Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Bone char" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone char (Latin: carbo animalis) is a porous, black, granular material produced by charring animal bones. Its composition varies depending on how it is made; however, it consists mainly of tricalcium phosphate (or hydroxylapatite) 57–80%, calcium carbonate 6–10% and carbon 7–10%. It is primarily used for filtration and decolorisation.

Fish bone charcoal adsorbent and preparation method and application thereof

InactiveCN104923159AIncrease capacityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentFishing

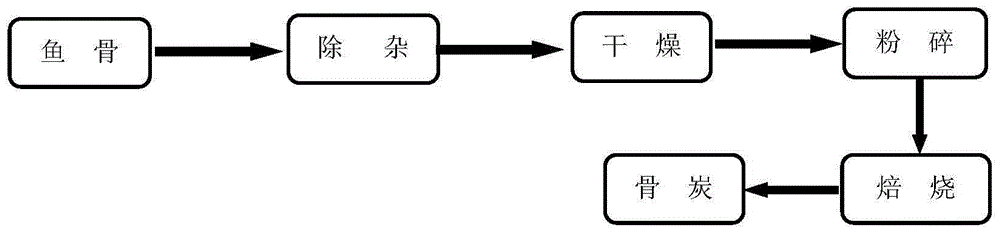

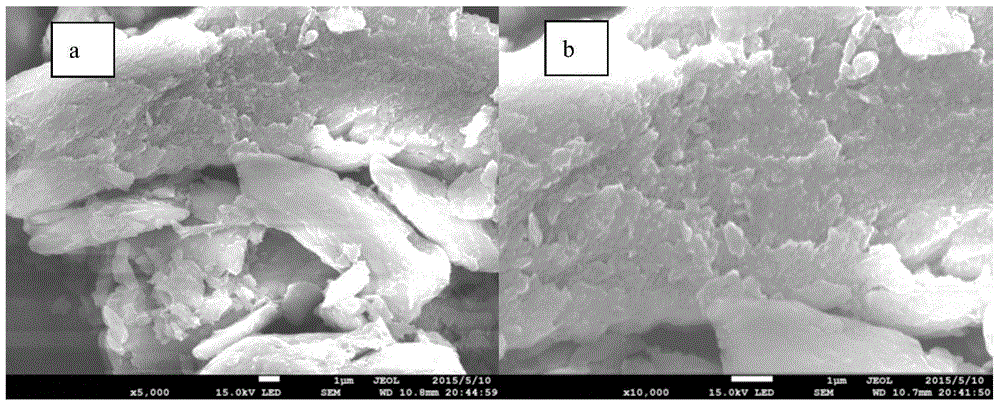

The invention relates to fish bone charcoal adsorbent, a preparation method thereof and application to heavy metal waste water. The preparation method includes the following steps of 1 impurity removing, wherein an obtained fish bone raw material is stirred and scalded in water to remove impurities; 2 drying, wherein the fish bones are put into a drying oven to be dried after the impurities are removed; 3 pulverizing, wherein the dried fish bones are pulverized in a pulverizer, and obtained fish bone dust serves as an adsorbent raw material; 4 high-temperature roasting, wherein the prepared fish bone dust is roasted and carbonized at high temperature, naturally cooled to the room temperature and then taken out to obtain the fish bone charcoal adsorbent. The preparation method has the following advantages that fish processing waste is low in price and easy to obtain, as the fish processing waste is prepared into fish bone charcoal, the potential value of the fish processing waste can be developed further, and the environmental pollution caused by discarding the fishing processing waste can be effectively reduced. In addition, the prepared bone charcoal is high in stability and adsorbability, easy to regenerate after absorption and reusable.

Owner:WUHAN UNIV OF TECH

Preparation method of high-performance bone black

InactiveCN103121681ALarge specific surface areaStrong adsorption and purification abilityCarbon compoundsFurnace temperatureAqueous solution

The invention discloses a preparation method of high-performance bone black. The preparation method comprises the following steps of: firstly, crushing animal bone which is subjected to de-fatting and degumming into grains of 1-5mm; secondly, feeding the granular animal bone into a carbonizing and activating furnace, raising the furnace temperature to be at 500-550 DEG C in velocity of 5-10 DEG C / min; subsequently adding a composite activating agent; continuously raising the temperature to be at 650-750 DEG C and keeping the constant temperature for 1-3hours; rapidly cooling the furnace temperature to be at 150-180 DEG C and stopping feeding the composite activating agent, and discharging when the furnace temperature is reduced to be at 100 DEG C; adding the carbonized and activated bone black into an alkali water solution, and introducing steam to boil and wash for 5-10 times; putting the boiled and washed bone black into a carbon dioxide water solution to be washed for 5-10 times so as to adjust the pH value to be at 7.0-8.0; and fishing out the bone black after being washed, drying in air or drying in an oven so as to obtain a finished product, namely, the high-performance bone black. The preparation method has the characteristics of simple process and low cost, and the prepared bone black is strong in adsorption and purification capability.

Owner:BEIJING ZHONGSHIHONG INSTALLATION ENG

Method of treating lead contaminated soil with bone charcoal

InactiveCN1810398AReduced bioavailabilityReduce absorptionContaminated soil reclamationChemical reactionPlant roots

The method of treating lead contaminated soil with bone charcoal is to use bone charcoal with wide source and low cost in chemical reaction with lead in soil to form stable compound, so as to lower biologically effective lead content in soil, reduce the absorption and accumulation of plant root system and treat lead contamination of soil. Specifically, bone charcoal is crushed into powder of 300-350 mesh and buried into soil in the amount of 2-16 g each kg soil.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of bone char fluoride removal agent loaded with aluminium ions

InactiveCN101596446AImprove adsorption capacityAnti-interferenceOther chemical processesWater/sewage treatment by sorptionHigh fluorideRoom temperature

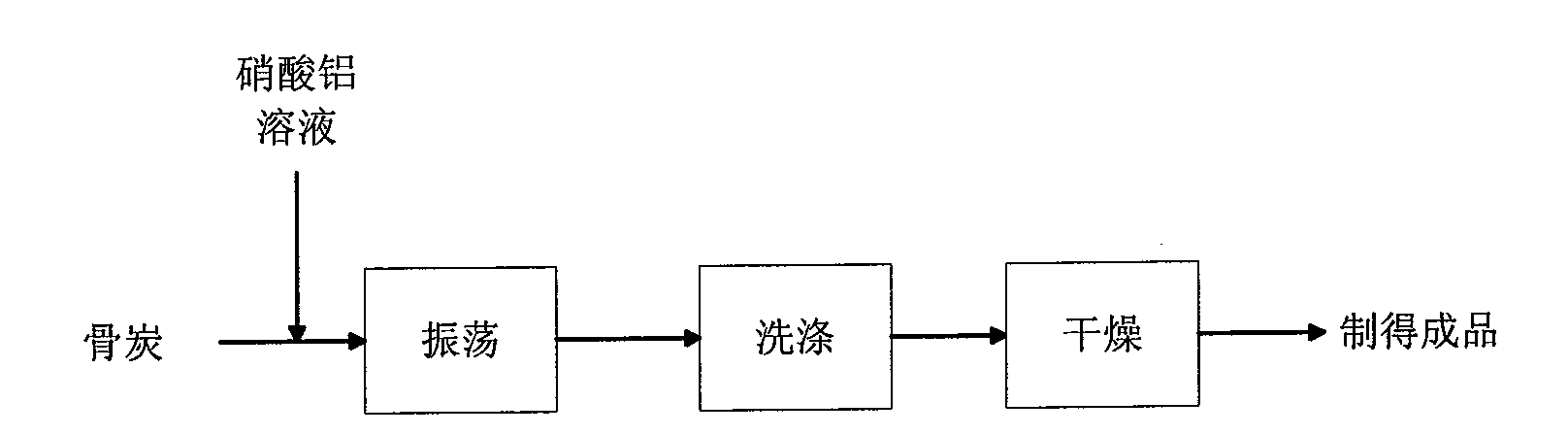

The invention relates to a preparation method of a bone char fluoride removal agent loaded with aluminium ions, belonging to the field of drinking water fluoride removal treatment. In the method, bone char of certain mass is put into an aluminium salt solution of certain volume; the mixture of the bone char and the aluminium salt solution is oscillated for certain time under certain condition; the bone char is taken out, washed by clear water and dried under room temperature. The mass ratio between the bone char and the aluminium salt solution is 1:8-1:12. The condition of the oscillation is as follows: the bone char and the aluminium salt solution is fully mixed in the process of oscillation, the time of oscillation is not less than 24h, the temperature of the mixture is kept at 20-40 DEG C during oscillation. Batch adsorption tests show that the adsorption capacity of the aluminium-loaded bone char fluoride removal agent is 60% higher than that of ordinary bone char fluoride removal agents. Used in the areas taking high-fluoride ground water as drinking water resource, the fluoride removal agent can effectively ensure the residents with drinking water safety, reduce the cost for producing water and the workload of daily maintenance of water supply engineering simultaneously.

