Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Cobalt octoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It was later discovered that cobalt octoate (synonym: cobalt-2-ethylhexanoate), a compound not listed on the manufacturer's material safety data sheet, was included as an accelerator in the polyester resin. She was then tested to cobalt octoate, which was also strongly positive.

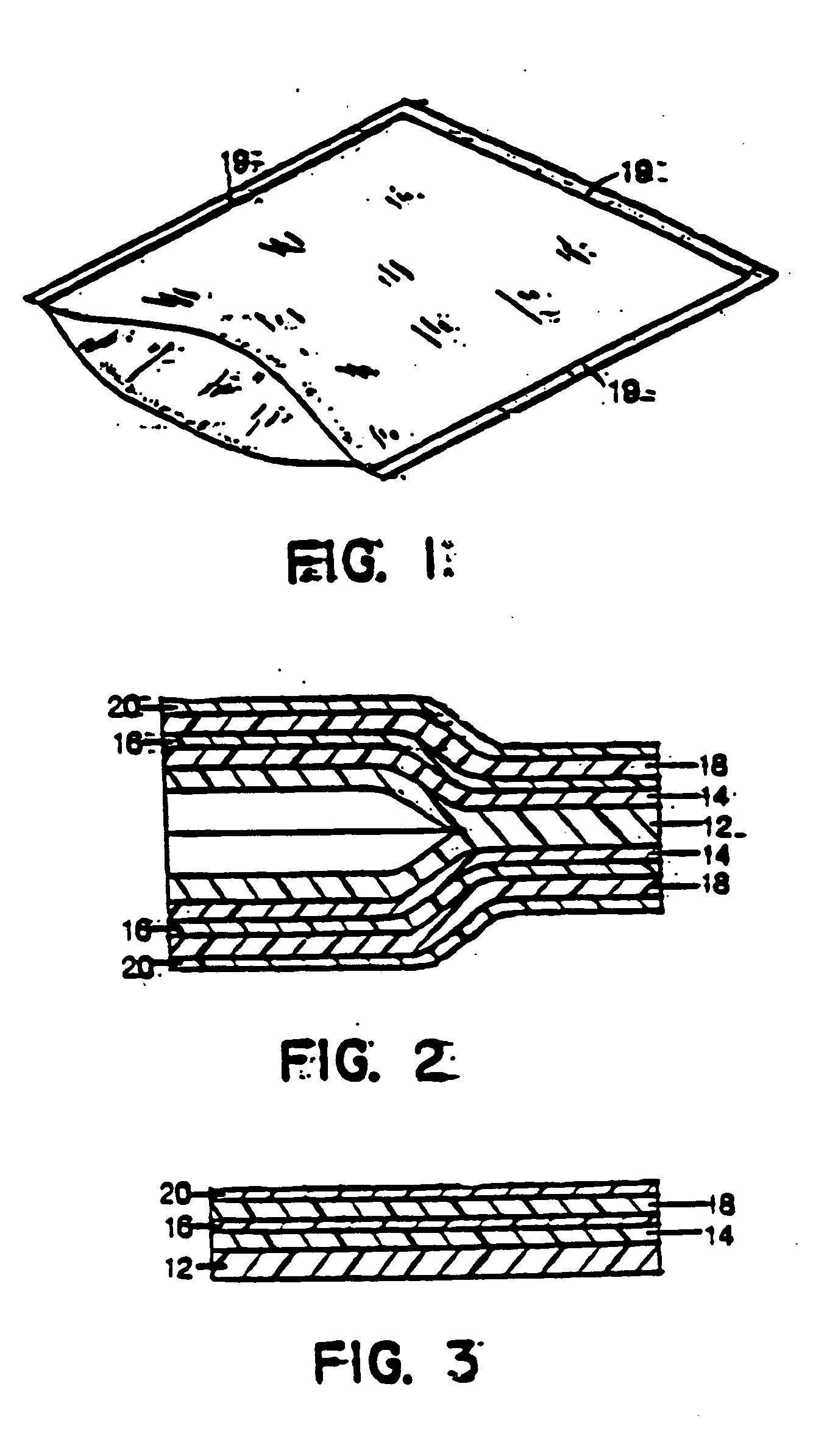

Barrier compositions and articles made therefrom

InactiveUS20050106343A1Improve barrier propertiesSynthetic resin layered productsThin material handlingPolyesterXylylene

