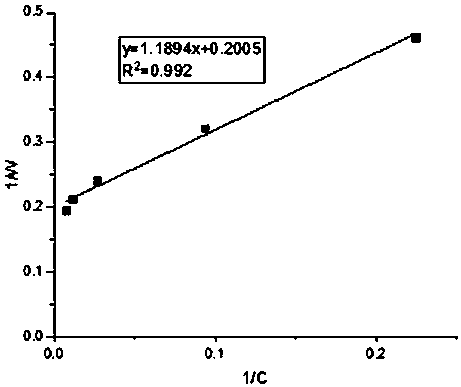

Lanthanum-doped metal organic framework material as well as preparation method and application thereof

ActiveCN107754765AFully generatedSimple and fast operationOther chemical processesWater contaminantsPhosphateMetal-organic framework

The invention provides a preparation method of a lanthanum-doped metal organic framework material. The preparation method comprises the following steps: firstly, fully reacting zirconium tetrachloridewith terephthalic acid to generate a base framework material; preferably reacting lanthanum chloride heptahydrate with the terephthalic acid while avoiding the reaction of the lanthanum chloride heptahydrate and the base framework material. The invention provides the lanthanum-doped metal organic framework material and application thereof in adsorption of phosphate radical. The lanthanum-doped metal organic framework material has two adsorption sites of zirconium ions and lanthanum ions which can be used for well adsorbing the phosphate radical. The results of the embodiment show that the maximal adsorption capacity of the lanthanum-doped metal organic framework material to the phosphate radical is 348.43mg / g; in the presence of more heteroions, the recognition of the phosphate radical can be maintained; after repeated use for five times, the adsorption capacity of La-UIO-66 to the phosphate radical is also kept at 100 percent; the lanthanum-doped metal organic framework material hasexcellent stability and recycling performance.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method for adsorbent capable of removing nitrogen and phosphorus simultaneously

ActiveCN106607006AImprove performanceImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionRare-earth elementSorbent

The invention discloses a preparation method for an adsorbent capable of removing nitrogen and phosphorus simultaneously. The preparation method comprises the following steps of (1) fly ash pretreatment, (2) preparation of zeolite synthesized from fly ash, (3) rare earth element modifier preparation, and (4) adsorbent preparation. According to the preparation method, by using the zeolite synthesized from the fly ash, salts with alkaline-earth elements are added in the alkalization treatment process of the fly ash, and the performance of the zeolite synthesized from the fly ash is improved; two rare earth elements of lanthanum and gadolinium are added into a rare earth modifier prepared from ethylene glycol and polyvinylpyrrolidone so that the zeolite synthesized from the fly ash can be subjected to modification treatment; and compared with methods that modification is conducted by using lanthanum chloride independently in the prior art, the performance for adsorbing ammonium ions and phosphorus is greatly improved and reaches 93% or above, in addition, the adsorption rate is also greatly increased, and the quite good practical application value is achieved.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

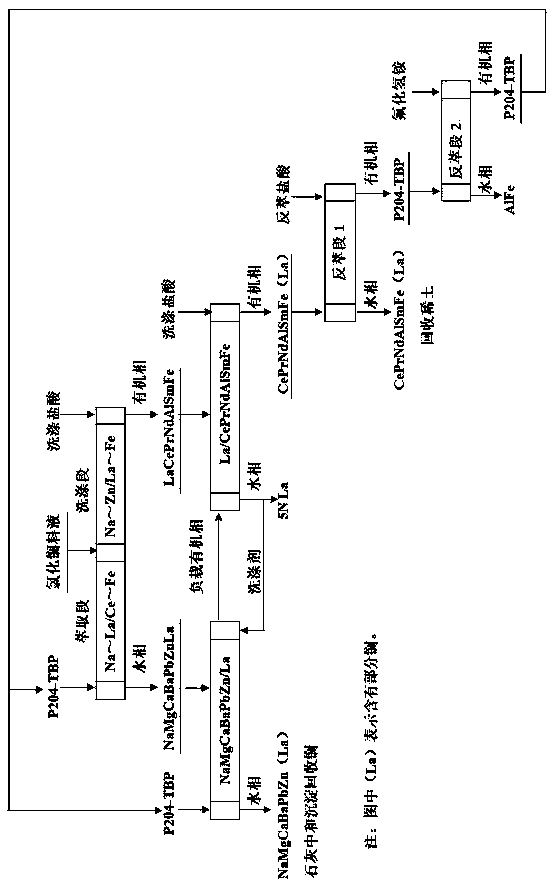

Process for preparing high-purity lanthanum by extraction method

InactiveCN108893625AReduce consumptionHigh purityProcess efficiency improvementCeriumLanthanum(III) chloride

The invention discloses a process for preparing high-purity lanthanum by an extraction method. The process comprises five steps: by adoption of a 3N industrial-grade lanthanum chloride aqueous solution as a feed liquid and adoption of P204-TBP as a composite extraction agent, specific fractionating and extracting separation of NaMgCaBaPbZnLa / LaCePrNdAlSmFe, fractionating and extracting separationof NaMgCaBaPbZn / La and fractionating and extracting separation of La / CePrNdAlSmFe as well as a reverse extraction stage 1 and a reverse extraction stage 2. By implementation of the process, the separation of lanthanum from metallic elements such as cerium, praseodymium, neodymium, samarium, iron, aluminium, zinc, lead, barium, calcium, magnesium and sodium and the like can be realized smoothly, and the relative purity of the high-purity lanthanum chloride solution is 99.9991%-99.9998%. The process disclosed by the invention has the characteristics of short process flow, low reagent consumption, low production cost, high purity of lanthanum chloride and high yield of lanthanum and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of low-impurity-entrainment lanthanum carbonate or cerium lanthanum carbonate

ActiveCN105502470AReduce concentrationConcentration is not dilutedRare earth metal carbonatesCeriumManganese

The invention relates to a preparation method of low-impurity-entrainment lanthanum carbonate or cerium lanthanum carbonate. The preparation method is characterized in that a lanthanum carbonate or cerium lanthanum carbonate solution is taken as a feed solution, an ammonium bicarbonate solution is taken as an ammonium bicarbonate, and new water or carbon precipitation supernatant is left at the bottom of a precipitation reaction kettle to serve as a base solution. The preparation method comprises the following steps: adding lanthanum carbonate or cerium lanthanum carbonate seed crystal in which seed crystal REO (Rare Earth Oxide) to feed solution REO is 1 percent by weight to 10 percent by weight; adding rare earth chloride and the ammonium bicarbonate solution into a reaction kettle at the same time at 20-50 DEG C to carry out a precipitation reaction, wherein the adding rate ratio is 1:1-3:1; at the end of the reaction, performing solid-liquid separation and water washing to obtain a carbonate lanthanum or cerium lanthanum carbonate product. The preparation method has the advantages that the process parameters of feeding way, relative feeding rate, precipitation pH value and final pH value of a ammonium bicarbonate precipitation lanthanum carbonate or cerium lanthanum carbonate solution are adjusted, so that manganese, copper and the like do not undergo the precipitation reaction, and the formed carbonate lanthanum or cerium lanthanum carbonate product has the characteristics of less soft agglomeration, small crystalline grain size and less entrainment of manganese and copper impurities.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS +2

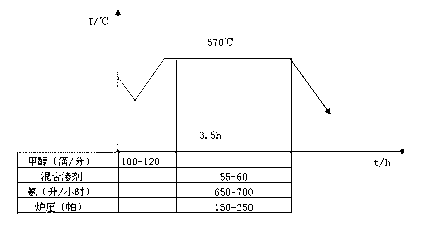

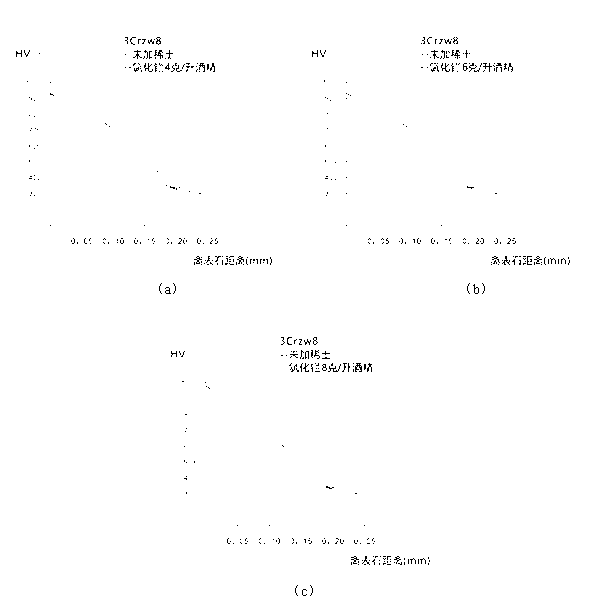

Rare earth catalyzed nitrocarburizing technology

InactiveCN102864407AHigh surface hardnessImprove the surface hardness valueSolid state diffusion coatingRare earthNitrogen

