Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

304results about How to "High artistic value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing titanium alloy artware by adopting selective laser melting

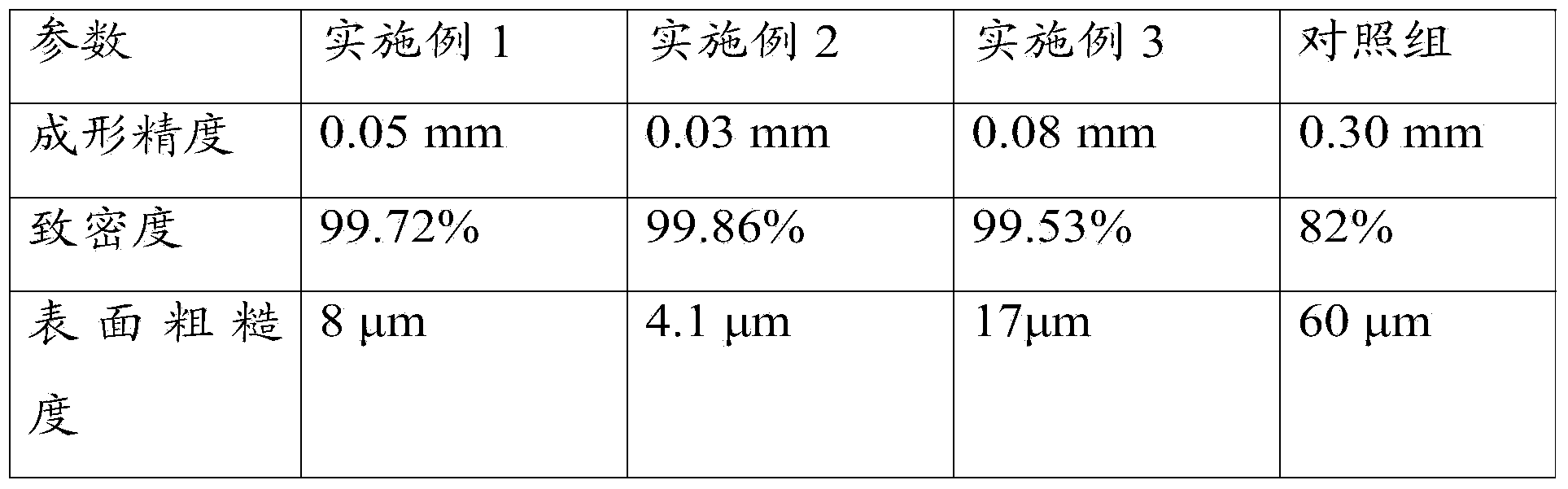

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

Paint hull painting process

InactiveCN1803311APlay a protective effectWith simplicityPretreated surfacesSpecial surfacesAgricultural engineeringEngineering

The invention discloses an imitation antique paint coating technology in the wood furniture domain, which comprises the following steps: disposing surface; painting fundamental color; disposing middle effect; spraying top-coat at 20-30 deg C coating temperature and 55-80 percent relative wetness. The technology can protect the fundamental furniture, which makes furniture possess artistic value and appreciation value.

Owner:东莞大宝化工制品有限公司

Manufacturing method of relief silverware

ActiveCN102922936AImprove appearance qualityGuarantee the appearance qualitySpecial ornamental structuresSilver plateAdhesive

The invention relates to the field of processing of silverware and specifically relates to a manufacturing method of relief silverware, which can solve the problems of low work efficiency, low degree of mechanization, poor appearance quality and the like of conventional manual manufacturing of the silverware. The manufacturing method comprises the following steps: melting silver water; casting a silver blank; forging and pressing the silver blank into a thin silver plate with the thickness being 0.3-1mm on a forging and pressing machine; stamping the thin silver plate to form the basic contour of all parts of the silverware on a rotary stretch forming machine; welding all the parts by adopting welding materials according to the shape requirements of the silverware, and forming a matrix of the silverware; casting a filling adhesive into the matrix of the silverware, cooling and then forming a plastic support; carving flowers or patterns; removing the plastic support; washing; and grinding and polishing. The manufacturing method disclosed by the invention can not only inherit a quantity of traditional processes of old folk silversmiths, but also integrate with modernized devices and processes; and during the manufacturing process, the forging and pressing machine and a stretch forming machine are utilized, the structure is simple, the design is reasonable, the operation is simple and convenient, the mechanized operation of forging, pressing and forming of a silver plate can be realized, the operation is time-saving and labor-saving, the efficiency is high, and high-efficiency and fine manufacturing requirements in manufacturing of the silverware can be met.

Owner:繁峙县星河银业有限公司

Method for preparing colored foam glass ceramic material from lithium tailings

InactiveCN108191230ASimple preparation processWide firing rangeGlass shaping apparatusPore distributionSlag

The invention provides a method for preparing a colored foam glass ceramic material from lithium tailings. According to the method, the material is prepared from a main material, an auxiliary material, fluxing agents, pore forming agents and colorants by blending and one-time high-temperature sintering, wherein the lithium tailings serve as the main material; cullet serves as the auxiliary material; the fluxing agents comprise sodium fluoride, potassium carbonate, sodium silicate, mirabilite and borax; the pore forming agents comprise calcium carbonate and silicon carbide; the colorants comprise copper oxide, iron oxide, cobalt oxide, chromium oxide, manganese oxide and zinc oxide. The problems of industrial slag accumulation and secondary pollution can be solved effectively with the method, and recycling of resources is realized; the preparation process is simple, the cost is low, and prepared foam glass ceramic is small in bulk density, uniform in pore distribution, adjustable in color, high in compressive strength and high in added value and has good industrial prospect.