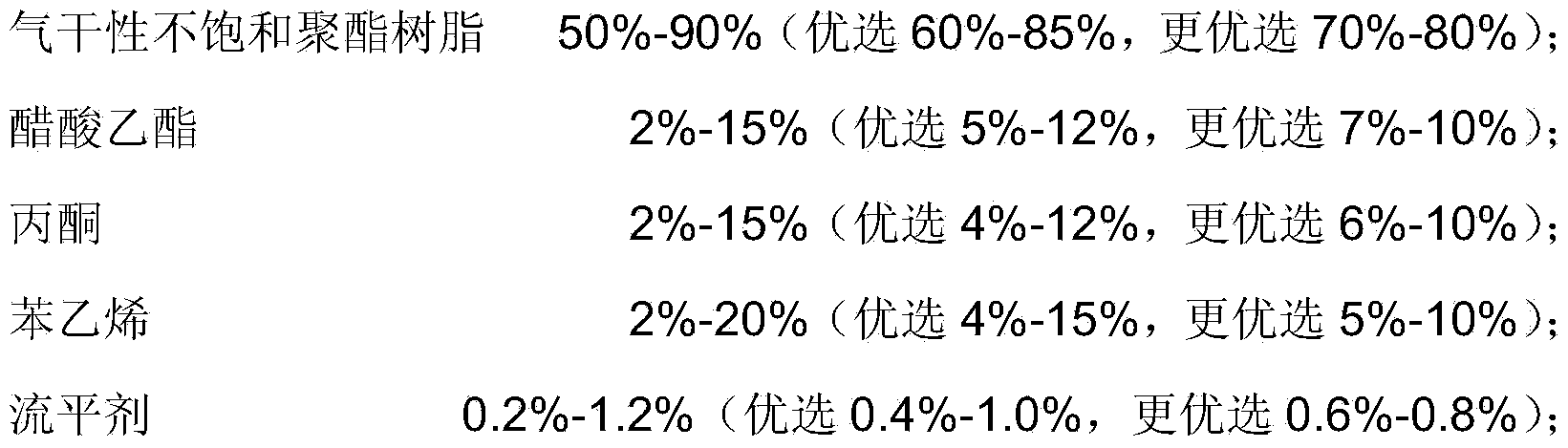

Improved oxygen barrier and oxygen absorbing compositions and structures comprising blends of xylylene group-containing polyamides and cobalt octoate and xylylene group-containing polyamides, polyesters and cobalt octoate are disclosed and claimed. These blends have superior barrier properties and clarity obtained by controlling the degree of orientation and the amount of cobalt. These novel blends are used as single layers and as the core layer in multiple layer films, structures and articles. When used in multiple layer structures, the adjacent layers are comprised of polyesters and / or polyamides. The structures made from the blends of the present invention have a clarity that is superior to structures previously known in the art.

Owner:BALL CORP

Improved stability of polyurethane polyol blends containing halogenated olefin blowing agents

InactiveUS20140051776A1Extended shelf lifeEnhance foam characteristic of foamOther chemical processesPolymer sciencePtru catalyst

A polyol pre-mix composition includes a blowing agent having a halogenated hydroolefin, a polyol, a surfactant, a catalyst composition, and a metal salt. The metal salt may be, for example, a carboxylate, acetylacetonate, alcoholate of a metal selected from the group consisting of Zn, Co, Ca, and Mg. The metal salt may be, for example, a carboxylate and / or alcoholate of a C1-C21 straight chain or branched aliphatic monocarboxylic acid or monoalcohol, such as magnesium formate, zinc octoate, calcium octoate, cobalt octoate, and magnesium octoate, and mixtures thereof. The metal acetylacetonate may be, for example, zinc acetylacetonate, cobalt acetylacetonate, magnesium acetylacetonate, or calcium acetylacetonate. A two-part system for producing a thermosetting foam blend includes (a) a polyisocyanate and, optionally, one or more isocyanate compatible raw materials; and (b) the polyol pre-mix composition. A method for producing a thermosetting foam blend includes combining: (a) a polyisocyanate; and (b) the polyol pre-mix composition.

Owner:ARKEMA INC

Epoxy modified lacquer putty

An epoxy modified puddy for metallic materials is composed of components A and B. Said component A is prepared from epoxy modified unsaturated polyester resin, functional filler, quinone substance, cobalt naphthenate (or isooctoate), polyvinyl chloride or SiO2 gas, and active diluent. Said component B is vinylamide polymer. Its advantages are long application time (60 min) and high low-temp high-moisture performance.

Owner:ZHUZHOU HUALIAN HI TECH

Method to make single-layer pet bottles with high barrier and improved clarity

InactiveUS20060246245A1Reduce yellownessEnvelopes/bags making machineryGroup 4/14 element organic compoundsPolyesterXylylene

The present invention comprises a blend of polyester and a partially aromatic polyamide with an ionic compatibilizer and a cobalt salt. This blend can be processed into a container that has both active and passive oxygen barrier and carbon dioxide barrier properties at an improved color and clarity than containers known in the art. The partially aromatic polyamide is preferably meta-xylylene adipamide. The ionic compatibilizer is preferably 5-sodiumsulfoisophthalic acid or 5-zincsulfoisophthalic acid, or their dialkyl esters such as the dimethyl ester (SIM) and glycol ester (SIPEG). The cobalt salt is selected form the class of cobalt acetate, cobalt carbonate, cobalt chloride, cobalt hydroxide, cobalt naphthenate, cobalt oleate, cobalt linoleate, cobalt octoate, cobalt stearate, cobalt nitrate, cobalt phosphate, cobalt sulfate, cobalt (ethylene glycolate), or mixtures of two or more of these. The partially aromatic polyamide is present in a range from about 1 to about 10 wt. % of said composition. The ionic compatibilizer is present in a range from about 0.1 to about 2.0 mol-% of said composition. The cobalt salt is present in a range from about 20 to about 500 ppm of said composition.

Owner:TREVIRA HLDG GMBH

Resin anchoring agent for initiation system

The invention discloses a resin anchoring agent for an initiation system. In the invention, cobalt octoate or cobalt naphthenate is used as a promoter, or cobalt octoate or cobalt naphthenate and tertiary amine promoters are mixed to form a compound promoter. A novel initiator is hydroperoxides, particularly methyl ethyl ketone peroxide and cyclohexanone peroxide. In the invention, resin anchoring agent of all models can be designed and produced, the longest gelation time can be adjusted to 10 hours or even a longer time, the curing can be continued later on when the curing of a reaction is inadequate, the curing degree is high, and the final strength is high. Moreover, the period of validity of the resin anchoring agent can be prolonged for over 1 time.

Owner:美亚高新材料股份有限公司

Four-component fuel hypergolic with 70%-98% of hydrogen peroxide

InactiveCN102863994ANot easy to age and deteriorateImprove specific impulseLiquid carbonaceous fuelsHigh concentrationKerosene

The invention relates to a four-component fuel hypergolic with 70%-98% of hydrogen peroxide. The fuel is a novel non-toxic hypergolic miscible fuel (NHMF). Aiming at the conditions that some problems exist in formulas and problem-free formulas do not open to the public in the prior art, the fuel takes alkyl-substituted alcamines compounds such as cobaltous acetate tetrahydrate, cobalt iso-octoate or cobalt acetylacetonate as main catalysts, takes dimethylethanolamine, diethylethanolamine, diisopropylethanolamine, dibutyl eth-anolamine as auxiliary catalysts, takes ethanol, propanol or butanol as a solvent, and takes aviation kerosene as an incendiary agent, and the four components are evenly mixed into an unsaturated solution. The novel fuel has the advantages of being non-toxic actually, not prone to aging and deterioration, high in specific impulse, short in ignition delay period, hypergolic and storable, capable of being applied to liquid rockets, igniters and fuel / air explosives, and the like; and is hypergolic with hydrogen peroxide with the relative high concentration.

