Anti-dazzle and anti-blue-light lens and preparation method thereof

An anti-blue light and anti-glare technology, applied in the field of lenses, can solve the problems of short coating time interval, waste of resources, uneven evaporation coating, etc., to achieve the effect of improving light absorption, slowing down mutual penetration, and improving waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

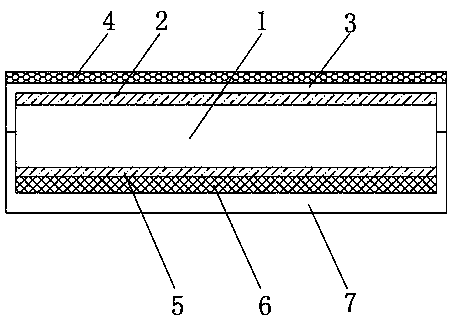

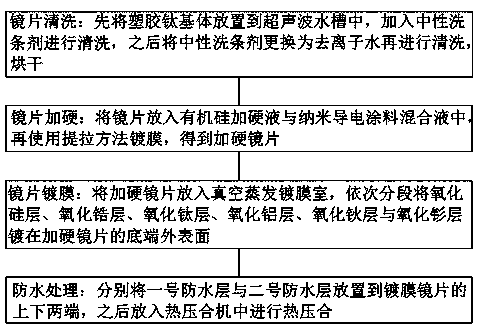

[0049] Such as Figure 1-2 As shown, an anti-glare and anti-blue light lens includes a plastic titanium base 1, a No. 1 strengthening layer 2 is provided on the top outer surface of the plastic titanium base 1, and a No. 1 waterproof layer 3 is provided on the top outer surface of the No. 1 strengthening layer 2. The outer surface of the top of the waterproof layer 3 is provided with a hydrophobic and oleophobic layer 4, the outer surface of the bottom end of the plastic titanium substrate 1 is provided with a No. 2 strengthening layer 5, and an anti-glare and anti-blue light layer 6 is provided on the outer surface of the bottom end of the No. 2 strengthening layer 5, The outer surface of the bottom end of the anti-glare and anti-blue light layer 6 is provided with a No. 2 waterproof layer 7 .

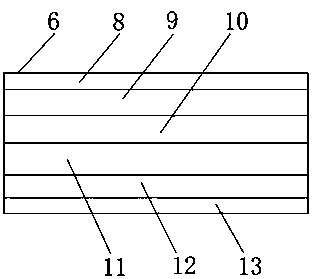

[0050] Such as figure 1 As shown, the anti-glare and anti-blue light layer 6 is provided with a silicon oxide layer 8 , a zirconium oxide layer 9 , a titanium oxide layer 10 , an alu...

Embodiment 2

[0058] Such as Figure 1-2 As shown, an anti-glare and anti-blue light lens includes a plastic titanium base 1, a No. 1 strengthening layer 2 is provided on the top outer surface of the plastic titanium base 1, and a No. 1 waterproof layer 3 is provided on the top outer surface of the No. 1 strengthening layer 2. The outer surface of the top of the waterproof layer 3 is provided with a hydrophobic and oleophobic layer 4, the outer surface of the bottom end of the plastic titanium substrate 1 is provided with a No. 2 strengthening layer 5, and an anti-glare and anti-blue light layer 6 is provided on the outer surface of the bottom end of the No. 2 strengthening layer 5, The outer surface of the bottom end of the anti-glare and anti-blue light layer 6 is provided with a No. 2 waterproof layer 7 .

[0059] Such as image 3 As shown, the anti-glare and anti-blue light layer 6 is provided with a silicon oxide layer 8 , a zirconium oxide layer 9 , a titanium oxide layer 10 , an alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com