Owner:WUHAN UNIV OF TECH

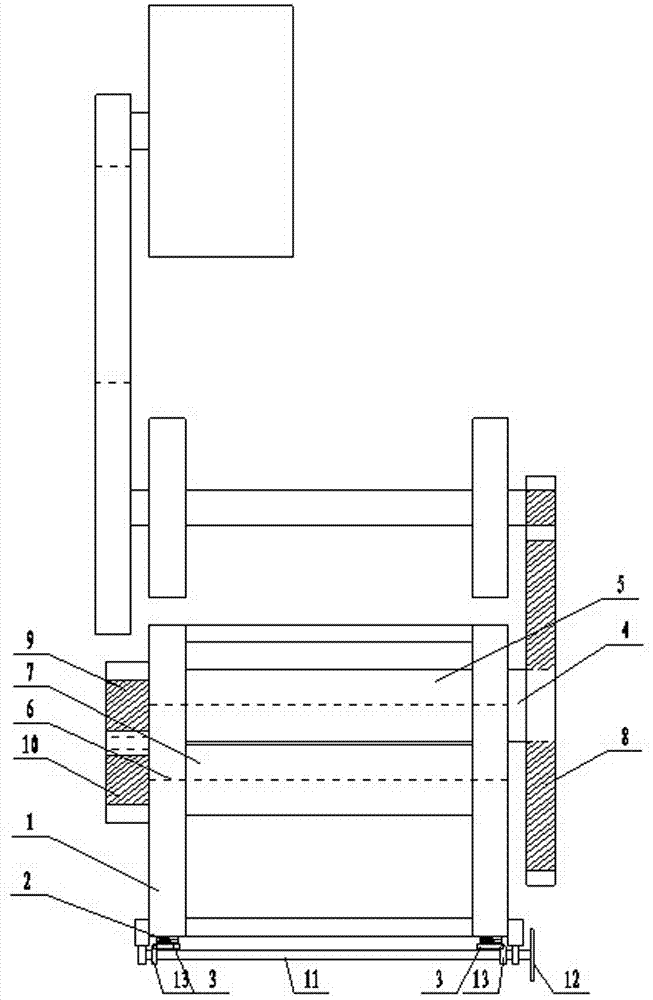

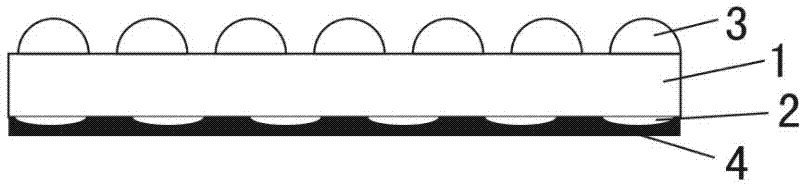

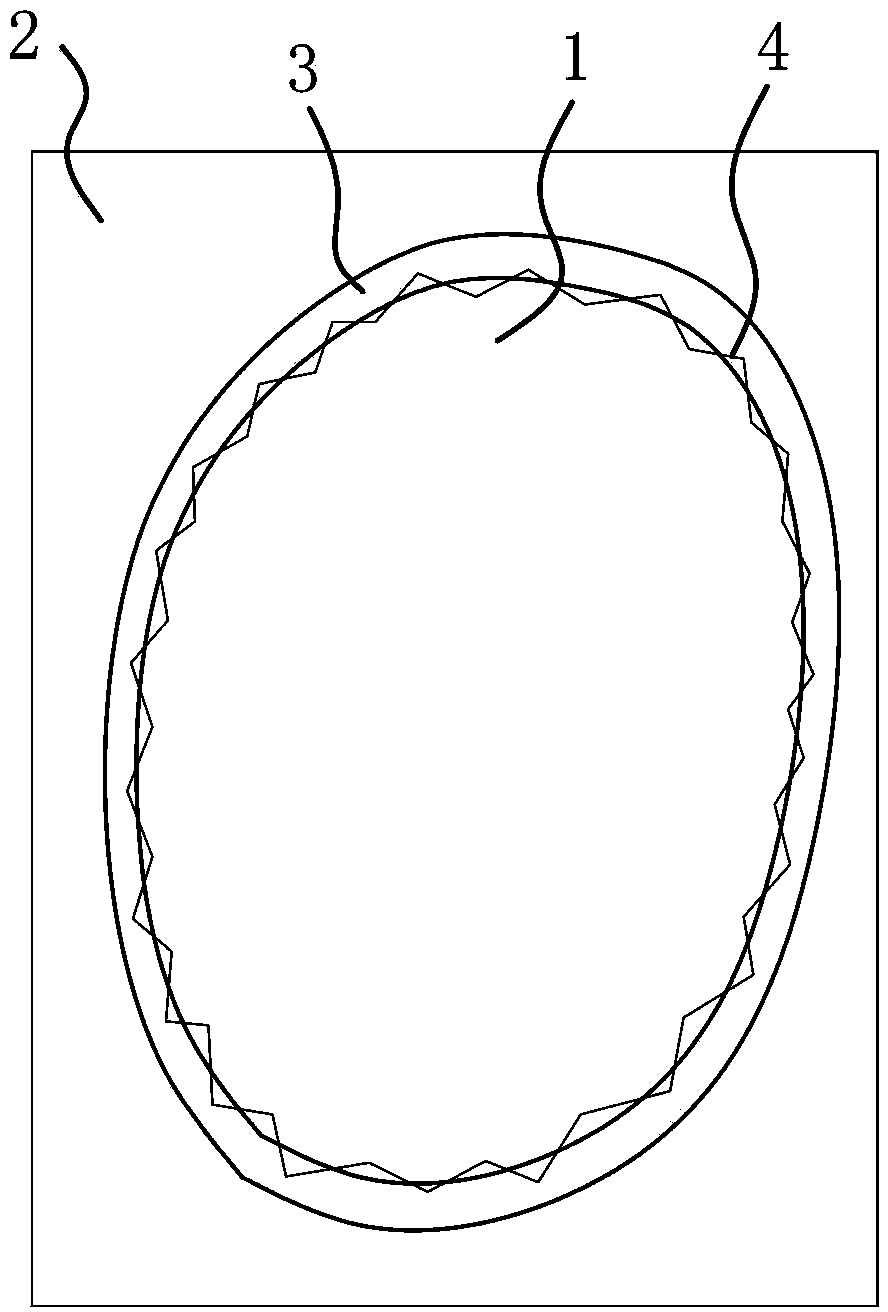

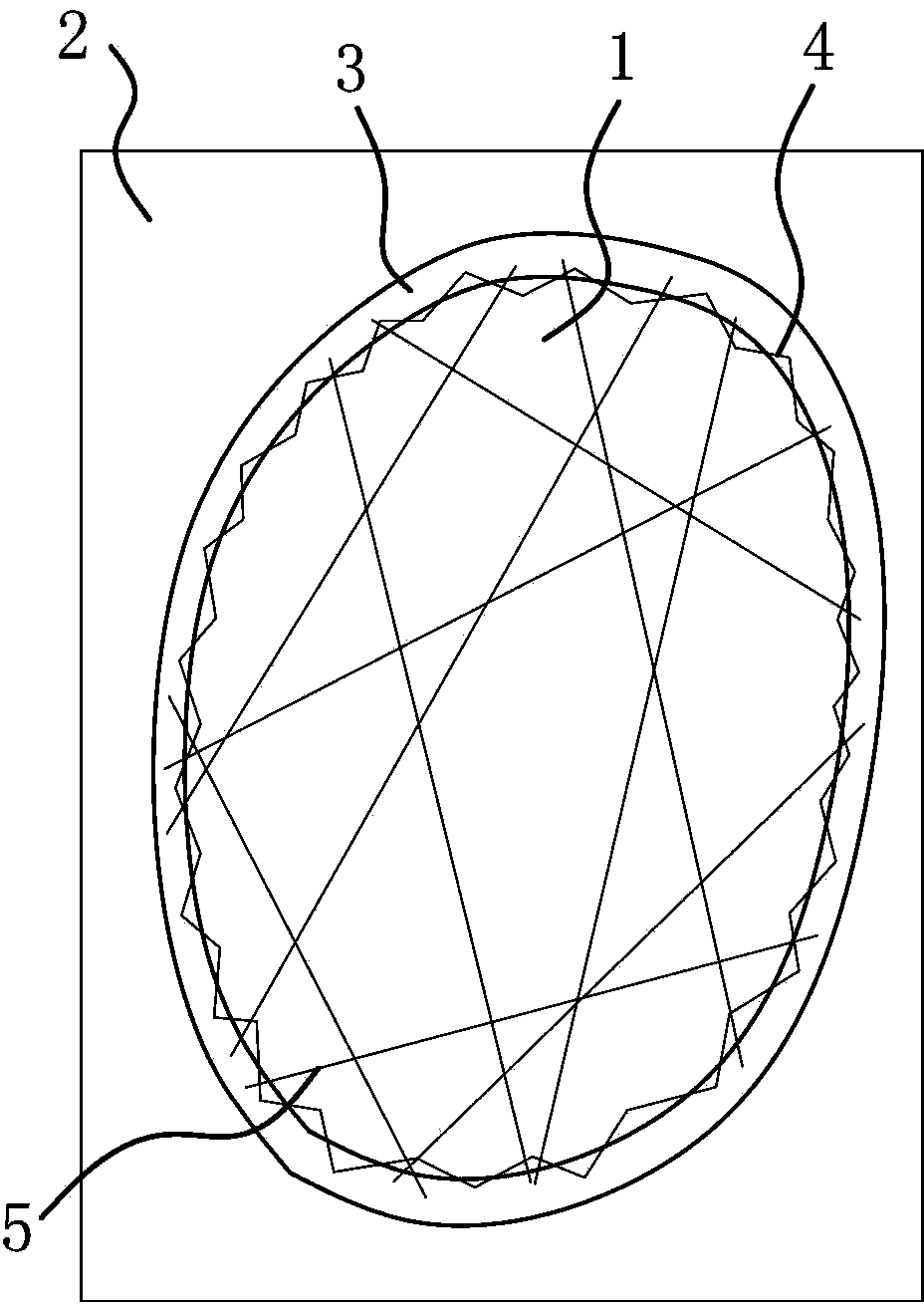

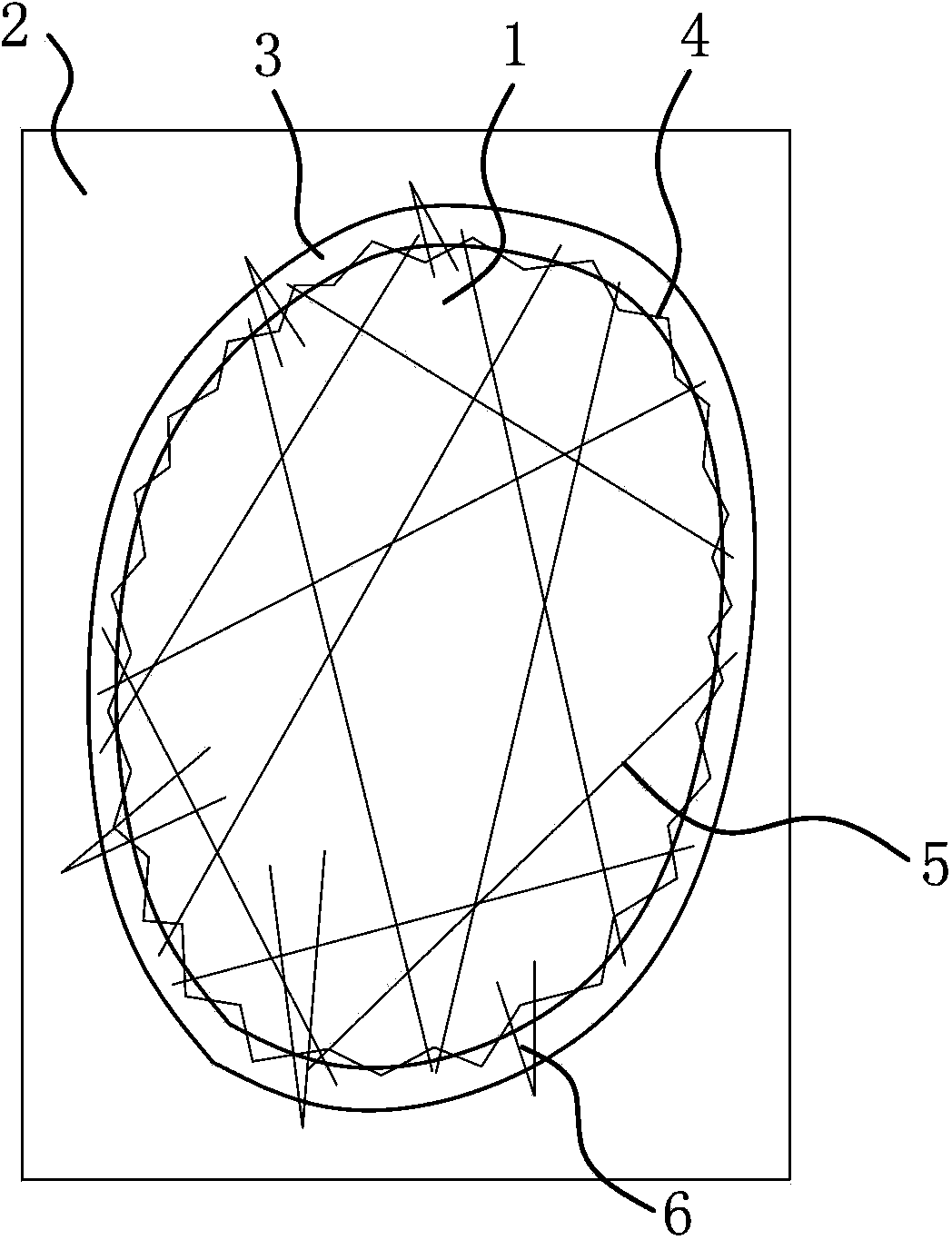

Stereograph and making method thereof

InactiveCN102398466ASimple structureLow costThree-dimensional effectsLight effect designsGratingLeft direction

The invention discloses a stereograph and a making method thereof. The stereograph comprises a transparent plate material, wherein one surface of the transparent plate material is a raster layer, and the other surface of the transparent plate material is provided with a raster image. The making method for the stereograph comprises the following steps of: (1) rasterizing a planar graph to acquire the raster image; (2) displaying the raster image on one surface of the transparent plate material; and (3) making the raster layer on the other surface of the transparent plate material and combining the raster image with the raster layer to acquire the stereograph. The making method for the stereograph is simple; and the stereograph made by the making method can clearly and completely display patterns for imaging in any direction, namely a left direction, a right direction, an upper direction and a lower direction and at any angle, has multiple stereo effects of getting into a screen, getting out of the screen, floating on the screen and the like and has an outstanding visual effect and extremely high enjoyment and artistic value.