Owner:葛明龙

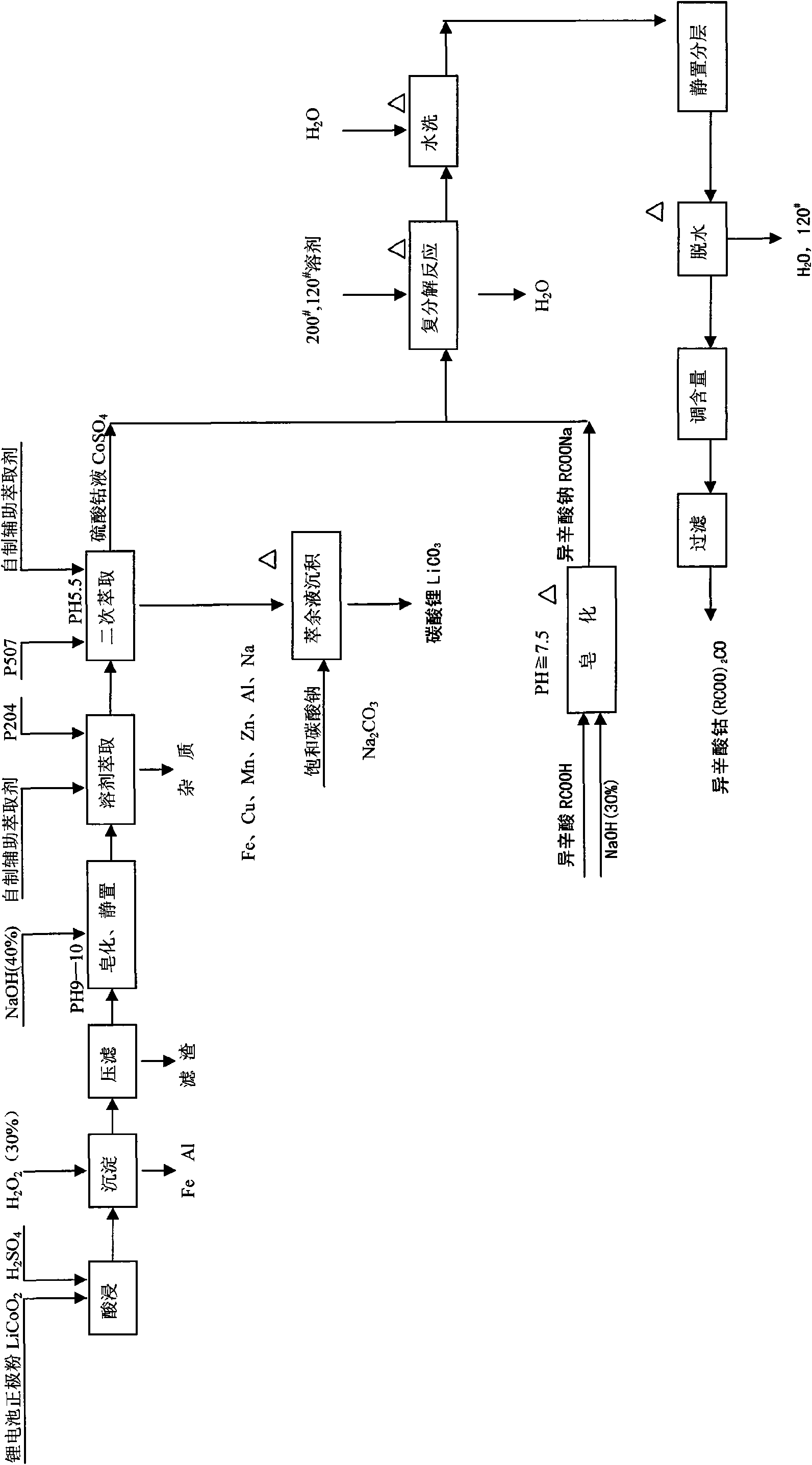

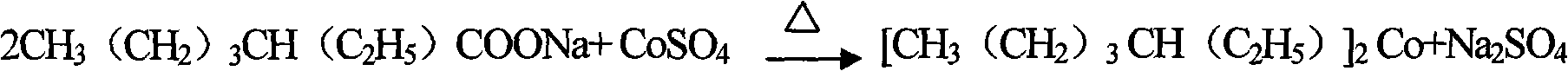

Method for preparing cobalt octoate by using LiCoO, anode material of waste lithium battery

ActiveCN101628869ALow costShorten the production cycleCarboxylic acid salt preparationDecompositionCobalt

The invention discloses a method for preparing cobalt octoate by using LiCoO, an anode material of a waste lithium battery, comprising the following steps: carrying out acidolysis on powder of the LiCoO, the anode material of the waste lithium battery by chemical extraction and back extraction, removing Fe and Al by chemical precipitation, filter pressing and deslagging, adding P204 self-made auxiliary extractant to remove impurities and adding P507 self-made auxiliary extractant to extract and separate Co from Li to prepare CoSO4 liquid with content of 75-80%, precipitating raffinate to prepare LiCO3 with primary deposition rate more than 75%, carrying out double decomposition reaction on sodium octoate obtained after saponification reaction between the prepared CoSO4 liquid and octoic acid as well as sodium hydroxide and preparing the product of cobalt octoate liquid through washing, standing to be layered, dehydrating, regulating metal contents and filtering. The rate of recovery of cobalt from the powder of the LiCoO, the anode material of the waste lithium battery is more than 97%.

