Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Holmium(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

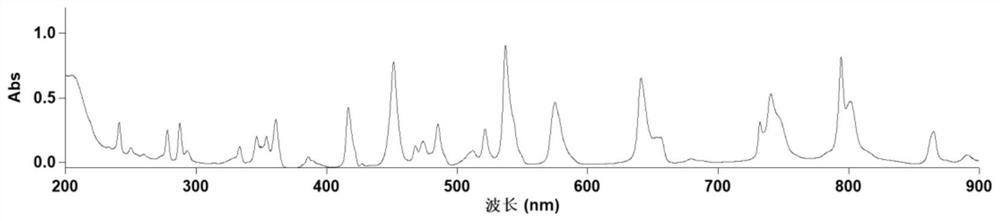

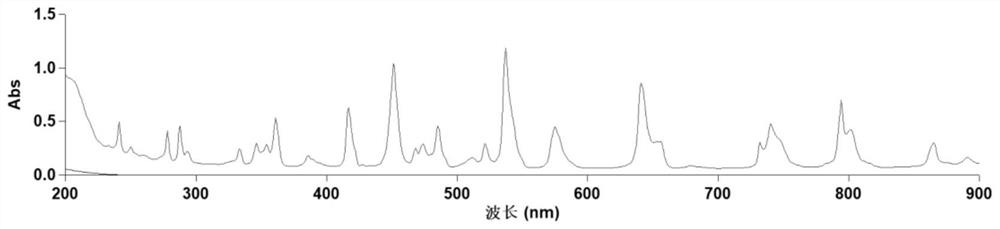

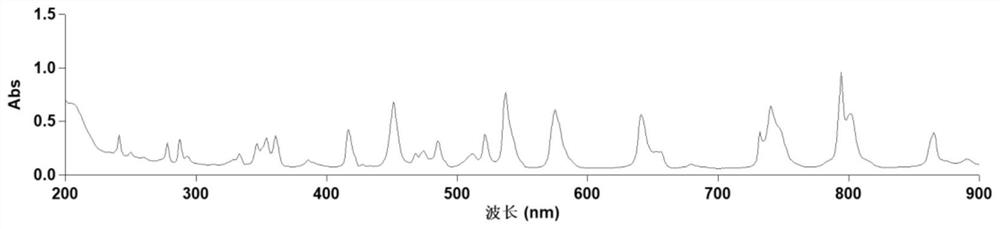

Holmium(III) oxide, or holmium oxide is a chemical compound of a rare-earth element holmium and oxygen with the formula Ho₂O₃. Together with dysprosium(III) oxide (Dy₂O₃) holmium oxide is one of the most powerfully paramagnetic substances known. The oxide, also called holmia, occurs as a component of the related erbium oxide mineral called erbia. Typically the oxides of the trivalent lanthanides coexist in nature and separation of these components requires specialized methods. Holmium oxide is used in making specialty colored glasses. Glass containing holmium oxide and holmium oxide solutions have a series of sharp optical absorption peaks in the visible spectral range. They are therefore traditionally used as a convenient calibration standard for optical spectrophotometers.

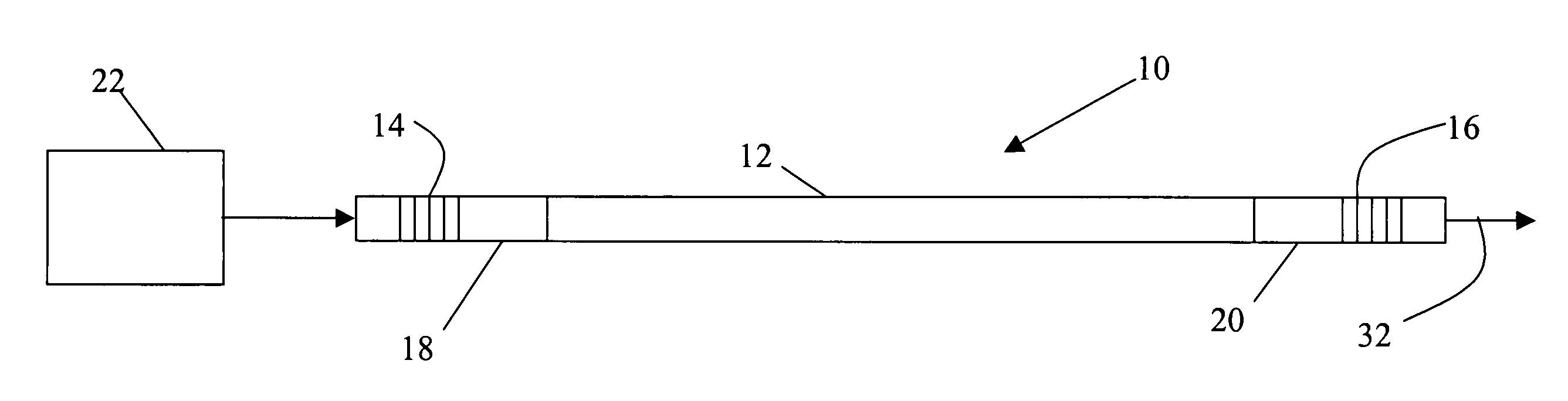

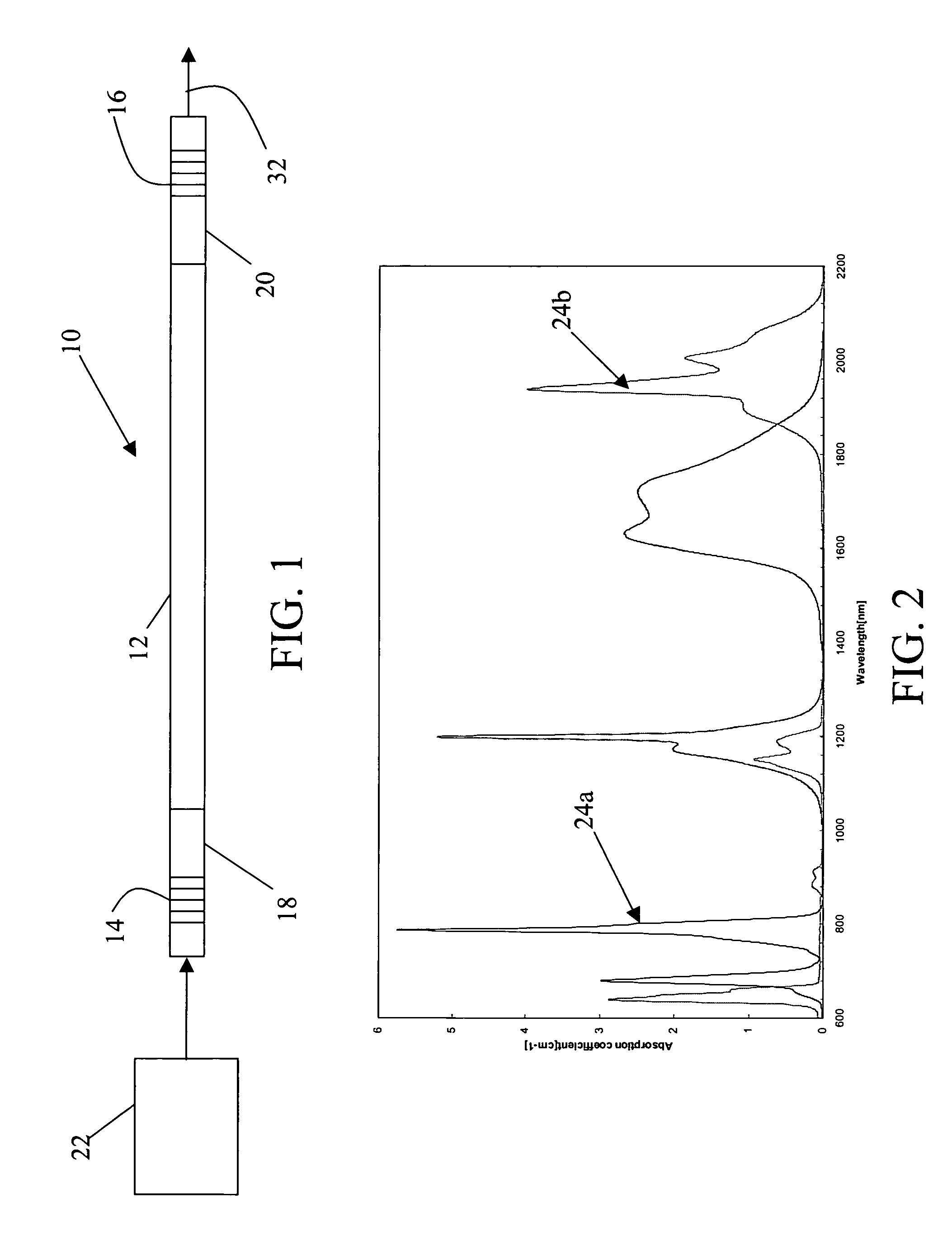

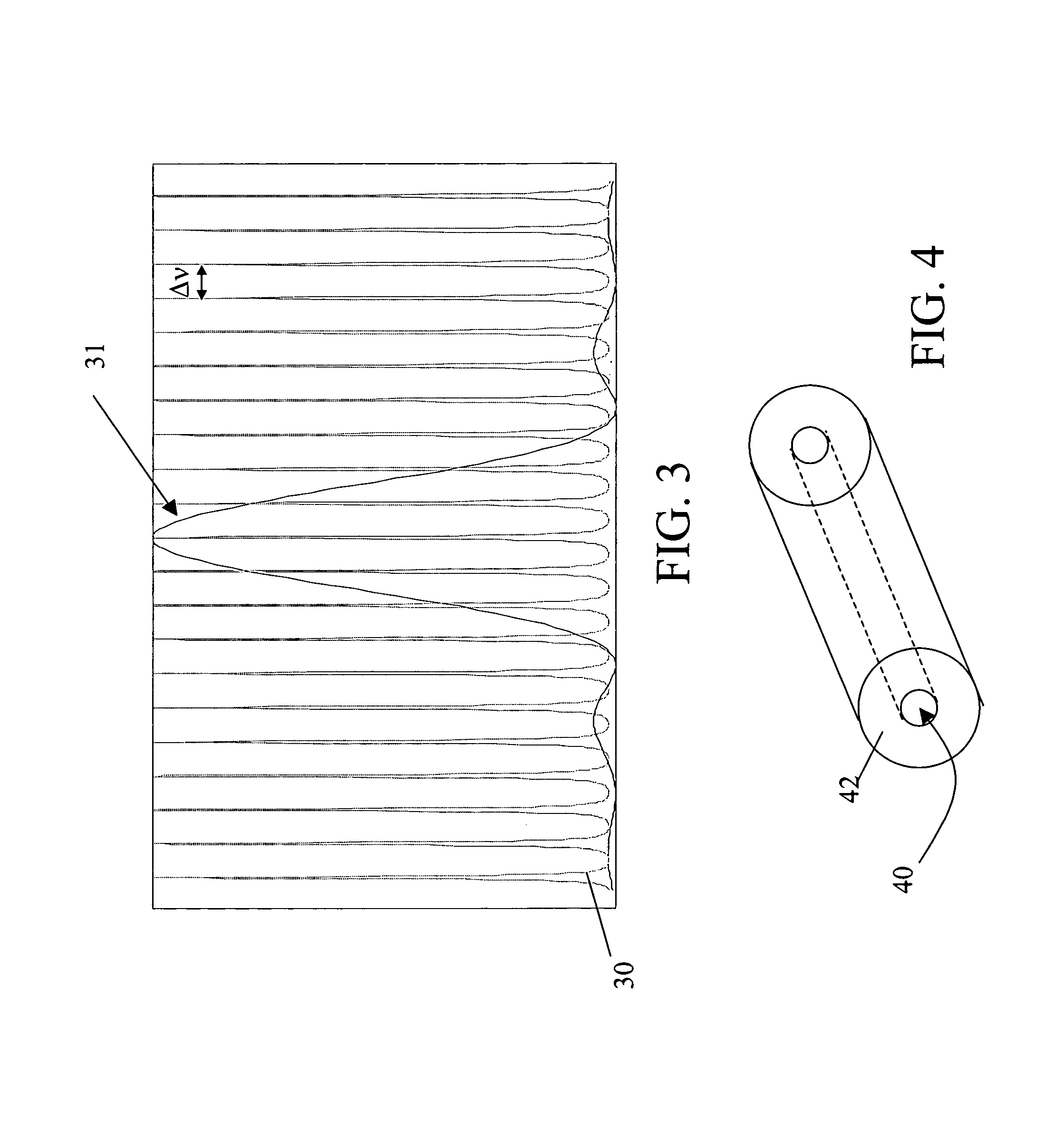

Single-frequency narrow linewidth 2 μm fiber laser

InactiveUS7106762B1Facilitating splicingGuaranteed uptimeLaser using scattering effectsOptical resonator shape and constructionLow noiseGrating

Owner:NP PHOTONICS A CORP OF DELAWARE

Up converting fluorescent material with nanometer level molybdate substrate and its prepn

The present invention belongs to the field of nano fluorescent material. Lanthanum oxide (or yttrium or gadolinium oxide), ytterbium oxide and erbiom oxide (or thulium or holmium oxide) are first dissolved in acid to prepare solution; complexone and sodium or potassium molybdenate are added into the solution to produce precipitate, which is centrifugally separated and water washed to prepare aqueous gel, aqueous gel or further prepared alcoholic gel is finally cinerated in a high temperature furnace or heated in a hydrothermal reactor to obtain the nano level up converting fluorescent material. The said material has lanthanum molybdenate as matrix and ytterbium molybdenate and erbium molybdenate as dopant. The material thus prepared has small and homogeneous size, average size 50-60 nm and high light glowing strength and may meet the requirement as biological molecular fluorescent mark material.

Owner:CAPITALBIO CORP +1

Method for preparing Ho-Fe alloy through molten salt electrolysis

The invention discloses a method for preparing Ho-Fe alloy through molten salt electrolysis, wherein a graphite crucible serves as an electrolyzer, a graphite flake serves as an anode, a pure iron rod serves as a cathode, a ferric crucible serves as a metal receiver, and holmium oxide serves as a raw material; and holmium fluoride and lithium fluoride serve as a binary system electrolyte and then are electrolyzed in a certain condition. The method comprises the following steps of: (1) drying the electrolyzer through an arching machine or a heating element oven; (2) switching on the power of the arching machine to 45kW, and continuously adding an electrolyte into the furnace continuously; (3) after the electrolyte is melted to a part which is 10cm far away from the upper edge of the electrolyzer, placing an iron crucible in the center of a furnace bottom, placing the pure iron rod above the iron crucible, and feeding a direct current to start electrolysis; (4) adding a small quantity of holmium oxide repeatedly or continuously and evenly adding holmium oxide during the electrolytic process, and intermittently adjusting the pure iron rod once intermittently; and (5) after the electrolysis is carried out for a period of time, taking out the iron crucible, pouring to obtain an ingot, and demoulding to obtain the Ho-Fe alloy after the cooling. The Ho-Fe alloy obtained by the invention is low in energy consumption, high in capacity and small in deviation, so that the Ho-Fe alloy is convenient for mass production.

