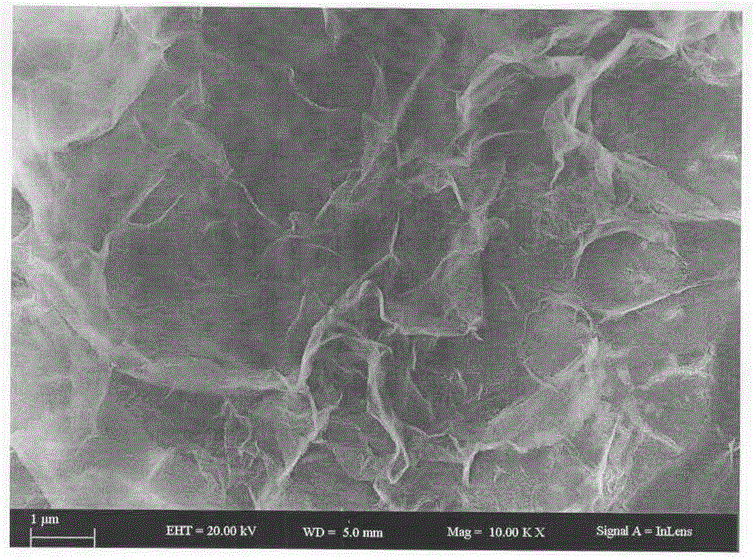

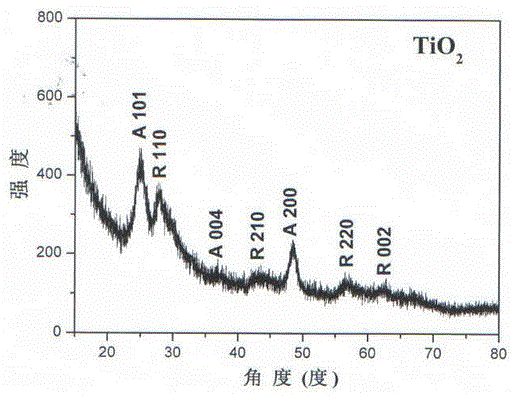

Preparation method of humidity sensing material based on ultrathin titanium dioxide nanosheets

A titanium dioxide and humidity sensing technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, and material analysis using radiation diffraction, to achieve excellent hysteresis performance, good humidity sensitivity performance, and easy deviceization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Dissolve polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) in absolute ethanol at a molar ratio of 1:3, and stir magnetically at room temperature for 30 minutes until completely dissolved A colorless and transparent A solution was formed;

[0036] b. Cool concentrated hydrochloric acid to 10°C and add it to tetrabutanol titanate at a molar ratio of 2:1, then place the mixed solution in a water bath to stir, control the temperature of the water bath to 10°C, and stir for 30 minutes to obtain colorless Transparent B solution;

[0037] c. Add the colorless and transparent solution A in step a dropwise to the solution B in the step, stir magnetically until the mixture is uniform, then place the mixed solution in a water bath, control the temperature of the water bath to 0°C, and stir for 30 minutes to obtain color transparent liquid;

[0038] d. Add the colorless transparent liquid obtained in step c to ethylene glycol at a volume rati...

Embodiment 2

[0043] a. Dissolve polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) in absolute ethanol at a molar ratio of 1:3, and stir magnetically at room temperature for 30 minutes until completely dissolved A colorless and transparent A solution was formed;

[0044] b. Cool concentrated hydrochloric acid to 0°C and add it to tetrabutyl titanate at a molar ratio of 2:1, then place the mixed solution in a water bath to stir, control the temperature of the water bath to 0°C, and stir for 30 minutes to obtain colorless Transparent B solution;

[0045] c. Add the colorless and transparent solution A in step a to the solution B in step b dropwise, stir magnetically until evenly mixed, then place the mixed solution in an ice bath, control the temperature of the ice bath to 0°C, and stir 10min, obtain colorless transparent liquid;

[0046] d. Add the colorless transparent liquid obtained in step c to ethylene glycol at a volume ratio of 1:1 to obtain a visco...

Embodiment 3

[0050] a. Dissolve polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) in absolute ethanol at a molar ratio of 1:3, and stir magnetically at room temperature for 30 minutes until completely dissolved A colorless and transparent A solution was formed;

[0051] b. Cool concentrated hydrochloric acid to 5°C and add it to tetrabutanol titanate at a molar ratio of 2:1, then place the mixed solution in a water bath to stir, control the temperature of the water bath to 20°C, and stir for 30 minutes to obtain colorless Transparent B solution;

[0052] c. Add the colorless and transparent solution A in step a to the solution B in step b dropwise, stir magnetically until evenly mixed, then place the mixed solution in a water bath, control the temperature of the water bath to 50°C, and stir for 60 minutes. A colorless transparent liquid was obtained;

[0053] d. Add the colorless transparent liquid obtained in step c to ethylene glycol at a volume ratio ...

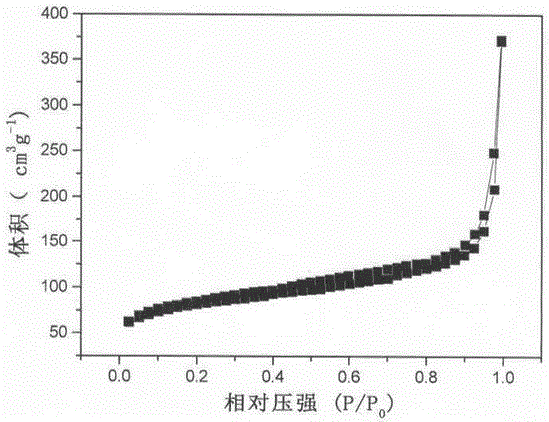

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com