Owner:SHENYANG ZHANGMING CHEM

Technique for making cloisonne amber crystal picture

InactiveCN101503042APromote value-addedHigh artistic valueDecorative surface effectsSpecial ornamental structuresCobalt octoateAdditive ingredient

The invention provides a manufacturing process of a cloisonne amber crystal drawing, comprising the following steps: firstly cutting a timber into wood blocks of 40 centimeters to 50 centimeters by special apparatus followed by polishing, fork joint bonding the wood blocks to shape a base board, then bonding a base frame and the base board; scanning a master drawing into a computer, printing the master drawing on the base board by a laser transfer machine; then coating adhesive sericin on a base body, cementing metallic threads on the base body; using an enamel-filling tube to evenly and flatly distribute the colored enamel on the drawing; finally polishing the drawing for twice to three times, drying for 30 minutes to 12 hours. The process takes unsaturated crystal resin as the main material and curing agent ethyl methyl ketone and accelerant iso-cobalt octoate as the accessory material, and at a temperature between 10 DEG C and 20 DEG C, the ingredient ratio is as follows: 8-12kg of unsaturated crystal resin, 14-16g of curing agent ethyl methyl ketone, and 0.7-1.4g of accelerant iso-cobalt octoate. Each product manufactured by the process in the invention is a piece of decoration product and a fine handicraft works having decorating, admiring and collecting values.

Owner:刘晶涛

Polypropylene material resistant to aging and impact at low temperature as well as preparation method of polypropylene material

InactiveCN105131425AImprove cold resistanceImprove anti-aging propertiesOctanoic AcidsPropanoic acid

The invention discloses a polypropylene material resistant to aging and impact at low temperature as well as a preparation method of the polypropylene material. The polypropylene material comprises the raw materials such as polypropylene resin, butadiene rubber, an ethylene-vinyl acetate copolymer, diethyl phthalate, triethylene glycol di-2-ethylhexoate(triglycol dioctate), dilauryl thiodipropionate, dibasic lead stearate, hexamethylenetetramine, tristearin, cobalt iso-octoate, ethyleneglycol dimethacrylate, a silane coupling agent KH550, erucicamide, hollow glass microspheres, andalusite powder and precipitated white carbon black. The butadiene rubber and the ethylene-vinyl acetate copolymer are added into polypropylene resin, so that the cold resistance of the polypropylene material is improved, and the resistance to impact at low temperature is enhanced; the hollow glass microspheres and the andalusite powder are added for combined utilization, so that the tensile strength and impact strength can be synergistically improved; through addition of triethylene glycol di-2-ethylhexoate(triglycol dioctate) and the like, the cold resistance of the polypropylene material is further improved; through addition of nanometer titanium phosphate, the aging resistance of the polypropylene material is improved under the joint action of zinc oxide, precipitated white carbon black and nanometer titanium phosphate.

Owner:蔡逸

Artificial agglomerated stone imitating natural cracks and production process thereof

The invention discloses artificial agglomerated stone imitating natural cracks. The artificial agglomerated stone comprises the following raw materials: calcium carbonate coarse sand, superfine calcium carbonate powder, unsaturated polyester resin, toner, titanium dioxide, methyl ethyl ketone peroxide, cobalt iso-octoate, a coupling agent, styrene, octadecanoic acid, sodium phenylpropionate and glycerol. Octadecanoic acid and sodium benzoate generate composite acid modification, and glycerol and styrene are added according to a ratio, so that the unsaturated acid content in the unsaturated polyester resin is reduced, the impact resistance of the unsaturated polyester resin is improved, the cracking condition of the artificial stone in the production process is reduced, and the defective rate of the artificial stone product is reduced; the base material is spread into the mold paved with the auxiliary material through the material distributing machine, and the auxiliary material and the base material in the mold can be molded into an artificial stone blank with imitated natural cracks through the artificial stone vibration molding machine in a vibration pressing manner, so that different crack patterns are presented on the artificial stone blank, and the appearance diversification of the artificial stone is improved.

Owner:广东省宝云石业有限公司

Electrostatic spraying PE op-coat paint

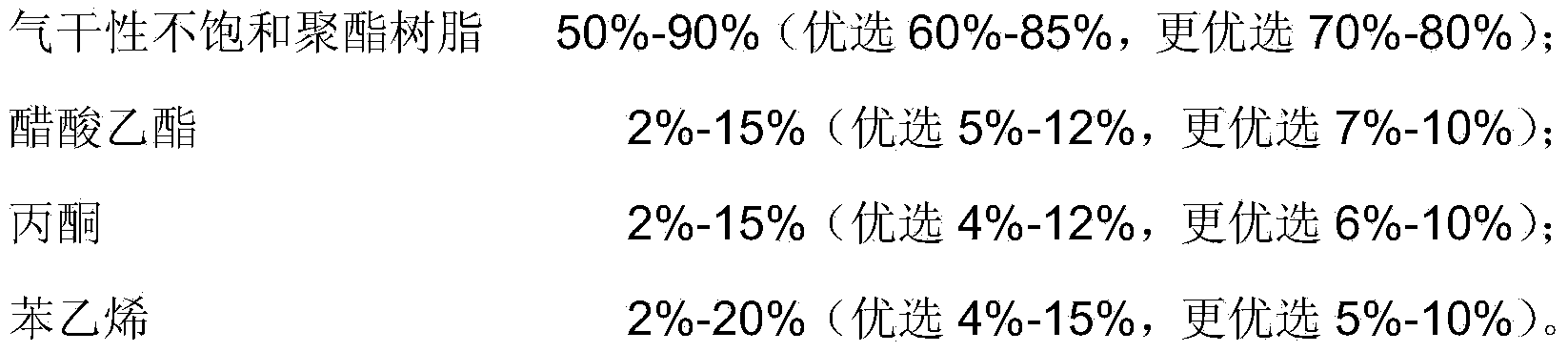

InactiveCN103849299AEasy constructionElectrostatic spraying realizationPolyester coatingsBenzoyl peroxideSolvent