Owner:JIANGSU JINSHI RARE EARTH CO LTD

Fused silica ceramic material containing holmium oxide and preparation method thereof

The invention relates to a fused silica ceramic material containing holmium oxide and a preparation method thereof, belonging to the field of high-temperature structural ceramic materials. The ceramic material is prepared from the following materials by weight percentage: 97% to 99% of fine fused silica powder and 1% to 3% of fine holmium oxide powder. The preparation method comprises the following steps: dry-mixing the fine fused silica powder and the fine holmium oxide powder; wet-mixing the mixture by adding polyvinyl alcohol solution as binding agent; further sieving, stirring and ageing the mixture to obtain the perform body for molding the green body; molding the green body by a hydraulic press with the molding pressure being higher than or equal to 50MPa; drying and sintering the green body at 1,200 to 1,400 DEG C; and standing for 1 to 3 hours to obtain the fused silica ceramic material containing holmium oxide. The invention provides a novel high-temperature structural material for glass melting, ferrous and non-ferrous metallurgy, electronics, military missiles, spacecraft and other fields in China and has wide application prospect and great significance in strengthening the national defense.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

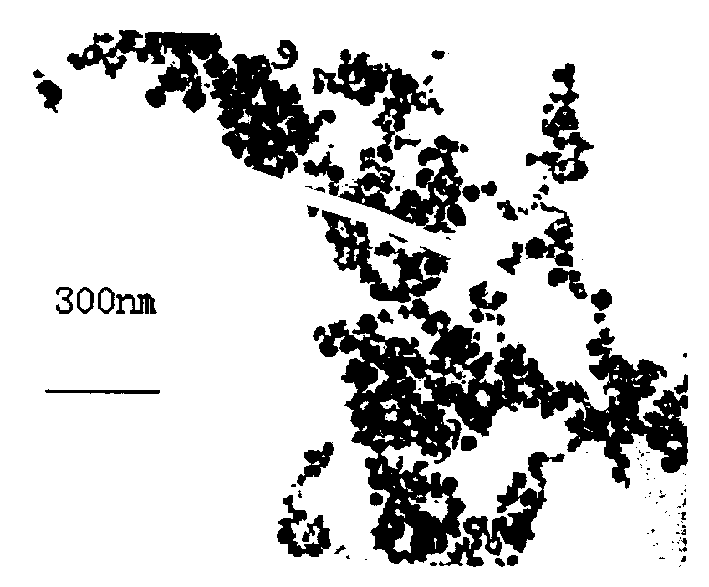

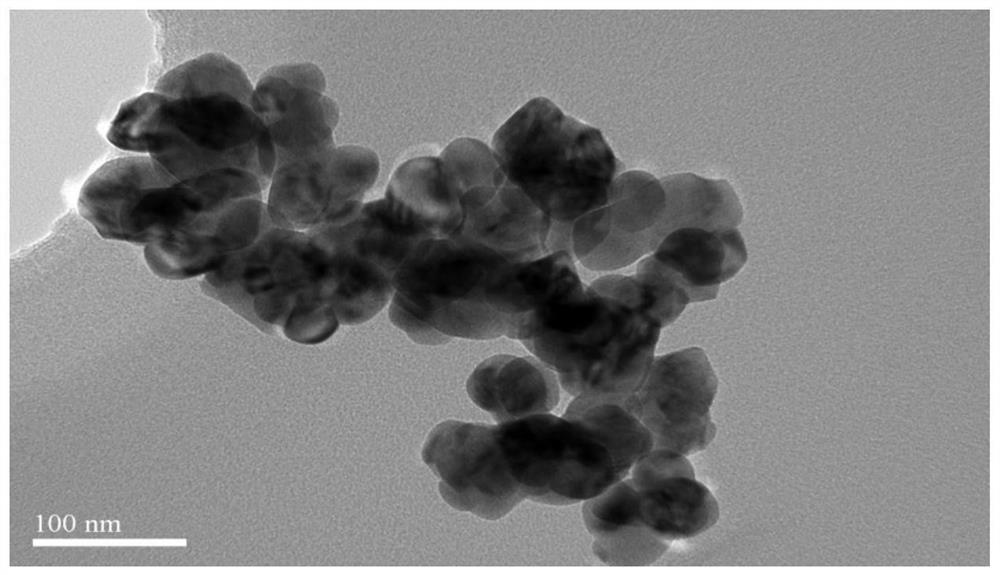

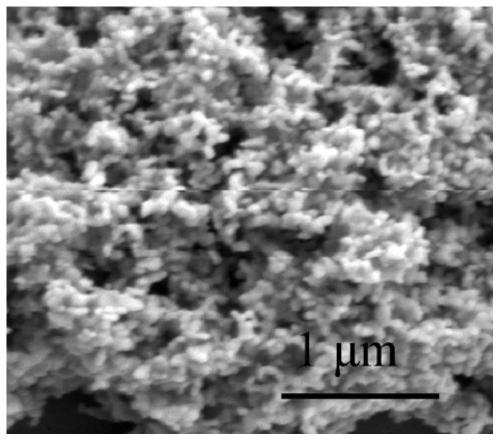

Nano-holmium oxide preparation method

InactiveCN106830047APositive effectUniform particlesMaterial nanotechnologyRare earth metal compoundsHolmiumRare earth

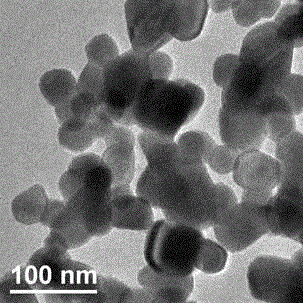

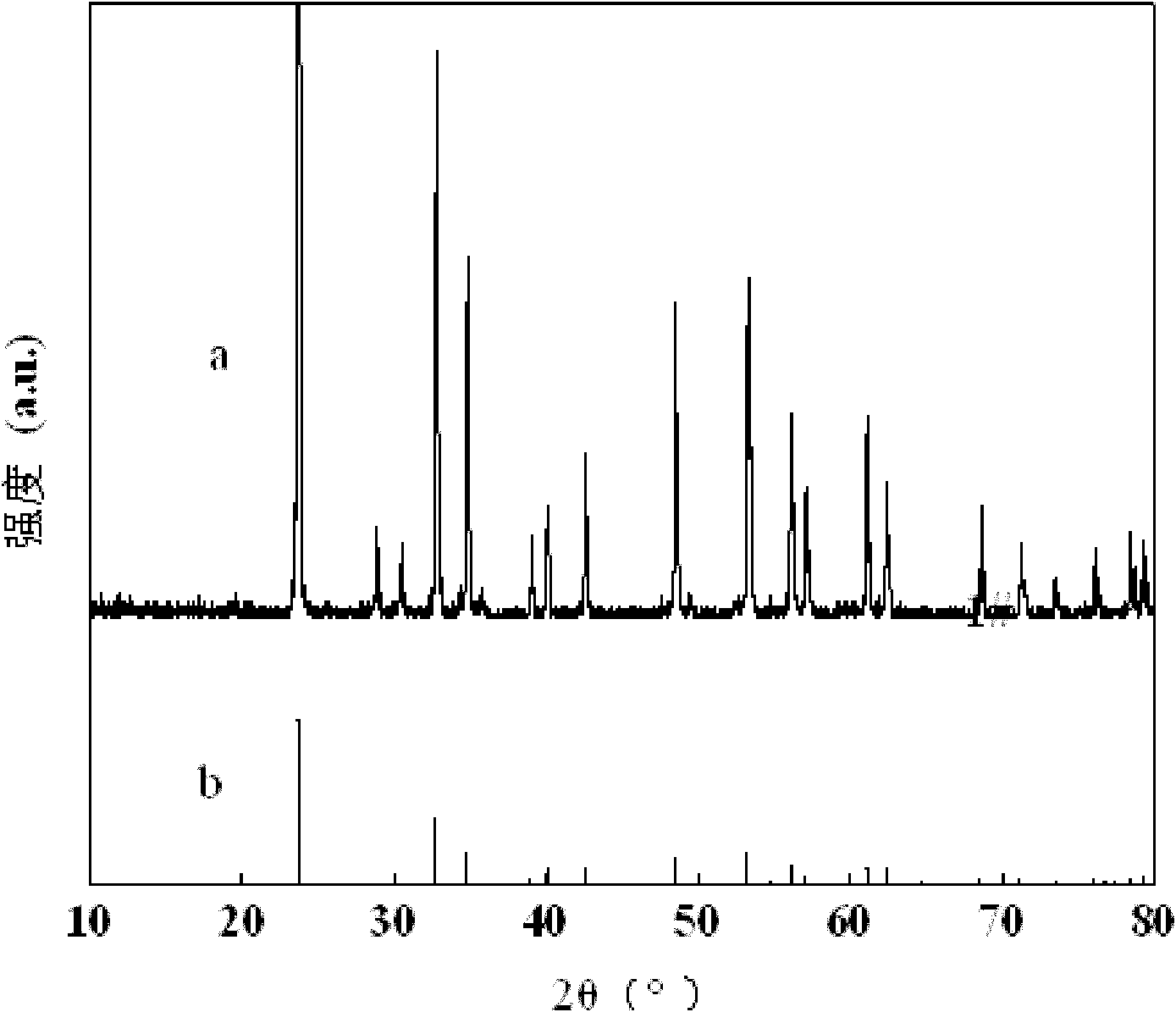

The invention relates to a nano-holmium oxide preparation method and belongs to the technical field of preparation of rare earth compounds. The nano-holmium oxide preparation method is characterized in that holmium oxide has the specific surface area of about 20 m<2> / g and the grain size of 50-70 nm, and grains are uniformly distributed in grain size. The nano-holmium oxide preparation method is simple in process condition, low in production cost and easy for realization of industrial production, and the whole preparation process conforms to the environmental requirement.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Ytterbium and holmium codoped lithium niobate crystals and preparation method thereof

InactiveCN102127814AImprove up-conversion luminous efficiencyGood resonance absorptionPolycrystalline material growthBy pulling from meltYTTERBIUM OXIDEHolmium

The invention discloses ytterbium and holmium codoped lithium niobate crystals and a preparation method thereof, and relates to doped lithium niobate crystals and a preparation method thereof, which solve the technical problems that the conventional lithium niobate crystals cannot be used as a laser crystal material. The ytterbium and holmium codoped lithium niobate crystals are prepared from niobium pentaoxide, lithium carbonate, ytterbium oxide and holmium oxide. The method comprises the following steps of: mixing the niobium pentaoxide, the lithium carbonate, the ytterbium oxide and the holmium oxide and baking to obtain polycrystal powder; growing crystals at equal diameter from the polycrystal powder in a single crystal growth furnace through seeding, necking, shouldering and folding by a crystal pulling method; and annealing to obtain the ytterbium and holmium codoped lithium niobate crystals. The ytterbium and holmium codoped lithium niobate crystals can emit red light and green light when activated by laser of 980nm and has a broad application prospect in the fields of optical data storage, submarine communication, optical display, color display, photoelectrons, medical diagnosis and the like.

Owner:HARBIN INST OF TECH

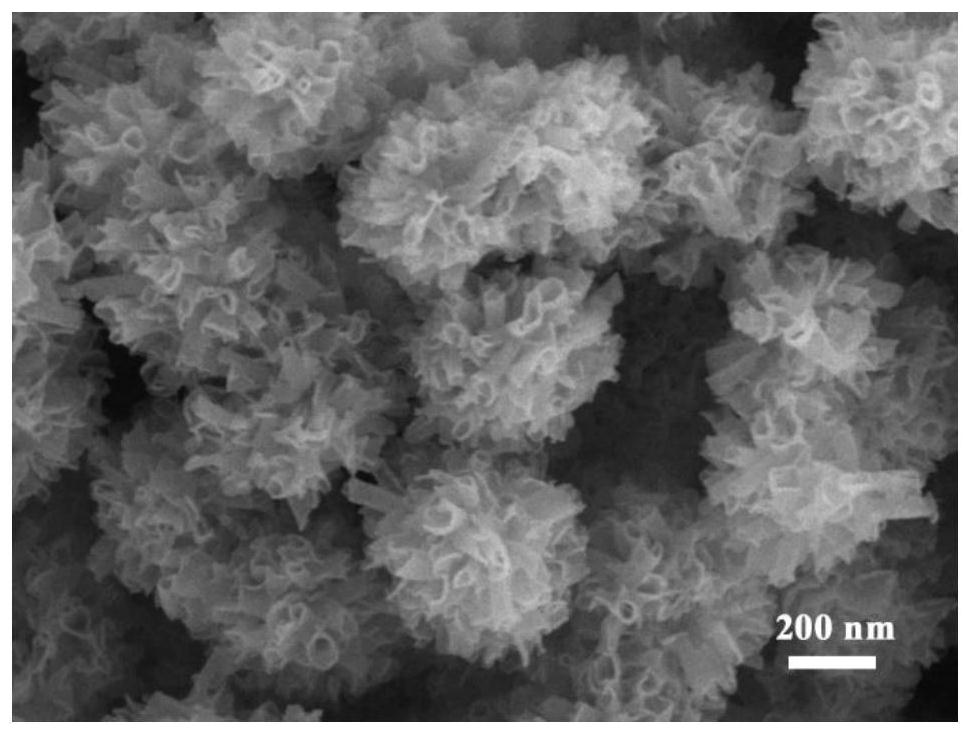

Method for preparing transparent magneto-optic holmium oxide ceramic

ActiveCN108358635AImprove optical qualityOvercome the problem of uneven distributionOxide ceramicRare earth

The invention discloses a method for preparing transparent magneto-optic holmium oxide ceramic. The method comprises the following steps: preparing a holmium nitrate solution and an ammonium fluoridesolution; dropwise adding ammonia water to the holmium nitrate solution, and performing aging to obtain a white precipitate; filtering and washing the white precipitate, adding the filtered and washedwhite precipitate to the ammonium fluoride solution, and performing a reaction to obtain a rare earth holmium-based layered compound precursor containing a fluorion group; sequentially washing, drying, grinding and sieving the rare earth holmium-based layered compound precursor containing the fluorion group, and then calcining the precursor to obtain holmium oxide nano-powder; and sequentially performing pre-pressing and cold isostatic press molding on the holmium oxide nano-powder, performing high-temperature pressureless sintering on the cold isostatic press molded product, and machining the high-temperature pressureless sintered product to obtain the transparent holmium oxide ceramic. The method avoids the problem of non-uniform distribution of a fluoride additive, and the prepared holmium oxide ceramic has good optical performances.