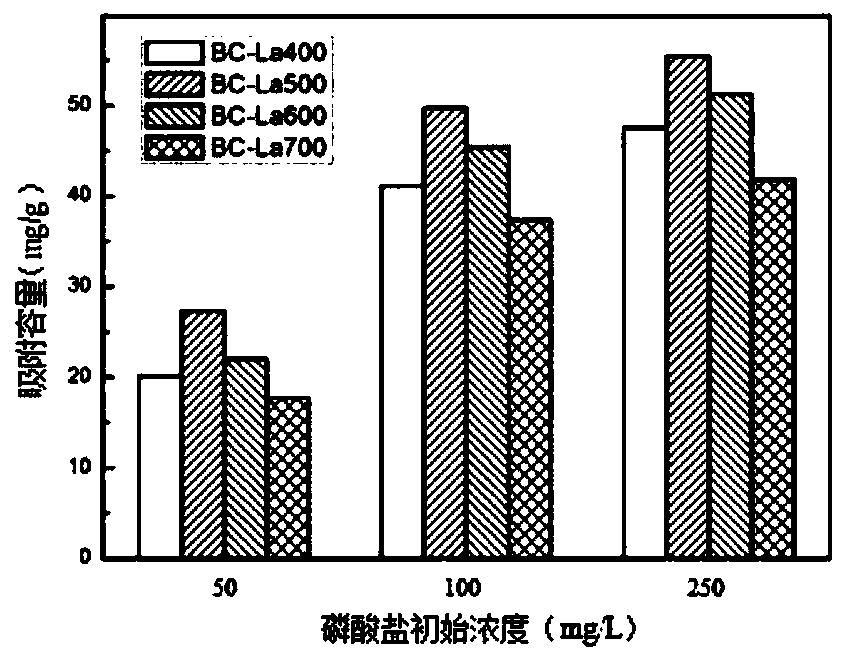

The invention relates to a rare earth catalyzed nitrocarburizing technology, characterized by preparing rare earth catalyst with different concentrations, selecting proper technological parameter s according to workpiece techniques to conduct nitrocarburizing, after completing nitrocarburizing, conducting oil cooling; preferably the rear earth catalysts are prepared by dissolving lanthanum chloride compound in ethanol; and further, the lanthanum chloride concentrations in the rear earth catalysts are respectively 4 g / per liter of ethanol,6 g / per liter of ethanol, and 8g / per liter of ethanol. Compared with the prior art, the technology disclosed herein thickens the white bright layer of the infiltrated layer, increases the infiltrated layer depth, raises the nitrocarburizing speed by 9-14%, shortens the technology time, raises the production efficiency, and raises the surface hardness of the workpiece and the diffusion layer hardness to flatten the hardness gradient, refine the infiltrated layer tissues, raise the dispersivity of nitrides, raise the usability and prolong service life of the workpiece.

Owner:TIANJIN SHANGRE METAL TECH

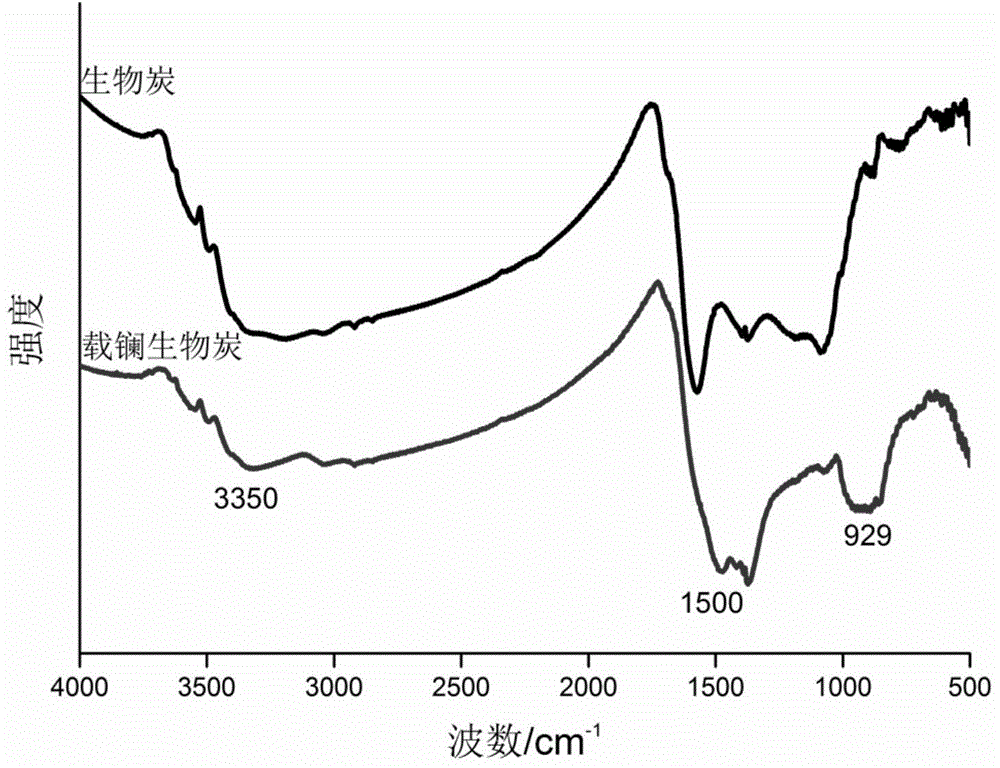

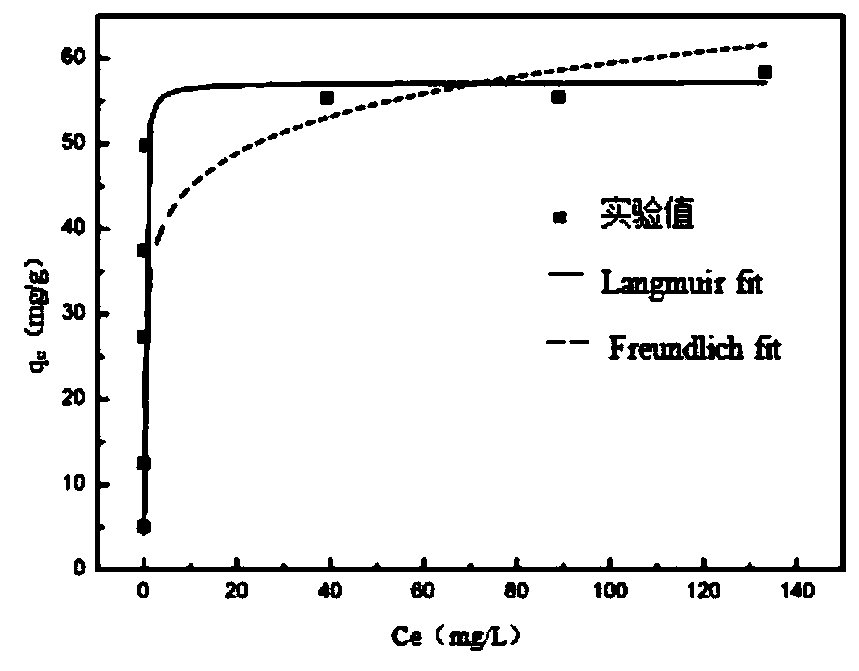

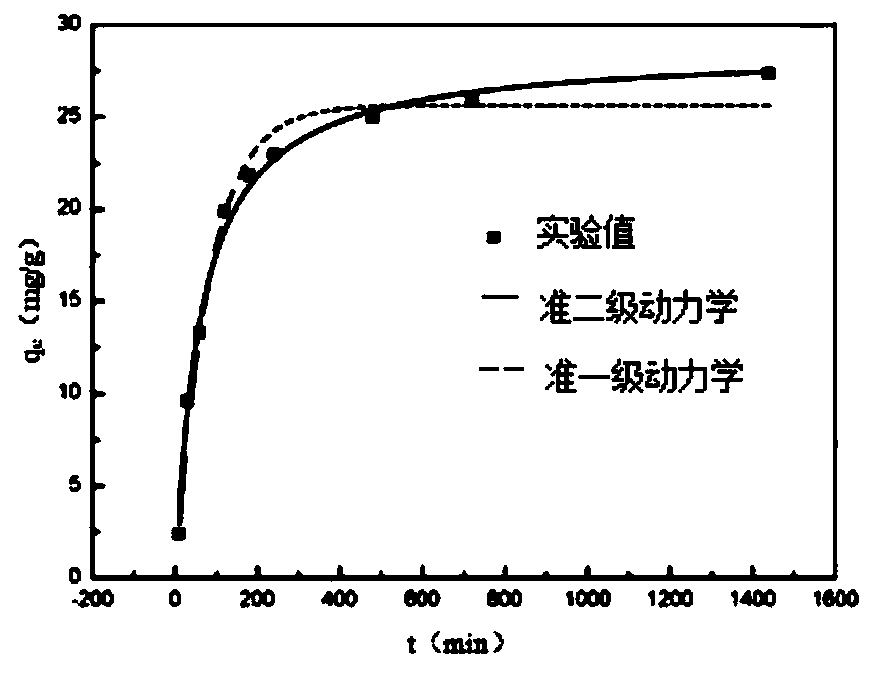

Lanthanum-modified biochar, and preparation method and application thereof

InactiveCN111589416AWell-developed pore structureLarge specific surface areaOther chemical processesWater contaminantsPhosphateLanthanum(III) chloride

The invention relates to the technical field of biochar, and especially relates to a lanthanum modified biochar, and a preparation method and application thereof. The preparation method provided by the invention comprises the following steps: pyrolyzing sheep manure to obtain sheep manure biochar; and washing the sheep manure biochar, dipping the washed sheep manure biochar in a lanthanum chloridesolution, and adjusting the pH value to 8-11 to obtain the lanthanum modified biochar. According to the record of the embodiment, the adsorption capacity of the lanthanum-modified biochar prepared bythe preparation method in the technical scheme on phosphate can reach 58.33 mg / g at most.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