Owner:TSINGHUA UNIV

Composite adsorption material for removing magnesium ions from natural water and preparation method for adsorption material

InactiveCN102872801AHigh porosityLow costOther chemical processesWater/sewage treatment by ion-exchangePhysical chemistryFree cooling

The invention discloses a composite adsorption material for removing magnesium ions from natural water and a preparation method for the adsorption material. A bone and sawdust are used as raw materials. The method comprises the following steps of: cooking and grinding the animal bone, boiling by using NaOH, flushing, drying, sieving, and drying; uniformly mixing the dried, ground and sieved sawdust, bone black and water, forming in a banded extruder, pelletizing in a pelletizer, drying in the shade, and drying; and heating and activating the dried material, naturally cooling, flushing, and drying to obtain the adsorption material. The preparation method is novel and unique, and the prepared material has a good adsorption effect on the magnesium ions in the water.

Owner:CHANGZHOU UNIV

Strong-flavor liquor pit mud

InactiveCN103695240AIncrease the fragranceImprove microbial activityAlcoholic beverage preparationBiotechnologyPeat

The invention discloses strong-flavor liquor pit mud which consists of the following raw materials in parts by weight: 95-100 parts of loess, 10-12 parts of fermented grains, 3-4 parts of yeast powder, 10-15 parts of yellow water, 6-8 parts of composite strain liquid, 3-5 parts of bone black, 10-20 parts of peat, 1-2 parts of seaweed powder, 20-30 parts of pit mud, 0.8-1 part of ethanol, 3-4 parts of tail liquor, 0.02-0.1 part of K2HPO4, 0.01-0.06 part of MgSO4 and 0.2-0.3 part of multifunctional powder. According to the pit mud disclosed by the invention, the raw materials are reasonably compounded; the microbial activity in the pit mud is high, and the pit mud has strong aroma without foreign smell; the liquor yield is increased, and the main aroma of the liquor is also greatly improved.

Owner:ANHUI LONGSHU LIQUOR IND

Anticorrosion and antibacterial aluminium alloy surface treating agent

InactiveCN104099021AImprove anti-corrosion and anti-bacterial abilityGood acid and alkali resistanceAntifouling/underwater paintsPaints with biocidesSodium Lauryl SarcosinateMeth-

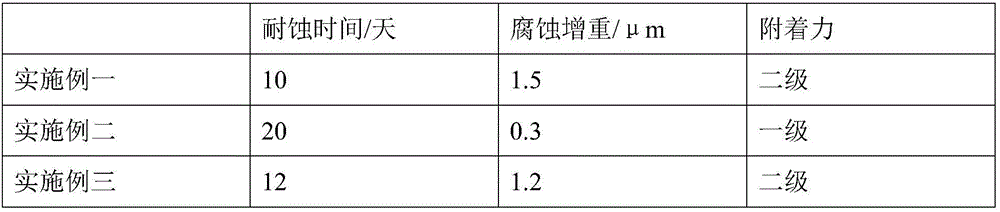

The invention discloses an anticorrosion and antibacterial aluminium alloy surface treating agent which comprises a component A and a component B, wherein the component A comprises the following materials in parts: 0.5-1 part of benzalkonium bromide, 0.4-1 part of flaxseed gum, 0.4-1 part of sodium N-lauroylsarcosinate, 2-4 parts of diethylene glycol, 3-4 parts of sodium phosphate, 0.9-1.5 parts of 3-methoxybutyraldehyde dimethyl acetal, 2-3 parts of glycerinum, 2-3 parts of silane coupler KH-858 and 40-50 parts of deionized water; the component B comprises the following materials in parts: 0.4-1 part of 1-methyl-2-pyrrolidinone, 1-2 parts of potassium iodide, 0.3-1 part of bone black, 1-2 parts of ammonium polyphosphate, 0.3-0.6 part of magnesium fluoride, 2-4 parts of a coalescing agent, 10-12 parts of a silane coupling agent KH560 and 70-90 parts of deionized water. According to the invention, a film formed on the surface of aluminium alloy by the surface treating agent is excellent in corrosion resistance, antibacterial property, acid-base resistance, salt frog resistance and high in rust resisting property; the film layer is firm, excellent in compactness, uniform in shape and high in adhesive force.

Owner:铜陵创能动力机械有限公司

Chromium-free passivant and preparation method thereof

InactiveCN106676508ANo pollution in the processLow costMetallic material coating processesWater basedChromium free

The invention discloses a chromium-free passivant composed of the following raw materials of, by weight, 2-8 parts of hexafluorozirconic acid, 10-20 parts of water-base resin, 1-5 parts of phytic acid, 3-10 parts of a silane coupling agent, and 5-10 parts of bone black. According to the formula, the heavy metal chromium is not introduced, and heavy metals in water can be removed. The invention further discloses a preparation method for the chromium-free passivant.