The invention discloses an electrostatic spraying PE op-coat paint which comprises three components, wherein a main agent comprises air-dried unsaturated polyester resin, ethyl acetate, acetone, styrene and an organic silicon flatting agent; an accelerant is selected from one or two of cobalt iso-octoate and cobalt naphthenate; and an initiator is selected from one or more of benzoyl peroxide, tert-Butyl peroxybenzoate and methyl ethyl ketone peroxide. The preparation method comprises the steps of preparing the main agent firstly under the condition that the weight ratio of the main agent to the accelerant to the initiator is 100: (1-3): (1-3); after the main agent is uniformly mixed, adding the accelerant, and uniformly stirring; and then adding the initiator, and uniformly stirring the obtained mixture, so that the obtained mixture can be subjected to electrostatic spraying. According to the invention, the resistance is controlled by using metal cobalt ions and a high polar solvent acetone under the condition of not using additional conductive agents, so that an effect of electrostatic spraying is achieved, and complex workpieces can be subjected to construction conveniently, thereby lowering the construction difficulty and improving the work efficiency.

Owner:SHANGHAI CHANGRUNFA PAINT

Polyester finishing coat for colourful stainless steel plate of mobile phone shielding case and preparation method of polyester finishing coat

ActiveCN103540244AHigh glossImprove adhesionPolyester coatingsPolymer scienceDimethylaniline N-oxide

The invention discloses polyester finishing coat for a colourful stainless steel plate of a mobile phone shielding case and a preparation method of the polyester finishing coat. The polyester finishing coat for the colourful stainless steel plate of the mobile phone shielding case is prepared from the following raw materials in parts by weight: 80-100 parts of unsaturated polyester resin, 2-3 parts of dibenzoyl peroxide, 5-10 parts of phenylethylene, 3-6 parts of butyl acetate, 0.2-0.4 part of dibutyltin dilaurate, 0.1-0.2 part of cobalt iso-octoate, 0.3-0.5 part of N,N-dimethylaniline, 3-5 parts of nano titanium dioxide, 5-10 parts of composite filler, 20-30 parts of phthalo blue, 0.4-0.6 part of Tego 750W wetting dispersant, 0.2-0.3 part of Ruifu L-520 defoaming agent and 0.5-0.8 part of BYK-340 levelling agent. The polyester finishing coat has high gloss, high adhesive force, high abrasive resistance and high hardness and is excellent in solvent resistance, water resistance, oil resistance, acid and alkali resistance, chemical resistance and weather resistance, film is full, surface can be polished, decorative property is high, flexibility is good, impact resistance is high, fragility is low, and the requirements of finishing coat for the colourful stainless steel plate of the mobile phone shielding case can be completely met.

Owner:安徽墙煌彩铝科技有限公司

High-efficiency and flame-retardation glass fiber reinforced plastic composite material

The invention discloses a high-efficiency and flame-retardation glass fiber reinforced plastic composite material. The high-efficiency and flame-retardation glass fiber reinforced plastic composite material comprises, by weight, 18-24 parts of alkali-free glass short fibers, 12-17 parts of epoxy vinyl resin, 0.4-1.1 parts of a flame retardant, 0.7-1.8 parts of cobalt octoate, 3-6 parts of aluminum hydroxide, 9-16 parts of hydrogen peroxide, 0.3-0.6 parts of dicyclopentadiene, 0.03-0.2 parts of hexamethylenetetramine, wherein the epoxy vinyl resin is one of bisphenol A epoxy vinyl ester resin and phenolic epoxy vinyl ester resin, and the flame retardant is polyphosphamide. The glass fiber reinforced plastic composite material has good chemical stability, strength and flame retardation effect.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Novel light-conversion plate and preparation method thereof

The present invention belongs to the field of novel plates, and discloses a novel light-conversion plate and a preparation method thereof, wherein the novel light-conversion plate is mainly prepared from the following materials by weight: 80-95% of an unsaturated polyester resin, 1-8% of methyl ethyl ketone peroxide, 1-8% of cyclohexanone peroxide, 1-8% of cobalt isooctanoate, and 0.5-5% of an organic light-conversion compound material. The preparation method comprises: dissolving an organic light-conversion compound material in an unsaturated polyester resin, carrying out mechanical or gas bubble acceleration dispersion in the unsaturated polyester, adopting a production line, adding cobalt isooctanoate to uniformly mix, adding methyl ethyl ketone peroxide to uniformly mix, dispersing the mixed resin on the polyester film, spreading lighting-grade glass yarns or chopped strand mat on the uniformly-distributed resin, infiltrating, covering the polyester film, carrying out accelerated shaping with an oven, and cutting, wherein the whole process is 5-18 min. A purpose of the present invention is to provide a novel light-conversion plate with characteristics of excellent light-conversion efficiency and long service life, and a preparation method thereof.

Owner:FOSHAN YINUO PLATE TECH CO LTD

Method to make single-layer pet bottles with high barrier and improved clarity

The present invention comprises a blend of polyester and a partially aromatic polyamide with an ionic compatibilizer and a cobalt salt. This blend can be processed into a container that has both active and passive oxygen barrier and carbon dioxide barrier properties at an improved color and clarity than containers known in the art. The partially aromatic polyamide is preferably meta-xylylene adipamide. The ionic compatibilizer is preferably 5-sodiumsulfoisophthalic acid or 5-zinesulfoisophthalic acid, or their dialkyl esters such as the dimethyl ester (SIM) and glycol ester (SIPEG). The cobalt salt is selected form the class of cobalt acetate, cobalt carbonate, cobalt chloride, cobalt hydroxide, cobalt naphthenate, cobalt oleate, cobalt linoleate, cobalt octoate, cobalt stearate, cobalt nitrate, cobalt phosphate, cobalt sulfate, cobalt (ethylene glycolate), or mixtures of two or more of these. The partially aromatic polyamide is present in a range from about 1 to about 10 wt. % of said composition. The ionic compatibilizer is present in a range from about 0.1 to about 2.0 mol-% of said composition. The cobalt salt is present in a range from about 20 to about 500 ppm of said composition.

