Holmium oxide-scandium oxide compositely-stabilized zirconium oxide and preparation method thereof, and electrolyte material of solid oxide fuel cell

A technology for stabilizing zirconia and solid oxides, applied in scandium oxide/scandium hydroxide, fuel cells, preparation/processing of rare earth metal compounds, etc. Development and other issues, to achieve the effect of simple preparation method, excellent grain boundary conductivity, excellent ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

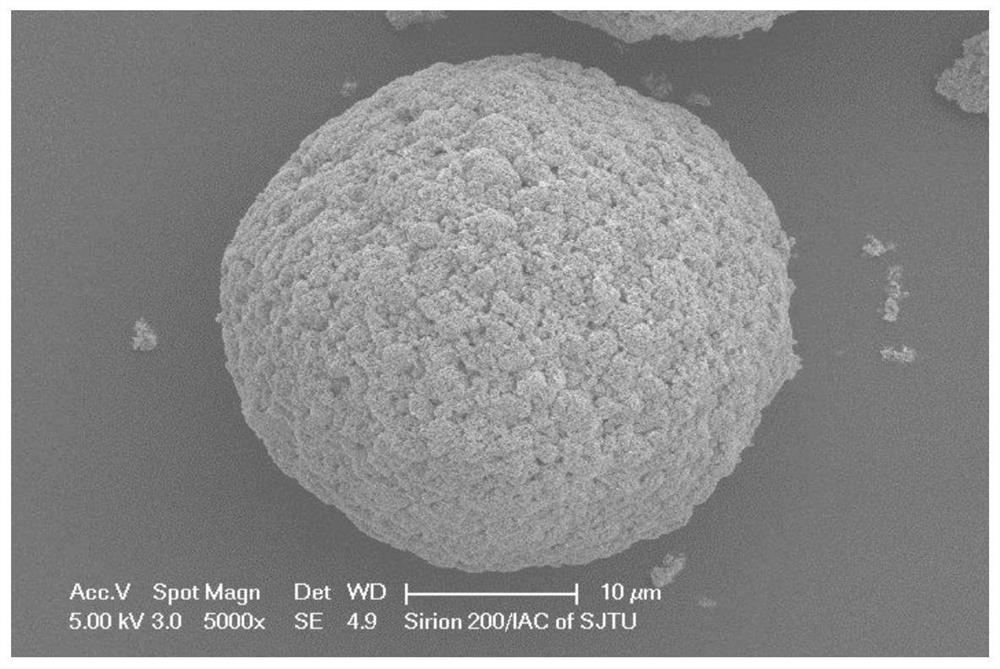

[0042] A preparation method of holmium oxide and scandium oxide composite stabilized zirconia, comprising the following steps:

[0043] Heating the mixed aqueous solution of zirconium oxychloride, scandium oxide and holmium oxide, adjusting the pH to obtain a mixed slurry, and then filtering, washing, drying, calcining and grinding;