Method for removing phosphorus in water body by using adsorption of nano-lanthanum oxide modified alkali lignin

ActiveCN108341459AImprove adsorption capacityEvenly distributedOther chemical processesWater contaminantsMannich reactionLanthanum(III) chloride

The invention discloses a method for removing phosphorus in a water body by using adsorption of nano-lanthanum oxide modified alkali lignin. The method comprises the following steps: dissolving the alkali lignin into water, adding polyethylenimine and a formaldehyde solution and carrying out a Mannich reaction in an alkaline environment; carrying out a hydrothermal reaction of a product by adopting lanthanum chloride as a lanthanum source in an ethanol aqueous solution to prepare the nano-lanthanum oxide modified alkali lignin; adding the nano-lanthanum oxide modified alkali lignin into a phosphorous-containing water body and removing the phosphorus in the water body by adsorbing. The surface of the lanthanum oxide modified alkali lignin prepared according to the hydrothermal method has highly-dispersed active lanthanum adsorption sites, and shows excellent removal effect and higher cyclic utilization rate for the phosphorus; in addition, the adsorption time is short and the treatmentefficiency is high; the adopted alkali lignin as a base body material is waste residue of a papermaking pulping process, and is wide in source and low in price, so that the aim of treating the wastesby wastes can be realized. The method for removing the phosphorus in the water body by using adsorption of the nano-lanthanum oxide modified alkali lignin, disclosed by the invention, has good economic and environmental benefits when being applied to removal of the phosphorus in the water body.