Owner:NINGBO UNIV

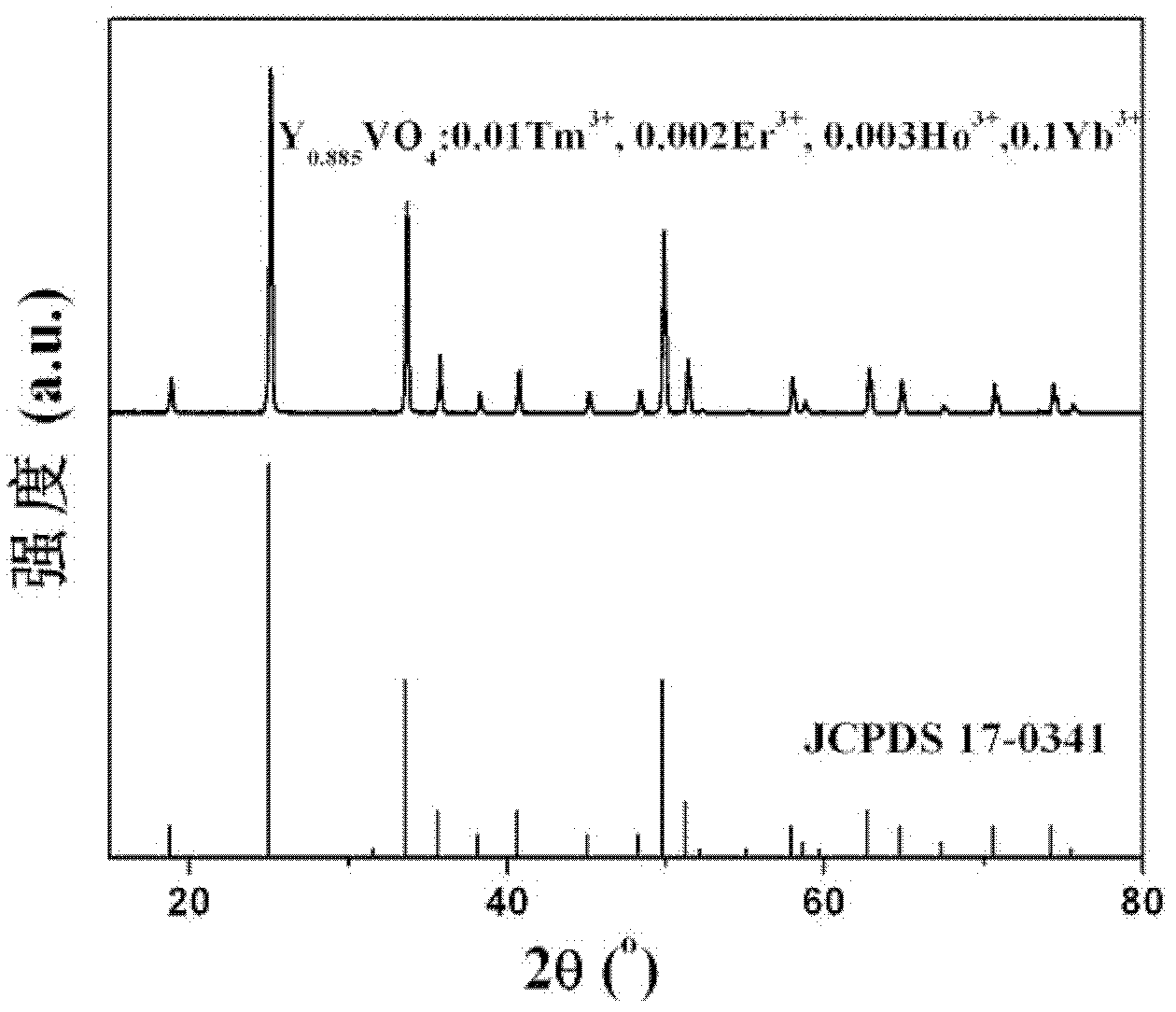

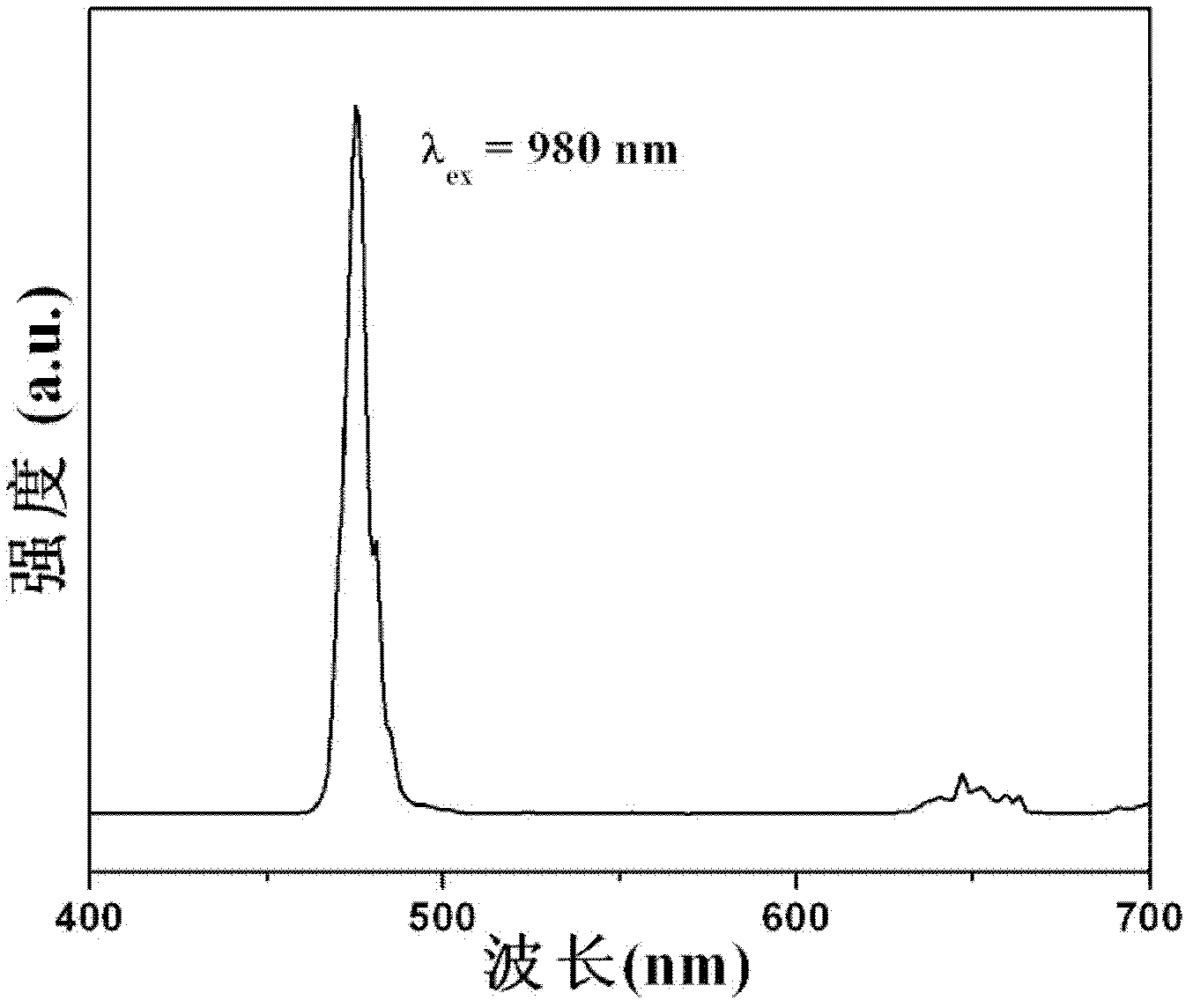

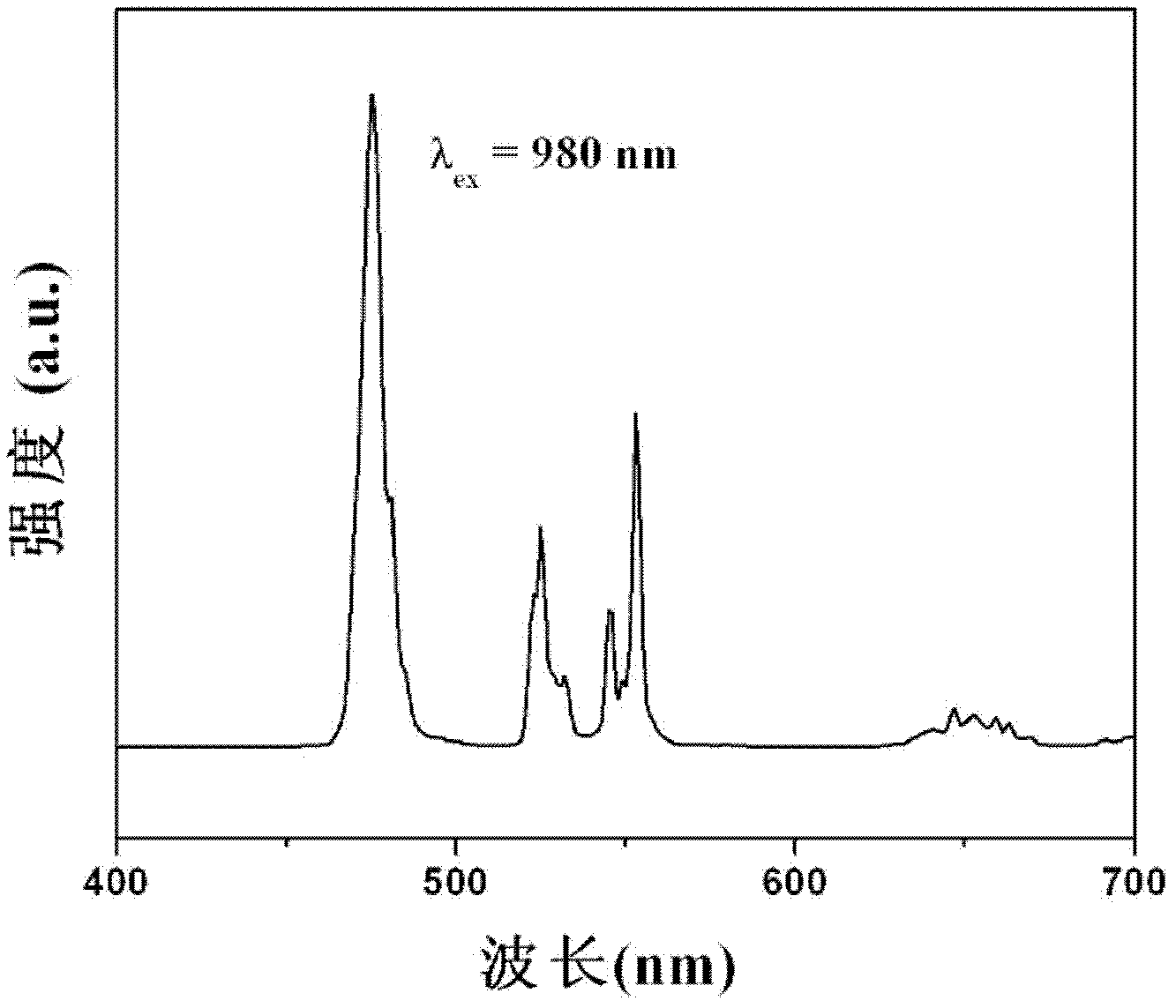

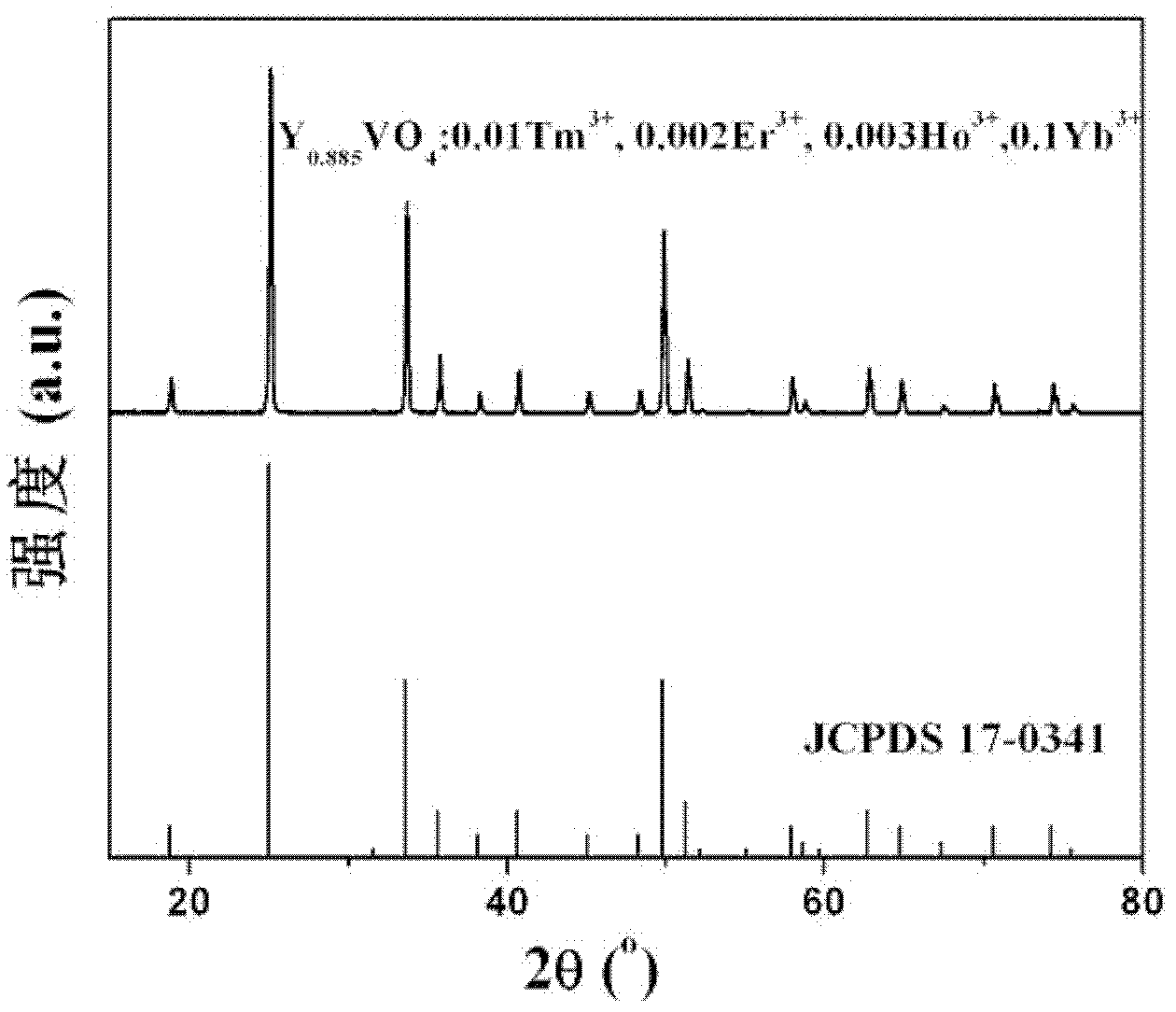

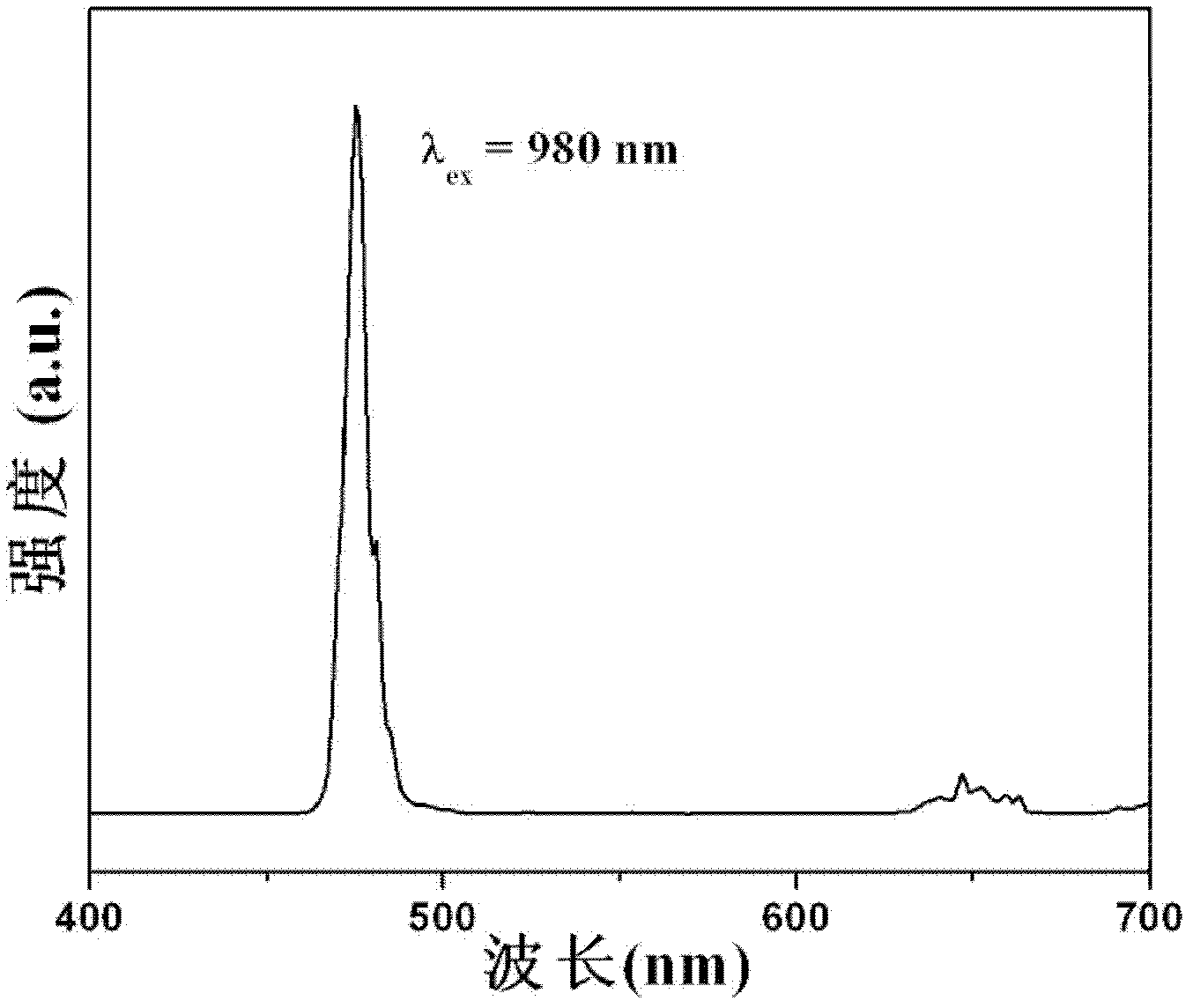

Vanadate upconversion material fluorescent powder, and preparation method and application thereof

InactiveCN102585827AAvoid pollutionGas discharge lamp usageLuminescent compositionsYTTERBIUM OXIDEVanadate

The invention discloses vanadate upconversion material fluorescent powder, and a preparation method and application thereof. The vanadate upconversion material fluorescent powder has a chemical composition formula Y0.89-x-yVO4:0.01Tm<3+> / xEr<3+> / yHo<3+> / 0.1Yb<3+>, wherein x is 0 to 0.002, and y is 0 to 0.003. The invention also discloses the preparation method for the material, and the preparation method comprises the following steps of: weighing yttrium oxide, vanadium pentoxide, thulium oxide, holmium oxide, erbium oxide and ytterbium oxide in a molar ratio of the chemical composition formula, grinding and mixing uniformly, pre-sintering at the temperature of 650 DEG C, and keeping constant temperature of 650 DEG C for six hours; cooling, grinding again, sintering at the temperature of 1,200 DEG C, and keeping the constant temperature of 1,200 DEG C for six hours; and cooling to obtain the vanadate upconversion material fluorescent powder. The vanadate upconversion material fluorescent powder is high in luminous efficiency and stability and meets the requirement of a white light light-emitting diode (LED).