Owner:宁波际超新材料科技有限公司

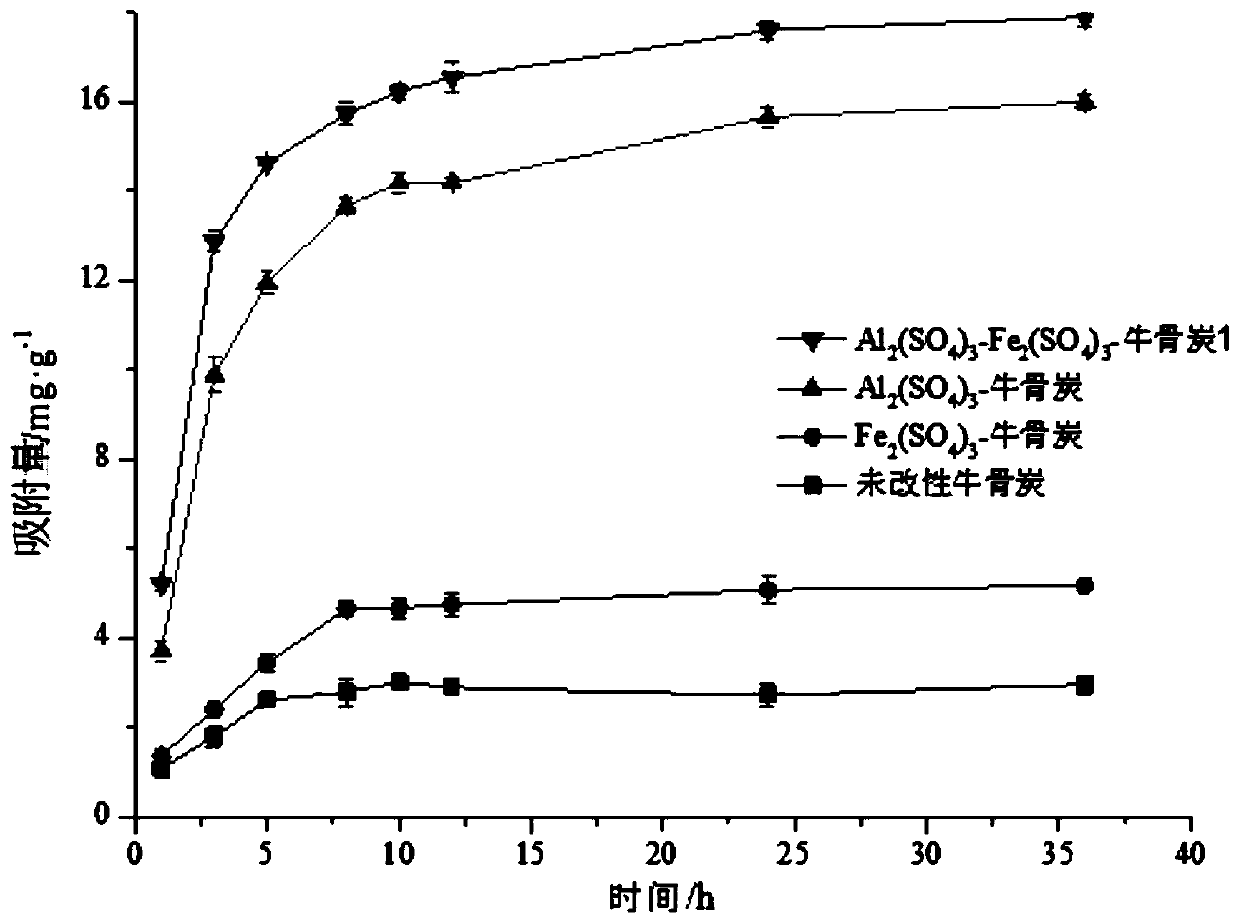

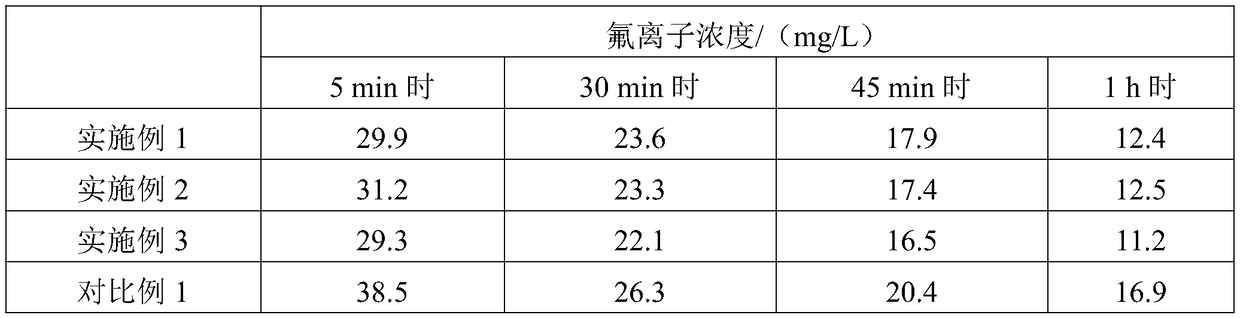

Production method of iron and aluminium compound bone char fluorine removal agent and produced fluorine removal agent

InactiveCN110013830AImprove the effect of fluoride removalEasy to useOther chemical processesSpecific water treatment objectivesLiquid ratioCarbonization

The invention provides a production method of an iron and aluminium compound bone char fluorine removal agent and the produced fluorine removal agent. The production method comprises the following steps of (1) thoroughly washing the surfaces of livestock bones, and at 400-450 DEG C, conducting carbonization for 1.5-2 h to obtain bone char; (2) grinding and sieving the bone char obtained in the step (1) after cooling the bone char obtained in the step (1), and conducting drying after conducting washing to obtain bone char particles; and (3) soaking the bone char particles obtained in the step (2) in a Fe2(SO4)3 solution in a mass percentage concentration of 2-8% according to a solid to liquid ratio of 1 to (2.5 to 10) for 0.3-0.7 h, conducting drying after conducting washing, then accordingto a solid to liquid ratio of 1 to (3 to 8), soaking the bone char particles in a Al2(SO4)3 solution in a mass percentage concentration of 3-10% for 0.5-1.5 h, and conducting drying after conductingwashing to obtain the Al2(SO4)3-Fe2(SO4)3 compound bone char fluorine removal agent. The adsorption capacity of the iron and aluminium compound bone char fluorine removal agent is 8.5 times of that ofbone char which is not loaded with iron and aluminium ions, so that a fluorine removal effect is excellent.

Owner:NANJING RONGZHONG ENVIRONMENTAL ENG RES INST CO LTD

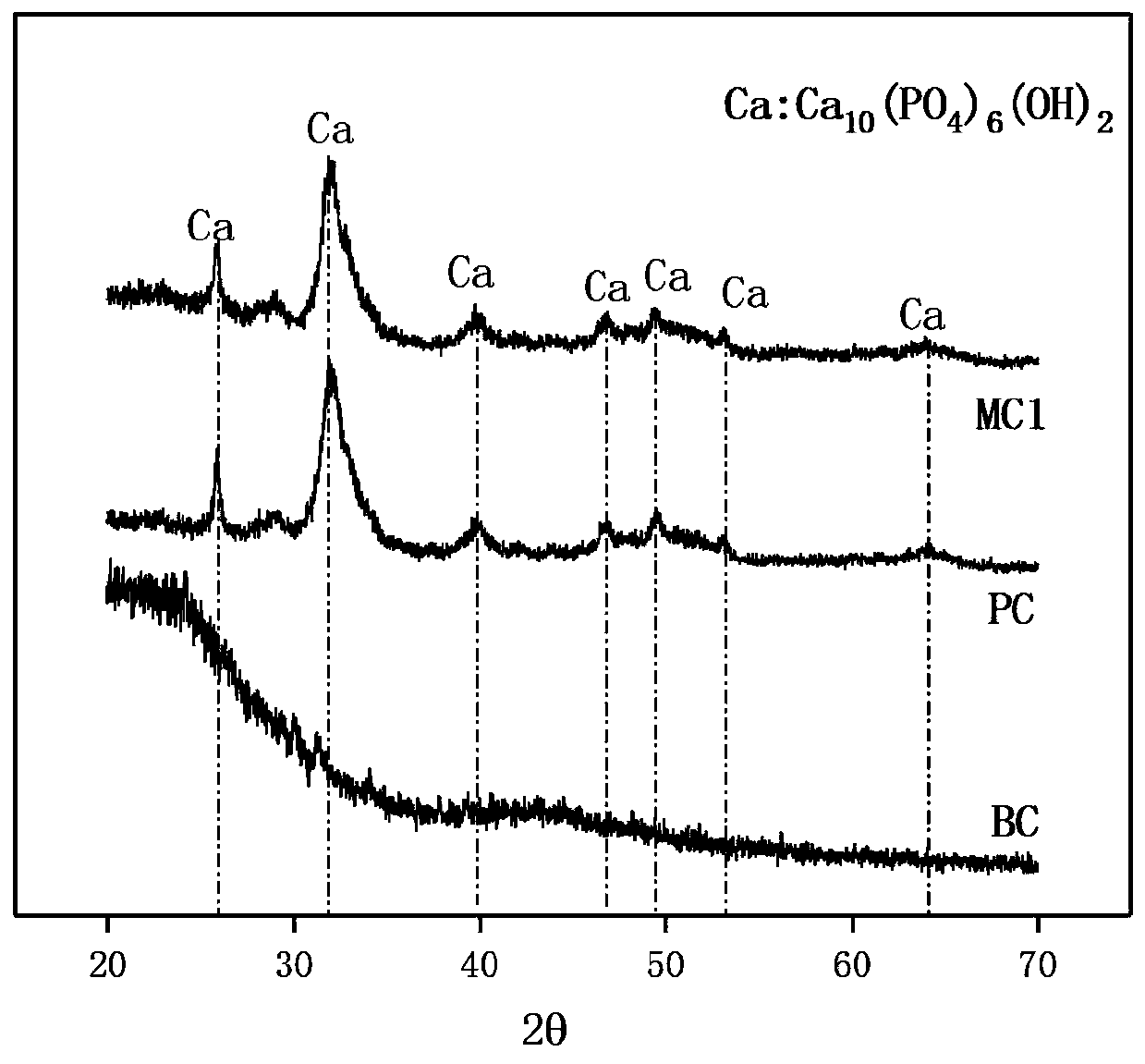

Preparation method of composite permeable bricks

InactiveCN109020494AHigh activityImprove self-cleaning abilityCeramic materials productionCeramicwareBrickSlag

