Method for preparing holmium oxide nano materials with different morphologies

A nanomaterial, a technology of holmium oxide, applied in the field of preparing holmium oxide nanomaterials, can solve the problems of complex synthesis steps, high difficulty, inability to synthesize nanotube morphology and three-dimensional structure holmium oxide nanomaterials, and achieve excellent performance and stable structure , the effect of excellent humidity sensitive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

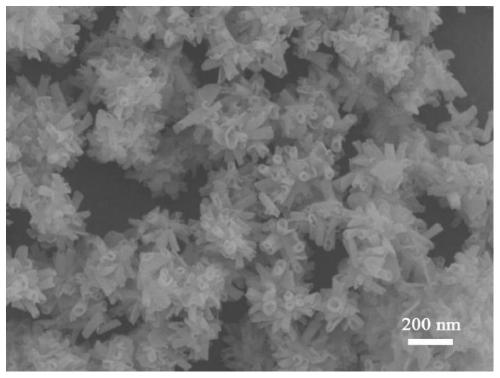

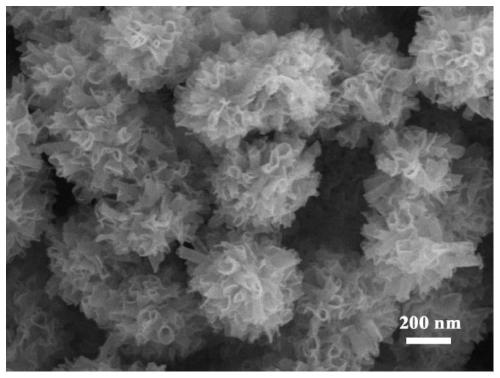

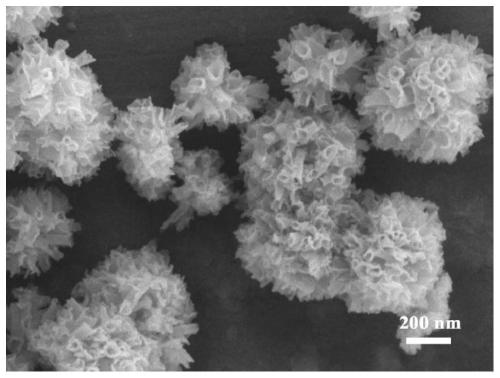

[0038] Specific embodiment one: a kind of method for preparing holmium oxide nanomaterials with different shapes described in this embodiment, it is carried out according to the following steps:

[0039] 1. Dissolve holmium acetylacetonate and urea in the solvent, and magnetically stir for 0.5h to 2h to obtain a uniformly stirred solution;

[0040] The molar ratio of described holmium acetylacetonate and urea is 1:(0.5~6); The volume ratio of the total moles of described holmium acetylacetonate and urea to solvent is 1mmol:(4~13)mL; The described Solvent is made up of ethylene glycol, polyethylene glycol 400 and deionized water; The volume ratio of described ethylene glycol and polyethylene glycol 400 is 1:(0.9~1.1); Described ethylene glycol and deionized The volume ratio of water is 1:(0.15~0.7);

[0041] 2. Place the uniformly stirred solution in a polytetrafluoroethylene-lined stainless steel reaction kettle and seal it, and react for 8h to 16h at a temperature of 140°C t...

specific Embodiment approach 2

[0047] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the holmium oxide nanomaterials prepared in step 2 have nanotubes, spheres formed by self-assembly of nanotubes, nanosheets, or spheres formed by self-assembly of nanosheets. . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, the light yellow precipitate is washed and then dried according to the following steps: wash several times with deionized water and ethanol respectively, and then Under the condition that the temperature is 70°C-100°C, vacuum dry for 5h-12h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com