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

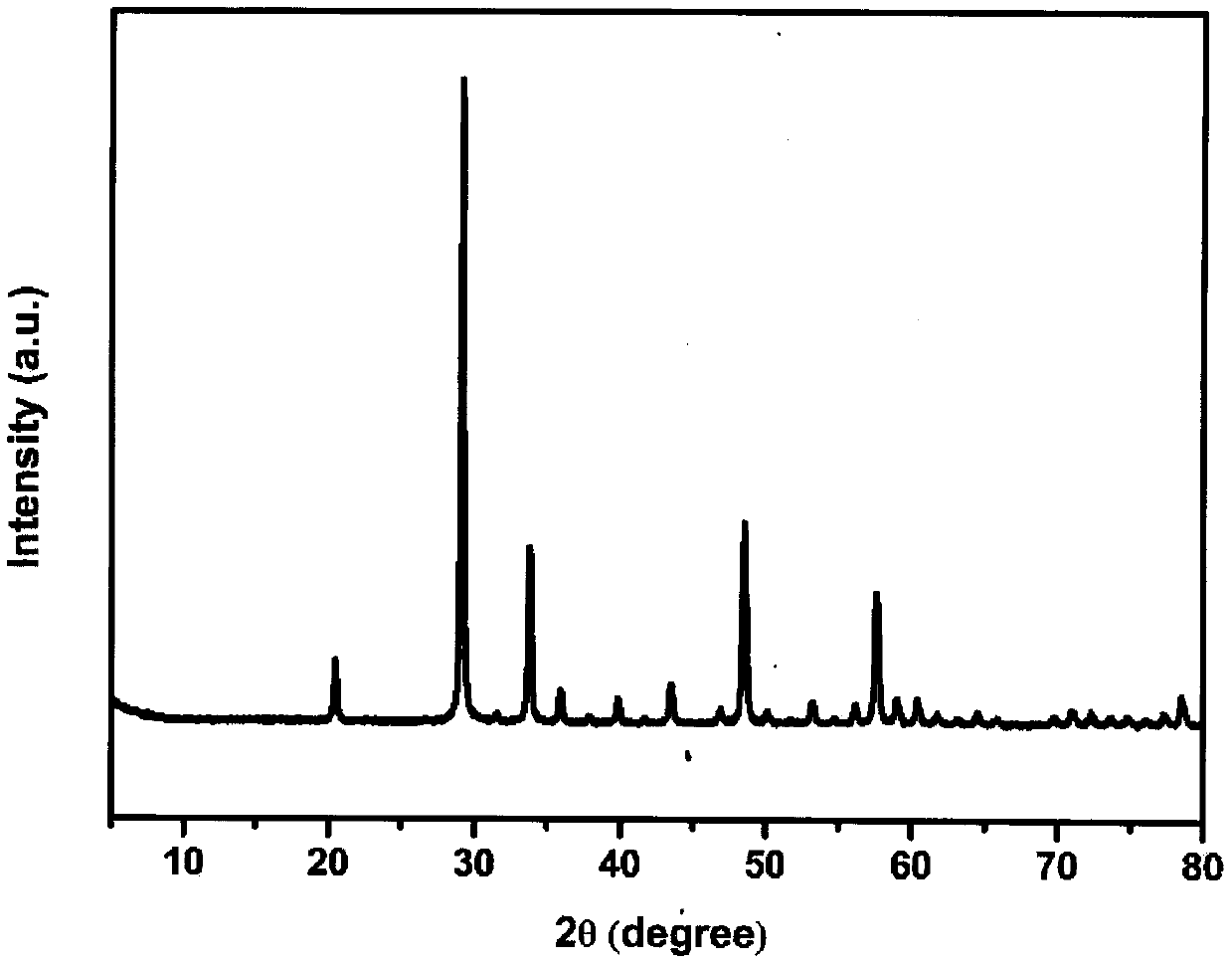

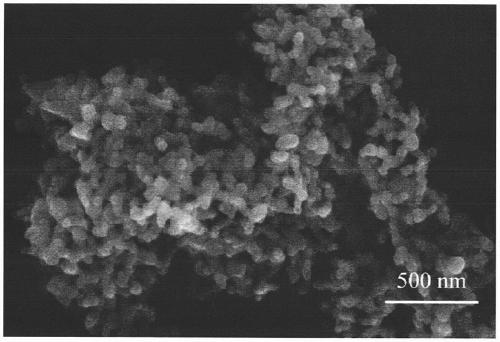

Rapid preparation method of Ho:Sc2O3 nano-crystal powder

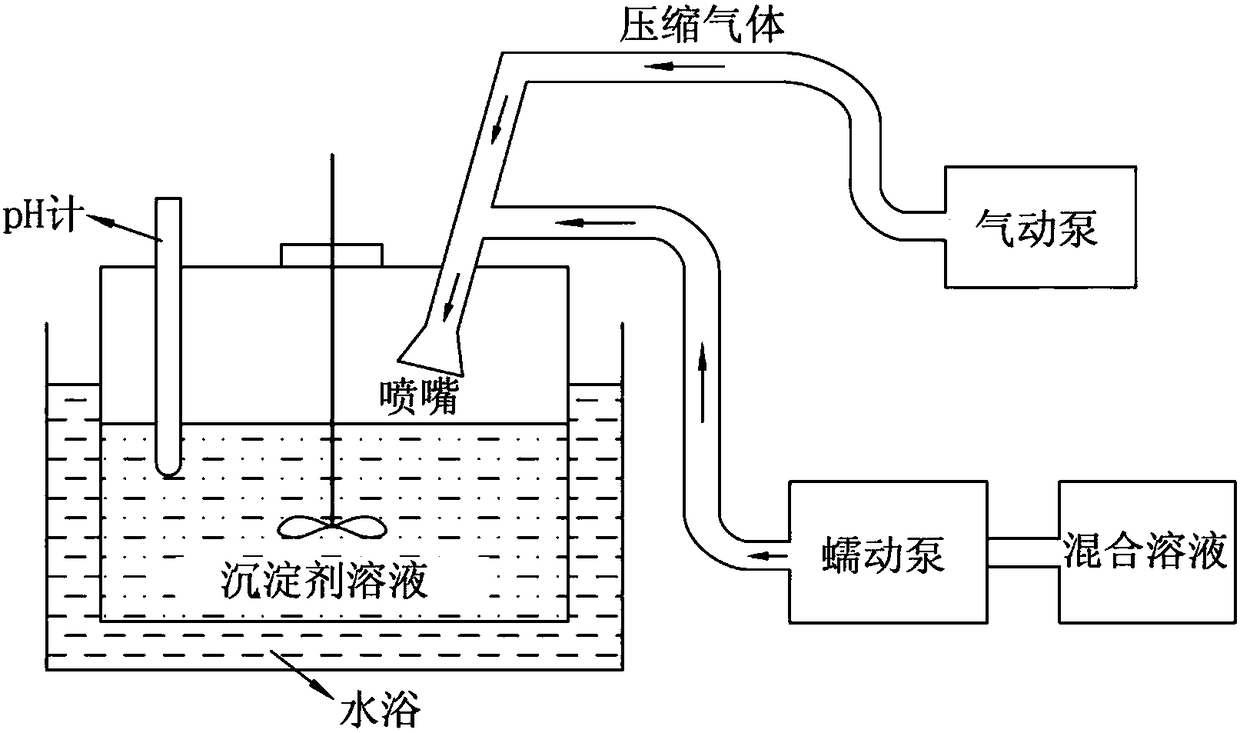

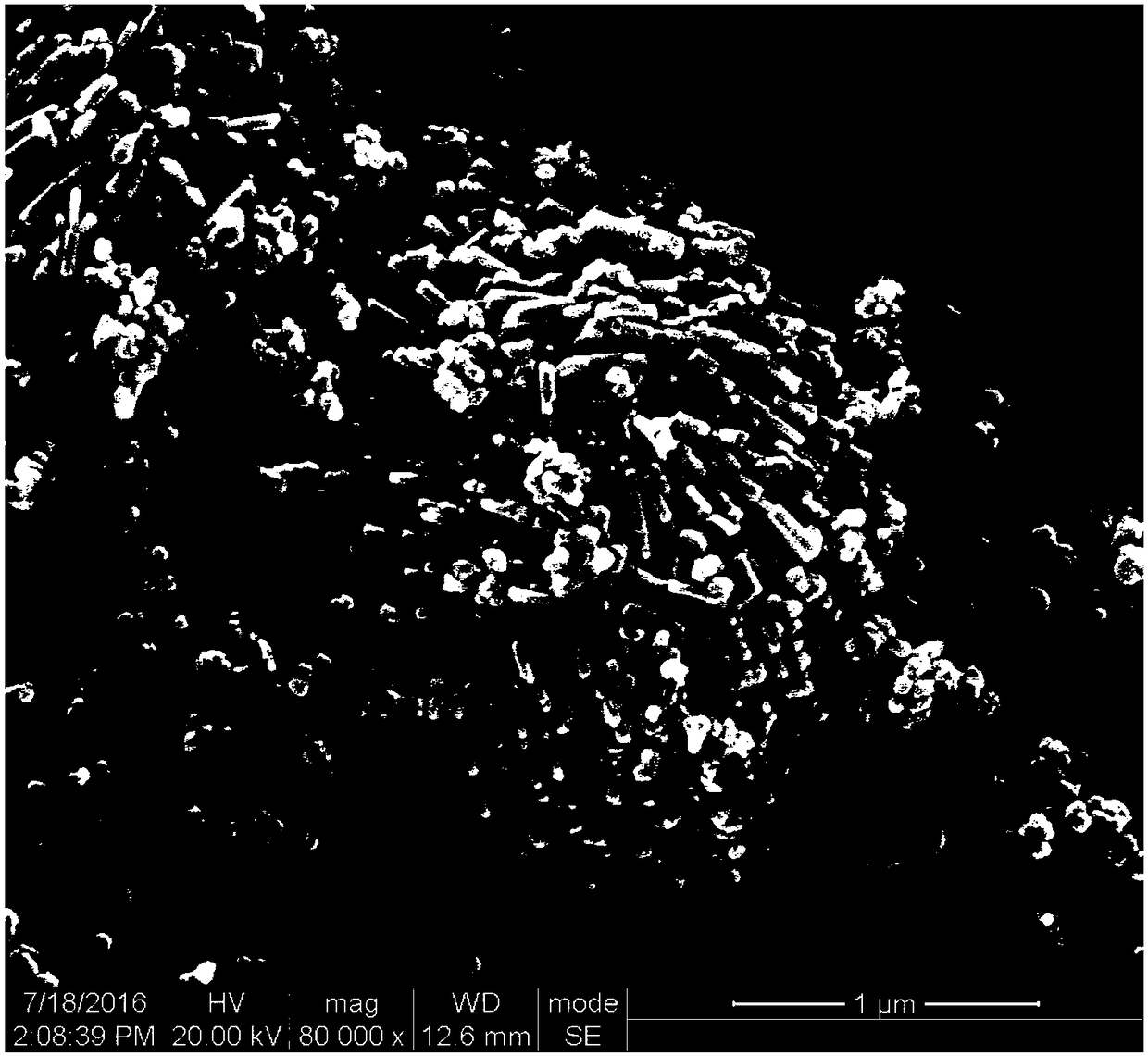

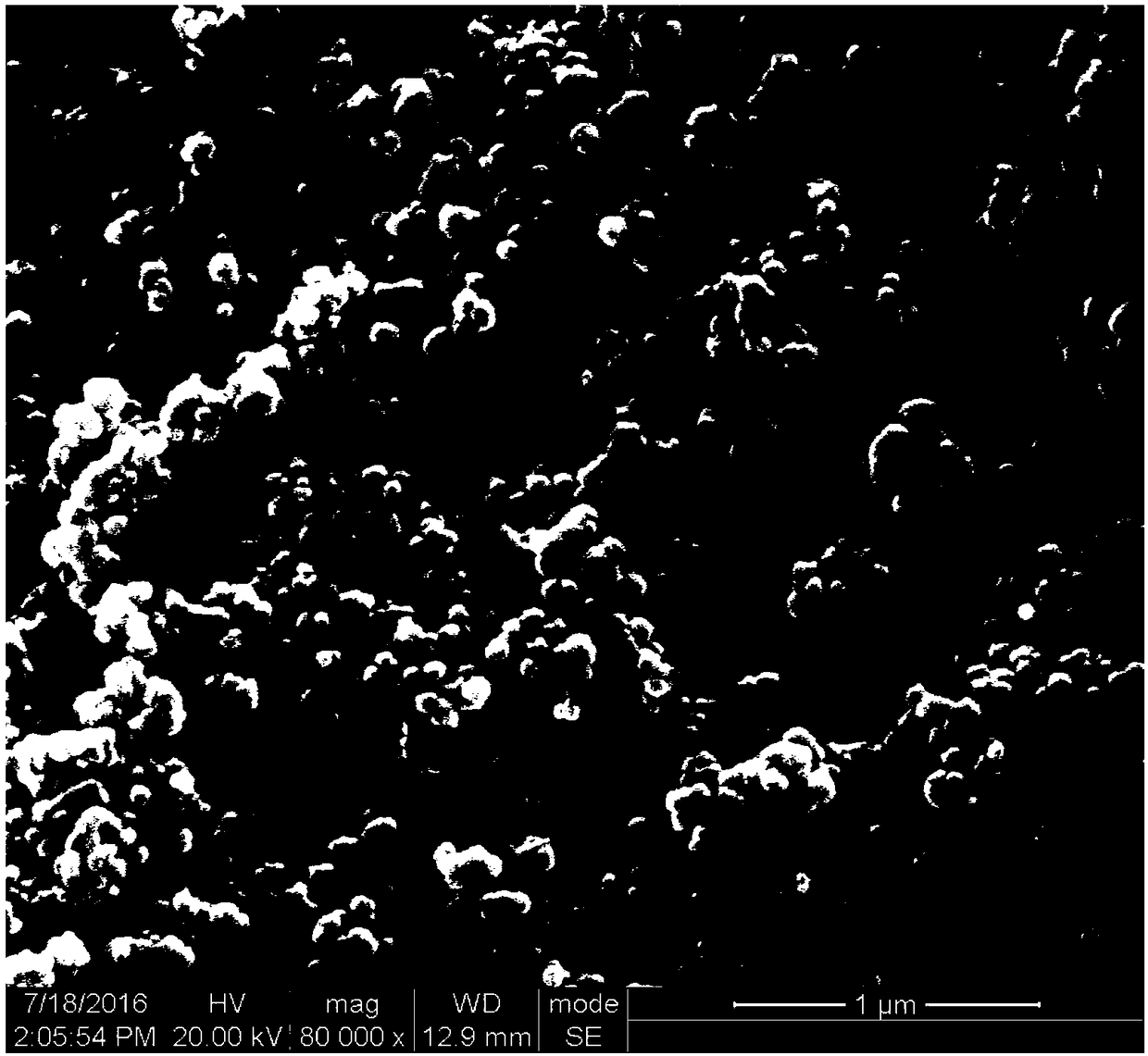

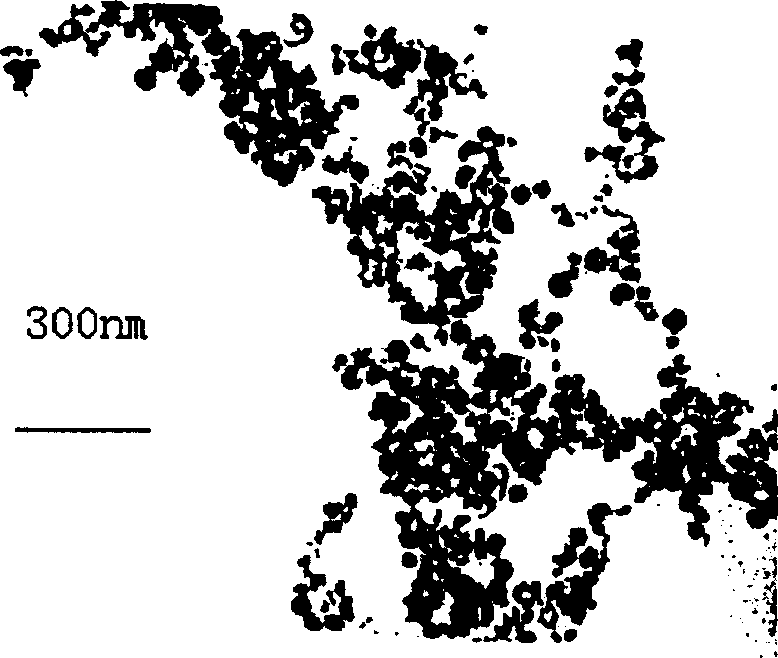

ActiveCN108069453AIncrease the drop rateEvenly dispersedRare earth metal oxides/hydroxidesNanotechnologyPeristaltic pumpHolmium

The invention discloses a rapid preparation method of a Ho:Sc2O3 nano-crystal powder. The rapid preparation method of the Ho:Sc2O3 nano-crystal powder comprises the steps of, firstly, preparing cationsalt solution, specifically, dissolving scandium oxide and holmium oxide into nitric acid to obtain scandium oxide solution and holmium oxide solution, uniformly mixing the scandium oxide solution and the holmium oxide solution to obtain the cation salt solution; secondly, preparing precipitant solution, specifically, preparing ammonium bicarbonate solution and at the meantime, adding in ammoniumhydroxide, then adding in ammonium sulfate dispersant to obtain the precipitant solution; thirdly, performing atomizing and precipitation processes, specifically, through a peristaltic pump, sprayingthe precipitant solution into the cation salt solution inside an ultrasonic device via a pneumatic atomizing nozzle to obtain a Ho:Sc2O3 precipitation precursor; fourthly, performing precipitation, filtering and washing processes; fifthly, calcinating the precipitation precursor to obtain the Ho:Sc2O3 nano-crystal powder. The prepared Ho:Sc2O3 nano-crystal powder is high in purity and dispersionand narrow in size distribution and reaches an average grain size of around 100 nm.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Cathode electronic powder for dual-group fluorescent lamp and its making method

InactiveCN101241822ALow conductivityReduce the starting voltageDischarge tube solid thermionic cathodesGas discharge lamp detailsHigh energyConductive materials

A fluorescent lamp cathode electric powder with two components is provided. The electric powder is constituted by conductive material A and ceramic material B, wherein the A component is constituted by tungsten powder Zro, Src and yttrium oxide additive; the B component is mixed by barium oxide, calcium oxide, strontium oxide, zirconium oxide, holmium oxide, and lanthanum oxide additive. The mass percent of the A component in the electric powder is 5-25%, B component 25-95%. The invention solves the problems that the fluorescent lamp cathode electric powder in the background technology is easy to fall off, split and has a high energy consumption, short life and small emission quantity.

Owner:西安天涂建筑工程有限公司

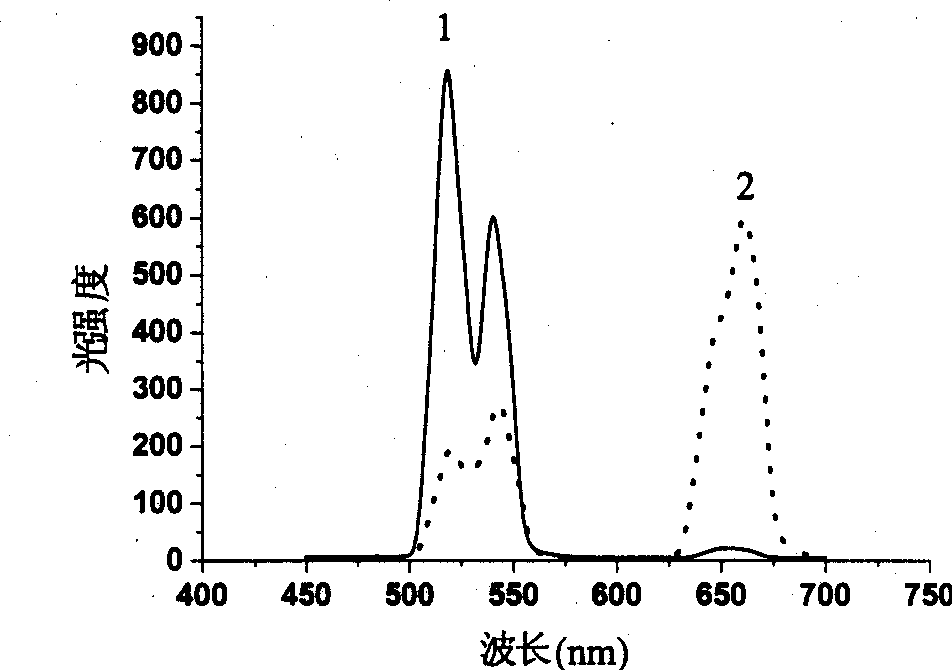

Up converting fluorescent material with nanometer level molybdate substrate and its prepn

InactiveCN1171972CHigh luminous intensityIncrease light intensityLuminescent compositionsYTTERBIUM OXIDEPotassium

The present invention belongs to the field of nano fluorescent material. Lanthanum oxide (or yttrium or gadolinium oxide), ytterbium oxide and erbiom oxide (or thulium or holmium oxide) are first dissolved in acid to prepare solution; complexone and sodium or potassium molybdenate are added into the solution to produce precipitate, which is centrifugally separated and water washed to prepare aqueous gel, aqueous gel or further prepared alcoholic gel is finally cinerated in a high temperature furnace or heated in a hydrothermal reactor to obtain the nano level up converting fluorescent material. The said material has lanthanum molybdenate as matrix and ytterbium molybdenate and erbium molybdenate as dopant. The material thus prepared has small and homogeneous size, average size 50-60 nm and high light glowing strength and may meet the requirement as biological molecular fluorescent mark material.