Owner:ZHENGZHOU HENGHAO GLASS TECH

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

Preparation technique of yarn-dyed jacquard fabric with printing texture characteristic

The invention discloses a preparation technique of a yarn-dyed jacquard fabric with printing texture characteristic. The preparation technique comprises the following steps of: (1) designing patterns, and selecting and layering colors; (2) designing and manufacturing a fabric texture board; (3) preparing weaving and knitting; (4) weaving and knitting on a machine; and (5) producing a finished product. The types of multicolor jacquard fabric products can be enriched by adopting the weaving and knitting method, the jacquard fabric not only can be kept with bright color, rich gradient layout and strong stereoscopic impression, but also has fine and smooth patterns of printing products, and the patterns are diversified and strong in stereoscopic impression. The disadvantages of the jacquard fabric on the expressing methods of patterns with real flowers, characters and scenes can be made up for.

Owner:HAINING ZHIDA TEXTILE WEAVING

Preparation method of ceramic plate decorative painting through colored engraving

The invention relates to a preparation method of a ceramic plate decorative painting through colored engraving. The method comprises the following steps: 1), a protective film is attached to the surface of a ceramic plate; 2), sidelines of a specified figure are engraved on the surface of the ceramic plate by a laser engraving machine; 3), the protective film at a to-be-etched part is removed so as to expose an engraving surface; 4), the surface of the ceramic plate is eroded by an abrasive material at a high flow rate, so that an uncolored solid figure is formed through engraving on the ceramic surface with the protective film removed, the pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 5), sand blasting is at least performed on a to-be-colored part of the surface of the ceramic plate so as to at least remove a glaze layer of the to-be-colored part and form a frosted surface, the sand blasting pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 6), the frosted surface of the ceramic plate prepared in the step 5) is cleaned and dried, a pattern is spray-printed and drawn, and a protective glaze layer is spray-printed; 7), the ceramic plate prepared in the step 6) is sintered rapidly.

Owner:MONALISA GRP CO LTD

Embroidery with silkworm cocoon and a silkworm-cocoon fixing embroidering method for the embroidery with the silkworm cocoon

ActiveCN103361917AImprove smoothnessImprove the three-dimensional effectEmbroidering machines apparatusTextile technologyEngineering

The invention provides an embroidery with a silkworm cocoon, and a silkworm-cocoon fixing embroidering method for the embroidery with the silkworm cocoon, belongs to the field of textile technology, and solves a problem that embroideries with silkworm cocoons at present have no implied meanings and artistic value. The method comprises a step of cleaning exterior impurities and an inner silkworm chrysalis of a silkworm cocoon; a step of embroidering an arrangement hole having a size matching the size of the silkworm cocoon in a tight embroidery cloth, and embedding the pretreated silkworm cocoon in the arrangement hole; and a step of fixing the silkworm cocoon on the embroidery cloth by using embroidery threads. The method adopts general stitches, and therefore the method is simple. The silkworm cocoon fixed by the method is advantaged in that firmness is high, stereo effects are strong and the embroidery is nature and harmonious. The embroidery with the silkworm cocoon has a main idea and a theme which return to the nature and the universe cycle, and has advantages of profound implied meanings, natural raw materials, unique appearances and high artistic value.

Owner:ZHEJIANG TAIXIU DRESS

Manual paper and its preparing process and use thereof

InactiveCN1995539ACoarse textureThick texturePretreatment with water/steamPulp beating/refining methodsSlurryPhotographic paper

The invention provides a hand made paper made of the root of stellera chamaejasme L. The manufacturing method comprises 1) selecting stock and cleaning, after the root of stellera chamaejasme L is cleaned and dried to use; 2) peeling, the outer raw skin is peeled; 3) water cooking, the inner skin is cut thin and is cooked soft; 4) washing stock, cooked slurry is set in the cloth bag to be washed by water; 5) beating, the slurry is set in slurry barrel to be beaten into slurry mud; 6) infiltrating paper, after the paper slurry is set in paper machine it is put into water to be weaved evenly, then it is supported out of water face; 7) drying, it is dried and torn down. The hand made paper in invention is provided with not eating by moth and mouse in one hundred, and acid and alkali resistance. In the method of invention, chemical can not be added in and there is no pollution to circumstance. As the hand made paper in invention is used as photographic paper, irregular texture process of the hand made paper is used to improve art and collection values of works. It is suitable for storing for a long time. The burr round hand made paper has the natural hand effect.

Owner:金平

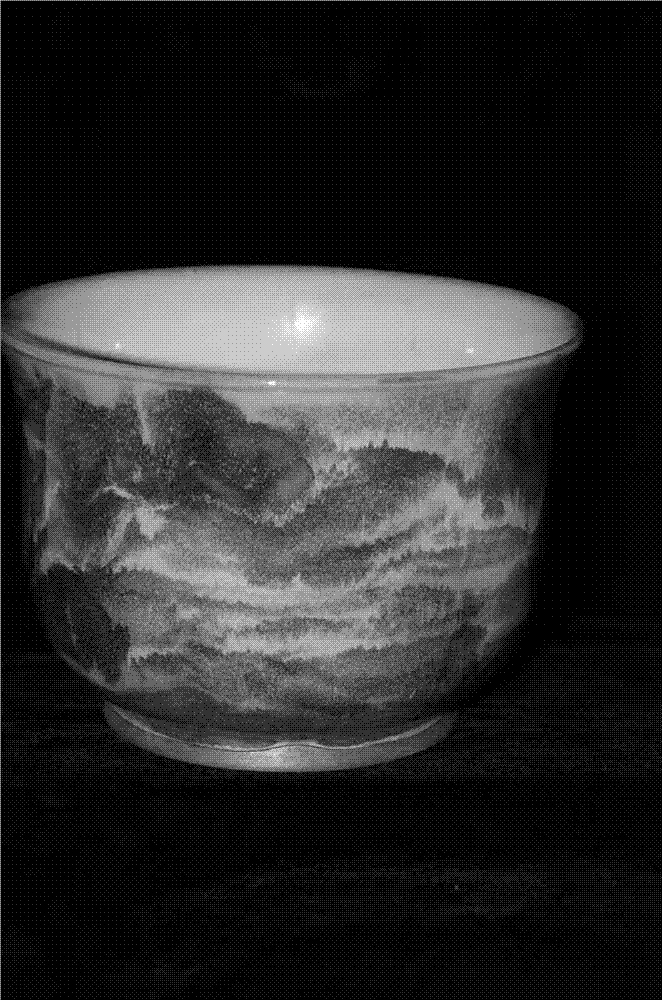

Preparation method of jun porcelain bluish-white glaze

The invention provides a preparation method of jun porcelain bluish-white glaze and the jun porcelain bluish-white glaze prepared by the method. Compared with the prior, through scientific and reasonable raw material matching and control on the firing process, the bluish-white glaze of which the glaze surface is laid with complicated landscape painting is prepared, and a new variety is provided for jun porcelain with the bluish-white glaze; moreover, the bluish-white glaze prepared by using ground glaze provided by the invention is blue and white in color, and bright and smooth, and by adding overglaze, nature landscape painting is formed on the prepared glaze surface, the glazing colors are rich and takes blue and red as the main colors, the landscape painting forming on the glaze surface is nature and vivid, and a relatively high artistic value is realized.