The invention relates to a preparation method of composite permeable bricks, belonging to the technical field of building materials. Coal gangue and blast furnace slag are used as basic materials; particles are activated by using hydrochloric acid to removing impurities, carrying out expanded void treatment and using a surfactant and a physical grinding-aid method; the activated particles with improved activity are then mixed with sea mud, animal bone powder and the like; a dispersing agent is used for improving the sufficient dispersing and mixing of the raw materials; in a calcination process, the sea mud is firstly enabled to form ceramic-like particles, and the gas generated by the decomposition of bamboo chips and additives in auxiliary agents is used for pore formation so as to formpores; secondly, bone char is formed by the animal bone powder, so that the biological activity and the water permeability are improved; finally, hydroxyl calcium phosphate is combined with calcium carbonate in the raw materials so as to form synthetic bone char, so that the activity is further improved; furthermore, tetrabutyl titanate is decomposed to generate dioxide silicon, so that the self-cleaning effect of the permeable bricks is improved; part of iron elements are loaded, so that the pore cleaning ability and the water permeability are improved.

Owner:FOSHAN WANHE NEW ENERGY TECH CO LTD

Pyrophyllite and bone black blended and modified heat dissipating coating material

InactiveCN103773130AImprove thermal conductivityImprove mechanical propertiesCoatingsSodium lactatePyrophyllite

The invention discloses a pyrophyllite and bone black blended and modified heat dissipating coating material. The pyrophyllite and bone black blended and modified heat dissipating coating material is prepared from the following raw materials in parts by weight: 93-100 parts of chlorinated polyethylene, 0.1-0.2 part of potassium dihydrogen phosphite, 2-3 parts of calcium fluoride, 1-2 parts of amyl acetate, 4-6 parts of maleic anhydride grafted polypropylene, 5-7 parts of wollastonite powder, 2-4 parts of graphite powder, 1-2 parts of benzotriazole, 2-3 parts of guar gum, 2-3 parts of mannitol, 1-2 parts of sodium lactate, 0.8-1 part of dimethylethanolamine and 7-10 parts of modifying filler. According to the heat dissipating coating material disclosed by the invention, the heat conducting effect of a coating is enhanced through adding the modifying filler and blending and modifying pyrophyllite and bone black, so that the heat dissipating performance is enhanced, and the physical and mechanical properties of the surface of the coating are improved.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Stevia rebaudianum organic fertilizer and preparation technology thereof

InactiveCN105461475APromote growthImprove defenseBio-organic fraction processingOrganic fertiliser preparationSesamum orientaleMonosodium glutamate

The invention discloses a stevia rebaudianum organic fertilizer and a preparation technology thereof. The organic fertilizer is prepared from, by weight, 15% of stevia rebaudianum fermentation powder, 9% of potassium sulfate, 10% of diammonium sulfate, 13% of cottonseed cakes, 22% of sesame meal, 18% of monosodium glutamate offal, 5% of fish meal, 4% of silkworm chrysalis and 13% of bone black; the N content of above raw materials is not lower than 8%, the P content of the raw materials is not lower than 7%, the K content of the raw materials is not lower than 4%, and the total content of organic matters is not smaller than 65%. The preparation technology comprises the following steps: screening all the raw materials, and detecting the respective content of components; respectively drying and crushing the raw materials; and stirring and mixing the raw materials in a V-shaped vacuum sealing tank according to above formula proportions, compacting the obtained mixture by a granulator to prepare particles, sieving the particles, and cooling and packaging the sieved particles to form a product. The fertilizer can improve the self immunity of plants, improves the growth of beneficial microbes in soil, improves the components of the soil, prevents soil ageing and continuous plowing work soil fatigue, decomposes chemical pesticides residual on crops and in soil, improves the quality of the crops, and can be applied to greenhouse vegetables, fruits, grain crops and other crops.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

Preparation method of fluorion adsorbent

InactiveCN108714412AImprove adsorption capacityLarge adsorption capacityOther chemical processesAluminium silicatesAluminium sulfateFiltration

The invention provides a preparation method of a fluorion adsorbent, and belongs to the technical field of adsorbents. The preparation method comprises the following specific preparation processes: cleaning natural zeolite with deionized water until no suspended impurities are generated, and then drying; putting the dried natural zeolite in an aluminium sulfate solution for soaking, then adding aNaOH solution, stirring and then performing vacuum filtration, and calcining a solid after vacuum filtration; uniformly mixing the calcined modified zeolite, kaolin, zirconium oxychloride and bone char; adding an acetic acid solution in the mixture to perform acidification; then adding a cerous nitrate solution and a titanium sulfate solution; and regulating the pH value of the solution until thesolution is alkaline, then standing, filtering, washing a filtered-out material with deionized water until the filtered-out material is neutral, and drying to prepare the fluorion adsorbent. The preparation method is low in cost, environmental-friendly and harmless, natural zeolite is modified with Al2O3, natural zeolite is combined with kaolin, zirconium oxychloride and bone char that have relatively strong fluorine ion adsorption capacity, and the synergistic interaction effect of bone char and other substances are used, so that the prepared product is high in fluorine ion adsorbability andhigh in fluorine ion adsorption capacity.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

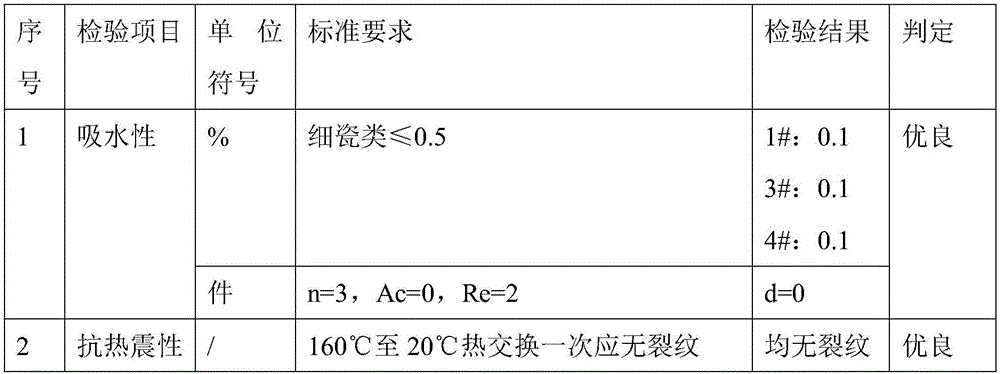

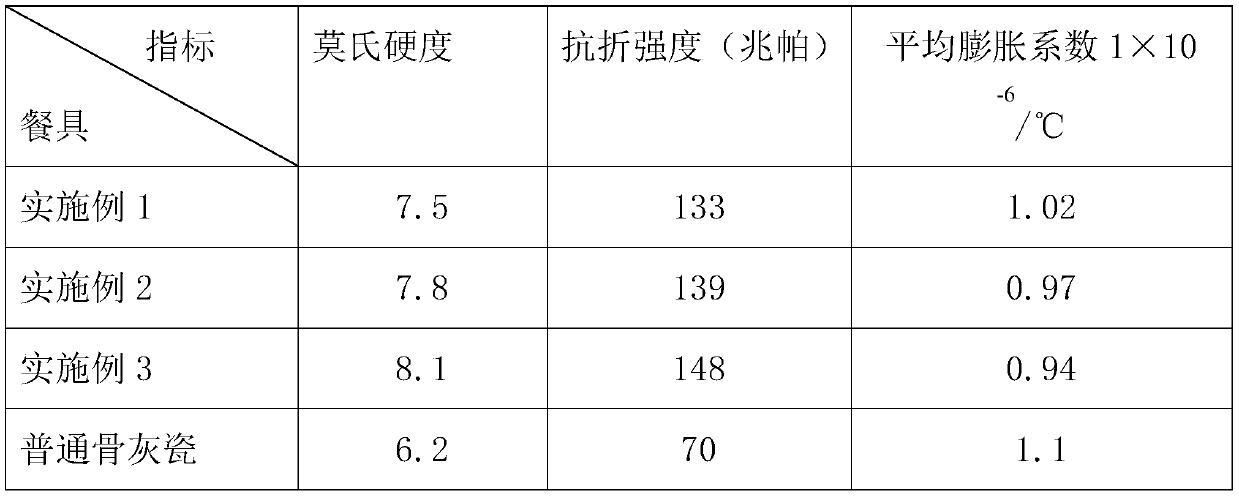

A reinforced bone china for daily use and a preparing method thereof

ActiveCN106242504AHigh mechanical strengthImprove thermal shock resistanceCeramic materials productionClaywaresPotassiumCadmium Cation