Owner:CAPITALBIO CORP +1

Rare earth RE2MnCuO6 material applied to low-temperature magnetic refrigeration and preparation method thereof

PendingCN110993230ALow costLarge and low temperature magnetic entropy changeInorganic material magnetismInductances/transformers/magnets manufactureGadolinium oxideCopper oxide

The invention relates to a rare earth RE2MnCuO6 material applied to low-temperature magnetic refrigeration and a preparation method thereof, and the rare earth RE2MnCuO6 material has an orthogonal crystal structure and belongs to a Pnma space group; under the magnetic field change of 0-2T, the isothermal magnetic entropy is changed into 4.2-6.4 J / kgK, and under the magnetic field change of 0-5T, the isothermal magnetic entropy is changed into 8.4-13.9 J / kgK; and under the change of a magnetic field of 0-7T, the isothermal magnetic entropy is changed into 11.5-15.8 J / kgK. The preparation methodcomprises the following steps: mixing one or more of gadolinium oxide, terbium oxide, dysprosium oxide, holmium oxide and erbium oxide with manganese oxide and copper oxide, then mixing with dilute nitric acid to form a uniform solution, adding citric acid dissolved by deionized water, and evaporating moisture to dryness to form gel; performing annealing to form a sinter; and tabletting, molding,sintering and cooling the sinter to obtain a finished product. The rare earth RE2MnCuO6 material applied to low-temperature magnetic refrigeration and the preparation method thereof can be applied tothe field of low-temperature zone magnetic refrigeration. The preparation method is simple in process and suitable for industrialization.

Owner:HANGZHOU DIANZI UNIV

Preparing method for rare earth holmium alloy and rare earth holmium alloy

The invention relates to a preparing method for rare earth holmium alloy and the rare earth holmium alloy. The preparing method for the rare earth holmium alloy is characterized in that a graphite block serves as an anode; a molybdenum or tungsten rod serves as an inert cathode; a molybdenum or tungsten crucible serves as a metal receiver; and a mixture of rare earth oxide and holmium oxide is added into a fluoride fused salt system composed of rare earth fluoride, holmium fluoride and lithium fluoride, direct current is introduced, and the rare earth holmium alloy is obtained through eutectoid electrolysis, wherein mass ratio of the rare earth fluoride, the holmium fluoride and the lithium fluoride in the fluoride fused salt system is (92-60):(5-30):(3-10), the mass percentage of the rare earth oxide and the holmium oxide in the fluoride fused salt system is (99-75):(1-25), and the electrolysis temperature is 1050-1150 DEG C. The preparing method for rare earth holmium alloy has beneficial effects that the rare earth holmium alloy is prepared in the mixed fluoride electrolyte system through eutectoid electrolysis of the mixed oxide, the technology process is simple, cost is low, product components are stable, only CO2 and a small amount of CO are generated in the technology process, pollution to the environment is low, and the preparing method belongs to the environment-friendly technology and is suitable for mass production.

Owner:BAOTOU RES INST OF RARE EARTHS

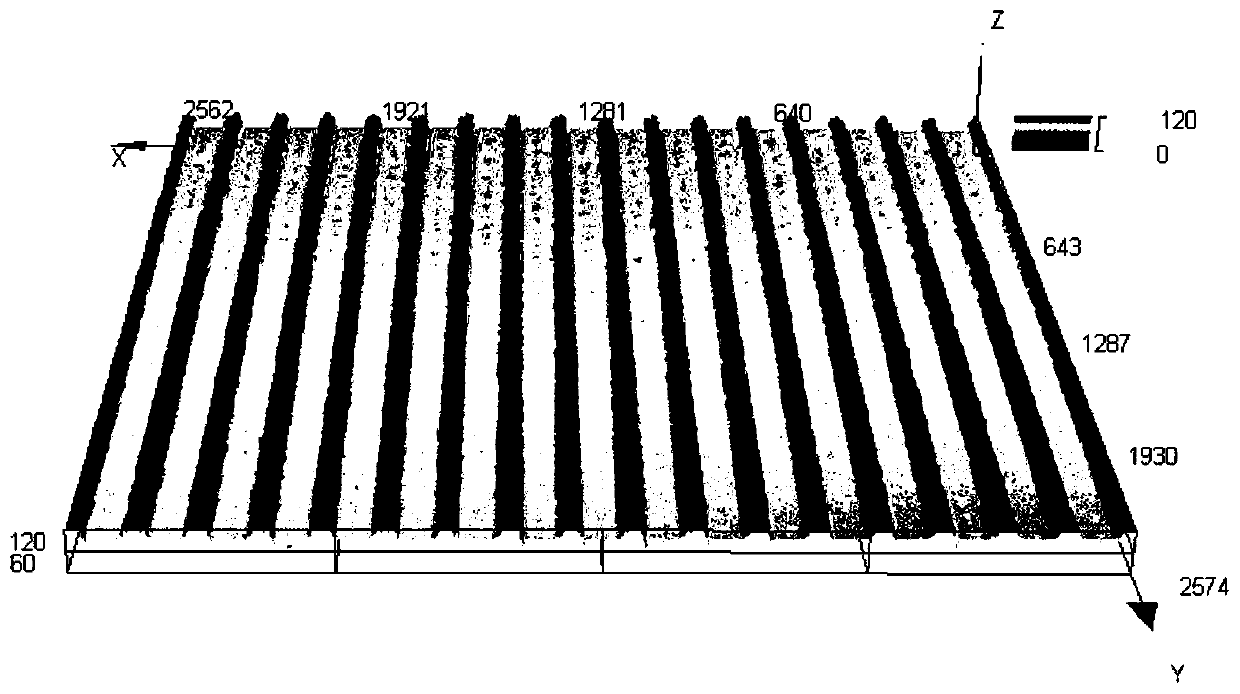

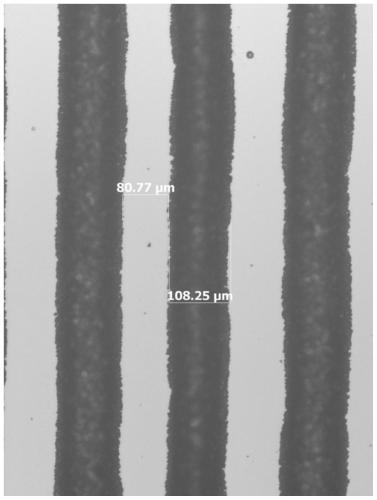

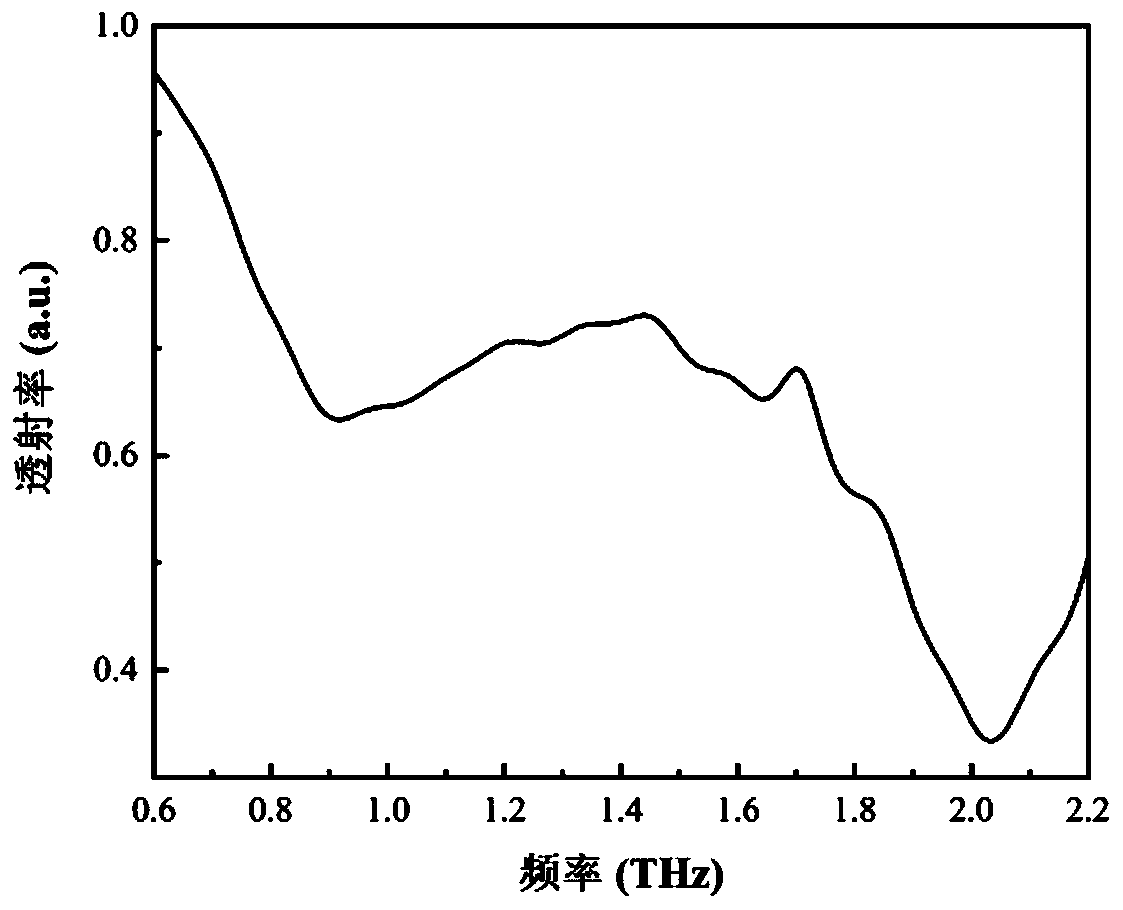

Holmium ferrite-based terahertz metamaterial, preparation method thereof and optical device