Owner:TREVIRA HLDG GMBH

Anticorrosion paint

InactiveCN104927433AImprove anti-corrosion performanceImprove wear resistanceAnti-corrosive paintsCelluloseFire retardant

An anticorrosion paint is made from, by weight, 4 to 8 parts of maleic anhydride, 6 to 9 parts of stannous chloride, 1 to 4 parts of sodium borate, 12 to 18 parts of dispersant, 11 to 16 parts of leveling agent, 13 to 17 parts of pollution-resistant aid, 7 to 14 parts of flame retardant, 6 to 12 parts of linseed oil, 8 to 13 parts of pentaerythritol, 4 to 6 parts of cobalt caprylate, 3 to 7 parts of abietic diacid, 4 to 8 parts of talcum powder, 9 to 15 parts of asphalt, 2 to 4 parts of hydroxyethyl cellulose, 6 to 9 parts of acrylic ester, and 3 to 6 parts of polysiloxane. The anticorrosion paint is excellent in corrosion resistance, good in wear resistance, heat tolerance and buckling resistance and free of environmental pollution.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Low-viscosity flame-retardant polyurethane metal paint

InactiveCN105385327AEvenly dispersedEvenly distributedFireproof paintsAnti-corrosive paintsSodium BentoniteDiethyl methylphosphonate

The invention discloses a low-viscosity flame-retardant polyurethane metal paint. The paint comprises the following raw materials in parts by weight: 80 to 85 parts of modified polyurethane, 6 to 9 parts of aqueous organic silicone resin, 12 to 15 parts of aqueous aldehyde-ketone resin, 22 to 25 parts of talcum powder, 3 to 6 parts of bentonite, 5 to 8 parts of kaolin, 8 to 12 parts of calcium carbonate, 10 to 14 parts of nano magnesium hydroxide, 3 to 4 parts of antiseptic, 2 to 3 parts of antifoaming agent, 2.5 to 4 parts of flatting agent, and 5 to 6 parts of pigment; wherein the modified polyurethane is prepared from the following components: polyhexanedioic acid-1,4-butanediol ester diol, polytetrahydrofuran, N,N-bis(2-hydroxyethyl)amino methylene diethyl phosphonate, modified polymerized 1,6-hexamethylene diisocyanate, 1,6-hexanediol, 1,4-butanediol-sodium sulfonate, epoxy resin, cobalt octoate, N-methyl diethanolamine, and diethanolamine, and modified polymerized 1,6-hexamethylene diisocyanate is prepared by the following steps: polymerizing 1,6-hexamethylene diisocyanate and then grafting hydroxyl siloxane to the polymerized 1,6-hexamethylene diisocyanate.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

Highly-waterproof water-soluble polyurethane resin and preparation method thereof

The invention discloses a preparation method of highly-waterproof water-soluble polyurethane resin. The method comprises the following steps: heating terephthalic anhydride polyester diol and poly(1,4-cyclohexanedimethanol adipate) diol for melting, carrying out heat insulation, and carrying out vacuum dehydration to obtain a material a; adding tetramethyl phenyldimethylene diisocyanate to the material a, heating, carrying out heat insulation, cooling, adding 1,5-pentanediol, melamine-formaldehyde resin and N-methyl pyrrolidone, adding cobalt octoate, heating, and carrying out heat insulation to obtain a material b; cooling the material b, adding a N-propyldiethanolamine and bis(2-hydroxyethyl)aniline mixed solution in a dropwise manner, heating, and carrying out heat insulation to obtain a material c; and adding propionic acid to the material c to neutralize, and carrying out vacuum distillation to obtain the highly-waterproof water-soluble polyurethane resin. The invention also discloses the highly-waterproof water-soluble polyurethane resin. The highly-waterproof water-soluble polyurethane resin has excellent waterproof property and hardness, and the method is stable and is easy to control.

Owner:安徽思敬齐环保材料有限公司

Flame-retardant polyurethane resin and preparation method thereof

The invention discloses a flame-retardant polyurethane resin which is prepared from the following raw materials in parts by weight: 37-40 parts of organic phosphorus polyester polyol, 52-55 parts of modified toluene diisocyanate, 2.5-4 parts of diglycol, 1.3-1.6 parts of tartaric acid, 7-10 parts of epoxy resin, 0.4-0.7 part of cobalt octoate, 3-4 parts of dimethylethanolamine and 3.5-5 parts of bis(2-hydroxyethyl)aniline. The invention also discloses a preparation method of the flame-retardant polyurethane resin, which comprises the following steps: uniformly mixing the organic phosphorus polyester polyol and modified toluene diisocyanate, heating, keeping the temperature, cooling, adding the diglycol, tartaric acid, epoxy resin and acetone, uniformly mixing, adding the cobalt octoate, heating, and keeping the temperature to obtain a material a; cooling the material a, dropwisely adding a solution containing the dimethylethanolamine and bis(2-hydroxyethyl)aniline, heating, and keeping the temperature to obtain a material b; and regulating the pH value of the material b to neutrality, and removing the acetone in vacuum to obtain the flame-retardant polyurethane resin.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Preparation method of self-cleaning composite artificial stone material

InactiveCN106495641AExtended service lifeReduce residual rateCeramic shaping apparatusSlagDecomposition

