Method for preparing transparent magneto-optic holmium oxide ceramic

A technology of transparent ceramics and holmium oxide, applied in the field of preparation of oxide transparent ceramics, can solve the problems of uneven distribution of fluoride additives and high linear transmittance of holmium oxide transparent ceramics, achieve high practical application value, and overcome uneven distribution. , The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

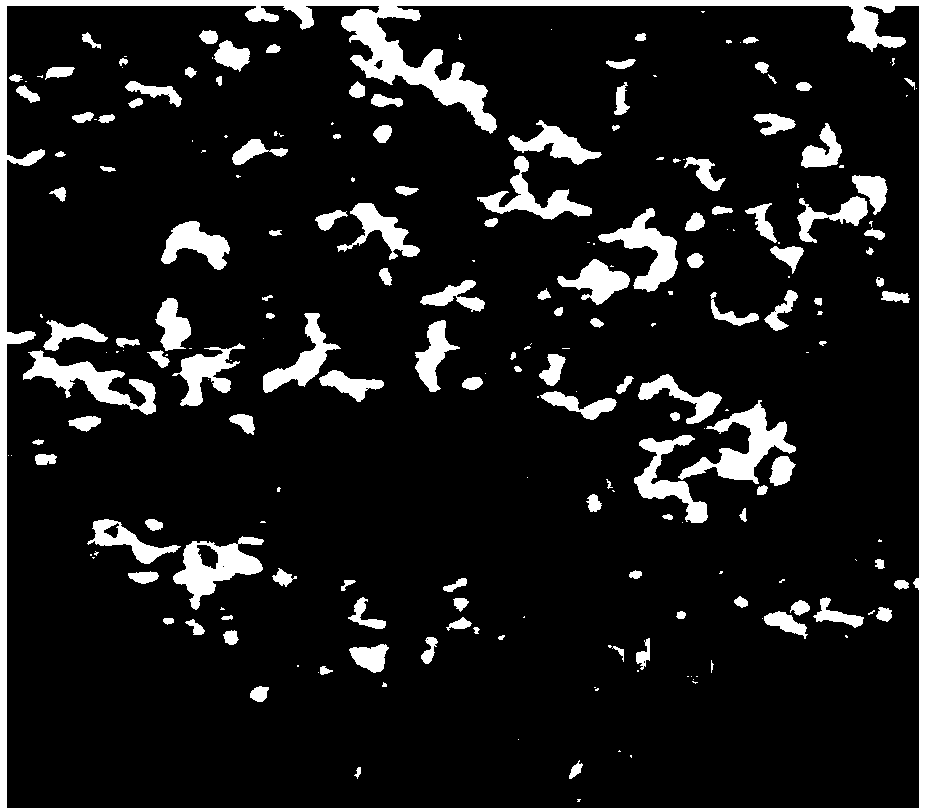

Image

Examples

Embodiment 1

[0034] A kind of preparation method of magneto-optic holmium oxide transparent ceramics proposed in this embodiment, it comprises the following steps:

[0035] Step 1: Prepare a holmium nitrate solution with a concentration of 0.25 mol / L; and prepare an ammonium fluoride solution with a concentration of 0.5 mol / L.

[0036]In this embodiment, the configuration process of the holmium nitrate solution is: dissolving holmium oxide in the nitric acid solution to obtain a holmium nitrate solution with a concentration of 0.25mol / L; the configuration process of the ammonium fluoride solution is: dissolving ammonium fluoride in Prepare in water to obtain an ammonium fluoride solution with a concentration of 0.5 mol / L.

[0037] Step 2: At a temperature of 0°C, add ammonia water with a concentration of 1mol / L to the holmium nitrate solution dropwise at a rate of 10mL / min, and make the pH value at the end point of the titration be 10, and continue to age after the titration. After 0.5h, ...

Embodiment 2

[0043] A kind of preparation method of magneto-optic holmium oxide transparent ceramics proposed in this embodiment, it comprises the following steps:

[0044] Step 1: Prepare a holmium nitrate solution with a concentration of 0.15 mol / L; and prepare an ammonium fluoride solution with a concentration of 0.03 mol / L.

[0045] In this embodiment, the configuration process of the holmium nitrate solution is: dissolving holmium nitrate in deionized water to obtain a holmium nitrate solution with a concentration of 0.15 mol / L; the configuration process of the ammonium fluoride solution is: dissolving ammonium fluoride in Configure in water to obtain ammonium fluoride solution with a concentration of 0.03mol / L.

[0046] Step 2: At a temperature of 2°C, add ammonia water with a concentration of 1mol / L to the holmium nitrate solution dropwise at a rate of 5mL / min, and make the pH at the end point of the titration 9.5, and continue to age after the titration. After 2 h, a white precipi...

Embodiment 3

[0052] A kind of preparation method of magneto-optic holmium oxide transparent ceramics proposed in this embodiment, it comprises the following steps:

[0053] Step 1: Prepare a holmium nitrate solution with a concentration of 0.1mol / L; and prepare an ammonium fluoride solution with a concentration of 0.01mol / L.

[0054] In this embodiment, the configuration process of the holmium nitrate solution is: dissolving holmium nitrate in deionized water to obtain a holmium nitrate solution with a concentration of 0.1mol / L; the configuration process of the ammonium fluoride solution is: dissolving ammonium fluoride in Prepare in water to obtain ammonium fluoride solution with a concentration of 0.01mol / L.

[0055] Step 2: At a temperature of 5°C, add ammonia water with a concentration of 1mol / L to the holmium nitrate solution dropwise at a rate of 3mL / min, and make the pH value at the end point of the titration be 9, and continue to age after the titration. After 1 h, a white precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com