Owner:禹州市神器钧窑有限公司

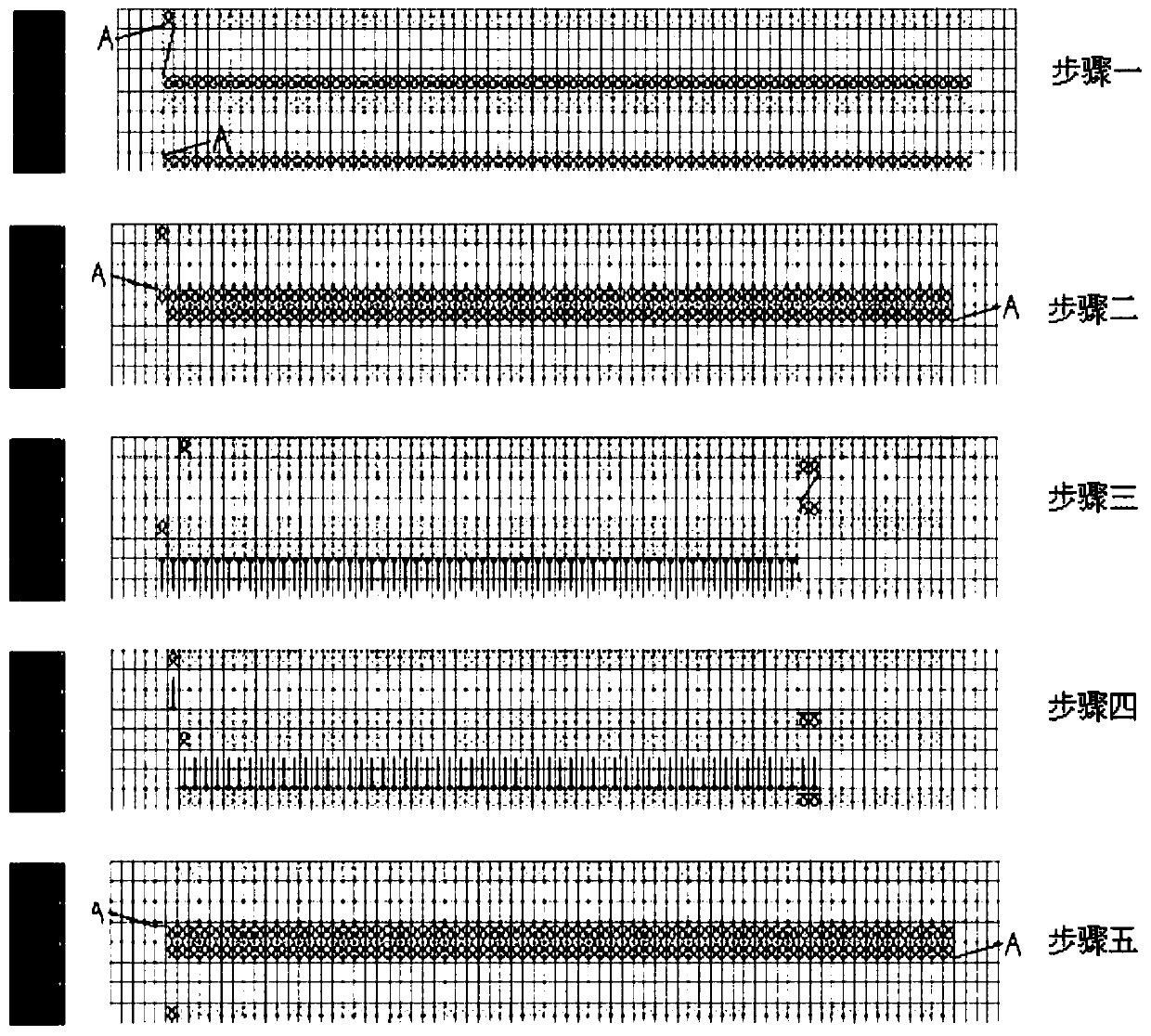

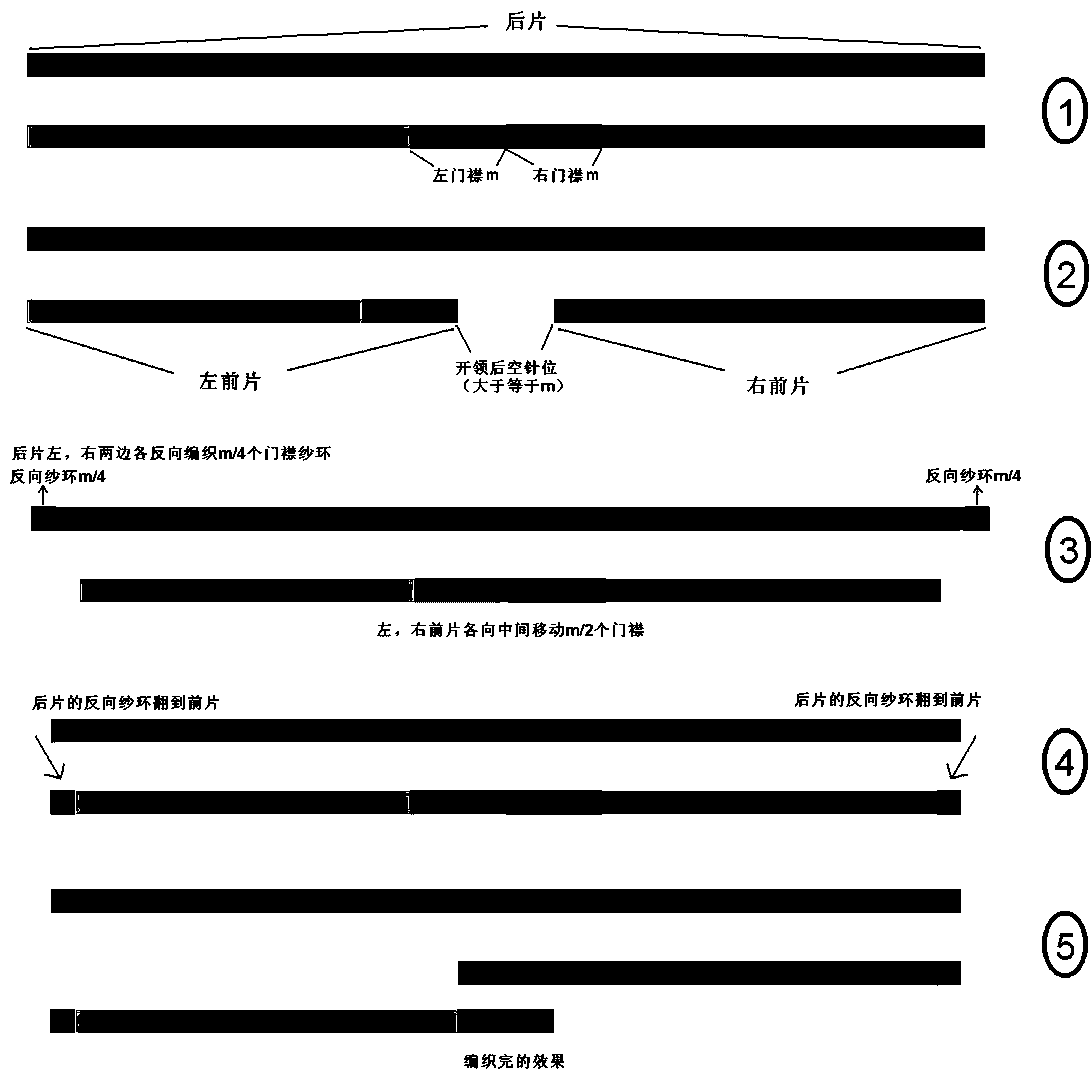

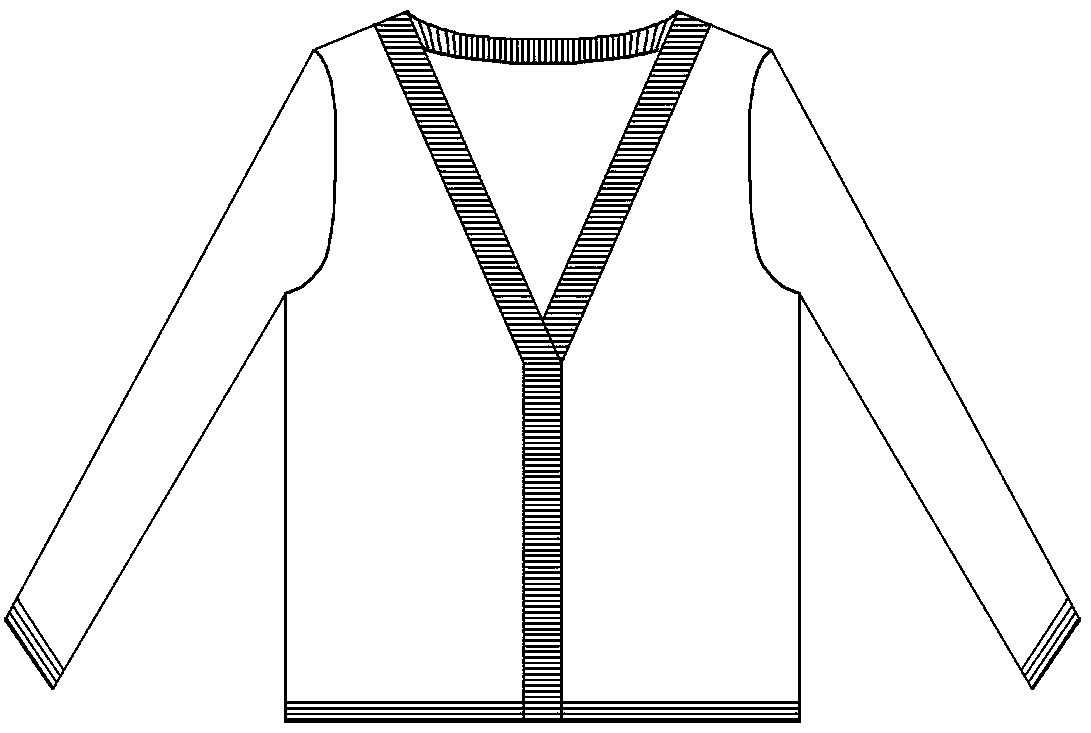

All-forming front-back varying narrowing knitting method and fabric formed through method

ActiveCN110042546ABreak through limitationsImprove design meansFlat-bed knitting machinesBiomedical engineering

The invention discloses an all-forming front-back varying narrowing knitting method and a fabric formed through the method. An all-forming flat knitting machine is utilized for weaving, the all-forming flat knitting machine is provided with at least one pair of front-back needle beds which extend in the left-right direction and oppositely arranged in the front-back direction, the needle beds can transversely move left and right, and loop transferring of loops can be carried out between the front needle bed and the rear needle bed. The front face facing the front needle bed is adopted as reference in the left-right direction, knitting needle, participating in narrowing, of the front needle bed are sequentially named a, b, c, d, e, f, g and h from left to right in this way. The all-forming front-back varying narrowing knitting method breaks through the limitation of an existing all-forming traditional narrowing structure, a front-back varying narrowing effect with a visual effect is achieved for an all-forming knitted product, and the advantages of optimizing the habilimentation style and the like are achieved.

Owner:嘉兴市蒂维时装有限公司

Preparation method for decorative picture of thousand-layer carved ceramic plate

The present invention relates to a preparation method for a decorative picture of a thousand-layer carved ceramic plate. The method comprises: 1) covering a layer of protective film on a surface of a ceramic plate; 2) using a laser carving machine to carve edge lines of a predetermined pattern on the surface of the ceramic plate, wherein the pattern comprises a plurality of parts; 3) removing the protective film gradually from each part of the pattern, and carving with sandblast until a complete multi-layer carved pattern is formed, wherein a sandblasting pressure adopted in the sandblasting carving is 1-10 kg / m<3>, and a flow rate is 5-20 m<3> / min; 4) sandblasting the surface of the ceramic plate to remove a glazed layer on the surface of the ceramic plate and form a frosted surface, wherein the sandblasting pressure is 1-10 kg / m<3>, and the flow rate is 5-20 m<3> / min; 5) after the frosted surface of the ceramic plate prepared in the step 4) is cleaned and dried, jet printing and drawing the pattern, and then jet printing a protective glazed layer; and 6) sintering the ceramic plate prepared in the step 5) rapidly.

