High-thermal-conductivity aluminum alloy and preparation method thereof

An aluminum alloy and high thermal conductivity technology, which is applied in the field of aluminum alloy materials, can solve the problems that the heat dissipation performance of aluminum alloy materials cannot meet the requirements, and achieve the effects of improving the use value, stabilizing the preparation process, and reducing cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

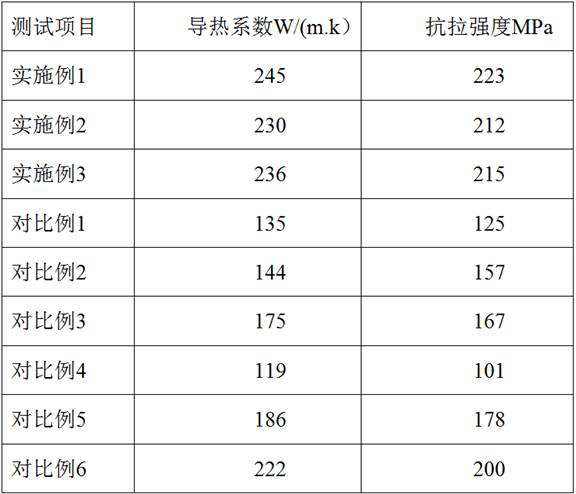

Examples

Embodiment 1

[0038] A raw material of a high thermal conductivity aluminum alloy comprises the following raw material components in parts by weight:

[0039] 1.8 parts of copper ingots, 1 part of iron ingots, 0.3 parts of quick-melting silicon, 0.08 parts of magnesium powder, 0.03 parts of rare earth oxides, and 97 parts of aluminum ingots;

[0040] The rare earth contains the following raw material components by weight: 25 parts of terbium oxide, 25 parts of dysprosium oxide, 17 parts of holmium oxide, 17 parts of thulium oxide, 8 parts of ytterbium oxide, and 8 parts of lutetium oxide.

[0041] The preparation method of the high thermal conductivity aluminum alloy is:

[0042] S1. Weigh each raw material, preheat the smelting furnace to 720°C, then add each raw material into the smelting furnace respectively, stir continuously to obtain an alloy melt, take 1.6% of the melt weight of the modified covering agent to cover the melt surface;

[0043] S2. When the melt is heated to 760°C, ta...

Embodiment 2

[0058] A high thermal conductivity aluminum alloy comprises the following raw material components by weight: 0.5 part of copper ingot, 0.1 part of iron ingot, 0.05 part of fast-melting silicon, 0.15 part of magnesium powder, 0.05 part of rare earth oxide, and 97.3 part of aluminum ingot;

[0059] The rare earth oxide contains the following raw material components by weight: 20 parts of terbium oxide, 20 parts of dysprosium oxide, 20 parts of holmium oxide, 20 parts of thulium oxide, 10 parts of ytterbium oxide, and 10 parts of lutetium oxide.

[0060] The preparation method of the high thermal conductivity aluminum alloy is:

[0061] S1. Weigh each raw material, preheat the smelting furnace to 710°C, then add each raw material into the smelting furnace respectively, continue stirring to obtain an alloy melt, and take 1.2% of the melt weight of the modified covering agent on the melt surface. ;

[0062] S2. When the melt is heated to 750°C, take a refining agent that accounts ...

Embodiment 3

[0077] A high thermal conductivity aluminum alloy comprises the following raw material components by weight: 2.5 parts of copper ingots, 1.5 parts of iron ingots, 0.05 parts of fast-melting silicon, 0.03 parts of magnesium powder, 0.01 parts of rare earth oxides, and 94.8 parts of aluminum ingots;

[0078] The rare earth oxide contains the following raw material components by weight: 30 parts of terbium oxide, 30 parts of dysprosium oxide, 10 parts of holmium oxide, 10 parts of thulium oxide, 10 parts of ytterbium oxide, and 10 parts of lutetium oxide.

[0079] The preparation method of the high thermal conductivity aluminum alloy is:

[0080] S1. Weigh each raw material, preheat the smelting furnace to 730°C, then add each raw material into the smelting furnace, stir continuously to obtain an alloy melt, take 1.8% of the melt weight of the modified covering agent to cover the melt surface;

[0081] S2. When the melt is heated to 770°C, take a refining agent that accounts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com