Method for manufacturing ocean glaze

A production method and marine technology, applied in the field of marine glaze production, can solve rare problems and achieve the effect of strong three-dimensional sense and high artistic ornamental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A manufacturing method of marine glaze includes the following steps:

[0029] (1) Prepare base glaze and top glaze according to the following components and parts by weight ratio;

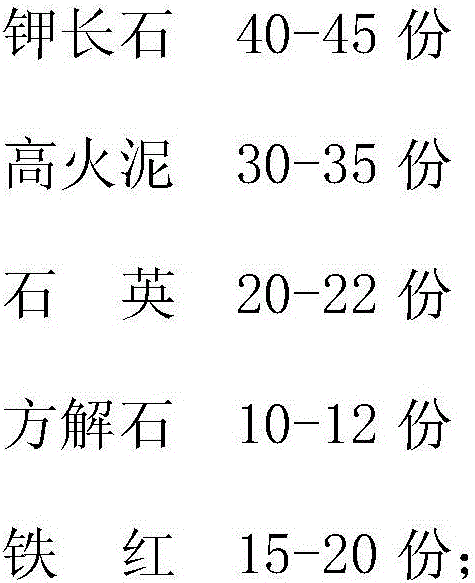

[0030] A. Base glaze

[0031] Potash feldspar 40 parts

[0032] 30 parts of high fire clay

[0033] Shi Ying 20 parts

[0034] 10 parts of calcite

[0035] Iron red 15 parts;

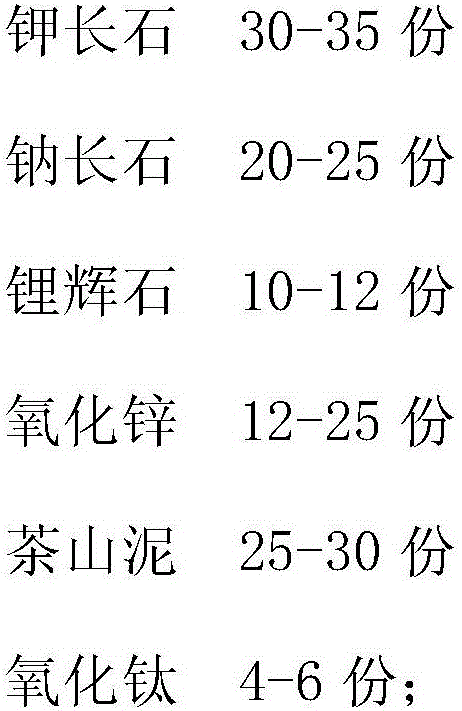

[0036] B. Surface glaze

[0037] 30 parts of potassium feldspar

[0038] 20 parts of albite

[0039] Spodumene 10 parts

[0041] 25 servings of tea mountain mud

[0042] 4 parts of titanium oxide;

[0043] (2) Wet ball mill the base glaze prepared in step (1) with the ball and water at a mass ratio of 1:2:0.5 for 16 hours. After ball milling, the glaze is passed through a 160 mesh sieve, and then adjusted to 45 Baume. The glaze slurry is manually applied to the body, and it will be used after natural drying;

[0044] (3) The surface glaze prepared in step (1) is wet-milled with the ball and water at a mass ra...

Embodiment 2

[0047] A manufacturing method of marine glaze includes the following steps:

[0048] (1) Prepare base glaze and top glaze according to the following components and parts by weight ratio;

[0049] A. Base glaze

[0050] 42 parts of potassium feldspar

[0051] 33 parts of high fire clay

[0052] Shi Ying 21 copies

[0053] 11 parts of calcite

[0054] Iron red 17 parts;

[0055] B. Surface glaze

[0056] Potash feldspar 32 parts

[0057] 22 parts of albite

[0058] 11 parts of spodumene

[0059] Zinc oxide 20 parts

[0060] 27 servings of tea mountain mud

[0061] 5 parts of titanium oxide;

[0062] (2) Wet ball mill the base glaze prepared in step (1) with the ball and water at a mass ratio of 1:2:0.5 for 15 hours. After ball milling, the glaze is passed through a 160-mesh sieve, and then adjusted to 40 Baume The glaze slurry is manually applied to the body, and it will be used after natural drying;

[0063] (3) The surface glaze prepared in step (1) is wet-milled with the ball and water at a mass...

Embodiment 3

[0066] A manufacturing method of marine glaze includes the following steps:

[0067] (1) Prepare base glaze and top glaze according to the following components and parts by weight ratio;

[0068] A. Base glaze

[0069] Potash feldspar 45 parts

[0070] High fire clay 35 parts

[0071] Shi Ying 22 copies

[0072] 12 parts of calcite

[0073] Iron red 20 parts;

[0074] B. Surface glaze

[0075] Potash feldspar 35 parts

[0076] 25 parts of albite

[0077] Spodumene 12 parts

[0078] 25 parts of zinc oxide

[0079] 30 servings of tea mountain mud

[0080] 6 parts of titanium oxide;

[0081] (2) Wet ball mill the base glaze prepared in step (1) with the ball and water at a mass ratio of 1:2:0.5 for 17 hours. After ball milling, the glaze is passed through a 160 mesh sieve, and then adjusted to 50 Baume The glaze slurry is manually applied to the body, and it will be used after natural drying;

[0082] (3) The surface glaze prepared in step (1) is wet-milled with the ball and water at a mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com