Owner:TAIZHOU UNIV

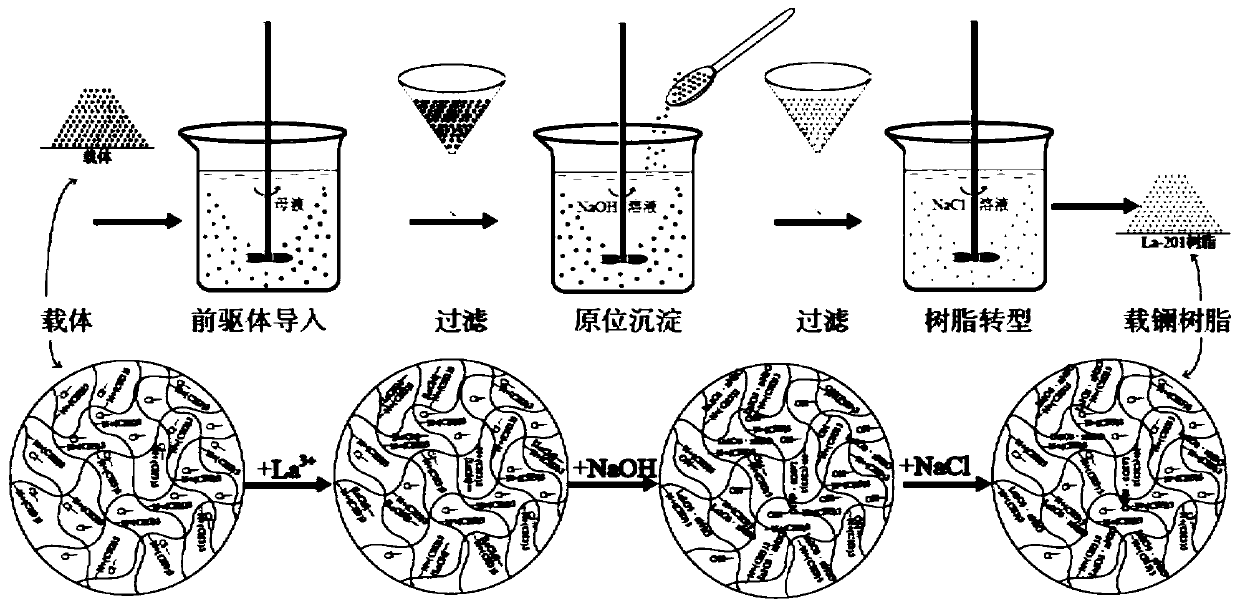

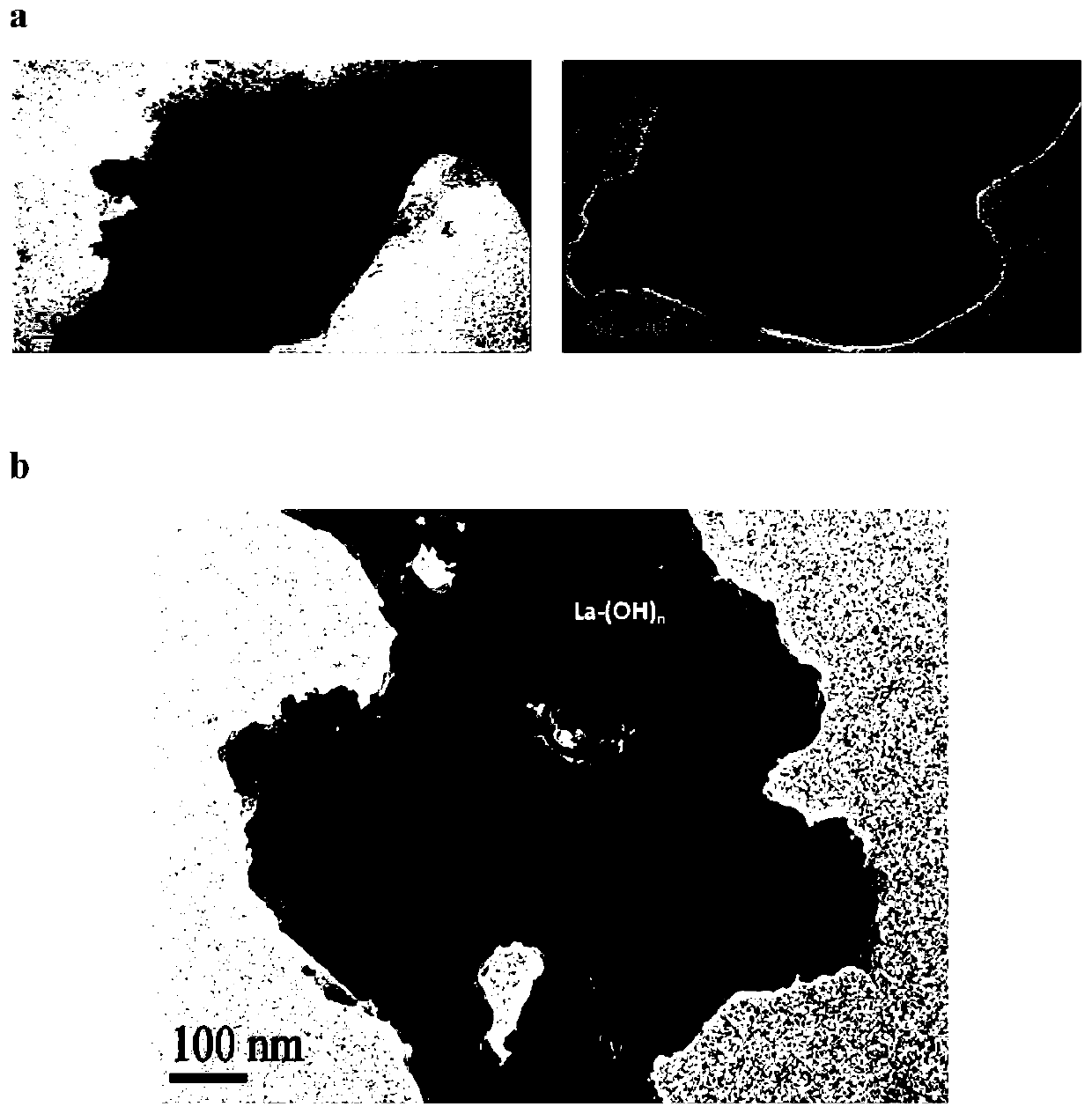

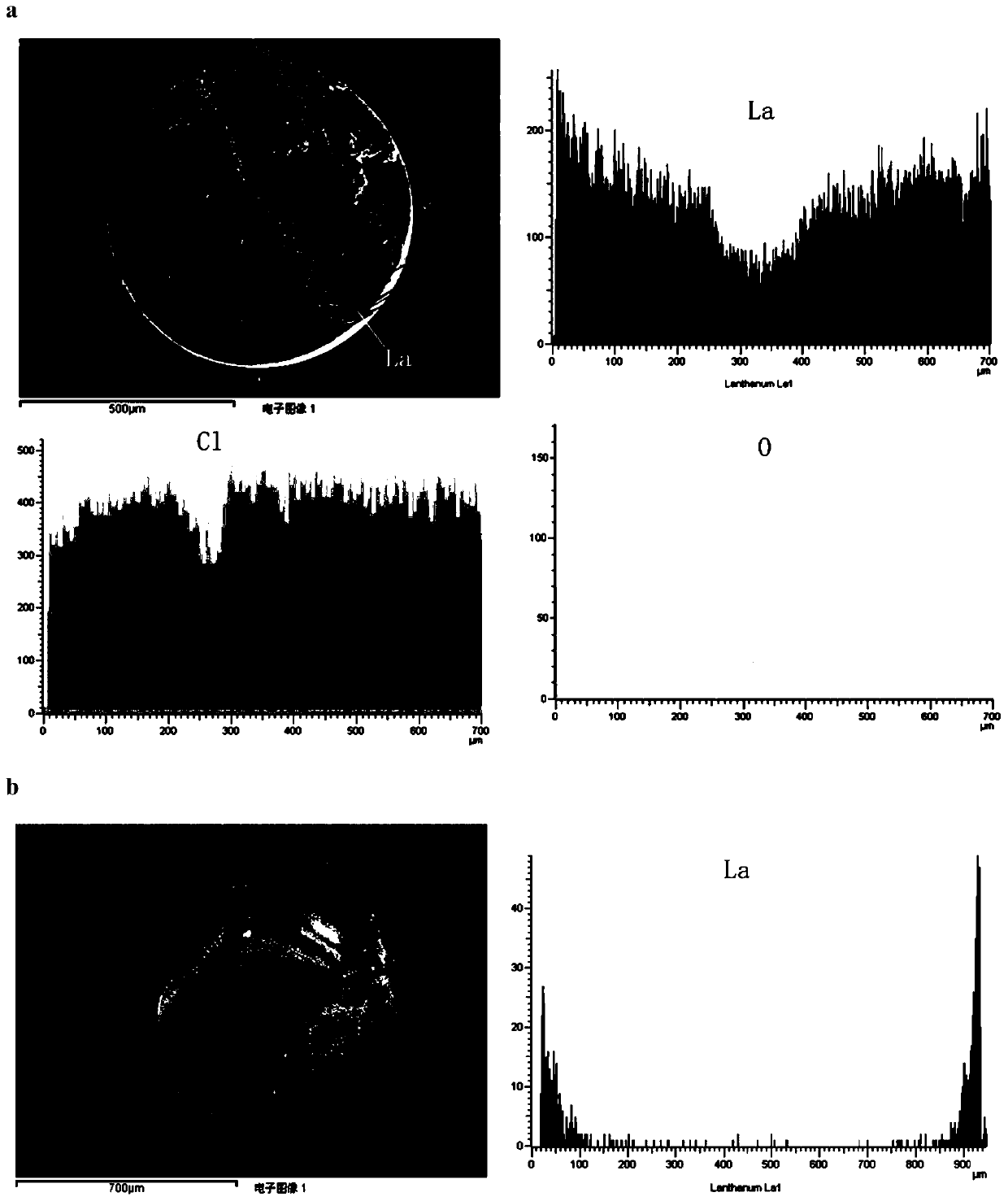

Resin-based nano-lanthanum material and preparation method and application thereof

ActiveCN110681368AEvenly distributedFacilitated DiffusionMaterial nanotechnologyOther chemical processesAlcoholPhysical chemistry

Owner:NANJING UNIV

Chestnut shell active carbon and preparation method thereof

InactiveCN103551109AWell-developed pore structureWell-developed structureOther chemical processesCerium nitrateHazardous substance

Chestnut shell active carbon is prepared by the following raw materials by weight: 120-140 parts of chestnut shell, 3-5 parts of zinc chloride, 4-6 parts of Arabic gum, 4-6 parts of periston, 25-30 parts of bentonite, 10-15 parts of alumina, 20-25 parts of pumice, 2-4 parts of lanthanum chloride, 2-4 parts of cerium chloride, 2-4 parts of scandium chloride, 2-4 parts of yttrium chloride, 2-4 parts of praseodymium chloride, 1-3 parts of lanthanum nitrate, 1-3 parts of cerium nitrate, 1-2 parts of scandium nitrate, 1-2 parts of yttrium nitrate, 1-2 parts of praseodymium nitrate, 4-5 parts of modified diatomite, and a proper amount of water. Chestnut shell is used as a raw material, so as that the active carbon has advantages of developed aperture structure, big specific surface area, high adsorption speed, and good adsorption capability on various solutes and dissociation gases; lanthanum chloride is used for activation so as to form active carbon, which has big gaps and strong adsorption capability, is suitable for absorbing organic matters in air and water and removing harmful substances like formaldehyde, is low in cost, and is suitable for industrialization production.

Owner:BENGBU PIONEER FILTER

Preparation method for SLTON perovskite NOx powder

InactiveCN104071845ASimple process routeReduce manufacturing costCalcium/strontium/barium compoundsTantalum compoundsAdjuvantHexamethylenetetramine

The invention discloses a preparation method for SLTON perovskite-type NOx powder. The method comprises the following steps: completely resolving a soluble strontium salt, a soluble lanthanum salt, a soluble tantalum salt and a combustion adjuvant in a methanol-water mixed solution, drying the solution, carrying out grinding till the raw materials are completely mixed uniformly, carrying out high-temperature calcination to form a precursor, and conducting nitriding high-temperature processing on the precursor to obtain the target product, wherein the molar ratio of the soluble tantalum salt to the combustion adjuvant is 1 to (1 to 500); the soluble strontium salt is one or the mixture of strontium chloride and strontium nitrate; the soluble lanthanum salt is one or the mixture of lanthanum chloride and lanthanum nitrate; the soluble tantalum salt is one or the mixture of tantalum pentachloride and tantalum ethylate; the combustion adjuvant is one or the mixture of urea, oxalic acid, citric acid and hexamethylenetetramine. The method has the advantages that the product purity is high; the impurity content is low; suitability for batch production and the fields of ferroelectricity, photo-electricity, photocatalysis, fuel cells and the like is realized.

Owner:BOHAI UNIV

Method for producing pentachloropyridine

InactiveCN102718699AReduce pollutionHigh utilization rate of raw materialsOrganic chemistryFixed bedLanthanum(III) chloride

The invention discloses a method for producing pentachloropyridine, and the method belongs to the field of agricultural chemical manufacture. The production method uses pyridine, nitrogen, chlorine, activated carbon-supported cobalt chloride, barium chloride and lanthanum chloride as raw materials, and produces pentachloropyridine by fluidized bed and fixed bed technologies. The reaction conditions are that the temperature of the fluidized bed and the fixed bed is in the range of 380 DEG C to 410 DEG C, the pressure is in the range of 0.10 to 0.12Mpa, the catalyst is the activated carbon-supported cobalt chloride, barium chloride and lanthanum chloride, the reaction transformation rate of the method reaches 98%, and the selectivity of the product pentachloropyridine is 91%. The production method has advantages of high utilization of raw materials, high product purity, simple process, and little environmental pollution, and is a relatively advanced synthetic method of pentachloropyridine at present.

Owner:张苏侠

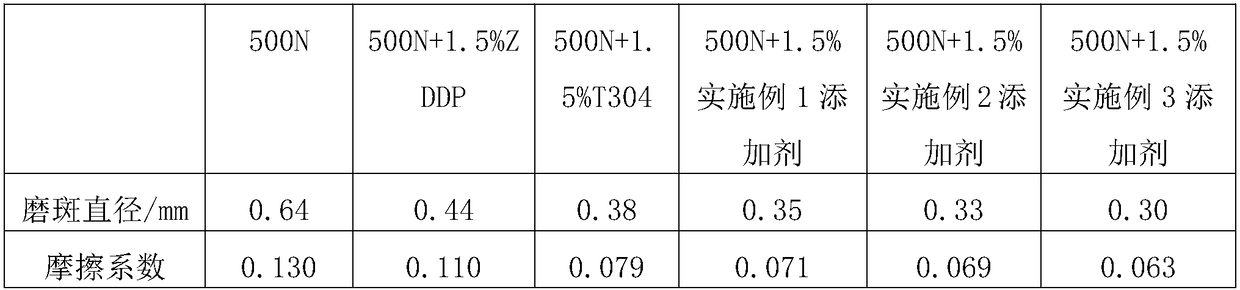

Anti-friction energy-saving additive with dispersed solution of modified nano lanthanum borate and basic oil and preparation method thereof

InactiveCN108774564AEnvironmentally friendlyIn line with the concept of green production and environmental protectionAdditivesFriction reductionDispersity

The invention discloses an anti-friction energy-saving additive with dispersed solution of modified nano lanthanum borate and basic oil and a preparation method thereof. The anti-friction energy-saving additive is prepared from a modified lanthanum borate nano composite material and basic oil, wherein the weight ratio of the modified lanthanum borate nano composite material to the basic oil is (5-15):(85-95); the modified lanthanum borate nano composite material is prepared from the following substances in parts by weight: 0.5-2 parts of sodium borate, 0.3-0.5 part of lanthanum chloride, 0.05-0.2 part of KH-550, 1-3 parts of oleic acid and 1-3 parts of petroleum ether. The anti-friction energy-saving additive and the preparation method thereof disclosed by the invention have the beneficialeffects that the modified lanthanum borate nanocomposite material is prepared by combination with a flotation method in the preparation process, the secondary particle-size distribution of a preparedproduct is narrow, the problem of settlement of the additive in lubricating oil is overcome, and meanwhile, the problem that a lanthanum-borate type product is decomposed when meeting water is solved; the additive shows outstanding anti-friction property in the lubricating oil, and has good dispersity in the lubricating oil; the effect of reducing the friction coefficient among workpiece equipment can be achieved, so that the effects of emission reduction, energy conservation and friction reduction and the like of the workpiece equipment are achieved.