ActiveCN111056828AExcellent adjustable characteristicsRegulatory modulabilityOptical elementsDielectricHolmium

The invention discloses a holmium ferrite-based terahertz metamaterial, a preparation method thereof and an optical device. The preparation method of the holmium ferrite-based terahertz metamaterial comprises the following steps: (1) weighing iron oxide and holmium oxide according to a stoichiometric ratio, mixing to form a raw material mixture, and then carrying out first sintering to form a holmium ferrite-based material; and (2) molding the holmium ferrite-based material. Iron oxide and holmium oxide are used as raw materials to prepare the all-dielectric-based metamaterial with the adjustable ratio of Ho atoms to Fe atoms, the amplitude and frequency of the terahertz metamaterial can be flexibly regulated, and meanwhile the problem of large absorption loss of electromagnetic waves, caused by precious metal metamaterials used in the prior art, is solved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Process for producing silicon nitride ceramic stabilized by rare-earth praseodymium and holmium

The invention relates to the technical field of ceramic materials, in particular to a method for producing high-performance silicon nitride (Si3N4) ceramic through pressureless sintering by taking praseodymium oxide and holmium oxide as additives. The ceramic comprises the following components in percentage by mass: 3 to 7 percent of holmium oxide, 5 to 8 percent of praseodymium oxide and 85 to 92 percent of Si3N4. The method for producing the high-performance Si3N4 ceramic through pressureless sintering by taking the praseodymium oxide and the holmium oxide as the additives aims to overcome the shortcomings in the prior art, and can be widely applied to manufacturing of parts used in fields such as chemical industry, machinery, metallurgy, aerospace and the like.

Owner:苏州中锆新材料科技有限公司

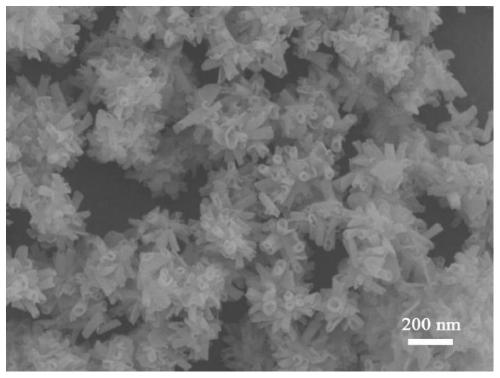

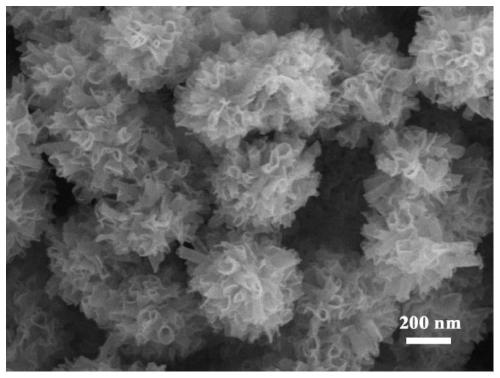

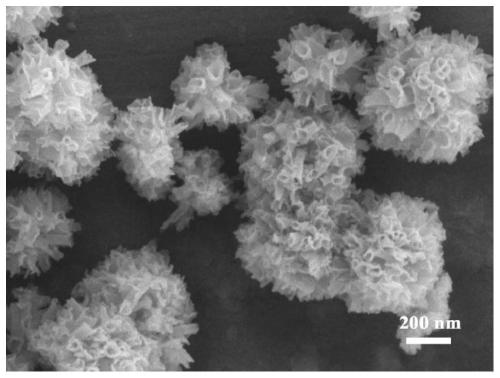

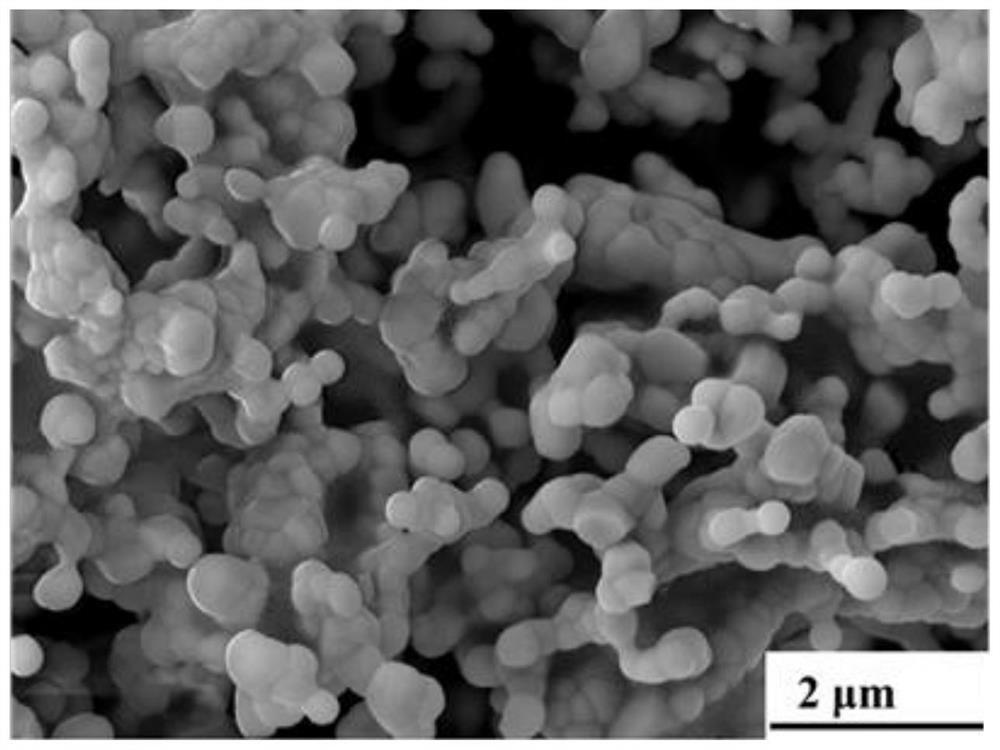

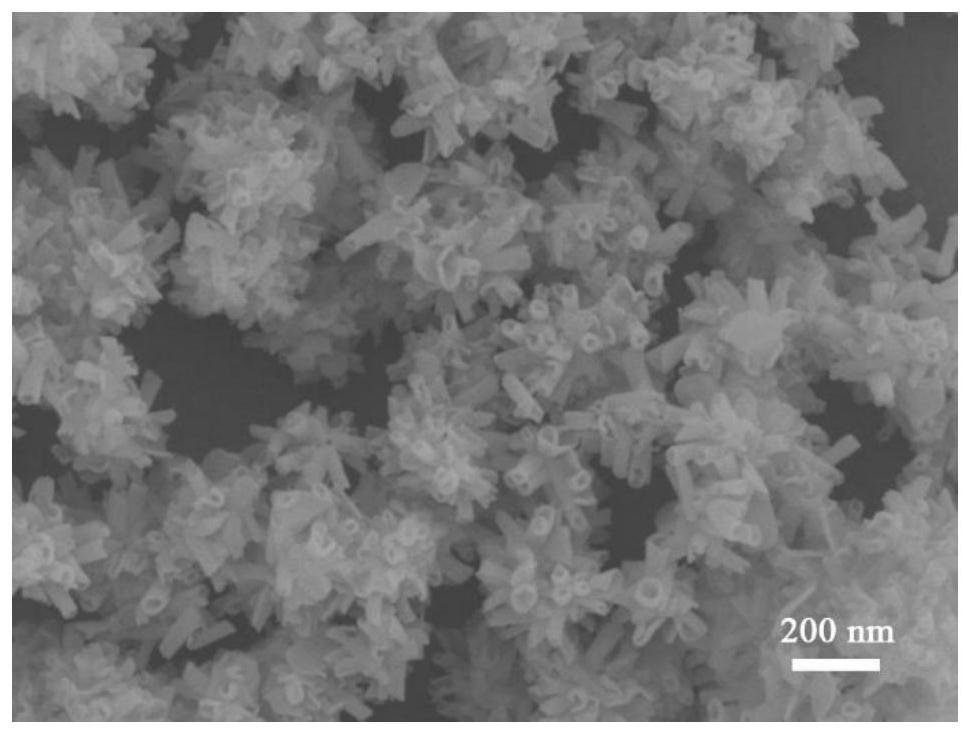

Method for preparing holmium oxide nano materials with different morphologies

ActiveCN111302380ABall structure is stableExcellent moisture sensitive performanceLanthanide oxides/hydroxidesNanotechnologyHolmiumHolmium(III) oxide

The invention discloses a method for preparing holmium oxide nano materials with different morphologies, relates to a method for preparing holmium oxide nano materials, and aims at solving the problems that the existing preparation method of the holmium oxide nano material cannot adjust reactants to realize regulation and control on the morphology of the holmium oxide nanomaterial, the synthesis steps are complex and high in difficulty, the nanotube morphology and the three-dimensional structure holmium oxide nanomaterial cannot be synthesized, and the prepared holmium oxide nanosheet is relatively thick in size and has no porous structure on the surface. The method comprises the following steps: 1, dissolving holmium acetylacetonate and urea in a solvent to obtain a uniformly stirred solution; and 2, carrying out a sealed reaction on the uniformly stirred solution, naturally cooling to room temperature, carrying out centrifugal separation to obtain a faint yellow precipitate, washingthe faint yellow precipitate, drying to obtain a holmium oxide nano-material precursor, and calcining the holmium oxide nano-material precursor under an air condition to obtain the holmium oxide nano-material. The method is used for preparing holmium oxide nano materials with different morphologies.

