Silicon capacitor vacuum sensor based on micro electro mechanical system (MEMS) technology

A technology of vacuum sensor and micro-electro-mechanical system, applied in vacuum gauges, instruments, measuring devices, etc., can solve problems such as film rupture and adhesion failure, and achieve the effects of reducing nonlinearity, high-precision measurement, and avoiding adhesion failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

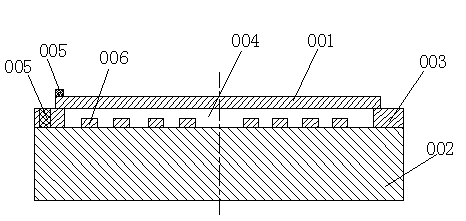

[0035] Embodiment 1: A silicon capacitive vacuum sensor based on MEMS technology, including an upper plate 001, a lower plate 002, an intermediate insulating layer 003, a vacuum chamber 004, and electric lead welding on the upper and lower plates (001, 002) The disc 005, the upper plate 001 is a silicon sensitive film, the vacuum chamber 004 is a sealed cavity formed between the upper plate 001, the intermediate insulating layer 003 and the lower plate 002, and an array of insulating support columns 006 is designed in the vacuum chamber 004. There is a gap between the top surface of the insulating support column 006 and the upper plate 001, the thickness of the silicon sensitive film is 5um, the intermediate insulating layer 003 is silicon dioxide, the thickness of the intermediate insulating layer 003 is 2um, and the insulating support column 006 The insulating support pillars 006 in the array are evenly distributed, the shape of the cross-section of the insulating support pil...

Embodiment 2

[0036] Embodiment 2: Referring to Embodiment 1, the thickness of the silicon sensitive film is 10um, the thickness of the intermediate insulating layer 003 is 5um, and each insulating support pillar in the array of insulating support pillars 006 is non-uniformly distributed, and the shape of the cross section of the insulating support pillar 006 is Square, different sizes and dimensions, the cross-sectional area of the insulating support column 006 is 1um 2 -1mm 2 The distance between the insulating support pillars 006 is the same, and the distance is 500 microns.

Embodiment 3

[0037] Embodiment 3, with reference to Embodiment 1, the vacuum chamber 004 is a sealed cavity formed between the upper plate 001 and the intermediate insulating layer 003, the intermediate insulating layer 003 is a composite of a silicon dioxide layer and a silicon nitride layer, and the intermediate insulating layer The thickness of the silicon sensitive film is 3um, and the thickness of the silicon sensitive film is 0.5um. The insulating support pillars in the array of insulating support pillars 006 are non-uniformly distributed. The cross-sectional area is 100um 2 , the spacing between the insulating support pillars 006 is different, and the spacing is between 0-800 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com