A reinforced bone china for daily use and a preparing method thereof are disclosed. The bone china for daily use is prepared from, by mass, 1-3 parts of an additive ZL, 40-45 parts of bone char, 10-12 parts of quartz, 10-12 parts of feldspar, 24-28 parts of kaolin, 48-52 parts of water, 1-3 parts of a crystal form improving agent, 1-2 parts of a mineralizer and 1-3 parts of a phosphosilicate targeting fluxing agent. Through scientifically introducing the phosphosilicate targeting fluxing agent, introduction of potassium-containing and sodium-containing mineral raw materials is significantly reduced, and the sintering temperature and the expansion coefficient of a blank are controlled well. Through introducing the additive ZL, the crystal form improving agent and the mineralizer into bone china pug, uniform crystal growth in a stage of vitrification to form the china is ensured, a phosphosilicate glass phase network is further complete, and mechanical strength and thermal shock resistance of the bone china are finally improved. The bone china for daily use is high in mechanical strength, smooth in glaze, easy to clean, significantly reduced in lead and cadmium dissolving-out amounts, and good in thermal shock resistance.

Owner:GUANGDONG BENING CERAMICS IND CO LTD

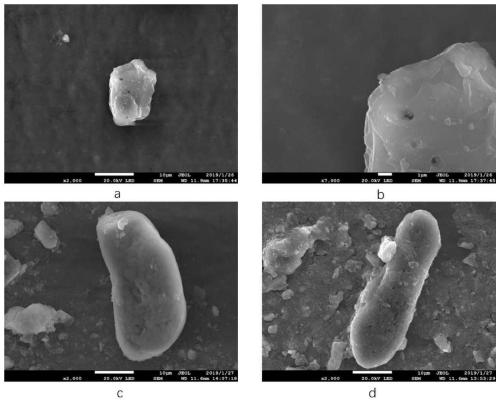

Preparation method and application of co-pyrolyzed biochar of pig bones and bamboo wood

ActiveCN109908865AImprove stabilityImprove adsorption capacityOther chemical processesWater contaminantsRoom temperatureWastewater

The invention relates to the technical field of biochar, in particular to a preparation method and application of co-pyrolyzed biochar of pig bones and bamboo wood. The preparation method comprises the following steps: (1) impurity removal: stirring and scalding the pig bones and the bamboo wood respectively in water of a certain temperature to remove impurities; (2) drying: drying the pig bones and bamboo wood after the impurities are removed at a certain temperature; (3) pulverizing: pulverizing the dried pork bones and bamboo wood respectively to obtain pork bone powder and bamboo powder; (4) co-pyrolysis: mixing the prepared pork bone powder with the bamboo powder in a certain ratio, then co-pyrolyzing at a certain temperature, and then cooling to room temperature to obtain the co-pyrolyzed biochar. The preparation method provided by the invention is simple, the raw materials are easy to obtain, the method is high in stability, the repeatability is high, the industrial production is facilitated, and the prepared co-pyrolyzed biochar of the pig bones and the bamboo wood combines the advantages of bone charcoal and bamboo charcoal, so that the effect of effectively treating mixedwastewater can be realized, and the effect is higher than that of single bone charcoal or bamboo charcoal.

Owner:WUHAN UNIV OF TECH

Preparation method of underglaze color bone ash porcelain

The invention discloses a preparation method of underglaze color bone ash porcelain. The bone ash porcelain comprises a bone ash porcelain green body and glaze; the green body is prepared from the following raw materials in parts by weight: bone black, anorthite, quartz, kaolin, sepiolite, sillimanite, vermiculite, diatomaceous earth, alumina and magnesia. The green body takes bone charcoal, anorthite, quartz and kaolin as main raw materials, supplemented by sepiolite, sillimanite, vermiculite and diatomaceous earth, so that the prepared bone ash porcelain has higher strength; sepiolite with higher thermal stability, sillimanite with higher compressive strength and diatomaceous earth with higher impact strength, tensile strength and tear strength cooperate with bone black, anorthite, quartz and kaolin, so that the finally prepared bone ash porcelain has high compressive strength and impact strength for use as a daily porcelain.

Owner:FUJIAN QUANZHOU LONGPENG GROUP

Oil baffle plate for high-speed gear case vent cap

ActiveCN106498259AImprove heat resistanceAccelerated corrosionMolten spray coatingFerric hydroxideMontmorillonite

The invention relates to an oil baffle plate for a high-speed gear case vent cap. The oil baffle plate comprises tungsten carbide, montmorillonite, kaolin, bone black, aluminum oxide, magnesium oxide, copper oxide, ferric oxide, AlN, wollastonite, diopside, talcum powder, an anti-aging agent RD, Fe, ferric hydroxide, Al, Zn, Mn, Cr, Ni, Cu, Mo, Ti, Pd, Pt, W, Ce, Eu, Lu, Au, Ag, Sn, Zr, Re and clay. According to the oil baffle plate for the high-speed gear case vent cap, both the bone black and metal raw materials are added into the raw materials, so that the structural strength of the oil baffle plate is improved, heat dispersion of the oil baffle plate is also greatly strengthened compared with that of a pure ceramic material, the condensation efficiency is improved, and thus the oil baffle efficiency of the oil baffle plate is also improved.

