Preparation method and applications of lanthanum-loaded biochar arsenic-removing adsorbent

A biochar and adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as poor adsorption capacity, and achieve the effect of simple operation, low cost, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

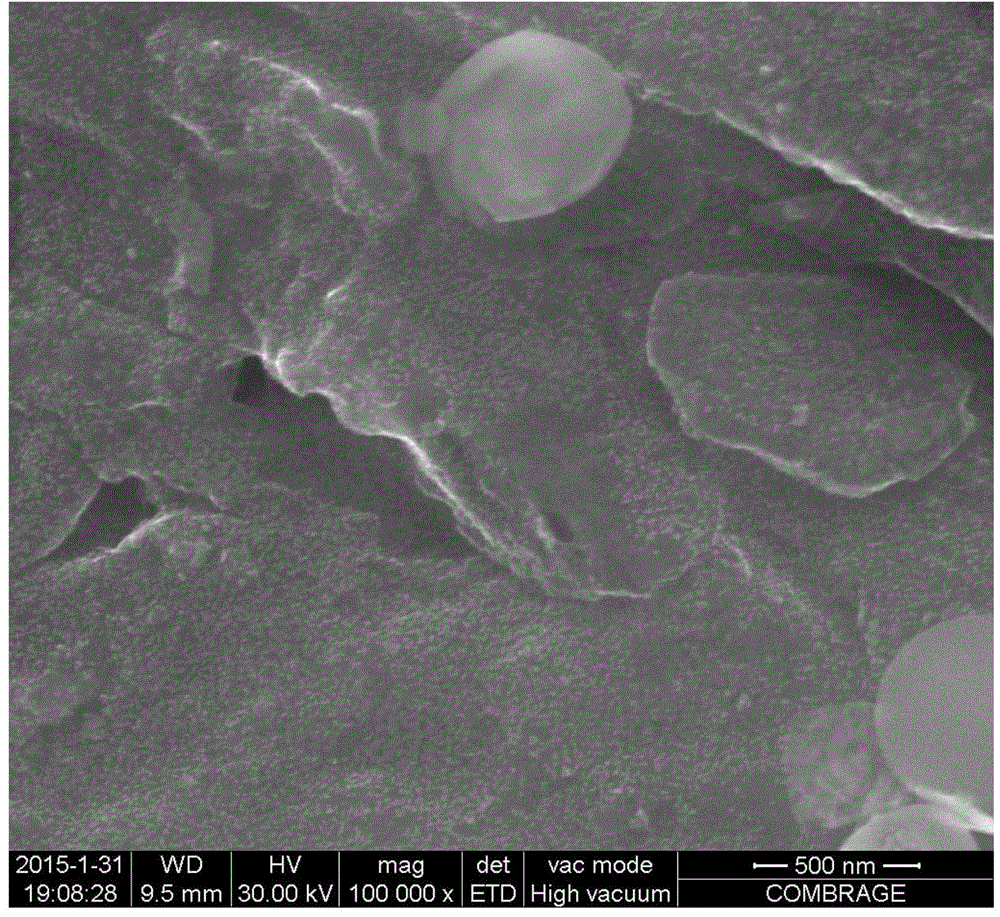

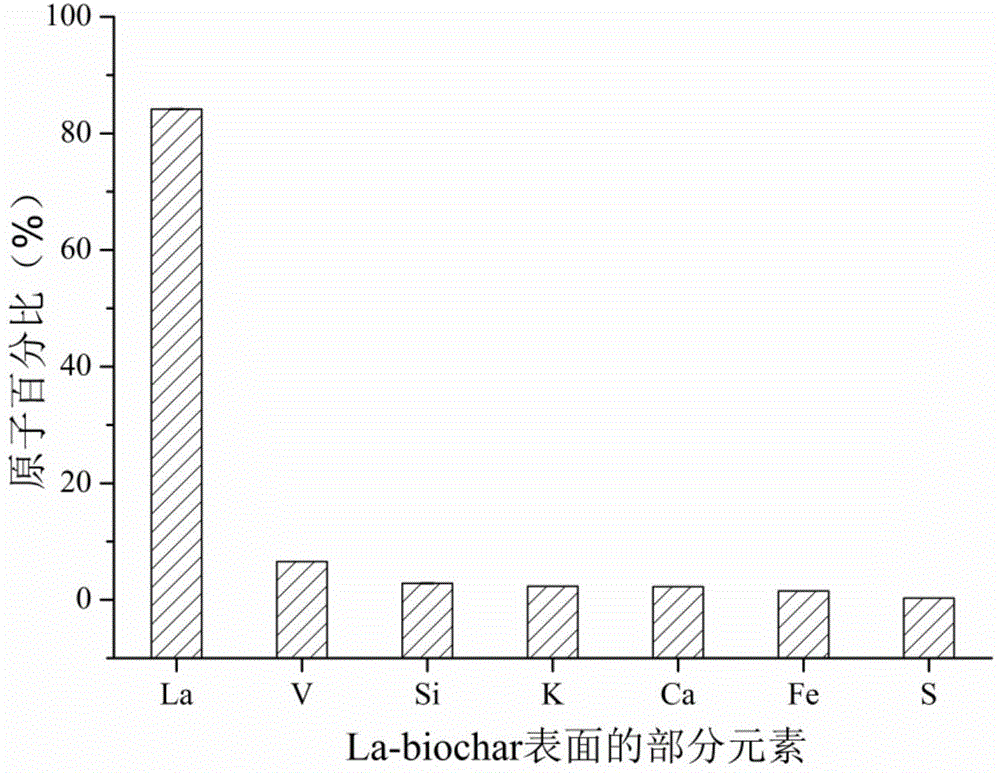

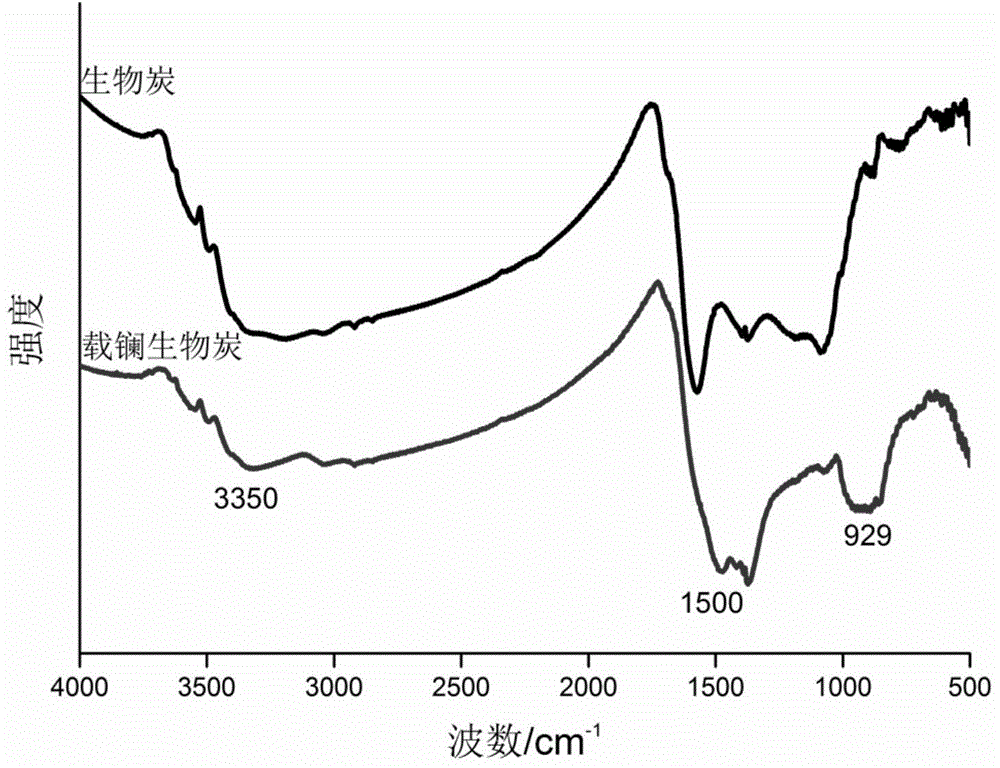

[0030] Use corn stalks as raw materials, wash and remove impurities, air-dry, crush, and pass through a 2mm sieve. Add 10 g of sieved corn stalk powder to 100 mL solution containing 1.2 g lanthanum chloride heptahydrate, add NaOH solution dropwise to the above mixed solution while stirring until the pH of the mixed solution is 8, and continue stirring for 30 min. The product obtained by stirring is centrifuged at a centrifugal speed of 2000 rpm and a centrifugation time of 2 min. After the centrifugation, the supernatant is discarded, and the remaining sediment solid is washed with 95% ethanol until no Cl is detected in the eluent. - (using 0.1M AgNO 3 to test). The cleaned solids were dried to constant weight, placed in a muffle furnace for anaerobic roasting, raised to 200°C at a heating rate of 20°C / min, and kept at this temperature for 10 minutes, and the carbonized product was taken out after cooling to room temperature , using deionized water to wash repeatedly until t...

Embodiment 2

[0032] Use corn stalks as raw materials, wash and remove impurities, air-dry, crush, and pass through a 2mm sieve. Add 10 g of sieved corn stalks to 100 mL of solution containing 2.06 g of lanthanum chloride heptahydrate, add NaOH solution dropwise to the above mixed solution while stirring until the pH is 