Owner:HEILONGJIANG UNIV

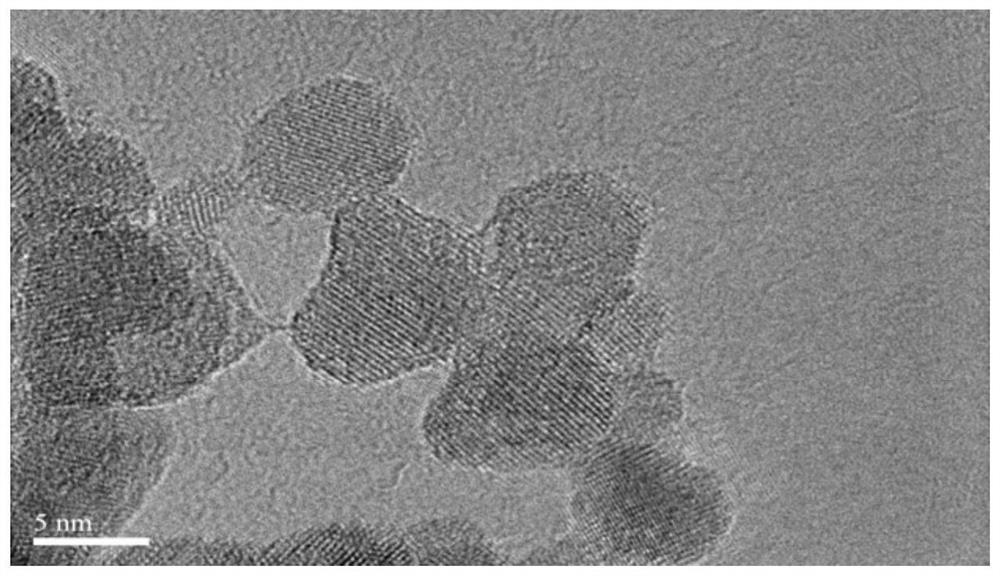

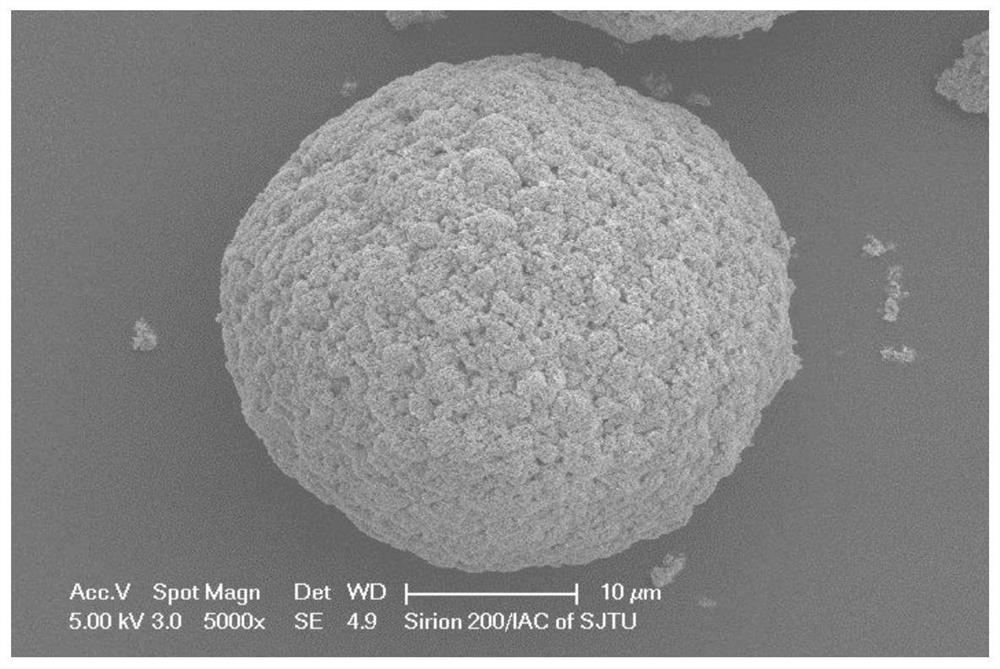

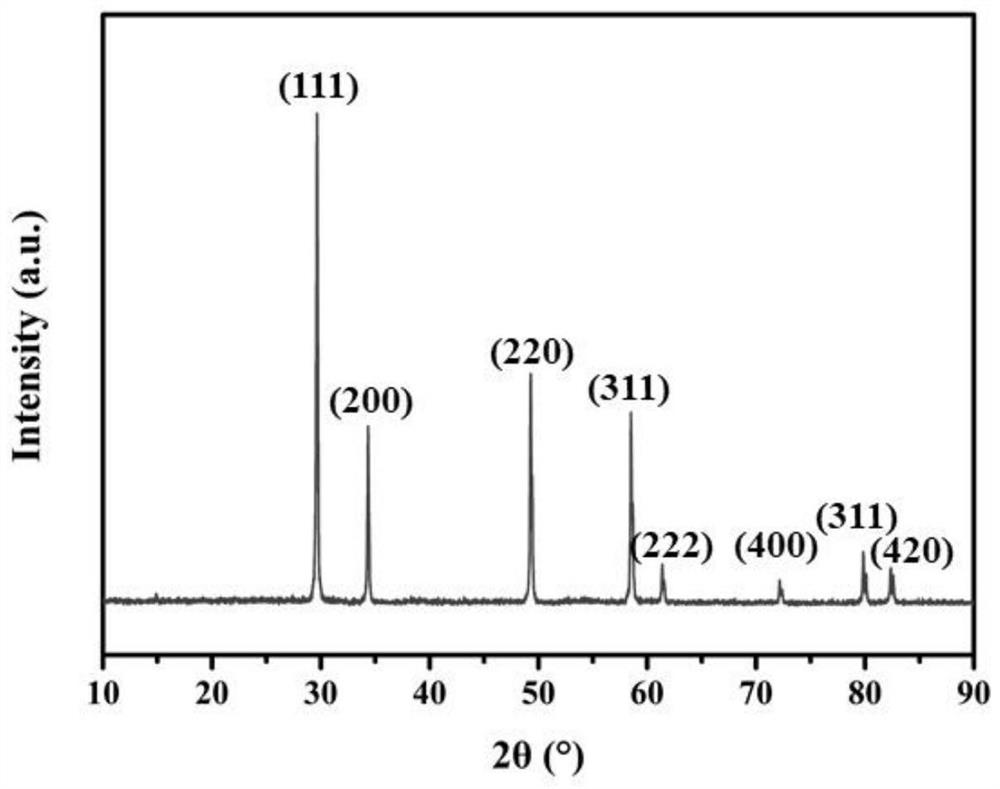

Holmium oxide-scandium oxide compositely-stabilized zirconium oxide and preparation method thereof, and electrolyte material of solid oxide fuel cell

PendingCN113511676ASimple manufacturing methodImprove ionic conductivityMaterial nanotechnologyLanthanide oxides/hydroxidesFuel cellsHolmium

The invention relates to the technical field of electrolyte materials of solid oxide fuel cells, in particular to holmium oxide-scandium oxide compositely-stabilized zirconium oxide and a preparation method thereof, and an electrolyte material of a solid oxide fuel cell. The preparation method of the holmium oxide-scandium oxide compositely-stabilized zirconium oxide comprises the following steps: heating a mixed aqueous solution of zirconium oxychloride, scandium oxide and holmium oxide, adjusting a pH value to obtain mixed slurry, and successively carrying out filtering, washing, drying, calcining and grinding, wherein in the mixed aqueous solution, a molar ratio of zirconium ions to scandium ions to holmium ions is (92-93): (6-7): 1. The method is simple and easy to implement, and the obtained holmium oxide-scandium oxide compositely-stabilized zirconium oxide has excellent ionic conductivity.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of carbon-clad holmium-doped lithium titanate composite negative material

InactiveCN103346310AImprove conductivityFast charge and discharge rateCell electrodesHolmium(III) oxideLithium electrode

The invention relates to a preparation method of a carbon-clad holmium-doped lithium titanate composite negative material. The preparation method comprises the following steps of: (1) preparing carbon particles for the cladding; (2) mixing lithium hydrogencarbonate, titanium dioxide and holmium oxide serving as raw materials, adding the carbon particles for the cladding accounting for 3 to 5 percent by weight of the general weight of the three raw materials, adding an acetone dispersing agent, carrying out ball milling on a ball milling machine, and carrying out vacuum drying on the mixture to obtain a carbon-clad holmium-doped lithium titanate precursor; (3) sintering the dried carbon-clad holmium-doped lithium titanate precursor under a helium atmosphere to obtain a product. According to the carbon-clad holmium-doped lithium titanate composite negative material for a lithium ion battery, the conductive performance of the lithium titanate is improved by doping the holmium with the lithium titanate, and the conductivity and cycling stability of the battery can be further improved by cladding the lithium titanate with the carbon particles which are prepared through a specific process and has a hollow structure.

Owner:SUZHOU YIYUAN HONGDA INTPROP AGENCYCO

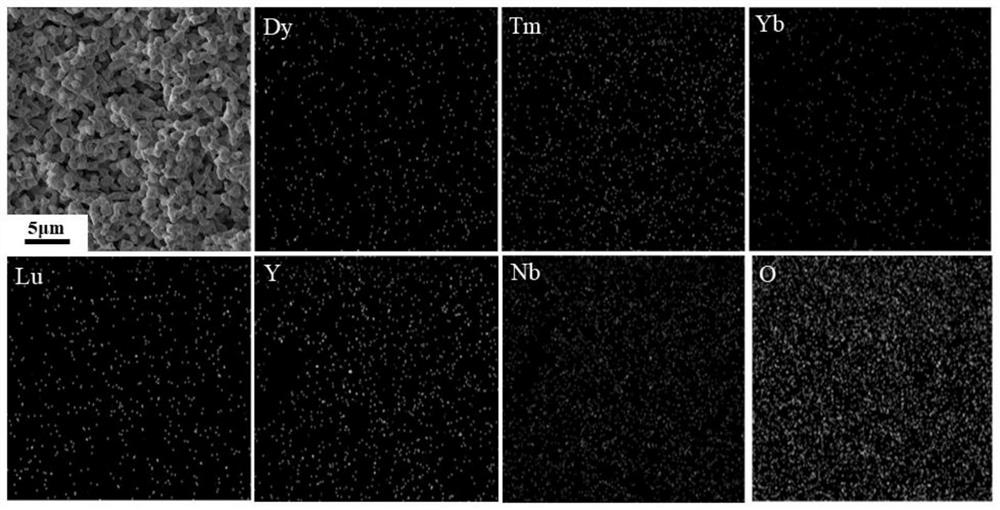

A kind of rare earth niobate high-entropy powder, porous high-entropy ceramic and preparation method and application

ActiveCN113620722BIncrease scatteringLower lattice thermal conductivityCeramicwareYTTERBIUM OXIDELutetium

The invention discloses a rare earth niobate high-entropy powder, a porous high-entropy ceramic, a preparation method and an application, and belongs to the technical field of high-entropy materials. The raw materials of the rare earth niobate high-entropy powder include rare earth trioxide and niobium pentoxide; the rare earth trioxide is dysprosium oxide, holmium oxide, erbium oxide, thulium oxide, ytterbium oxide, lutetium oxide, and yttrium oxide. In the mixture of 5-7 different trioxides, in any two trioxides, the molar ratio of the trioxide with a large amount to the trioxide with a small amount is 1-3. The present invention introduces different rare earth metal cations through the high entropy of niobate ceramic components. Due to the difference in atomic size in the high entropy phase, its atomic occupancy is shifted, which further leads to lattice distortion and increases the Phonon scattering; Rare earth niobate porous high-entropy ceramics have excellent thermal insulation properties due to the introduction of pore structure that reduces the solid-phase thermal conductivity of the material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

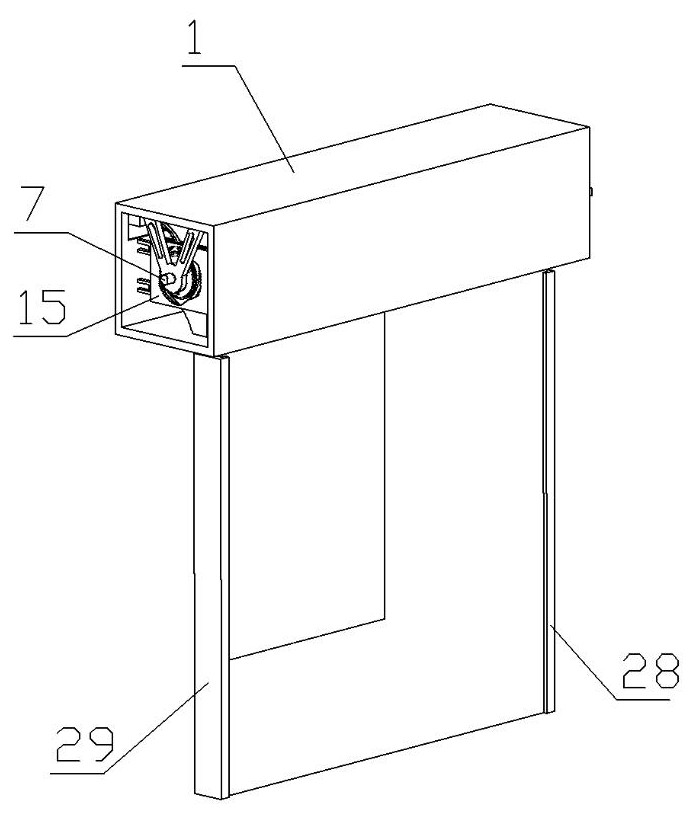

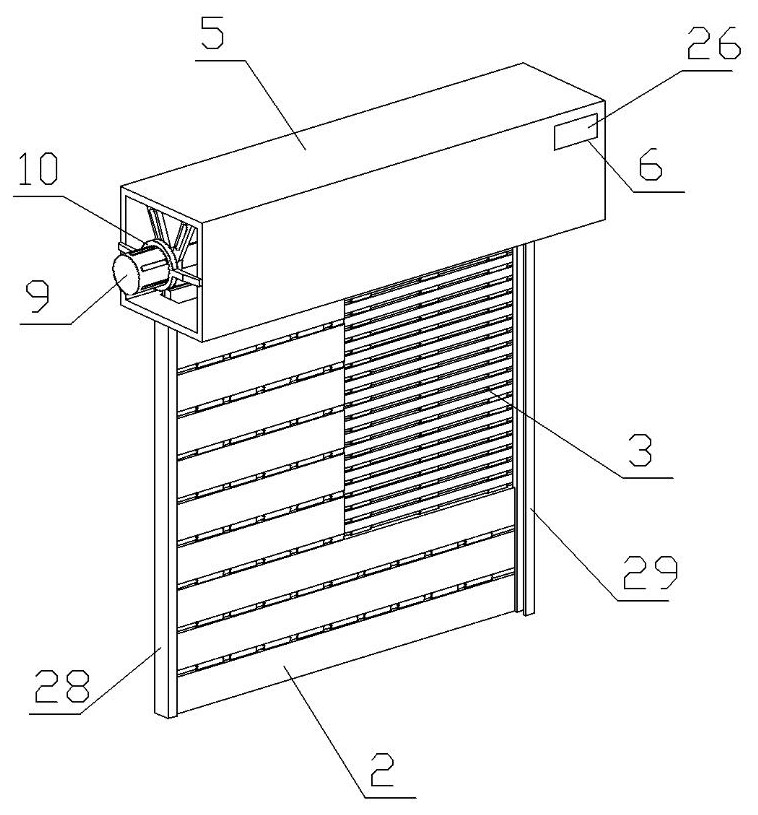

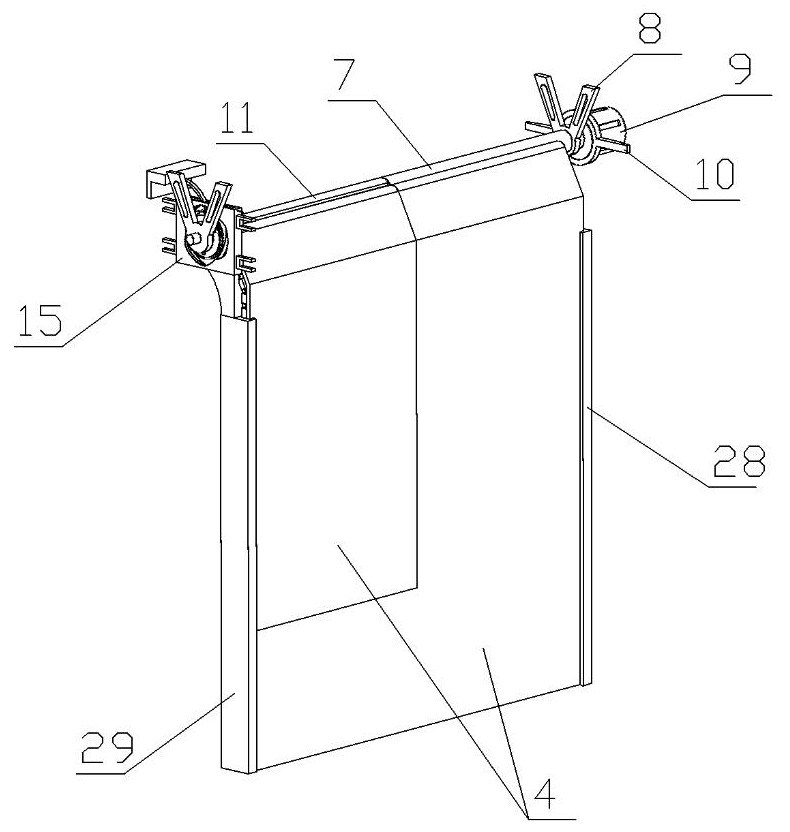

High silica glass fiber, preparation method thereof and fireproof equipment

ActiveCN112341001AHigh strengthReduce high temperature viscosityGlass making apparatusShutters/ movable grillesFiberBoron trioxide

The invention relates to the technical field of glass fiber preparation, in particular to high-silica glass fiber and a preparation method thereof. The high silica glass fiber is mainly prepared fromthe following raw materials in parts by weight: 70-80 parts of silicon dioxide, 10-20 parts of silicon carbide, 2-5 parts of aluminum oxide, 5-15 parts of diboron trioxide, 10-15 parts of sodium oxideand 0.05-0.1 part of rare earth oxide. The rare earth oxide is composed of holmium oxide and niobium pentoxide according to the weight ratio of (1-3): 5. The holmium oxide and niobium pentoxide are introduced according to the optimized proportion, so that the high-temperature viscosity and forming temperature of the glass are effectively reduced, the ductility of the frit is enhanced, and the high-strength glass fiber is obtained at relatively low melting temperature and wiredrawing temperature.

Owner:LINYI HAOQUAN SILICA SAND TECH

Method for preparing holmium oxide magneto-optical transparent ceramic with high Verdet constant and high optical quality by using nickel ion uniform doping technology

The invention relates to a method for preparing high-performance holmium oxide magneto-optical transparent ceramic by using a nickel ion uniform doping technology. The method comprises the following steps: preparing a mixed solution of holmium nitrate and nickel chloride and carrying out uniform stirring; dropwise adding a sodium hydroxide solution into the mixed solution to obtain a light green precipitate, continuing stirring, performing ageing, and successively carrying out filtering and washing to obtain a nickel-doped holmium oxide precursor; then adding the precursor into an ammonium sulfate solution for a reaction, washing, drying, grinding and sieving the obtained derivative, and carrying out calcining at a high temperature to obtain ultrafine nickel-doped holmium oxide powder; andcarrying out molding, high-temperature sintering and machining on the powder to obtain the nickel-doped holmium oxide magneto-optical transparent ceramic. The method has the advantages that the nickel component in the product generated by a direct precipitation route of sodium hydroxide is uniformly distributed; the calcined product has high sintering activity; and particularly, nickel oxide withantiferromagnetism is adopted for doping, so the holmium oxide ceramic with high optical quality is obtained, and the Verdet constant of the ceramic is improved.