Owner:南京创贝高速传动机械有限公司

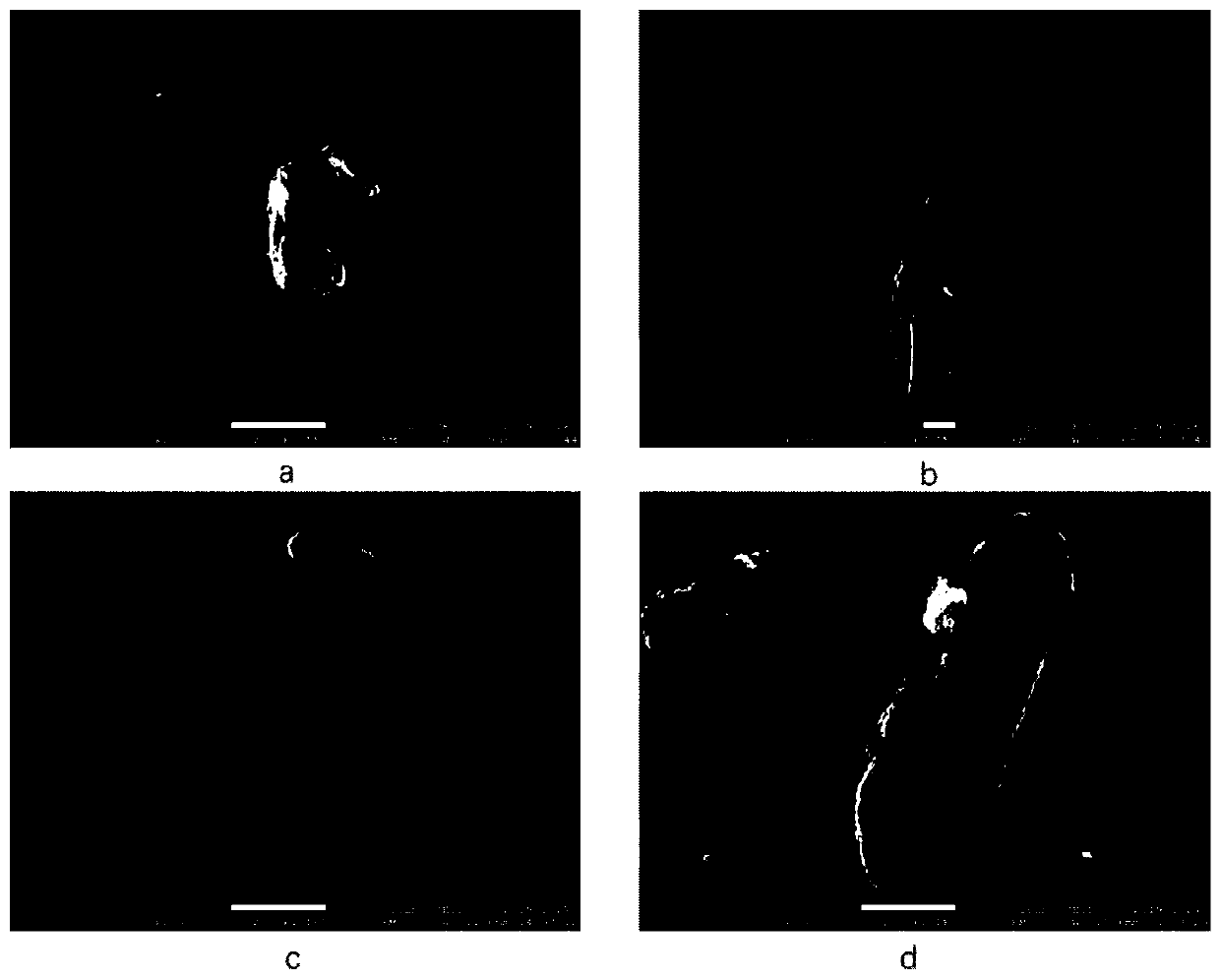

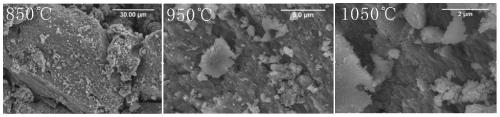

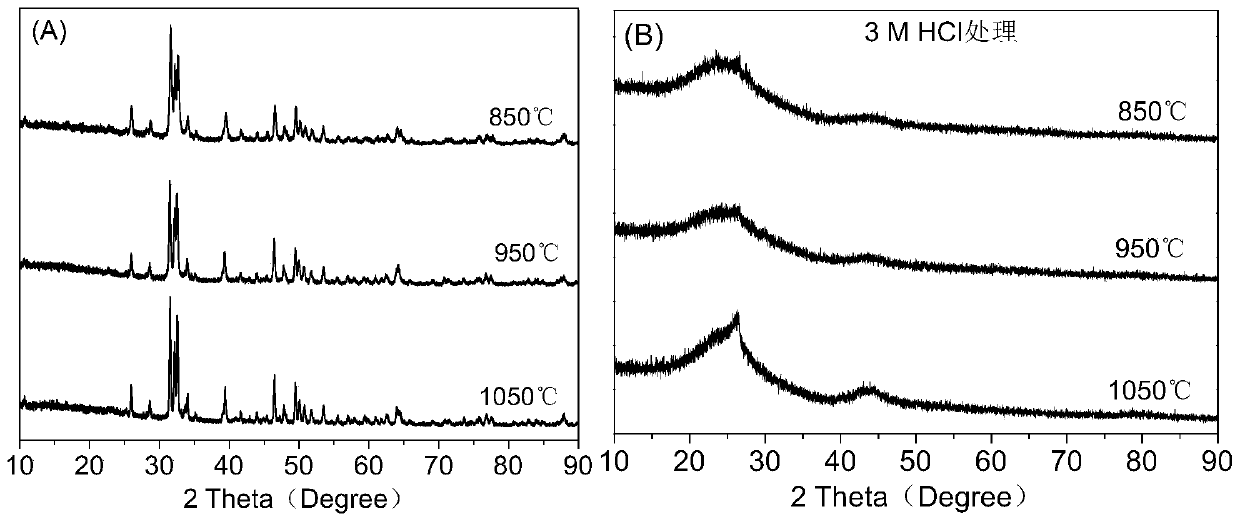

Bone black capable of efficiently oxidizing trivalent arsenic in water and application of bone black

ActiveCN111389364AEfficient oxidationSynchronized OxidationOther chemical processesWater contaminantsArsenic pollutionEnvironmental engineering

The invention discloses bone black capable of efficiently oxidizing trivalent arsenic in water and application of the bone black. The bone charcoal is prepared by the following steps: crushing ox bones into particles with the particle size of less than 0.5 cm, then cleaning ox bone powder with water, and drying the ox bone powder; putting the ox bone powder into a vacuum tube furnace, heating to 500-1100 DEG C under the protection of nitrogen or inert gas, and keeping for 1-3 hours to obtain bone black before acid treatment; soaking the prepared bone black before acid treatment in an acid solution, then washing with water until the pH value of the solution does not change and finally drying to obtain the bone black capable of efficiently oxidizing trivalent arsenic in water. The bone blackhas an ultra-large specific surface area (more than 1000m < 2 > / g) and can directly utilize oxygen to generate reactive oxygen species so that rapid oxidation of As (III) is realized, no additional chemical oxidation reagent is needed, an effective material can be provided for trivalent arsenic pollution remediation in environments such as water bodies, and the bone black is beneficial to application in practical engineering.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