Owner:李立强

Method for preparing ion exchanger for removing available phosphorous in water body

The invention relates to a method for preparing a ion exchanger for removing available phosphorous in a water body, which belongs to the technical field of environmental protection. The method mainly comprises the steps of: adding a well prepared lanthanum chloride solution and aluminum chloride solution into zeolite, simultaneously adding a precipitator for carrying out precipitation reaction, and heating to obtain a solid precipitate; and leaching the solid precipitate, washing with distilled water, drying and calcining to obtain a product, namely the ion exchanger for removing the available phosphorous in the water body. The ion exchanger is used for rapidly removing the available phosphorous in the water body by mainly utilizing various chemical substances which are harmless to aquatic organisms and human bodies through an ion exchange effect and a complexing effect, so as to control the eutrophication of the water body. The ion exchanger is convenient to use, is free from the influence of environmental condition and climatic factors, is low in dosage, has fast response and high efficiency after being used and can be used for obviously removing the available phosphorous in thewater body and effectively controlling the eutrophication of the water body.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI +1

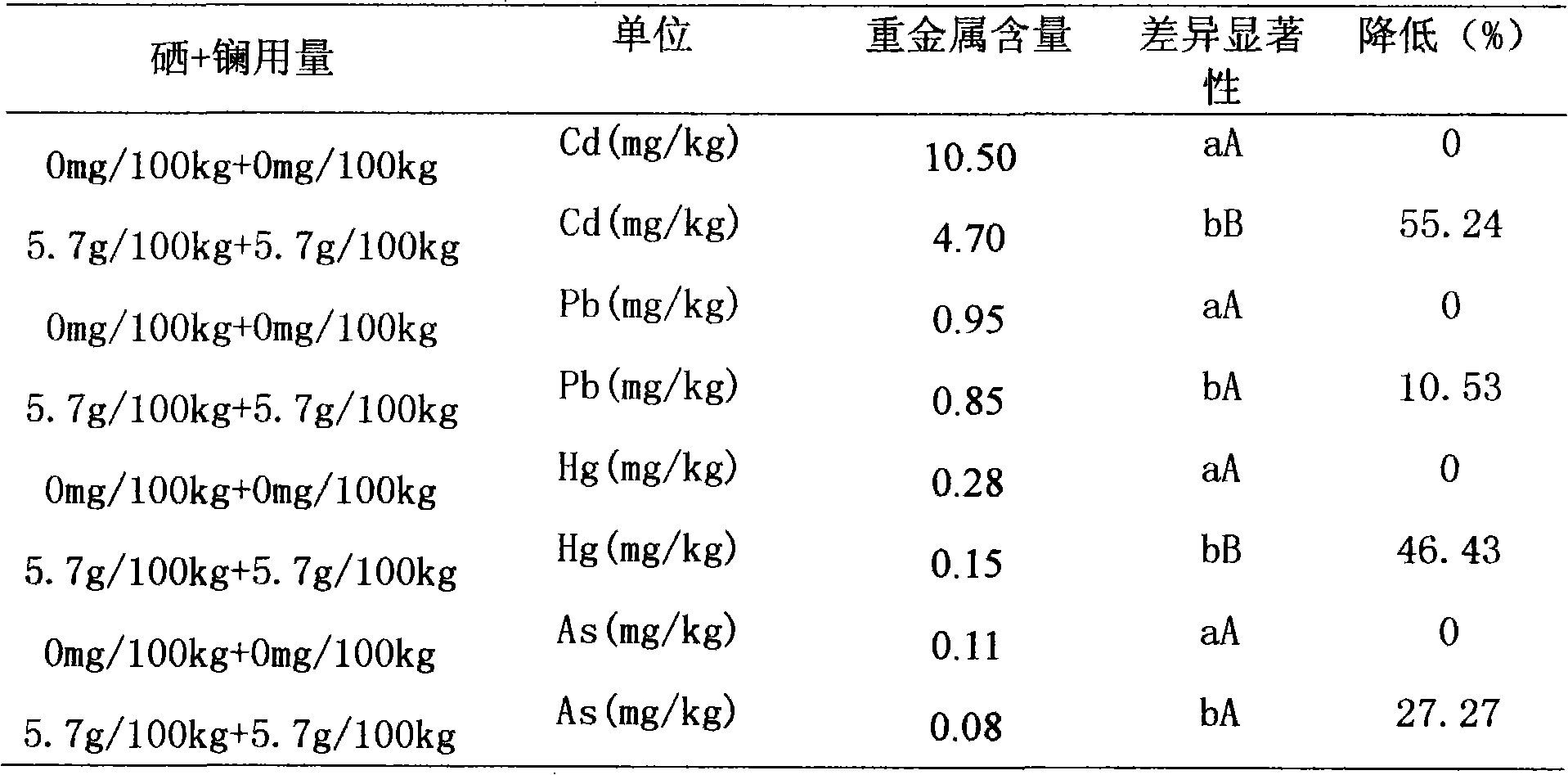

Cultivation method for high-quality agaricus blazei by using selenium and lanthanum as dirt reducing agent

The invention provides a cultivation method for high-quality agaricus blazei by using selenium and lanthanum as a dirt reducing agent. Raw materials and auxiliary materials commonly used for the cultivation of the existing agaricus blazei are adopted as cultivation materials. The method comprises the following steps: selecting fresh raw materials and drying the raw materials for standby; selecting a mushroom house or a cultivation room; uniformly mixing the raw materials and the auxiliary materials; sterilizing and packaging the raw materials and the auxiliary materials in bags; sterilizing and inoculating the materials; transferring the bags to a bed in the cultivation room for cultivation; and managing the bags as well as picking and harvesting the agaricus blazei before and after the fruiting. The method is characterized in that a selenium-lanthanum dirt reducing agent composition containing the selenium and the lanthanum (rare earth element) is added in every 100kg of dry cultivation materials as a dirt removing auxiliary agent, and the selenium-lanthanum dirt reducing agent composition consists of 4-10g of sodium selenite and 3-10g of lanthanum chloride. In the invention, the content of various heavy metals in agaricus blazei fruiting bodies can be reduced, wherein the content of cadmium is reduced to less than 5mg / kg; and the content of beneficial elements is also increased; therefore, the nutritional quality of the agaricus blazei can be obviously improved.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

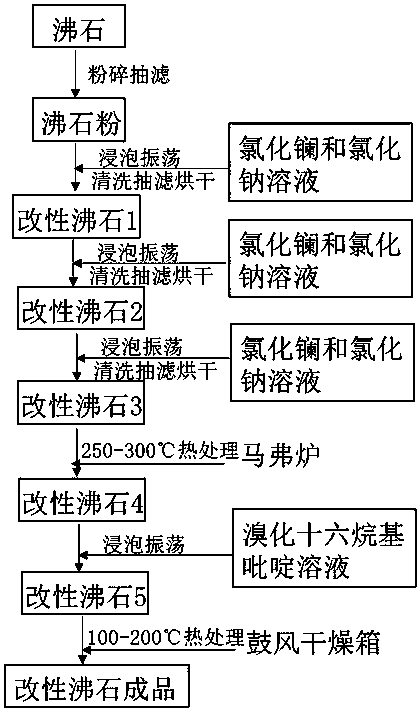

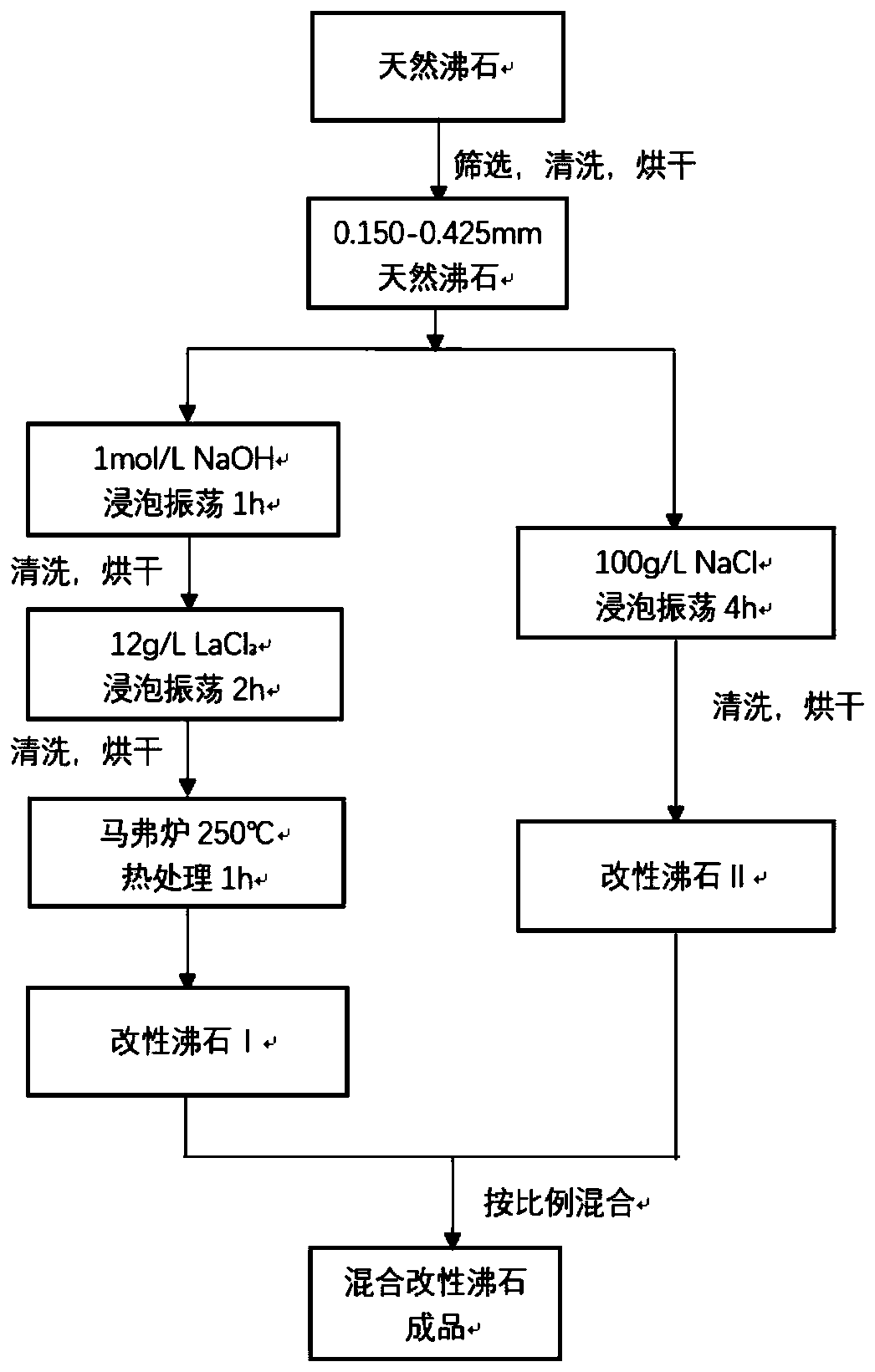

Preparation method for modified zeolite used for synchronously deeply processing nitrogen and phosphorus