Owner:SHENZHEN LOTUT INNOVATION DESIGN CO LTD

Vanadate upconversion material fluorescent powder, and preparation method and application thereof

InactiveCN102585827BAvoid pollutionGas discharge lamp usageLuminescent compositionsYTTERBIUM OXIDEVanadate

The invention discloses vanadate upconversion material fluorescent powder, and a preparation method and application thereof. The vanadate upconversion material fluorescent powder has a chemical composition formula Y0.89-x-yVO4:0.01Tm<3+> / xEr<3+> / yHo<3+> / 0.1Yb<3+>, wherein x is 0 to 0.002, and y is 0 to 0.003. The invention also discloses the preparation method for the material, and the preparation method comprises the following steps of: weighing yttrium oxide, vanadium pentoxide, thulium oxide, holmium oxide, erbium oxide and ytterbium oxide in a molar ratio of the chemical composition formula, grinding and mixing uniformly, pre-sintering at the temperature of 650 DEG C, and keeping constant temperature of 650 DEG C for six hours; cooling, grinding again, sintering at the temperature of 1,200 DEG C, and keeping the constant temperature of 1,200 DEG C for six hours; and cooling to obtain the vanadate upconversion material fluorescent powder. The vanadate upconversion material fluorescent powder is high in luminous efficiency and stability and meets the requirement of a white light light-emitting diode (LED).

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Standard substance for calibrating wavelength in ultraviolet visible region as well as preparation method and application of standard substance

InactiveCN113092399AEvenly dispersedReduce the impactPreparing sample for investigationColor/spectral properties measurementsHolmiumHolmium(III) oxide

The invention provides a standard substance for wavelength calibration in an ultraviolet-visible region as well as a preparation method and application of the standard substance. The standard substance for wavelength calibration in the ultraviolet-visible region comprises the following components in parts by weight, 20-80 parts of holmium oxide, 6-24 parts of neodymium oxide and an acid solution. The standard substance for ultraviolet visible region wavelength calibration provided by the invention is wide in application range, wide in wavelength coverage range, narrower in half width of an absorption peak, more accurate in peak positioning and convenient in absorbance adjustment.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

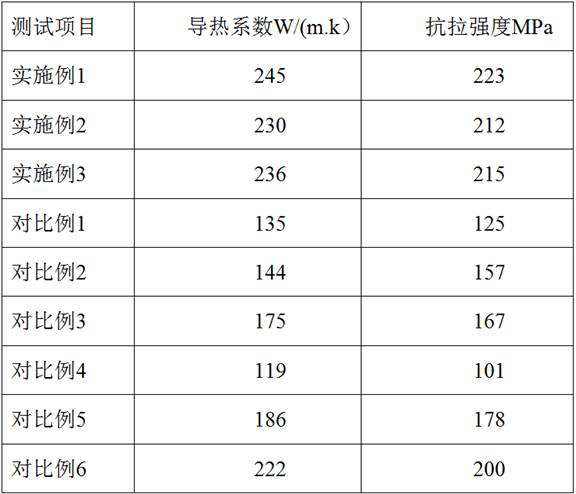

High-thermal-conductivity aluminum alloy and preparation method thereof

PendingCN114836660ASolve the status quo of step-by-step additionThe preparation process is stableYTTERBIUM OXIDELutetium

Owner:瑞晟通金属(广东)有限公司

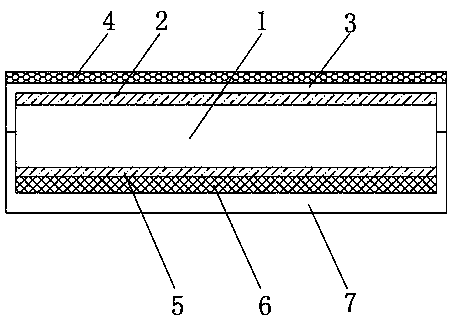

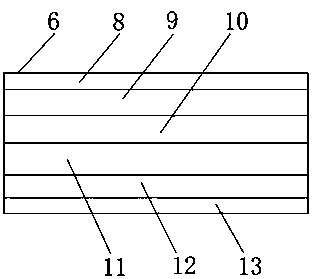

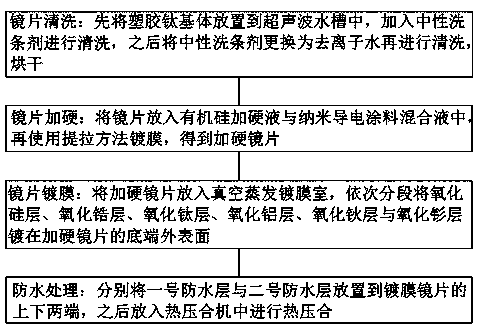

Anti-dazzle and anti-blue-light lens and preparation method thereof

InactiveCN110780463APromote absorptionImprove protectionOptical partsOptical elementsHolmiumUltraviolet lights

The invention discloses an anti-dazzle and anti-blue-light lens and a preparation method thereof. The anti-dazzle and anti-blue-light lens comprises a plastic titanium substrate, the outer surface ofthe top end of the plastic titanium substrate is provided with a first reinforcing layer, and the outer surface of the top end of the first reinforcing layer is provided with a first waterproof layer.According to the anti-dazzle and anti-blue-light lens and the preparation method thereof, a holmium oxide layer and a samarium oxide layer are arranged in an anti-dazzle and anti-blue-light layer toimprove the absorption of ultraviolet light and light of short-wave blue light regions; when evaporation coating is performed, plating is performed for 1 to 2s, pausing is performed afterwards, plating layers form a to-be-solidified state on the surface of the lens to slow down the mutual permeation between the plating layers and improve the uniformity of the plating layers, after each layer is subjected to evaporation coating, the uniformity of the plating layers can be improved and the integrity of the plating layers can be better ensured by shaking the lens, and after plating coating is completed on the upper layer, the next layer is subjected to evaporation coating immediately to improve the firmness of the connection between the plating layers.

Owner:江苏汇鼎光学眼镜有限公司

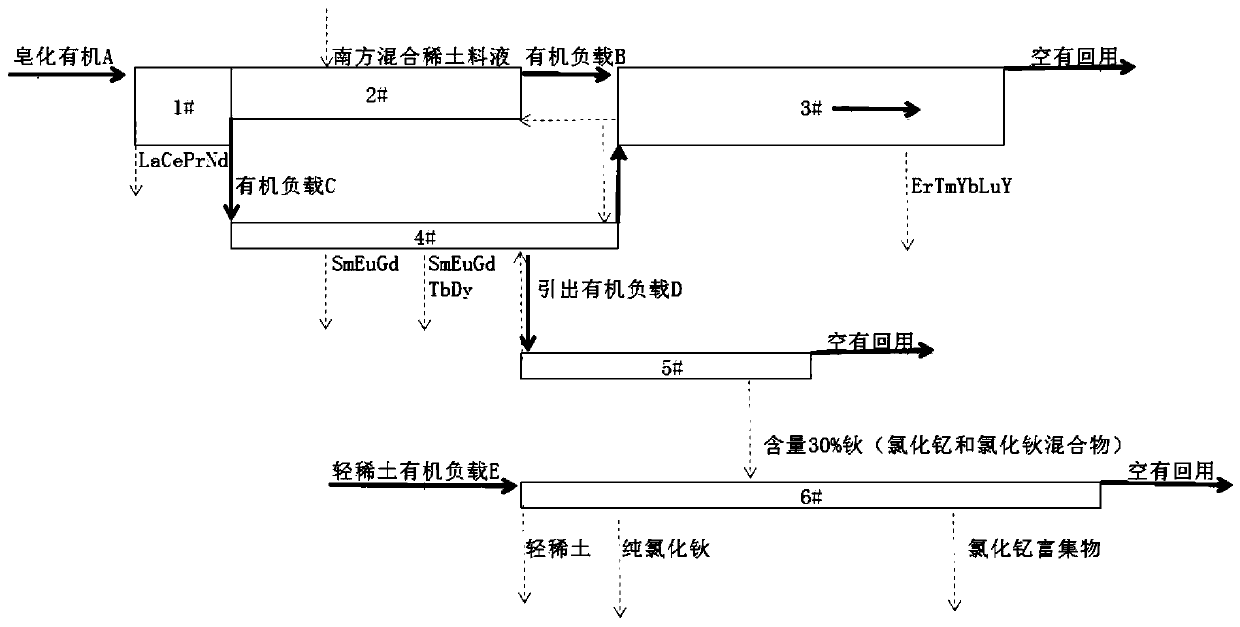

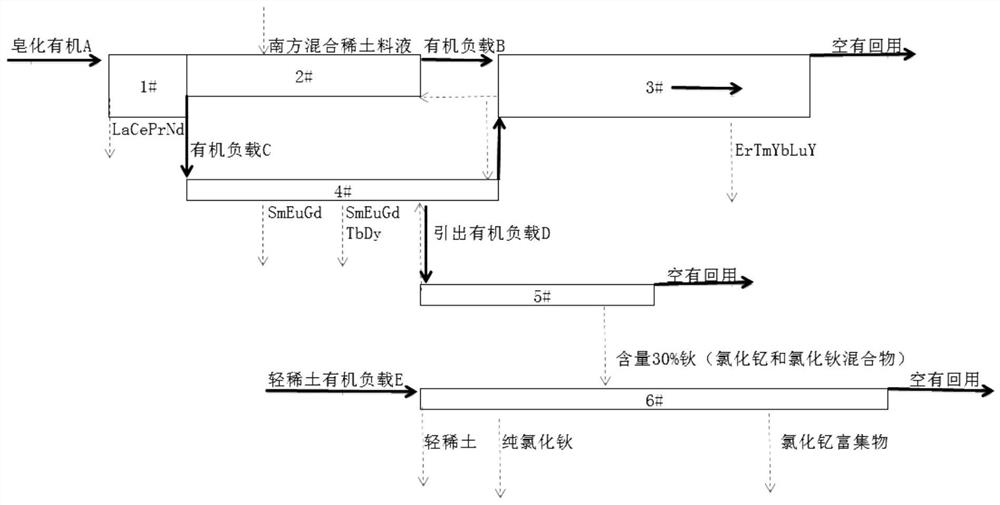

Holmium oxide separation process

ActiveCN111410225AReduce the amount of separationReduce consumptionLanthanide oxides/hydroxidesRare earth metal compounds preparation/treatmentOXALIC ACID DIHYDRATEPhysical chemistry

The invention provides a holmium oxide separation process which comprises the following steps: carrying out saponification reaction on a mixture of P507 and sulfonated kerosene to obtain an organic load A, and adding the organic load A into a 1# extraction tank; dissolving southern ion ore with acid, adding the dissolved southern ion ore into a 2# extraction tank communicated with a 1# extractiontank for separation and extraction, and respectively leading out an organic load B and an organic load C; washing the organic load B in a 3# extraction tank to obtain medium rare earth and enriched holmium feed liquid containing a small amount of yttrium; introducing into a 4# extraction tank for separation and extraction, and leading out an organic load D; adding the mixture into a 5# extractiontank for separation and extraction to obtain a mixture of yttrium chloride and holmium chloride; adding a light rare earth organic load E into the 6# extraction tank, and introducing a mixture of yttrium chloride and holmium chloride for separation and extraction to respectively obtain enriched substances of pure holmium chloride and yttrium chloride; sequentially subjecting pure holmium chlorideto oxalic acid precipitation, cleaning and firing, and obtaining holmium oxide. The holmium oxide separation process is low in energy consumption, high in efficiency and low in cost.

Owner:中稀(宜兴)稀土新材料有限公司

A method for preparing holmium oxide nanomaterials with different shapes

ActiveCN111302380BBall structure is stableExcellent moisture sensitive performanceLanthanide oxides/hydroxidesNanotechnologyHolmiumHolmium(III) oxide

A method for preparing holmium oxide nanomaterials with different shapes, the invention relates to a method for preparing holmium oxide nanomaterials. The present invention aims to solve the problem that the existing method for preparing holmium oxide nanomaterials cannot realize the regulation and control of the morphology of holmium oxide nanomaterials through the adjustment of reactants. Holmium nanomaterials, the prepared holmium oxide nanosheets are thicker, and there is no problem of porous structure on the surface. Method: 1. Dissolve holmium acetylacetonate and urea in a solvent to obtain a uniformly stirred solution; 2. Seal the evenly stirred solution for reaction, then naturally cool to room temperature and centrifuge to obtain a light yellow precipitate, wash the light yellow precipitate After drying, the holmium oxide nanomaterial precursor is obtained, and the holmium oxide nanomaterial precursor is calcined under air conditions to obtain the holmium oxide nanomaterial. The invention is used for preparing holmium oxide nanometer materials with different shapes.

Owner:HEILONGJIANG UNIV

Preparation method of silicon nitride-doped holimium oxide ceramic

The invention relates to the technical field of a ceramic material, in particular to a method for producing high-performance silicon nitride (Si3N4) by adopting holimium oxide (Ho2O3) as an additive via pressureless sintering. The component and mass percentages are as follows: 3-12% of holimium oxide and 85-97% of silicon nitride. The invention aims at overcoming disadvantages of the prior art and providing a method for producing high-performance silicon nitride by adopting holimium oxide as the additive via pressureless sintering. The method can be widely applied to preparing parts in fields such as chemical industry, machinery, metallurgy, aerospace and the like.

Owner:苏州中锆新材料科技有限公司

A kind of preparation method of magneto-optic holmium oxide transparent ceramic

ActiveCN108358635BImprove optical qualityOvercome the problem of uneven distributionOxide ceramicHolmium

The invention discloses a method for preparing transparent magneto-optic holmium oxide ceramic. The method comprises the following steps: preparing a holmium nitrate solution and an ammonium fluoridesolution; dropwise adding ammonia water to the holmium nitrate solution, and performing aging to obtain a white precipitate; filtering and washing the white precipitate, adding the filtered and washedwhite precipitate to the ammonium fluoride solution, and performing a reaction to obtain a rare earth holmium-based layered compound precursor containing a fluorion group; sequentially washing, drying, grinding and sieving the rare earth holmium-based layered compound precursor containing the fluorion group, and then calcining the precursor to obtain holmium oxide nano-powder; and sequentially performing pre-pressing and cold isostatic press molding on the holmium oxide nano-powder, performing high-temperature pressureless sintering on the cold isostatic press molded product, and machining the high-temperature pressureless sintered product to obtain the transparent holmium oxide ceramic. The method avoids the problem of non-uniform distribution of a fluoride additive, and the prepared holmium oxide ceramic has good optical performances.

Owner:NINGBO UNIV

A kind of holmium oxide separation process

ActiveCN111410225BReduce the amount of separationReduce consumptionLanthanide oxides/hydroxidesRare earth metal compounds preparation/treatmentPhysical chemistryHolmium(III) oxide

The invention provides a holmium oxide separation process, which comprises the following steps: saponifying the mixture of P507 and sulfonated kerosene to obtain organic load A, which is added to 1# extraction tank; Separation and extraction are carried out in the 2# extraction tank connected with the 1# extraction tank, and the organic load B and the organic load C are respectively drawn out; the organic load B is washed in the 3# extraction tank to obtain middle rare earth and holmium containing a small amount of yttrium after enrichment. Feed liquid; introduce it into 4# extraction tank for separation and extraction, and draw out organic load D; add it to 5# extraction tank for separation and extraction to obtain a mixture of yttrium chloride and holmium chloride; add light to 6# extraction tank Rare earth is organically loaded with E, and a mixture of yttrium chloride and holmium chloride is introduced for separation and extraction to obtain enrichments of pure holmium chloride and yttrium chloride respectively; Get holmium oxide. The holmium oxide separation process of the present application has low energy consumption, high efficiency and low cost.

Owner:中稀(宜兴)稀土新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com