Owner:MONALISA GRP CO LTD

Light greenish blue matte glaze for pottery product and preparation method of light greenish blue matte glaze

The invention discloses light greenish blue matte glaze for a pottery product and a preparation method of the light greenish blue matte glaze. A process formula of the light greenish blue matte glaze is prepared from the following components in percentage by mass: 27 to 32 percent of feldspar powder, 12 to 17 percent of calcium carbonate, 6 to 8 percent of dolomite, 7 to 14 percent of talc, 6 to 8 percent of barium carbonate, 2 to 9 percent of zirconium silicate, 5 to 10 percent of frit, 0 to 4 percent of zinc oxide, 0 to 9 percent of aluminum oxide, 3 to 5 percent of carnelian cobble and 4 to 10 percent of kaolin. The preparation method comprises the following steps: weighing all the components according to the formula, then fully mixing, and adding into a grinding tank; adding water of which the weight is equivalent to 45 to 50 percent of the weight of dry powder, and grinding for 10 to 15 hours, wherein the ratio of materials to spheres to the water is 1:1.5:0.65; afterwards, deironing and sieving glaze slip subjected to ball milling, and adjusting the concentration until the true specific gravity is 50 to 54 degrees; glazing the pottery product by adopting spraying, soaking or other decoration methods, wherein the thickness of a glaze layer is 1 to 3mm; drying, then feeding into a kiln, performing oxidation firing at the temperature of 1200 to 1235DEG C, naturally cooling and then discharging from the kiln. The prepared light greenish blue matte glaze has the advantages of stable color, high rate of finished product and high artistic value.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

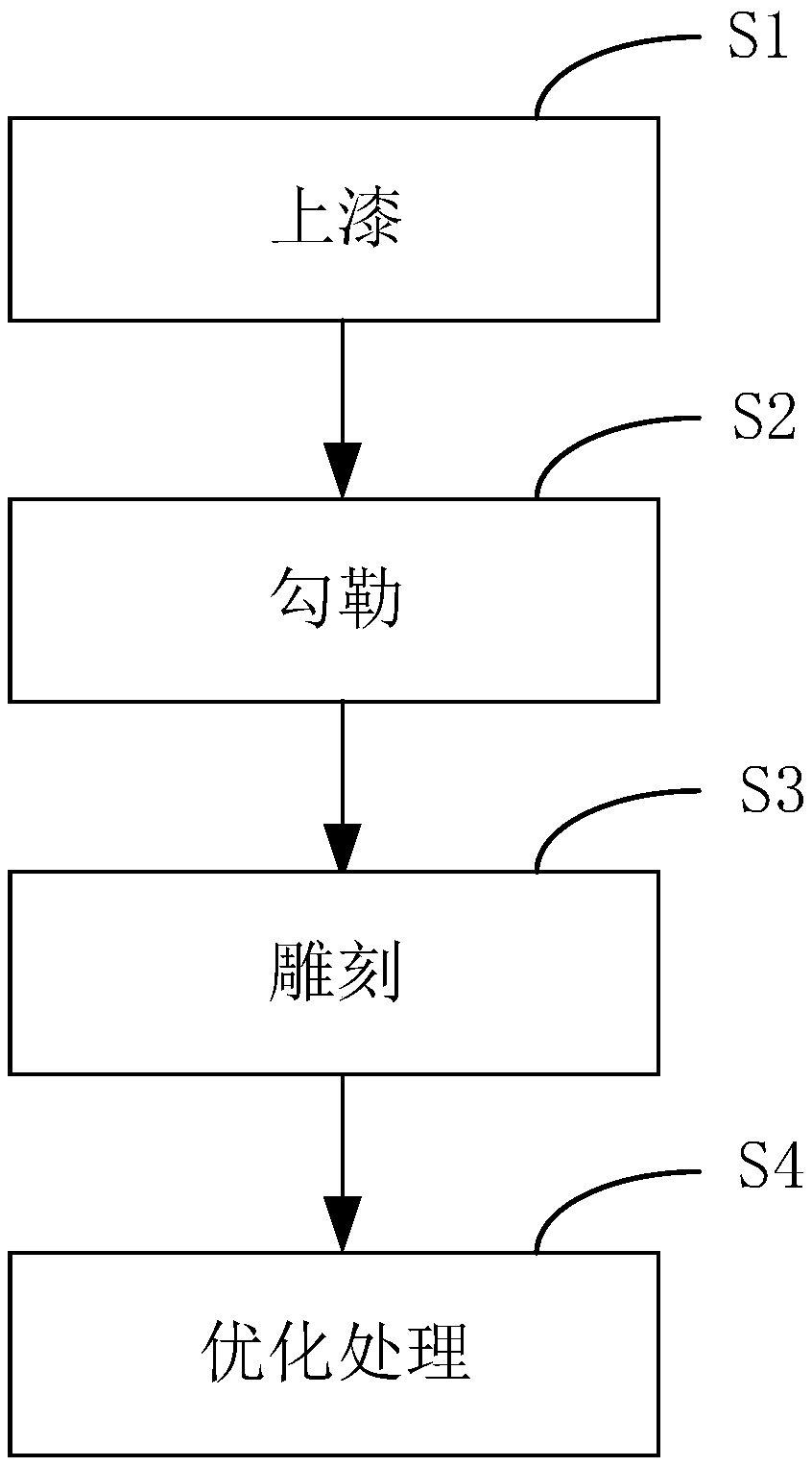

Colorful wood shadow sculpture and manufacture method

ActiveCN108973501AHigh artistic valueStrong three-dimensional senseDecorative surface effectsSpecial ornamental structuresColor depthMaterials science

The invention relates to the technical field of artware sculptures, in particular to a colorful wood shadow sculpture and a manufacture method. The manufacture method comprises the following steps: lacquering, drawing the outline, sculpturing and carrying out optimal processing. The step of lacquering is characterized in that the plate surface of a plate material is covered with a paint layer, andthe paint layer gradually darkens from inside to outside; the step of drawing the outline is characterized in that the outline of a pattern is drawn on the surface of the paint layer; the step of sculpturing is characterized in that a graver is used for sculpturing the surface of the paint layer according to the outline, the sculpturing depth of the graver is regulated according to the color depth of the pattern to realize different light and shade effects, different sculpturing angles are applied to the lines of the pattern to realize various different reflection effects of ray; the step ofoptimal processing is characterized in that luminance, shade and texture are optimized. According to the arrangement, the manufacture method for the colorful wood shadow sculpture is simple, is easy in selecting materials and is favorable for reducing cost and improving manufacture efficiency. In addition, the colorful wood shadow sculpture can show an obvious three-dimensional effect and strong stereoscopic impression and is favorable for improving the own artistic value of artware.

Owner:邢志鹏

Weaving method for fully-fashioned cardigan top fly overlapping

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Production process of underglaze five-color ceramics with fine brushwork traditional Chinese painting carving

ActiveCN103601471AHigh artistic valueImprove economyMould separation apparatusSpecial ornamental structuresCeramicGypsum

The invention discloses a production process of underglaze five-color ceramics with fine brushwork traditional Chinese painting carving, belonging to the production process field of art ceramics. The production process comprises the following steps: (1) design; (2) plaster master stamper manufacturing; (3) painting; (4) carving; (5) mould opening;(6) slip casting; (7) finishing and washing; (8) bisque firing; (9) polishing; (10) colouring: delineating, pigment solution coating and color spraying; (11) roasting; (12) applying transparent glaze; and (13) firing. According to the process provided by the invention, a fine brushwork traditional Chinese painting process, a carving process and a underglaze five-color coloring process are combined organically, so that the picture of the ceramics is relatively delicate, and has sense of space, sense of layering and third dimension, and the artistic value and added value of products of the ceramics are improved.