ActiveCN108079940AExpand the scope of useEasy to useOther chemical processesAluminium silicatesFiltrationHexadecylpyridinium bromide

The invention discloses a preparation method for modified zeolite used for synchronously deeply processing nitrogen and phosphorus, and belongs to the field of the deep treatment of sewage. The methodcomprises the following steps: preparing zeolite, lanthanum chloride and sodium chloride solution; smashing the zeolite, carrying out suction filtration, and washing; putting the zeolite into the lanthanum chloride and sodium chloride solution under an alkaline condition to be dipped and oscillated; cleaning the zeolite, carrying out the suction filtration on the zeolite, and drying at the temperature of 105 DEG C; preparing the lanthanum chloride and sodium chloride solution; putting the zeolite into the lanthanum chloride and sodium chloride solution under the alkaline condition to be dipped and oscillated; cleaning the zeolite, carrying out the suction filtration on the zeolite, and drying at the temperature of 105 DEG C; preparing the lanthanum chloride and sodium chloride solution; putting the zeolite into the lanthanum chloride and sodium chloride solution under the alkaline condition to be dipped and oscillated; moving the zeolite out of the solution, and carrying out thermal treatment on the zeolite at the temperature of 250-300 DEG C; preparing hexadecylpyridinium bromide solution; dipping and oscillating the zeolite in CPB (Bromohexadecyl Pyridine) solution; removing thezeolite out of the solution, and carrying out thermal treatment on the zeolite at the temperature of 100-200 DEG C. According to the modified zeolite disclosed by the invention, efficiency for removing nitrogen and phosphorus in water can be obviously improved.

Owner:广州市创景市政工程设计有限公司

Electrochemical synthesis method of 1,1'-diindolylmethane derivatives

InactiveCN106567104AGood reaction selectivityHigh yieldElectrolysis componentsElectrolytic organic productionSynthesis methodsElectrochemistry