The invention relates to a preparation method of a self-cleaning composite artificial stone material, and belongs to the technical field of building materials. The preparation method of the self-cleaning composite artificial stone material utilizes methyl methacrylate, polyurethane and polyethylene resin as raw materials, cobalt octoate as a catalyst, sodium silicate as a modifying agent and triethoxysilane as a coupling agent; a self-cleaning binder is synthesized; the self-cleaning capacity of a surface of an artificial stone material is increased; meanwhile, the wear-resistance capacity of the artificial stone material is increased; afterwards, building waste soil, bentonite and blast-furnace slag are used a mixture; micro-content metallic elements such as titanium and the like in the mixture are utilized as a pholocatalyst; the decomposition capability, to a pollutant, of the artificial stone material is increased; finally, the composite artificial stone material is made and obtained by vibration, extrusion and drying. The preparation method effectively solves problems that the surface of the artificial stone material is easily corroded after the surface of the artificial stone material is subjected to pollution treatment, and meanwhile, the surface of the artificial stone material loses a gloss after being washed; the effect of self-cleaning, without a washing agent for washing, of the artificial stone material is realized.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Water mill for stone machining and preparation method thereof

ActiveCN103056787AImprove grinding forceImprove polishing effectAbrasion apparatusGrinding devicesEpoxyCarbide silicon

The invention discloses a water mill for stone machining and a preparation method thereof. The water mill is prepared through black silicon carbide, silica, polyethylene glycol, epoxy resins, methyl ethyl ketone peroxide, cobalt iso-octoate and magnesium sulfate. The method comprises placing the polyethylene glycol and the epoxy resins in a reaction still to be heated and stirred evenly; putting the black silicon carbide, silica and the magnesium sulfate in a mixer to be stirred and mixed evenly; putting the evenly stirred mixtures in the mixer to be stirred evenly, adding methyl ethyl ketone peroxide and cobalt iso-octoate in the mixtures to be heated and stirred evenly to be discharged to obtain a mixed material; and putting the mixed material in a mould, and molding and drying the material naturally under the normal pressure and temperature to obtain the product water mill. The water mill prepared through the method has a higher grinding effect, surface smoothness and brightness than an ordinary grinding head, and ideal effects of users can be achieved without wool wheel polishing.

Owner:郑州新安华砂轮有限公司

High wear resistance high strength nano resin material

The invention discloses a high wear resistance high strength nano resin material comprising a main raw material of unsaturated resin, a stabilizer, a toughening agent, a plasticizer, a colorant, a flame retardant and other additives are added, after solidification effect of catalysts of methyl ethyl ketone and cobalt isooctanate, the unsaturated resin is mixed with other additives, and 8%-12% of SiC nano powder, 2%-5% of far infrared nano material particles with the wave length of 8-15 micron, carbon nanotubes (CNTs) with methyl methacrylate (MMA) grafted on the surface and surface-hydrophobic-modified nano TiO2 are added; the high wear resistance high strength nano resin material is obtained by a production line of the process of coating a sheet-shape continuous substrate, rolling, extruding or squeezing; and a further improvement is that the far infrared nano material particles with the wave length of 8-15 micron are selected from titanium dioxide, zinc oxide and silicon oxide. The high wear resistance high strength nano resin material has the advantages of high strength, high wear resistance and good antibacterial, antistatic and health care functions.

Owner:TAIZHOU HUALI PLASTIC

Non-toxic environment-friendly oil paint

InactiveCN106543902AImprove environmental performanceSmall tasteRosin coatingsBiodieselUnsaturated Oils

The invention discloses non-toxic environment-friendly oil paint. The non-toxic environment-friendly oil paint is prepared from the following ingredients in parts by mass: 40-50 parts of rosin resin, 6-10 parts of rosinyl diacid, 5-7 parts of sodium carboxymethyl cellulose, 20-40 parts of flaxseed oil, 6-8 parts of zeolite powder, 20-30 parts of jatropha curcas biodiesel oil, 1-3 parts of cobalt octoate, 15-25 parts of unsaturated oleic acid and 1-2 parts of essential oil. The non-toxic environment-friendly oil paint is pollution-free and does not endanger environments and human.

Owner:张振宾

Plastic containing colophony powder and polyvinyl chloride

The invention discloses plastic containing colophony powder and polyvinyl chloride. The plastic comprises raw materials in parts by weight as follows: 100-106 parts of ammonium polyphosphate, 1.3-2 parts of glacial acetic acid, 1.3-2 parts of ethyl cellulose, 3-4 parts of tetraethoxysilane, 16-20 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 30-34 parts of 90-95% ethyl alcohol, 160-200 parts of a 0.5 mol / l aniline aqueous solution, 5-10 parts of sodium peroxide, 460-500 parts of polyvinyl chloride, 2-3 parts of colophony powder, 6-10 parts of calcined gypsum powder, 2-3 parts of PTMG, 0.1-0.12 parts of cobalt iso-octoate, 13-18 parts of iso-octyl methacrylate and 1-2 parts of ammonium sulfate. According to the plastic, firstly, surface coating is performed on the ammonium polyphosphate with a sol-gel treatment technology, the surface strength and the water resistance are improved, then polyaniline coating is performed, the flame retardance and the thermal decomposition performance are improved, and the dispersity and the compatibility of an additive in the plastic are effectively improved.

Owner:HEFEI JIKE NEW MATERIALS

Knitting machine cross beam and production process thereof

InactiveCN110331509ASolve problems that cannot meet real-world needsReduce usageWeft knittingWarp knittingGlass fiberEpoxy

The invention discloses a knitting machine cross beam and a production process thereof. The cross beam comprises a cross beam body, wherein a first groove is formed in the left side of an inner cavityof the cross beam body, a second groove is formed in the top of the cross beam body, a convex plate is fixedly connected to the rear side of the cross beam body, and five fixing holes are formed in the top of the convex plate. Preferably, a production formula of the cross beam of the knitting machine comprises raw materials as follows: 65%-70% of epoxy resin, 1%-2% of a cobalt octoate promoter, 2%-4% of a methyl ethyl ketone peroxide curing agent, 10%-14% of glass fiber and 5%-7% of polyurethane rubber. The problem that a finished product cannot meet the actual demands since the existing knitting machine cross beam and the production process thereof are backward is solved; the knitting machine cross beam and the production process thereof have the advantage that the use is convenient, andthe produced cross beam has high wear resistance, high mechanical strength, low production cost and long service life, meets the actual demands of enterprises and promotes further development of knitting machines.