10, and continue stirring for 60 min. The product obtained by stirring is centrifuged at a speed of 3500 rpm and a centrifugation time of 5 min. After the centrifugation, the supernatant is discarded, and the remaining sediment solid is washed with 95% ethanol until no Cl is detected in the eluent. - (using 0.1M AgNO 3 to test). The cleaned solids were dried to constant weight, placed in a muffle furnace for anaerobic roasting, raised to 300°C at a heating rate of 20°C / min, and kept at this temperature for 20 minutes, and the carbonized product was taken out after cooling to room temperature , using deionized water to wash repeatedly until the pH of the eluent is neutral, ...

Embodiment 3

[0034] Use corn stalks as raw materials, wash and remove impurities, air-dry, crush, and pass through a 2mm sieve. Add 10 g of sieved corn stalks to 100 mL solution containing 3 g of lanthanum chloride heptahydrate, add NaOH solution dropwise to the above mixed solution while stirring until the pH is 12, and continue stirring for 300 min. The product obtained by stirring is centrifuged at a speed of 5000 rpm and a centrifugation time of 10 min. After the centrifugation, the supernatant is discarded, and the remaining sediment solid is washed with 95% ethanol until no Cl is detected in the eluate. - (using 0.1M AgNO 3to test). The cleaned solids were dried to constant weight, placed in a muffle furnace for anaerobic roasting, raised to 600°C at a heating rate of 20°C / min, and kept at this temperature for 100 minutes, and the charred product was taken out after cooling to room temperature , use deionized water to wash repeatedly until the pH of the eluent is neutral, dry, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com