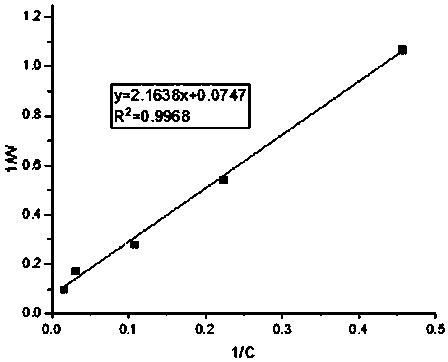

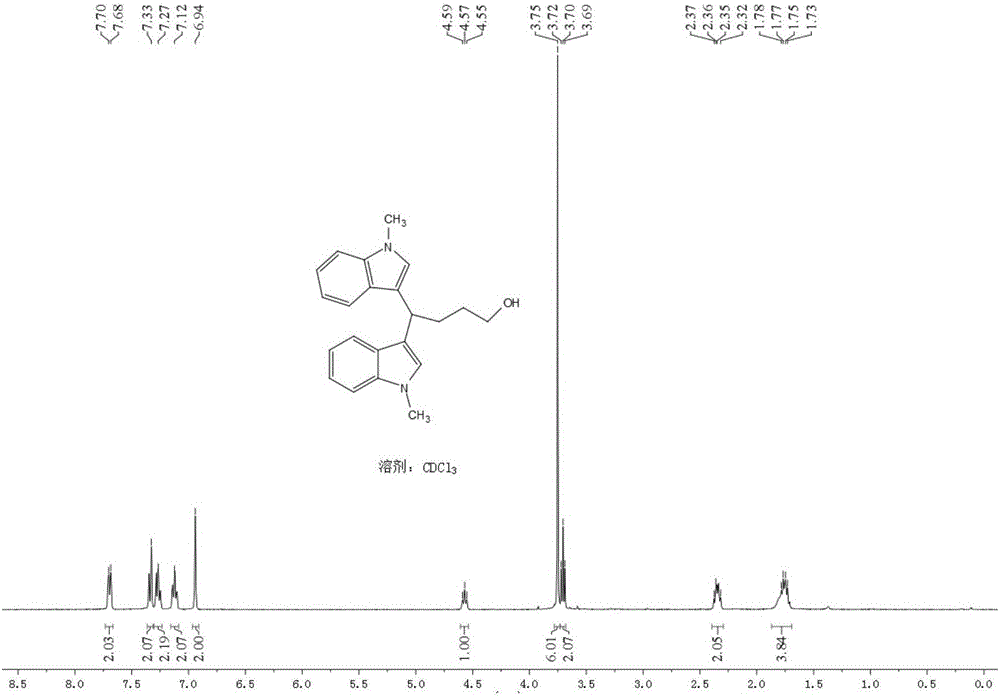

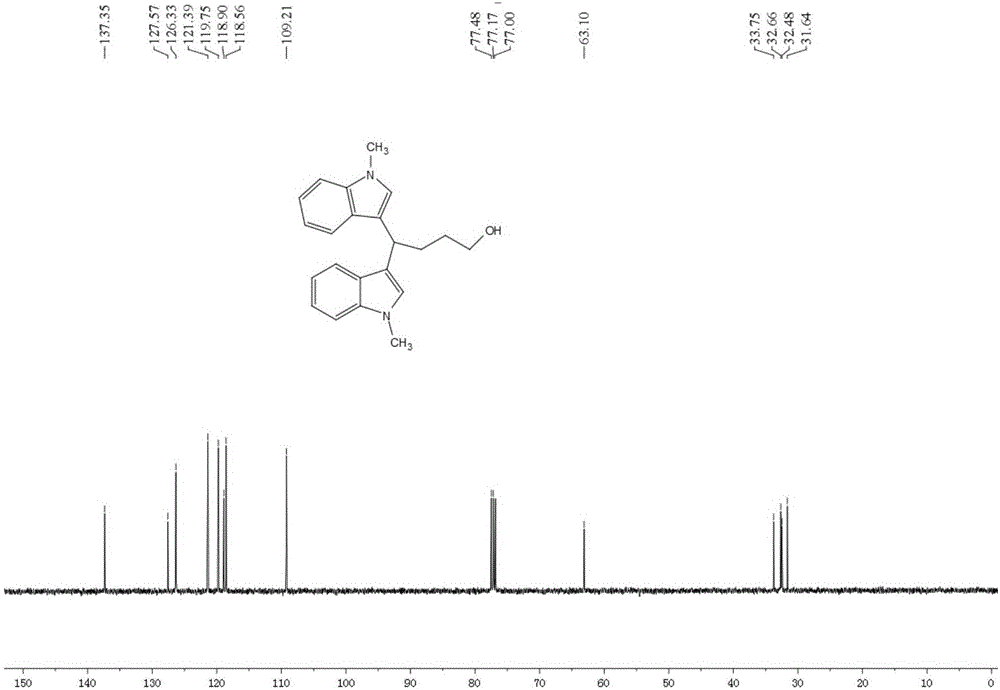

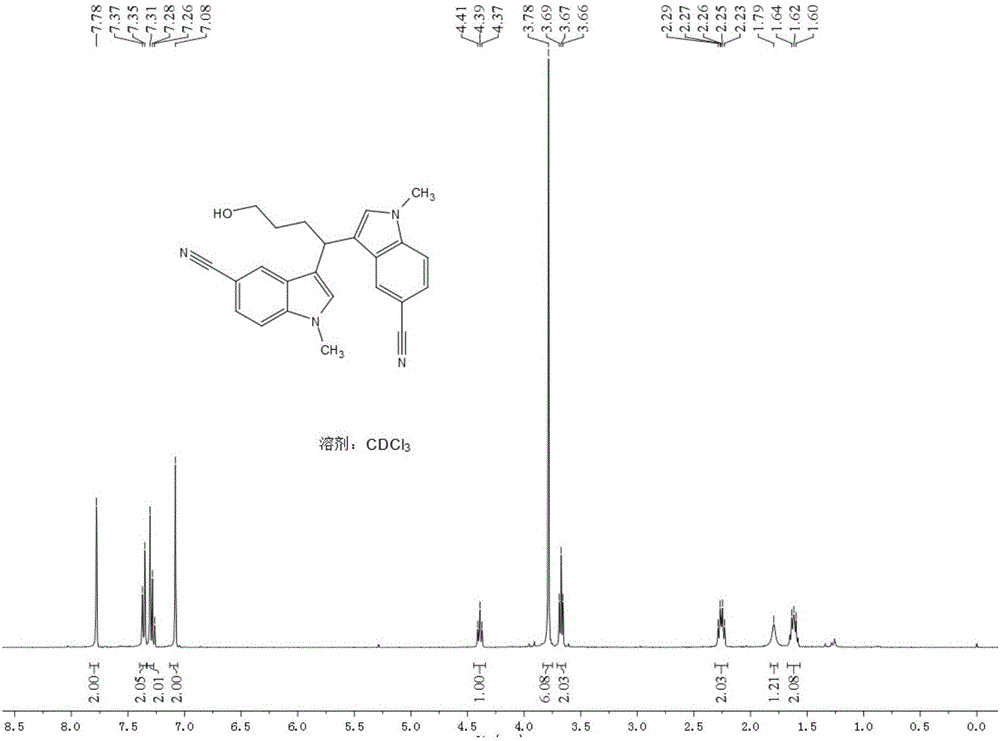

The invention discloses an electrochemical synthesis method of 1,1'-diindolylmethane derivatives. According to the method, indole derivatives, tetrahydrofuran and tetrahydrofuran derivatives are used as raw materials for synthetizing the 1,1'-diindolylmethane derivatives under the electrochemical condition. The method specifically comprises the following steps that the indole derivatives are taken and added into a mixed solvent of the tetrahydrofuran or tetrahydrofuran derivatives with acetonitrile, and a catalytic amount of lanthanum chloride and electrolyte lithium perchlorate are added; a platinum electrode is inserted into reaction liquid, stirring is conducted at the room temperature, and a reaction is carried out through electrification until the complete reaction is conducted; and the reaction liquid is extracted, concentrated and separated, and the 1,1'-diindolylmethane derivatives is obtained. Electricity is used for catalysis, expensive metal catalyzers and other oxidizing agents are not needed, stoichiometric lewis acid, protonic acid and heating are not needed either, reaction can be carried out mildly at the room temperature, the selectivity is good, the yield is high, and the whole process is simple and feasible; and the method is environmentally friendly and conforms to the idea of green chemistry.

Owner:SOUTH CHINA UNIV OF TECH

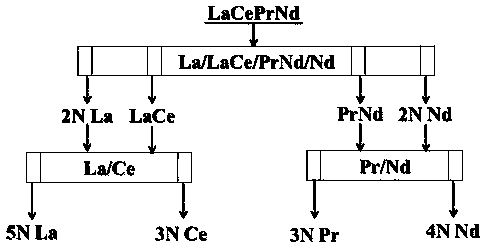

Technology for separating light rare earth from southern ion-absorbing type rare earth ore

InactiveCN110306047AHigh yieldImprove separation efficiencyProcess efficiency improvementRare earthCerium

The invention provides a technology for separating light rare earth from southern ion-absorbing type rare earth ore. The technology is implemented by adopting an aqueous light rare earth chloride solution obtained by grouping separation from the southern ion-absorbing type rare earth ore as a feed liquid and P507 as an extraction agent, and comprises three fractional extraction systems, and the three fractional extraction systems comprise a La / LaCe / PrNd / Nd four-outlet fractional extraction and separation system, a La / Ce two-feed-inlet fractional extraction and separation system and a Pr / Nd two-feed-inlet fractional extraction and separation system. By means of combination of the three fractional extraction systems, four separation products including 5N-grade lanthanum chloride, 3N-grade cerium chloride, 3N-grade praseodymium chloride and 4N-grade neodymium chloride are obtained directly. The technology has the advantages of high purity of a target separation product, high yield of rareearth element, low acid-base consumption, short technological process, low separation cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Plating auxiliary for steel

InactiveCN107740021AImprovement ingredientsReduce releaseHot-dipping/immersion processesSTANNOUS OXIDECerium

The invention discloses a plating auxiliary for steel. The plating auxiliary for the steep is characterized by comprising, by weight, 5-10% of zinc chloride, 15-30% of ammonium chloride, 0.1-2% of sodium fluoride, 0.05-0.2% of fluoride surfactant, 0.1-1% of stannous oxide, 0.5-2% of rare earth chloride, and the balance water; the rare earth chloride comprises at least one of lanthanum chloride, cerium chloride, lanthanum-cerium chloride and zirconium oxychloride; the plating auxiliary can improve the surface quality of a plating of a plating part while reducing the release amount of hydrogen chloride and ammonia gas, so that the zinc plating layer is uniform in thickness and high in smoothness, and zinc materials are saved.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

Adsorbent and method for synchronously removing ammonia nitrogen and phosphorus in sludge removal water

ActiveCN110975801AReduce loadLow costSludge treatmentOther chemical processesAmmoniacal nitrogenSludge

The invention relates to an adsorbent and a method for synchronously removing ammonia nitrogen and phosphorus in sludge removal water. The adsorbent is formed by mixing modified zeolite I and modifiedzeolite II, the modified zeolite I is zeolite modified by lanthanum chloride and roasted under alkaline conditions, and the modified zeolite II is zeolite modified by sodium chloride. The adding massratio of the modified zeolite I to the modified zeolite II is K, and K is in a certain relational expression with ammonia nitrogen concentration C in sludge removal water and total phosphorus concentration x in the sludge removal water; the addition amount y of the modified zeolite I and the total phosphorus concentration x in the sludge removal water form a certain relational expression, so thatthe addition amount of the modified zeolite II is obtained, then the sludge removal water is treated under a certain condition, and after treatment, the phosphorus residual concentration reaches thefirst-grade A standard (2mg / L), and the ammonia nitrogen removal rate can reach 90%.

Owner:WUHAN UNIV OF TECH

Manufacturing method of chlorine-lanthana film sensitive element for detecting carbon dioxide

InactiveCN1547005ASimple processLow priceMaterial analysis by electric/magnetic meansWater bathsLanthanum(III) chloride

The invention refers to a kind of lanthanum oxychloride film sensitive element for measuring carbon dioxide and the manufacturing method, which belongs to semiconductor sensor and sensitive element manufacturing process technology field. The invention mainly uses sol-gel process, the character lies in: at first, the lanthanum oxychloride is dissolved in alcohol liquid, and then adds in acrylamide as dispersant, heats and back flows, then it is aged in water, acquires the sol; the preprocessed gold polar and the aluminum oxide lining ruthenium oxide resistance heating layer is immersed in the abovementioned sol, then takes them out to be dried; the element can be acquired through heating process. The product has a high sensitivity; the method is simple, cheap.

Owner:SHANGHAI UNIV

Fluorescent substance based on amino acid deep eutectic solvent and preparation method of fluorescent substance

ActiveCN109385271AAvoid the problem of uneven sizeEasy to degradePhotovoltaic energy generationLuminescent compositionsFluorescenceRare earth

The invention relates to the technical field of chemical engineering and particularly discloses a fluorescent substance based on an amino acid deep eutectic solvent and a preparation method of the fluorescent substance. The fluorescent substance based on the amino acid deep eutectic solvent comprises the following ingredients: the deep eutectic solvent and rare earth chloride at a mass ratio of (10-20):1, wherein rare earth chloride is at least one of europium chloride, lanthanum chloride, terbium chloride or gadolinium chloride; and the deep eutectic solvent comprises an alcohol compound andamino acid at a mole ratio of (5-10):1. The fluorescent substance based on the amino acid deep eutectic solvent can achieve a uniform luminescence effect, and is good in heat stability, green and environmentally friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

