Solar cell electrode slurry, preparation method, cell electrode and solar cell

A technology of solar cells and electrode pastes, which is applied to conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, and can solve the problem of affecting the quality of silver-coated copper powder, performance characteristics and coating effect Insufficient stability and reliability, prone to hydrolysis and other problems, to achieve the effect of reducing material cost, reducing volume resistivity, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

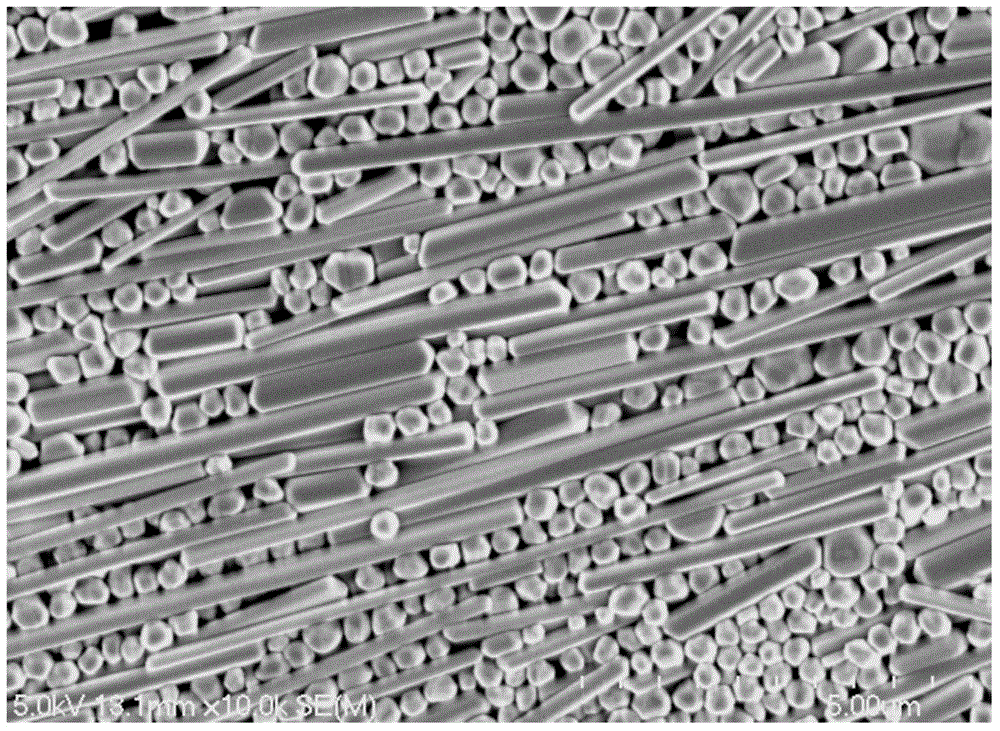

Image

Examples

preparation example Construction

[0058] In another embodiment of the present invention, a method for preparing an electrode slurry is provided, comprising the steps of:

[0059] (1) Slurry mixing: Add the silver powder, glass powder, organic vehicle and a part (40-60%) of the defoamer in sequence to a ball mill for stirring and mixing, and then ultrasonically disperse and mix to further adjust the viscosity of the slurry. Among them, the ultrasonic dispersion process parameters of the defoamer are: the ultrasonic vibration frequency is 100KHz, the power is 500W, and the processing time is 18Min; the ball mill stirring process parameters of the mixed slurry are: the grinding ball particle size is 2mm, and the ball-to-material weight ratio is 1:10, the ball milling time is 0.2 hour, the ball milling speed is 150r / min; the ultrasonic dispersion process parameters of the mixed slurry are: ultrasonic vibration frequency 300KHz, power 500W, treatment time 20Min.

[0060] (2) Slurry degassing: According to the formu...

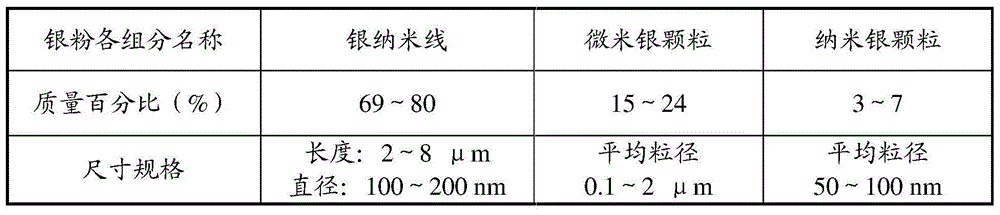

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com