Artificial stone toolframe and its production process

A technology of knife holder and artificial stone, which is applied in the direction of table utensils, household utensils, table utensils, etc., can solve the problems of bacteria breeding, easy degumming, unhygienic use of knife holders, etc., and achieves easy cleaning, simple production process operation, and convenient surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

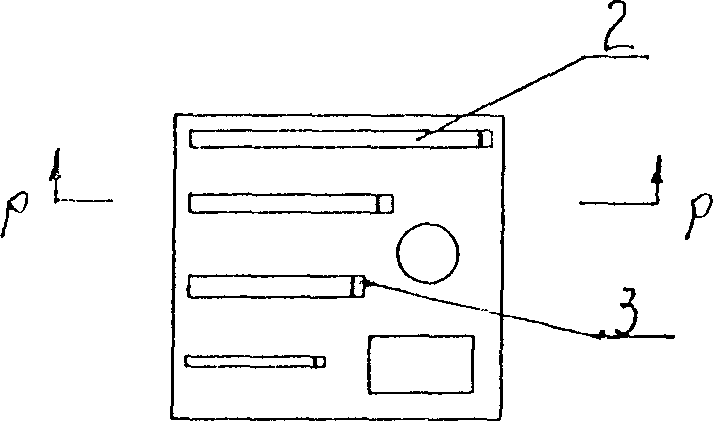

Image

Examples

Embodiment 1

[0044] Raw material formula (percentage by weight):

[0045] Unsaturated resin 30%

[0046] Aluminum hydroxide powder 65%

[0047] Methyl ethyl ketone 1.5%

[0048] Cobalt octanoate 1.5%

[0049] Color paste 2%

[0050] The production process is:

[0051] (1) Making tool holder molds;

[0052] (2) Prepare the raw materials according to the ratio of the raw material formula, and put the prepared raw materials in the mixer

[0053] Stir evenly at a speed of 120-200 rpm;

[0054] (3) Vacuum treatment is carried out to the stirred raw materials to eliminate air bubbles;

[0055] (4) Pouring the vacuum-treated raw material into the tool holder mould;

[0056] (5) After 15-30 minutes, the raw materials in the mold are polymerized and molded, and the film removal process is carried out;

[0057] (6) Carry out high-temperature curing treatment to the semi-finished product after stripping, and bake at 120-160°C for 5-7

[0058] Hour;

[0059] (7) Po...

Embodiment 2

[0062] Raw material formula (percentage by weight):

[0063] Unsaturated resin 55%

[0064] Aluminum hydroxide fine powder 40%%

[0065] Methyl ethyl ketone 2%

[0066] Cobalt octoate 2%

[0067] Color paste 1%

[0068] The manufacturing process is the same as in Example 1.

[0069] Present embodiment is provided with the knife groove 2 of various specifications on the side of knife rest seat, and other parts are identical with embodiment 1.

Embodiment 3

[0071] Raw material formula (percentage by weight):

[0072] Unsaturated resin 35.5%

[0073] Aluminum hydroxide fine powder 49%

[0074] Methyl ethyl ketone 2%

[0075] Cobalt octoate 2%

[0076] Color paste 1.5%

[0077] Color artificial stone synthetic particles 10%

[0078] The manufacturing process is the same as in Example 1.

[0079] In this embodiment, the upper end surface or / and side surfaces of the knife rest seat can be provided with various specifications of the knife grooves, and the whole of the knife rest seat can be a solid structure or a hollow structure at the bottom. Its surface is covered with colored artificial stone synthetic particles, the whole is transparent, and the appearance effect is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com