Owner:景德镇手都陶瓷有限公司

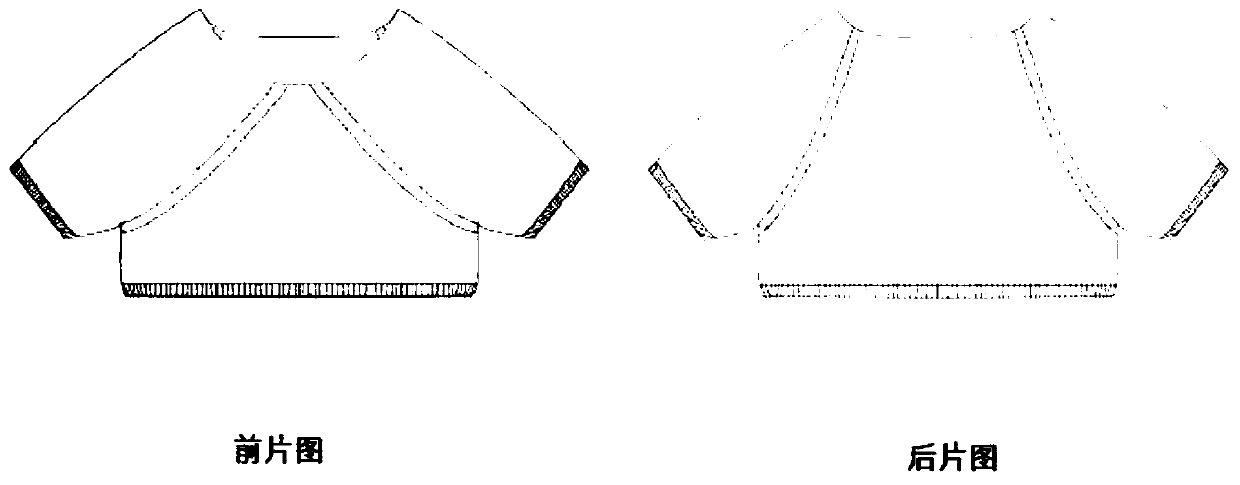

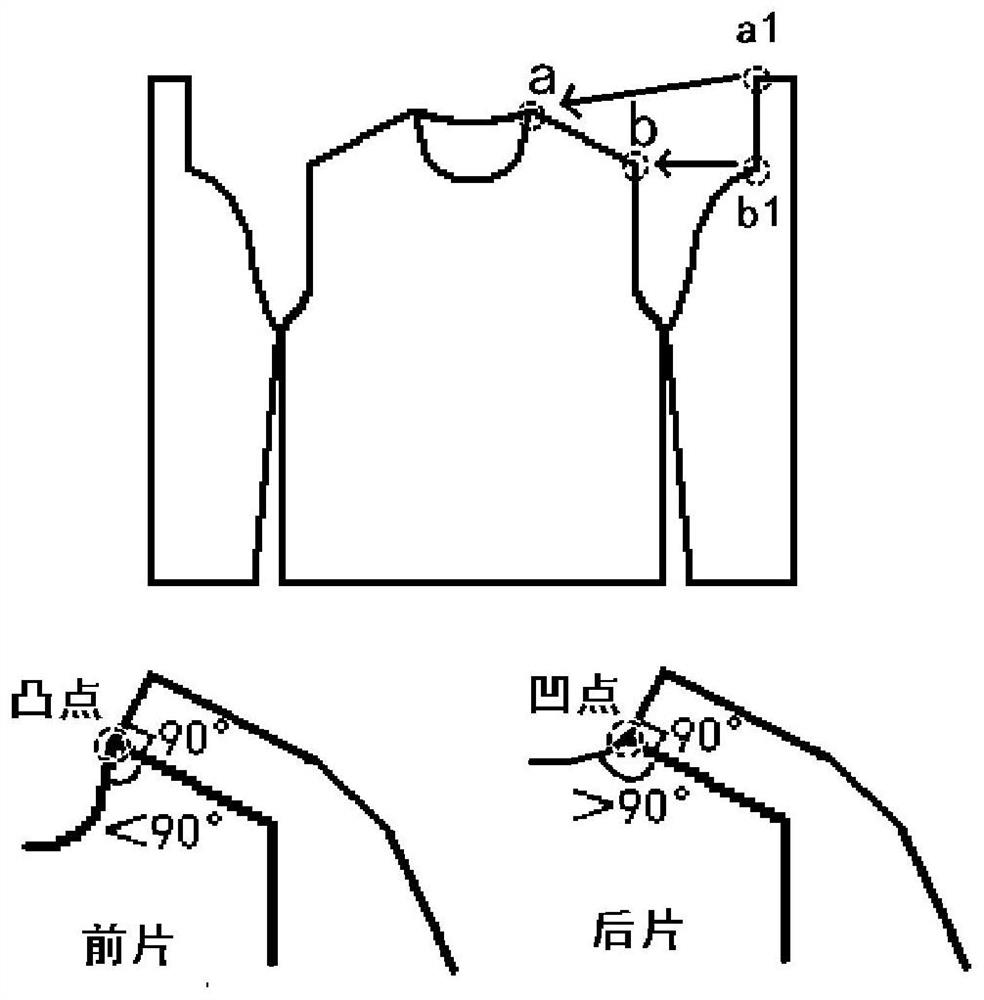

Knitting method and knitted fabric of fully-formed saddle shoulder collar type structure

ActiveCN112593338AMeet needsPromote international influenceWeft knittingNeck collarMechanical engineering

The invention discloses a knitting method and knitted fabric of a fully-formed saddle shoulder collar type structure. According to a fully-formed square shoulder type shoulder line forward-moving knitting method, a front piece and a rear piece achieve the natural difference in the knitting process, and therefore a shoulder line forward-moving effect is naturally shown after style forming. The knitting method of the fully-formed saddle shoulder collar type structure breaks through the limitation of a traditional product process method, and a knitting method combination with front and back differences is set according to the characteristics of the front and back collar types of a saddle shoulder, so that the front and back collars are smoother, the product quality and the wearing comfort areimproved, and the customer requirements can be better met.

Owner:嘉兴市蒂维时装有限公司

Manufacturing technology of cloisonne amber crystal drawing

InactiveCN104960374APromote value-addedAchieve full utilizationDecorative surface effectsSpecial ornamental structuresManufacturing technologyAfter treatment

A manufacturing technology of a cloisonne amber crystal drawing comprises the following technological processes that 1, a drawing board is firstly pressed, and a dual-layer non-deformation wood clamping board is adopted as a bottom board; 2, designed pattern lines are drawn on the drawing board; 3, wire inlay, namely, wiry enamel, is carried out on the wood board with gold wires, silver wires and metal wires of various colors according to the lines; 4, enamel application is carried out, cloisonne glazes are mixed with crystal glue after being washed, the drawing board with wire inlay completed is filled with colors through a scraper knife, and a picture identical to an original design drawing is formed; 5, the drawing board is put in a drying chamber for high-temperature shaping; and 6 resin glue is used for crystal film coating, mounting and other post production procedures are carried out after treatment of many times, and a finished product is obtained. The cloisonne amber crystal drawing manufactured through the method is plain and elegant, resplendent and magnificent and noble in taste and suits both refined and popular tastes.

Owner:贺月红

Ancient green crackled glaze for ceramic decorations and preparation method of ancient green crackled glaze

The invention provides ancient green crackled glaze for ceramic decorations and a preparation method of the ancient green crackled glaze. The ancient green crackled glaze comprises the following components: 50-70 percent of nepheline orthoclase, 10-15 percent of talc, 10-15 percent of CaCO3, 3-8 percent of MgCO3, 4-8 percent of kaolin and 0.5-1.0 percent of CuCO3. The preparation method comprises the following steps of: weighing all the components, then sufficiently mixing the components, adding the mixture to a grinder, adding water which accounts for 50-60 percent of the dry powder, grinding for 5-12 hours, testing the granularity, and screening the ground mixture by using a 350-mesh screen, wherein residues are about 1-3g; and then blending the concentration of the ground glaze to true specific gravity at 42-45 DEG C, spraying or soaking the glaze onto a ceramic product, airing, then feeding the ceramic product into a kiln, carrying out glaze firing at 1185-1200 DEG C for 9-10 hours, finally naturally cooling and discharging the finished product from the kiln. The prepared ancient green crackled glaze is fine and soft in glaze surface, rich in texture and ancient in color and luster.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