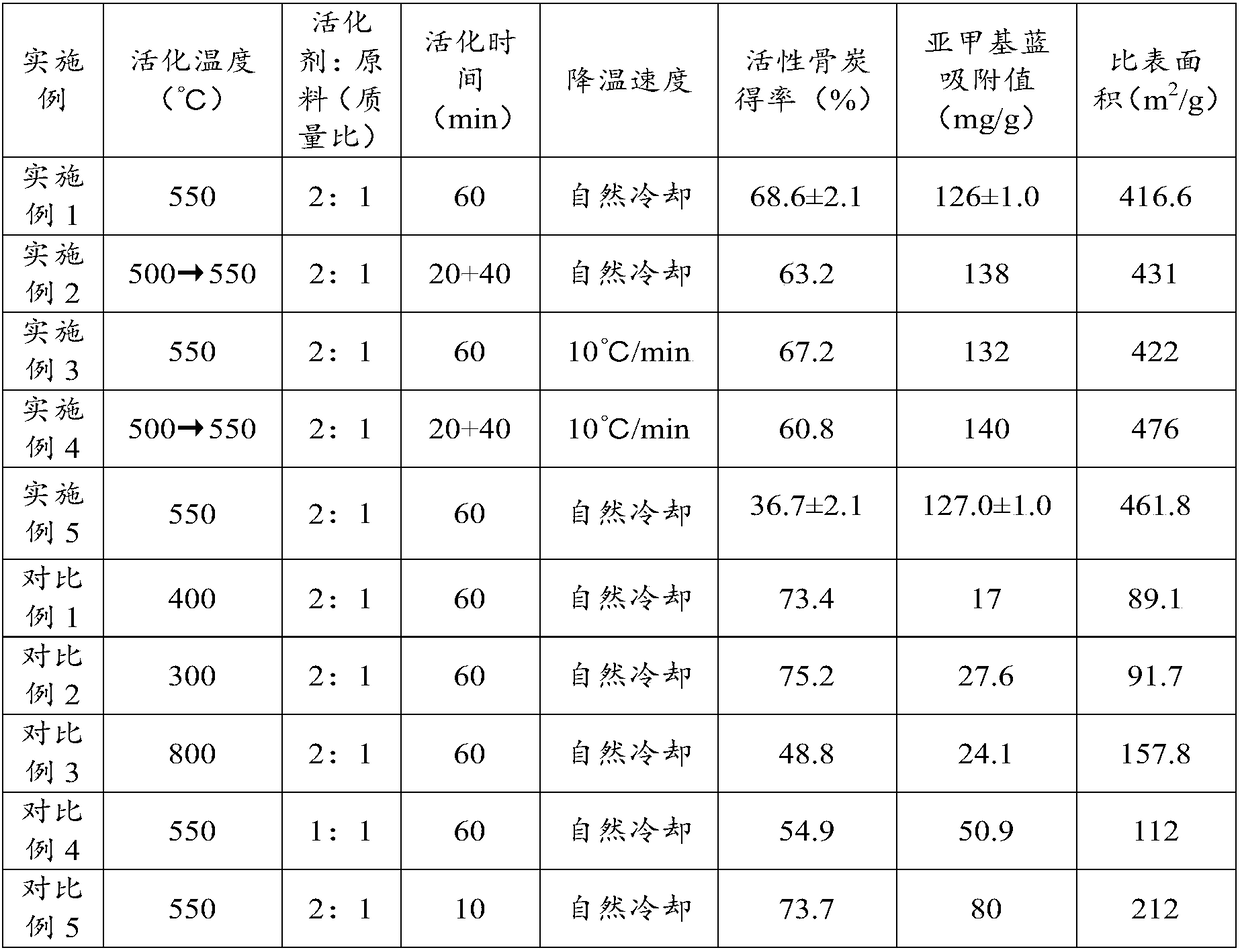

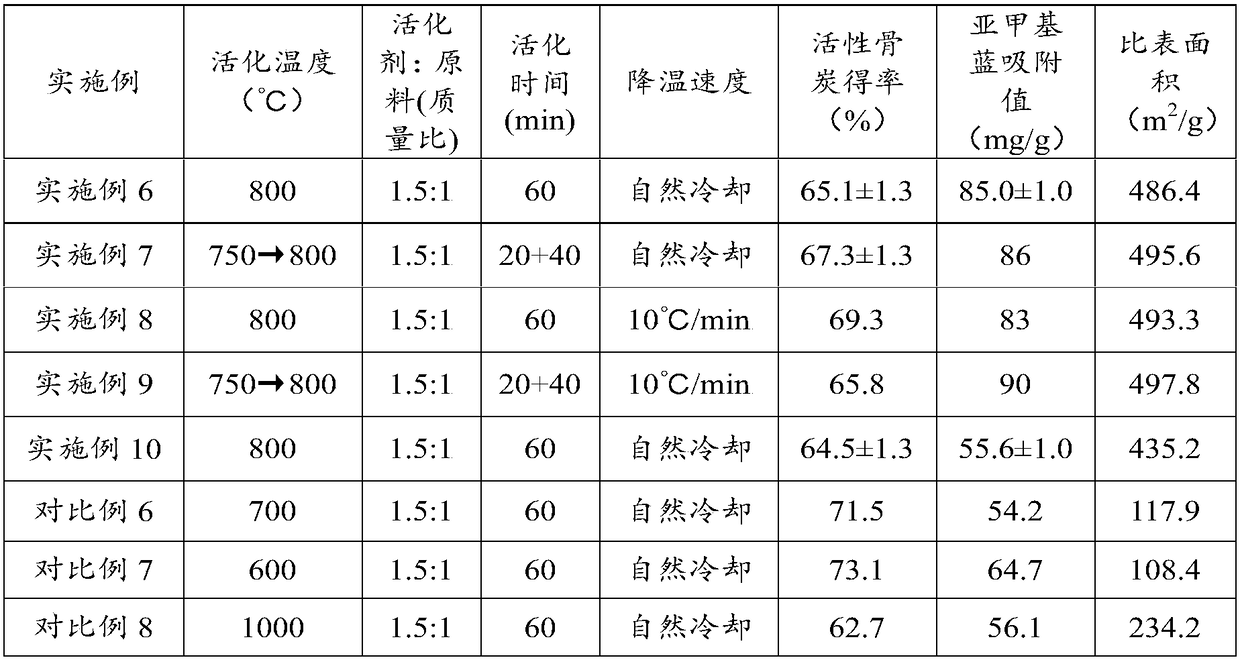

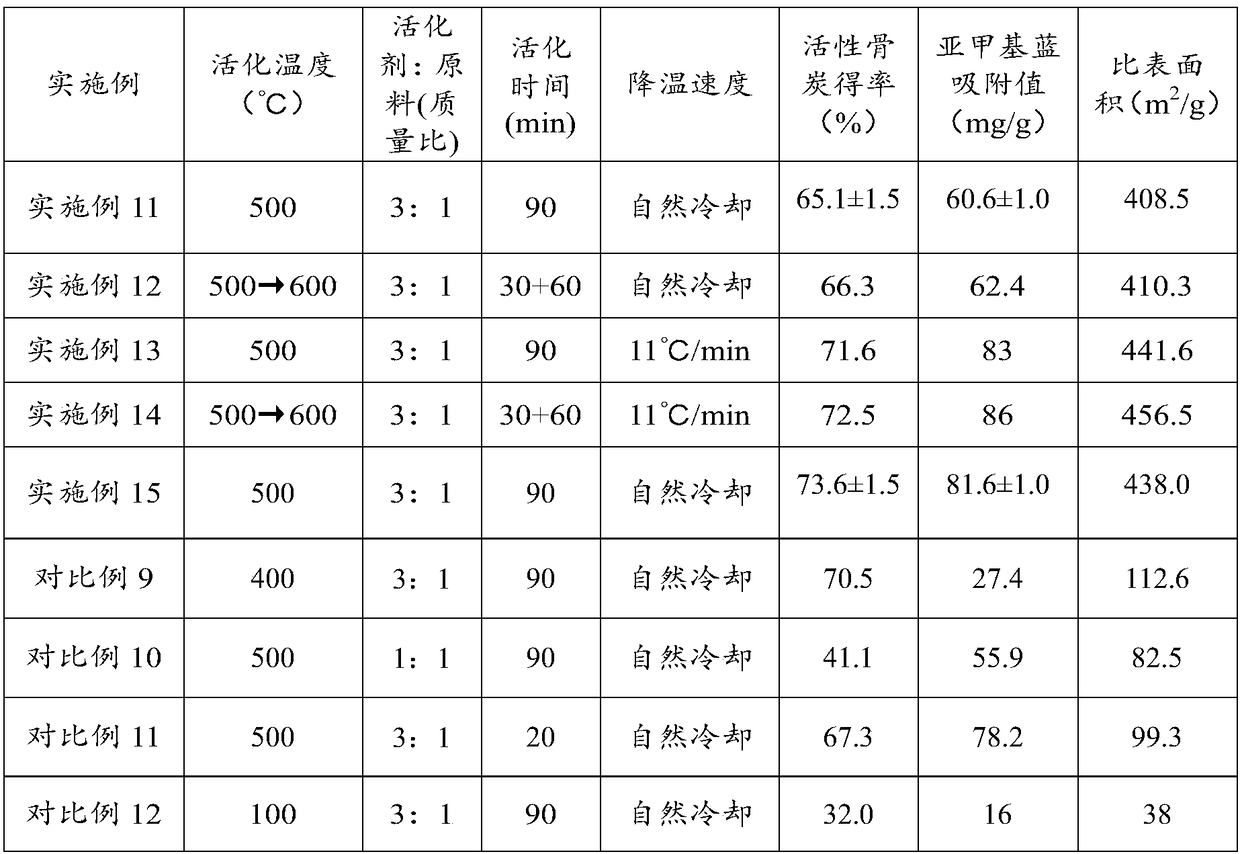

Active bone coal and preparation method thereof

ActiveCN109110757AConducive to the realization of resource utilizationSave resourcesCarbon compoundsActivated carbonCoal

The invention relates to the field of adsorbing materials and provides an active bone coal and a preparation method thereof. The preparation method for the active bone comprises the following steps: mixing the smashed waste animal bones with an activator and steeping for 12-20h; activating for 60-90min at 500-850 DEG C, thereby acquiring an activated material; directly washing the activated material with water till pH value is 6-8, and then drying, thereby acquiring the active bone coal. The active bone coal has a specific surface area of 200-500m2 / g and a methylene blue absorbing value of 30-130mg / g. The invention is beneficial to the recycling of various waste animal bones and the saving of resources, such as timbers, coal and coconut shells. The prepared various animal bone-based activebone coals can be used for locally replacing the traditional active carbon products; no inert gas shielding is required in the preparation process; the process is simple; the preparation method is easy for industrial production.