Owner:嘉兴市中泰冶金设备有限公司

Artificial stone toolframe and its production process

The present invention relates to an antificial stone knife holder, and is characterized by that the knife slots with various sizes are cut on the upper end face or / and side face of the knife holder seat for receiving knifes. Said knife holder is made up by using polymer solid material, and the composition of the described polkymer solid material (called artificial stone) includes unsaturated resin, methyl-ethyl ketone and cobalt caprylate. Said knife holder possesses several advantages of mildew prevention, resisting corrosion, resisting bacteria, beautiful appearance, smooth surface, no deformation and durability, etc. and is mainly applicable to kitchen and cooking room of restaurant, etc.

Owner:李勤

High-adhesion automobile putty and preparation method thereof

InactiveCN107841181AThe formula is scientific and reasonableStrong adhesionFilling pastesCyclohexanoneBasalt fiber

The invention discloses high-adhesion automobile putty which is prepared from the following components in parts by weight: 350-400 parts of high viscosity polyester resin, 10-20 parts of diisocyanate,50-100 parts of 20-30wt% of shell-lac ethanol solution, 5-10 parts of nano metal powder, 5-10 parts of octadecanethiol 50-80 parts of nano-kaolin, 10-20 parts of magnesium oxide, 20-30 parts of magnesium chloride, 10-20 parts of basalt fibers, 5-10 parts of sodium fluoride, 20-30 parts of styrene, 100-150 parts of talcum powder, 50-60 parts of titanium dioxide, 5-10 parts of cobalt octoate and 200-250 parts of cyclohexanone peroxide. The high-adhesion automobile putty disclosed by the invention is high in adhesive force, high in drying speed, easy in knife coating, excellent in construction performance, smooth, flat and crack-less in appearance after curing and easy to polish. The invention further provides a preparation method of the high-adhesion automobile putty. The preparation methodis simple in process steps and high in operability and does not have special requirement on equipment.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Environment-friendly paint

InactiveCN104927458AImprove adhesionGood acid and alkali resistanceCoatingsPolymer scienceAcrylic resin

Environment-friendly paint is made of, by weight, 15-24 parts of thermoplastic acrylic resin, 2-5 parts of defoamer, 6-11 parts of weather-fastness pearl powder, 7-9 parts of ester solvent, 15-24 parts of rosin diacid, 4-7 parts of cobalt caprylate, 4-6 parts of cobalt iso-octoate, 7-8 parts of glycerin, 3-7 parts of inorganic antibacterial micro powder, 6-8 parts of ferrum dioxide nanoscale micro powder, 4-7 parts of water soluble resin, 11-17 parts of butyl stearate, 6-10 parts of acrylonitrile, 3.5-10 parts of unsaturated oleic acid, 2-5 parts of sodium phosphate powder, 7-10 parts of chromic anhydride, 1-4 parts of absorbent and 1.3-5 parts of polyhydric alcohol. The environment-friendly paint has the advantages that the environment-friendly paint is non-toxic, less harm to environment and human body, good in adhesion and acid-base resistance and wider and wider in application range.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Wood fiber modified enhanced unsaturated polyester composite and preparation method thereof

The invention discloses a wood fiber modified enhanced unsaturated polyester composite and a preparation process of the wood fiber modified enhanced unsaturated polyester composite. The wood fiber modified enhanced unsaturated polyester composite is characterized by taking vinyl isocyanate, poplar powder, cobalt octoate, methyl ethyl ketone peroxide, KH550, ammonium polyphosphate, melamine, expansible graphite, encapsulated red phosphorus, and a crylic acid solution as raw materials. The poplar powder is soaked in the crylic acid solution and the KH550 / ethanol solution, the dispersity of a modified wood fiber in a matrix is high, the compatibility of the modified wood fiber is high, and the interface bonding performance with the matrix is improved; and the tensile strength, the bending strength and the impact toughness of the composite are improved, and the mechanical properties and the heat resistance of the composite are improved. After being activated and modified by melamine, ammonium polyphosphate is mixed and ball-milled with expansible graphite and encapsulated red phosphorus, the materials mutually produce a synergistic effect, and a composite flame retardant is obtained and used for improving the flame retardant property of the composite.

Owner:JMINDUSTRIES GRP +1

Unsaturated polyester resin accelerant as well as preparation method and application thereof

ActiveCN114249864AThe highest exothermic peak is moderateImprove curing effectSolid waste managementPolymer scienceCobalt octoate

The invention belongs to the technical field of accelerators, and particularly relates to an unsaturated polyester resin accelerator as well as a preparation method and application thereof. The unsaturated polyester resin accelerant is prepared from the following raw materials in percentage by mass: 69 to 89.5 percent of methanol, 0.5 to 1 percent of copper acetate, 5 to 10 percent of cobalt iso-octoate and 5 to 20 percent of water. The invention also provides a preparation method of the unsaturated polyester resin accelerator, which comprises the following steps: mixing methanol, copper acetate, cobalt iso-octoate and water, and stirring for 30-60 minutes to obtain the unsaturated polyester resin accelerator. The accelerator product system is stable, the layering phenomenon cannot occur after long-time standing, and the problem of layering of an existing accelerator system is solved. A resin product prepared from the accelerator is good in curing effect and high in hardness, and the phenomenon that the resin is sticky to hands and becomes soft is avoided. The unsaturated polyester resin accelerator can shorten the gelling time and improve the production efficiency, the highest exothermic peak temperature in the resin curing process is similar to that of commercially available products, the curing effect is ideal, and the unsaturated polyester resin accelerator can replace existing products.

Owner:GUANGDONG MEIHENG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com