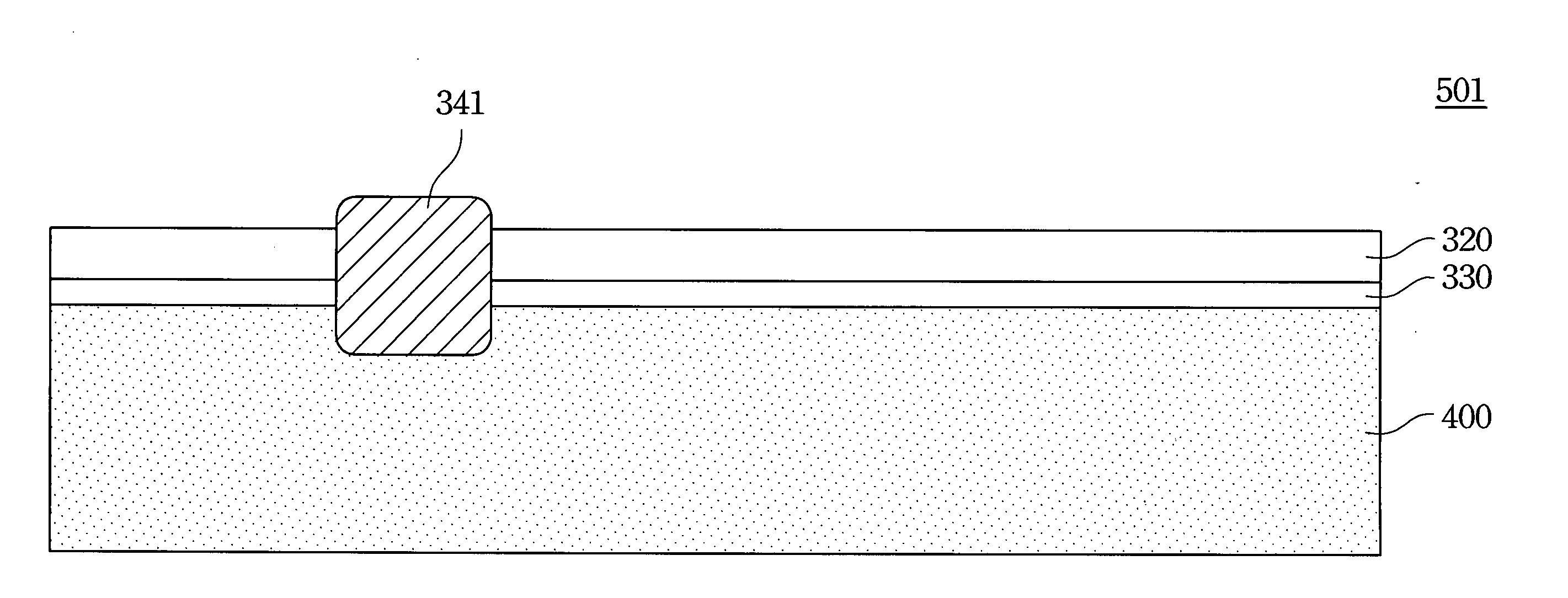

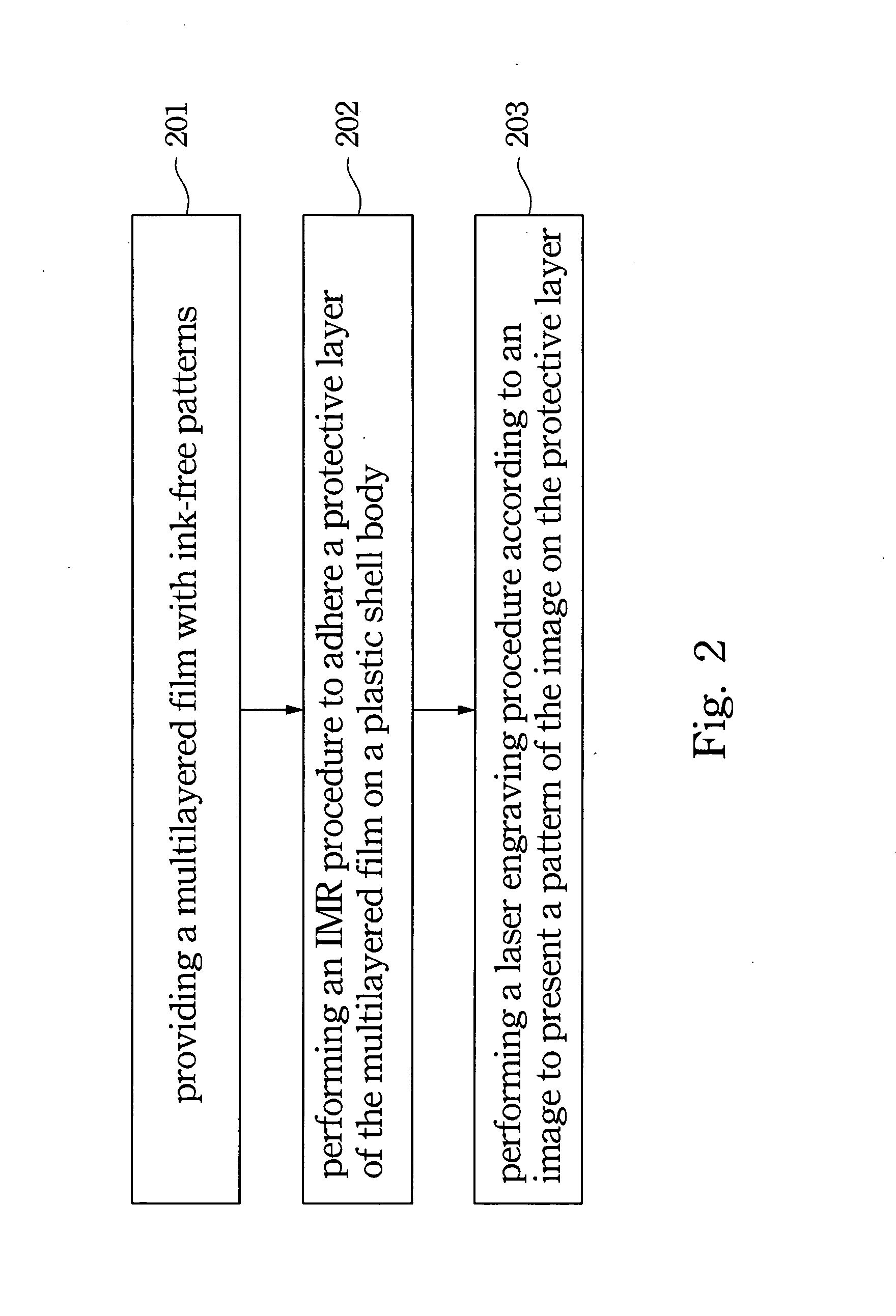

Plastic shell with ink-free pattern and its manufacturing method thereof

ActiveUS20110097540A1Speed upLow priceDecorative surface effectsDuplicating/marking methodsLaser engravingEngineering

A plastic shell with ink-free pattern and its manufacturing method thereof are provided. The manufacturing method includes a step of providing a multilayered film with ink-free pattern, a step of adhering a protective layer of the multilayered film on a surface of a plastic shell body, and a step of performing a laser engraving procedure to present a relief pattern on a surface of the protective layer.

Owner:QUANTA COMPUTER INC

Technique for making cloisonne amber crystal picture

InactiveCN101503042APromote value-addedHigh artistic valueDecorative surface effectsSpecial ornamental structuresCobalt octoateAdditive ingredient

The invention provides a manufacturing process of a cloisonne amber crystal drawing, comprising the following steps: firstly cutting a timber into wood blocks of 40 centimeters to 50 centimeters by special apparatus followed by polishing, fork joint bonding the wood blocks to shape a base board, then bonding a base frame and the base board; scanning a master drawing into a computer, printing the master drawing on the base board by a laser transfer machine; then coating adhesive sericin on a base body, cementing metallic threads on the base body; using an enamel-filling tube to evenly and flatly distribute the colored enamel on the drawing; finally polishing the drawing for twice to three times, drying for 30 minutes to 12 hours. The process takes unsaturated crystal resin as the main material and curing agent ethyl methyl ketone and accelerant iso-cobalt octoate as the accessory material, and at a temperature between 10 DEG C and 20 DEG C, the ingredient ratio is as follows: 8-12kg of unsaturated crystal resin, 14-16g of curing agent ethyl methyl ketone, and 0.7-1.4g of accelerant iso-cobalt octoate. Each product manufactured by the process in the invention is a piece of decoration product and a fine handicraft works having decorating, admiring and collecting values.

Owner:刘晶涛

Technology for embedding metal into blue and white porcelain

The invention discloses a technology for embedding metal into blue and white porcelain. The technology comprises the following steps: (1) sketching blue and white patterns and metal patterns on a manufactured porcelain body, digging ink mark slots along the ink marks of the metal patterns, then putting the porcelain body into a kiln and firing for the first time; (2) coloring the blue and white patterns, then putting the porcelain body into the kiln and firing for the second time; (3) enabling the bottom surfaces and the walls of the ink mark slots to be evenly coated with white vaseline, enabling the metal to be melted, pouring the melted metal into the ink mark slots, enabling the melted metal to be solidified, grinding and leveling; and (4) spraying clear glaze onto the porcelain body, then putting the porcelain body into the kiln and firing for the third time. According to the technology, the porcelain body is fired for three times, so that the blue and white patterns can fully present colors, and better metallic luster is realized; the metal and the porcelain are combined into a whole, so that the product not only has the freshness and beauty of the blue and white porcelain, but also is endowed with the grave and deep feeling of the metal; and therefore, the artistic value and the commercial value of the product are greatly improved.

Owner:景德镇蓝印子陶瓷有限公司

Jun porcelain fancy glaze and preparation method thereof

The invention discloses jun porcelain fancy glaze and a preparation technology thereof. Prepared fancy glaze porcelain has a high yield, manufacturing cost is reduced, and the prepared fancy glaze porcelain has very high artistic value and economical value. Used spodumene can react with kaolin and quartz in a firing process to form a little mullite crystal, and the mullite crystal can greatly improve the mechanical strength of jun porcelain; the spodumene is added into a formula, so that a firing speed is improved, and product crack is avoided; thus, energy consumption is reduced, a yield is about 85%, and the manufacturing cost is reduced.

Owner:杨鹏飞

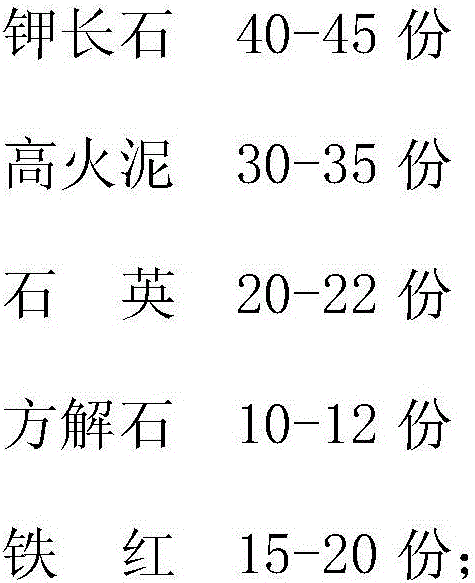

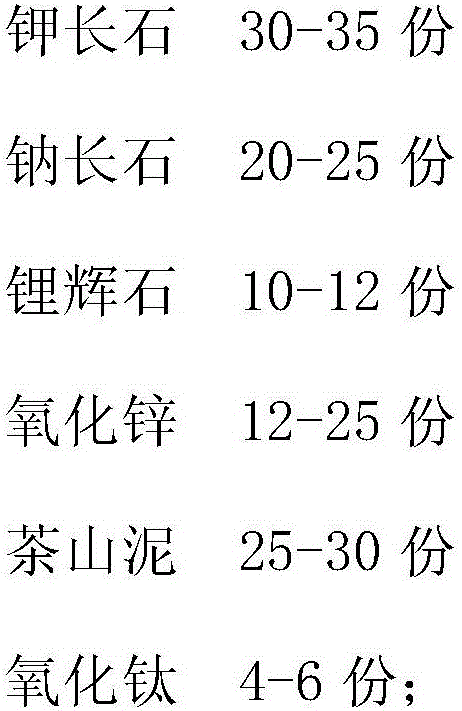

Method for manufacturing ocean glaze

A method for manufacturing ocean glaze comprises a step (1) of preparing ground glaze and cover glaze, wherein the ground glaze is prepared from 40-45 parts of potassium feldspar, 30-35 parts of high duty fire clay, 20-22 parts of quartz, 10-12 parts of calcite and 15-20 parts of iron oxide red; and the cover glaze is prepared from 30-35 parts of potassium feldspar, 20-25 parts of albite, 10-12 parts of spodumene, 12-25 parts of zinc oxide, 25-30 parts of Chashan clay and 4-6 parts of titanium oxide; a step (2) of performing wet method ball milling on the ground glaze, balls and water, performing sieving, forming glaze slip at 40-50 baume degrees, manually applying the glaze slip to a green body, and performing natural drying; a step (3) of performing wet method ball milling on the cover glaze, balls and water, performing sieving, forming glaze slip at 30-40 baume degrees, brushing the cover glaze slip onto the green body coated with the ground glaze, and forming the product through firing at a temperature of 1100-1200 DEG C. The manufactured ocean glaze is high in stereoscopic impression and attractive, has high art enjoying value, and is deeply welcome by consumers.

Owner:HUNAN LILING CHUHUA CERAMIC INDAL

Combining technology of ceramic wafer and precious metal

ActiveCN105599522AImprove finenessTightly boundDecorative surface effectsSpecial ornamental structuresMetallurgyPrecious metal

A combining technology of a ceramic wafer and precious metal comprises the steps of firstly performing primary moulding on the ceramic wafer, and forming a blind hole in the side wall of the ceramic wafer; then fitting the precious metal around the edge of the ceramic wafer, and meanwhile forming a through hole, matched with the blind hole in the ceramic wafer, in the precious metal; finally enabling a precious metal wire to pass through the through hole, putting the precious metal wire into the blind hole, welding the precious metal wire with the precious metal, and performing secondary moulding to obtain a finished product combining the ceramic wafer and the precious metal. According to the technology, the ceramic wafer and the precious metal are remoulded and are combined into a new whole in a welding way, the technology is fine and concise, too much time does not need to be consumed in the whole technological process, a characteristic that the modern technology is high in manufacturing efficiency is accorded with, and the finished product as new works of art endows the ceramic wafer with new appreciation value, artistic value and economic value.