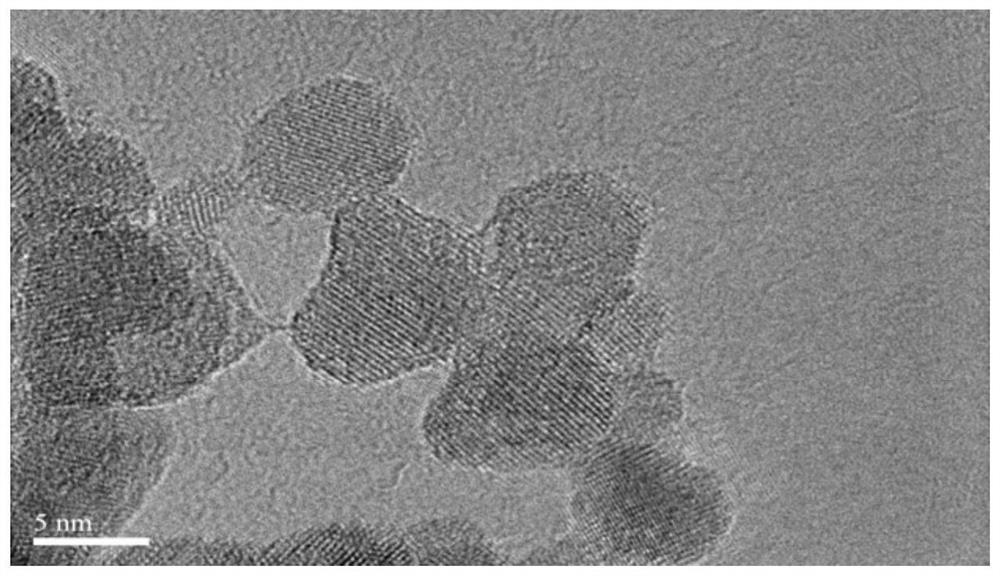

[0044] In the mixed aqueous solution, the molar ratio of zirconium ions, scandium ions and holmium ions is (92-93):(6-7):1.

[0045] Oxygen ions have the highest diffusion coefficient in cubic structure zirconia, and the corresponding ion conductivity is also the best. The appearance of the rhomboid structure seriously destroys the ion conductivity of zirconia materials. The present invention succeeds in doping with a specific amount of holmium oxide. The transition from scandium oxide-stabilized zirconia cubic structure to rhombohedral structure is suppressed, so that the obtained holmium oxide and scandium oxide composite stabilized zirconia ha...

Embodiment 1

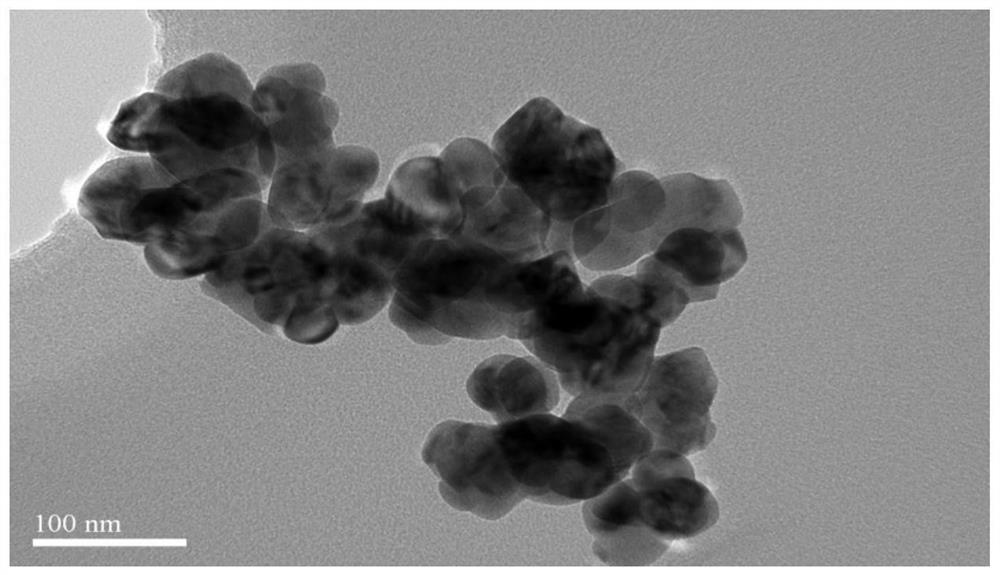

[0082] A preparation method of holmium oxide and scandium oxide composite stabilized zirconia powder, comprising the following steps:

[0083] Weigh 6.44Kg zirconium oxychloride octahydrate and dissolve it in 1000L water in the enamel reaction kettle. The pH value of the solution after complete dissolution is figure 1 shown.

Embodiment 2

[0085] A preparation method of holmium oxide and scandium oxide composite stabilized zirconia powder, comprising the following steps:

[0086] Weigh 12.88Kg zirconium oxychloride octahydrate and dissolve it in 1000L deionized water in an enamel reactor. The pH value of the solution after complete dissolution is figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com