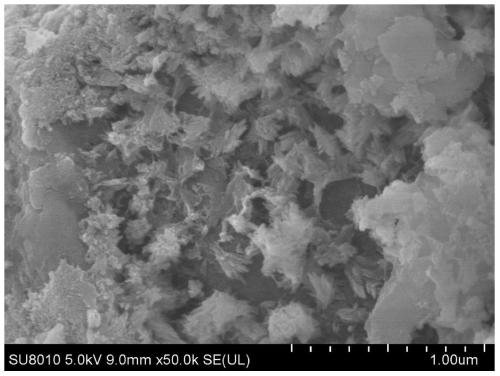

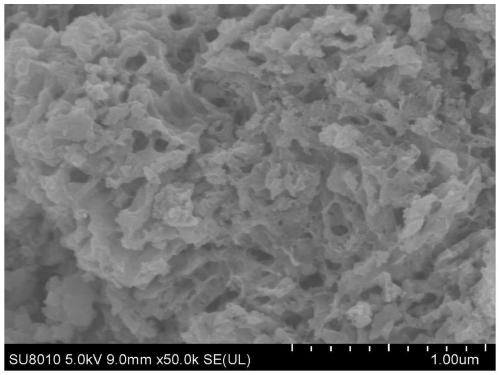

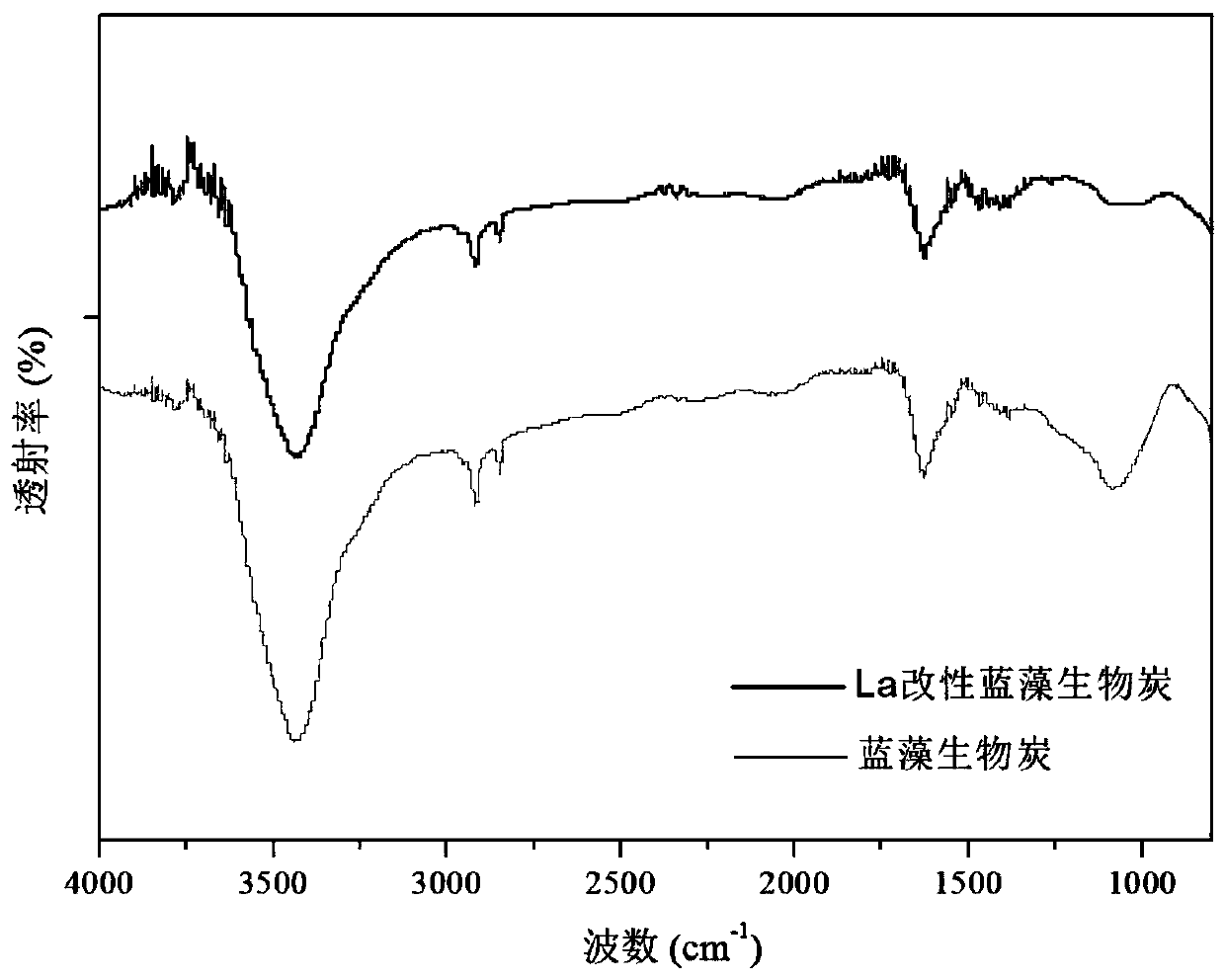

Modified biochar and preparation method, use method and recycling method thereof

InactiveCN111569830ARealize resource utilizationSolve the accumulationOther chemical processesWater contaminantsEngineeringEnvironmental engineering

The invention discloses modified biochar and a preparation method, a use method and a recycling method thereof. The modified biochar is lanthanum chloride modified cyanobacteria biochar, the mass ratio of cyanobacteria to lanthanum chloride is 1: (2.5-5), and the preparation method comprises the following steps: drying cyanobacteria, and adding the dried cyanobacteria into a lanthanum chloride solution for dipping modification; and filtering, drying, pyrolyzing and grinding the cyanobacteria subjected to dipping modification. The invention also provides the recycling method of the modified biochar. The modified biochar has advantages of efficient adsorption, low cost and environmental protection, and the preparation method has characteristics of simple operation, low production cost, environmental protection of raw materials, and is suitable for large-scale industrial production.

Owner:NANJING NORMAL UNIVERSITY

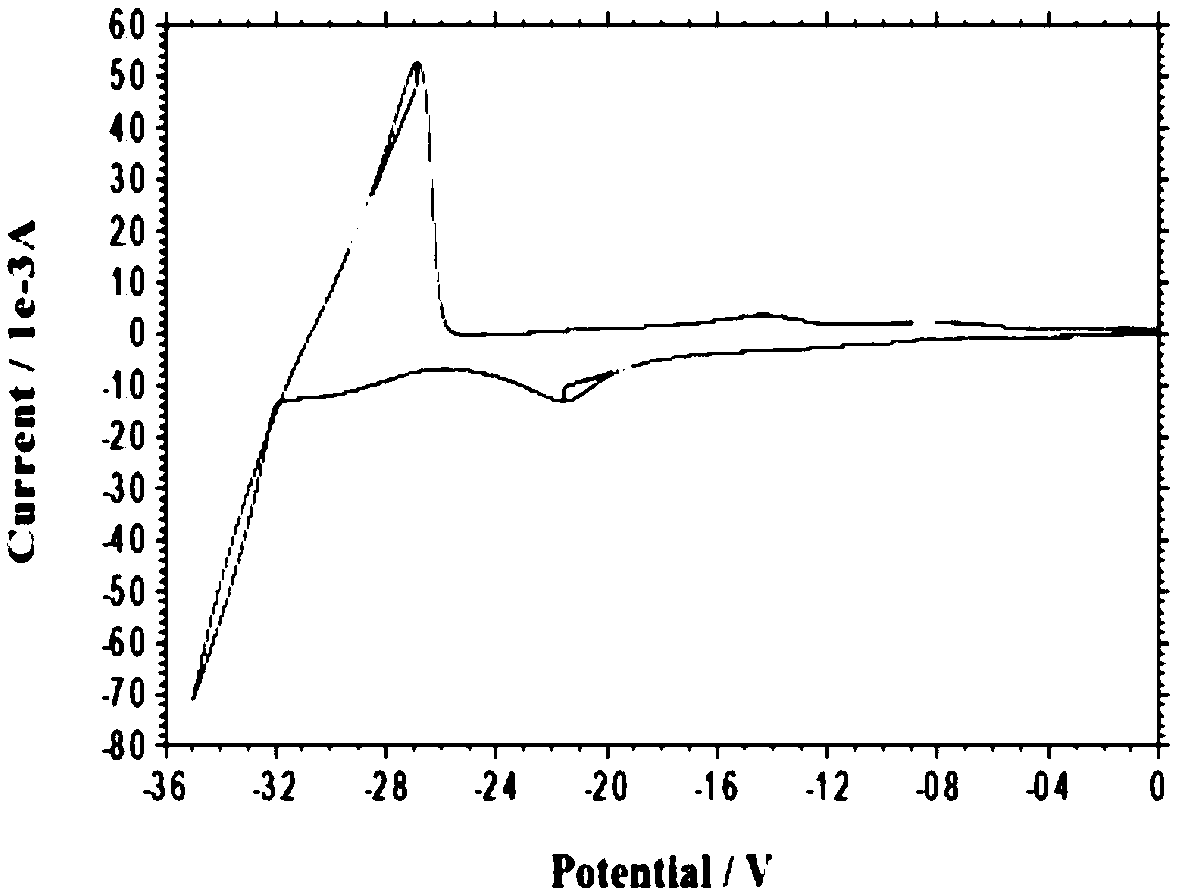

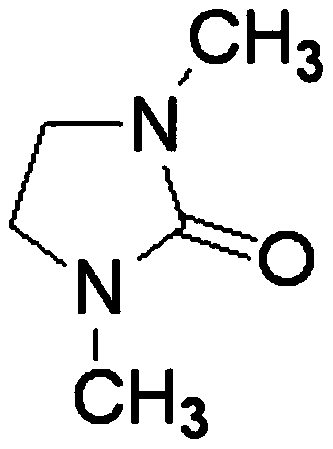

Method for preparing lanthanum metal by low-temperature electrodeposition by taking lanthanum chloride as raw material

ActiveCN109136990AShort processReduce production energy consumptionPhotography auxillary processesProcess efficiency improvementRare earthLanthanum(III) chloride

The invention relates to a method for preparing lanthanum metal by low-temperature electrodeposition by taking lanthanum chloride as a raw material and belongs to the field of low-temperature extraction of rare earth metals. The method for preparing the lanthanum metal by the low-temperature electrodeposition by taking the lanthanum chloride as the raw material comprises the following process steps: dissolving lithium nitrate in DMI at a room temperature to obtain a DMI electrolyte of the lithium nitrate, putting the DMI electrolyte of the lithium nitrate in an electrolytic bath, adding anhydrous lanthanum chloride, and stirring and mixing in the electrolytic bath to form a uniform transparent system, wherein the temperature of the whole system is controlled to be 25-75 DEG C, and the electrolytic voltage range is controlled to be from -2.0 to -2.5 V vs Ag; in the electrolytic process, adding the anhydrous lanthanum chloride in the electrolytic bath at set intervals and controlling themolar concentration of the lanthanum chloride to be + / -3 percent of the starting concentration. The method provided by the invention has the advantage that while the rare earth lanthanum metal is efficiently prepared, the energy consumption and the production cost are significantly reduced.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com