Owner:河南弘宝汝瓷坊有限公司

Black-base red-speckle oil-drop temmoku glaze ceramic and a preparing process thereof

The invention belongs to the field of ceramic products, and particularly relates to black-base red-speckle oil-drop temmoku glaze ceramic and a preparing process thereof. The ceramic includes an iron matrix blank and a red-spotted oil-drop glaze material. According to the ceramic and the method, the fired ceramic has a purple black matrix, the red-spotted oil-drop glaze material shows dark red speckles from inside to outside, crystallized particles are preserved in a glaze layer, and a flowing sense during high-temperature molding of the glaze can be observed obviously when the ceramic is observed with a magnifying lens. During firing, a reducing atmosphere is used and nitrogen is fed during firing to perform a reaction, and elements in the red-spotted oil-drop glaze material and the iron matrix blank are extracted to help combustion so that glaze raw materials are changed and recombined. The ceramic has beautiful colors, warm and humid hand feel, and high value of appreciation and artistic value.

Owner:福建德化陶知然陶瓷文化创意有限公司

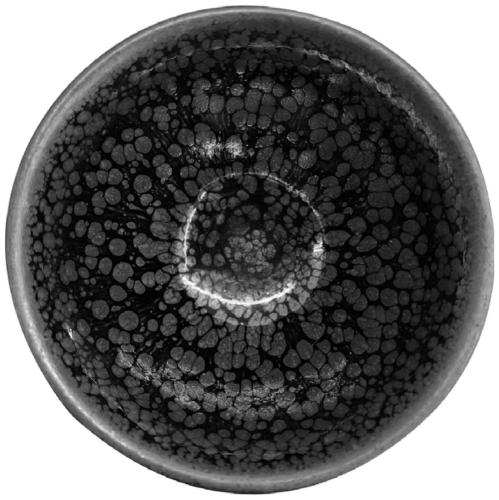

Jian tea bowl firing process

The invention discloses a Jian tea bowl firing process which comprises the following steps: preparing a green body raw material and glaze slip, drawing and forming the green body raw material, performing trimming to obtain a green body, glazing the green body, firing the green body for the first time, putting the qualified green body into a kiln again, roasting the green body, naturally cooling the product and discharging the product. The process flows such as the formula, the firing atmosphere and the temperature curve are clear and easy to control, the stability is good, and the rate of finished products is high. Uniform and fine hairs penetrate through a black glaze layer of a fired rabbit hair Jian tea bowl, are clear, have proper density and are radial, the stripes are attractive, andthe Jian tea bowlhas extremely high artistic value and appreciation value.

Owner:蔡炳盛

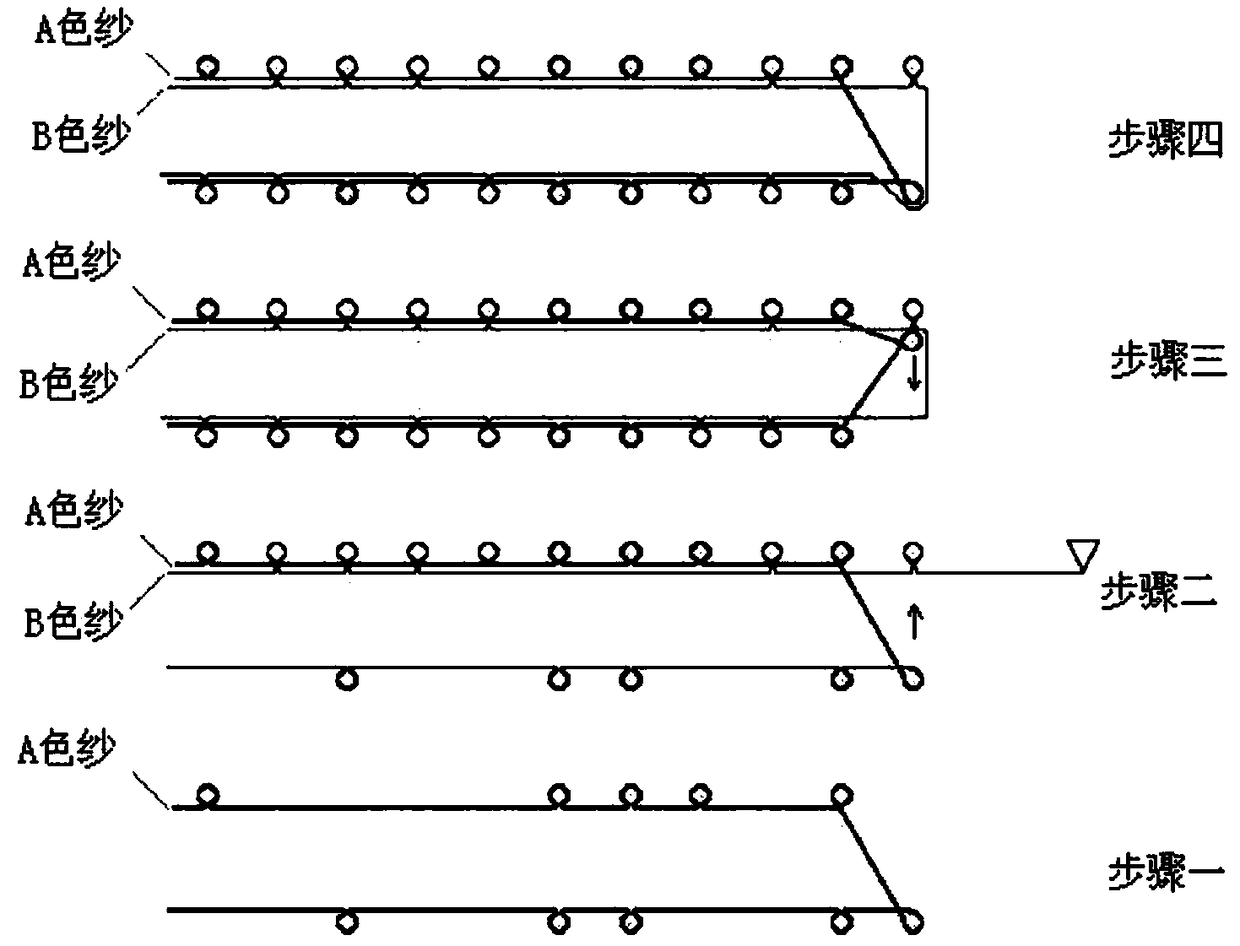

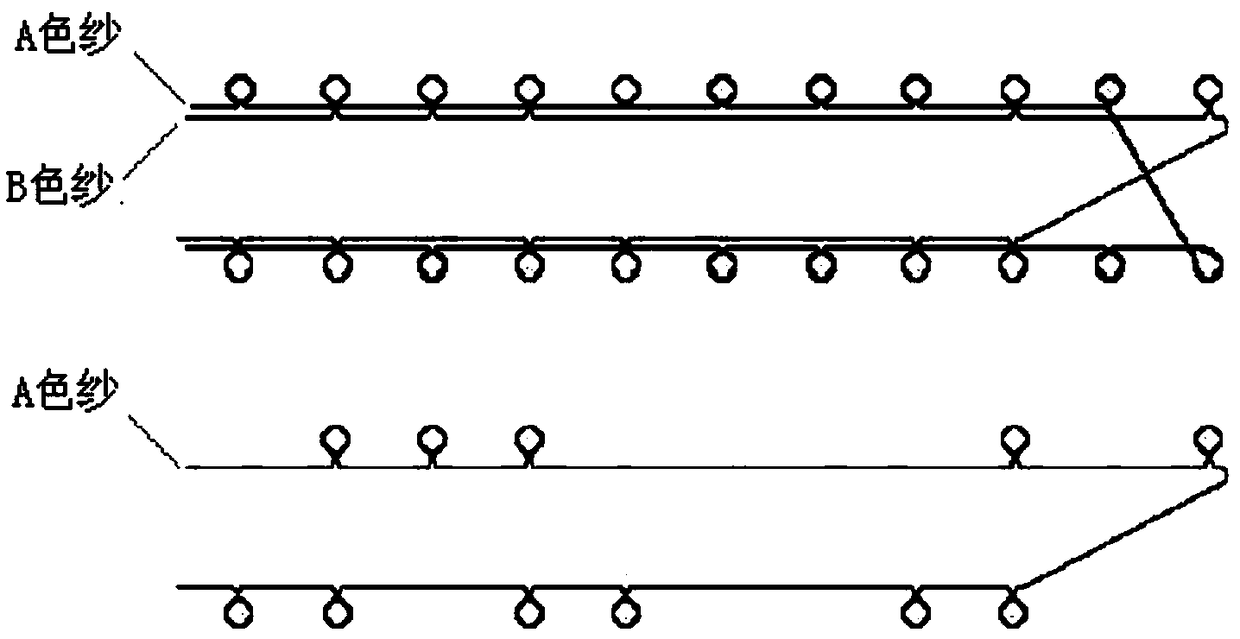

Weaving method of fully-fashioned floating thread jacquard

The invention discloses a weaving method of fully-fashioned floating thread jacquard. The method includes the following steps that 1, A-color yarn and B-color yarn are selected, and the A-color yarn is woven through a rear lower needle bed and a front lower needle bed by means of cylinders; 2, when a rear lower needle bed of the B-color yarn is used for weaving to the right edge, loops on the front lower needle bed at the right edge of the A-color yarn are turned to a rear upper needle bed. The weaving method of the fully-fashioned floating thread jacquard breaks through the limitation of a traditional jacquard knitting technology, so that cloth covers on the two sides of a fully-fashioned fabric are flat and do not bulge.

Owner:嘉兴市蒂维时装有限公司

Fair-faced concrete and preparation method thereof

The invention provides fair-faced concrete and a preparation method thereof and relates to the field of building materials. The fair-faced concrete comprises the following raw materials in parts by weight: 370-460 parts of cement, 50-100 parts of fly ash, 1250-1640 parts of aggregate, 20-30 parts of diatomite, 3-5 parts of cellulose, 5-10 parts of fiber, 5-10 parts of rubber powder, 10-15 parts ofan expanding agent and 10-15 parts of an additive. According to the invention, the technical problem of lack of fair-faced concrete with good fluidity and high appearance quality after pouring in thedomestic market can be solved, and the purpose of improving the effect of the fair-faced concrete after pouring is achieved.

Owner:江西蓝宝新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com