Owner:QINGHAI UNIV FOR NATITIES

Preparation method of bone charcoal

The invention provides a method for preparing bone charcoal. The bone charcoal is prepared from bone-made calcium hydrogen phosphate which is a by-product in the preparation of bone gelatin. The method comprises the steps of material portioning, mixing, molding and calcining; specifically, the method comprises the following steps: 1, adding bone-made calcium hydrogen phosphate and light calcium carbonate or heavy calcium carbonate according to the weight ratio being 100:(10-40) (wt%); 2, evenly mixing; 3, adding carboxymethyl cellulose (5% solution) accounting for 5% to 10% of the total weight and evenly mixing; 4, pressing the mixed material into a certain shape by a molding machine; and 5, drying and then calcining in a kiln for no less than 30 minutes at 1200 DEG C to 1400 DEG C; and cooling. Compared with the firing of animal bones, waste gases released during the calcining process of the method provided by the invention are less, so that the pollution is reduced; and the method provided by the invention is low in cost. In the current industrial experiment, the natural bone charcoal taking the replacement quantity of 30% to 80% according to different processes is used for manufacturing ceramic products.

Owner:梅河口市红梅骨炭有限公司

Frost crystal glaze and preparation method thereof

The invention discloses frost crystal glaze and a preparation method thereof. The glaze comprises the following components in parts by mass: 20 parts of quartz; 7 parts of calcite; 15 parts of zinc oxide; 10 parts of spodumene; 10 parts of titanium dioxide; 10 parts of Jiepai mud; 18 parts of bone black; 10 parts of a high-boron frit; 2 parts of cobalt oxide; and 2 parts of copper oxide. The crystal provided by the invention shows an effect of forming stripe-shaped scattered radiation outwards from the central crystal nucleus, so that the decorative effect of the existing glaze is greatly improved.

Owner:湖南泰鑫瓷业有限公司

Mill tailing air-entraining brick

InactiveCN104987006AHigh strengthImprove stabilitySolid waste managementGlycidyl methacrylatePolyvinyl alcohol

The invention discloses a mill tailing air-entraining brick. The mill tailing air-entraining brick is composed of the following raw materials of, by weight, 0.8-2 parts of molybdenum oxide, 0.1-0.2 part of titanous sulfate, 4-6 parts of sea-foam stone powder, 10-20 parts of mill tailings, 1-2 parts of potassium zirconium carbonate, 0.1-0.4 part of dimethylethanolamine, 2-3 parts of bone charcoal, 2-3 parts of high-boron calcium borate, 4-6 parts of celestite powder, 2-3 parts of volcanic ash, 0.2-0.4 part of aluminum sulfate, 260-300 parts of pulverized coal, 42-46 parts of quick lime, 0.3-0.5 part of aluminum powder, 37-40 parts of ordinary portland cement and 5-10 parts of a biomass resistance enhancement agent. According to the mill tailing air-entraining brick, the biomass resistance enhancement agent is added, waste resource barks and coconut shells are adopted as biomass raw powder, after enzyme treatment and alkali treatment, fiber materials with good pliability can be obtained, the fiber materials are blended with methylacrylic acid glycidyl ester and subjected to modification, the surface resistance is improved, then the modified substance is mixed with saline solutions, polyving alcohol and the like and dried, so that the effective recycle of resources is achieved, and meanwhile the stability of promoters is also improved.

Owner:合肥蓝科新材料有限公司

Industrialized production method of catalytic composite defluorinating filter material

The present invention relates to the field of water treatment material manufacture, and especially aims at an industrialized production method of a catalytic composite defluorinating filter material. A working principle of the catalytic composite defluorinating filter material is the same as that of bone black; and an exchange reaction between carboxyl and fluoride ions is conducted to reduce fluorine content in water. Materials for producing the catalytic composite defluorinating filter material comprise a main material, an auxiliary material and a chemical additive. The main material is a mixture or single substance of fragments of waste shell and eggshell; the accessory material is attapulgite clay; and the chemical additive is phosphoric acid. The catalytic composite defluorinating filter material is prepared through six production processes. Waste shell and eggshell are used as the main materials to substitute animal bones for generation of carboxylic calcium phosphate, so as to retain advantages of fluoride removal by bone black, as well as overcome fatal defects of weird smell and easy breaking. The attapulgite clay substitutes other organic and inorganic matters as a binder, and not only has high adhesion but also is associated with functions of multiple defluorinating and catalysis. The defluorinating filter material is processed into a ceramic ball shape, so as to eradicate a common terminal disease of filter material hardening during usage, as well as form abundant nano space and adsorption pores like habijabi shape. The three measurements form the catalytic composite filter material into an organic whole indispensable of any measurement, and the catalytic composite filter material has characteristics of high efficiency, strong interference resistance to raw water quality, no secondary pollution generation, waste utilization low carbon and environment-friendliness. Therefore, the invention will play an important role in livelihood project of rural drinking water safety in China.

Owner:刘威

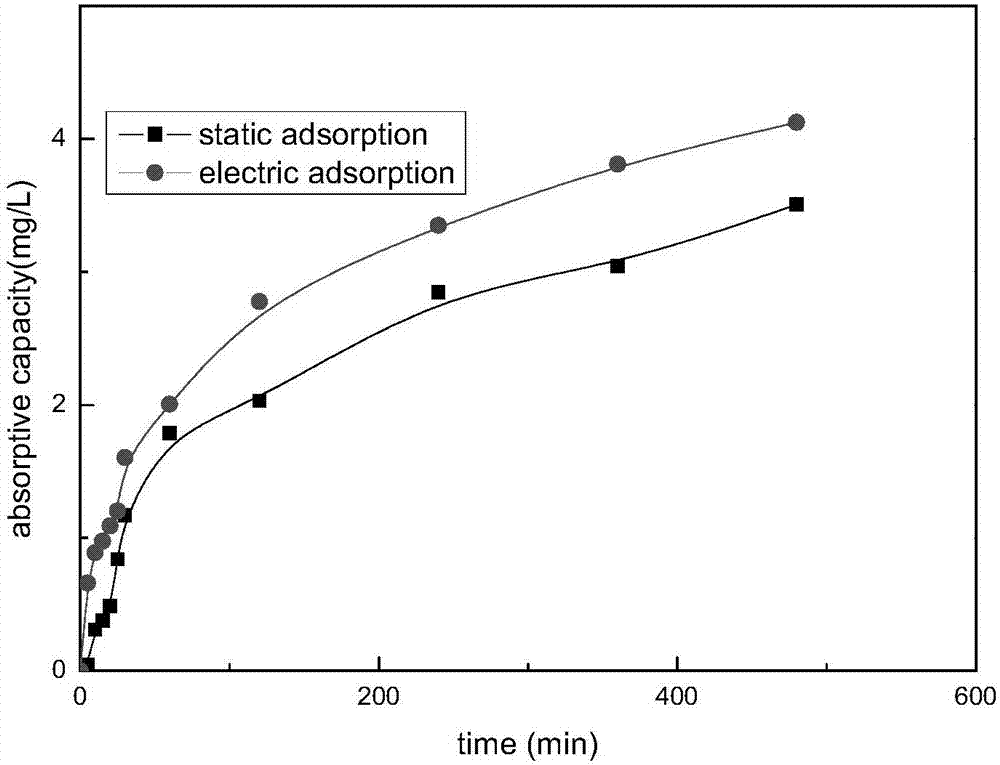

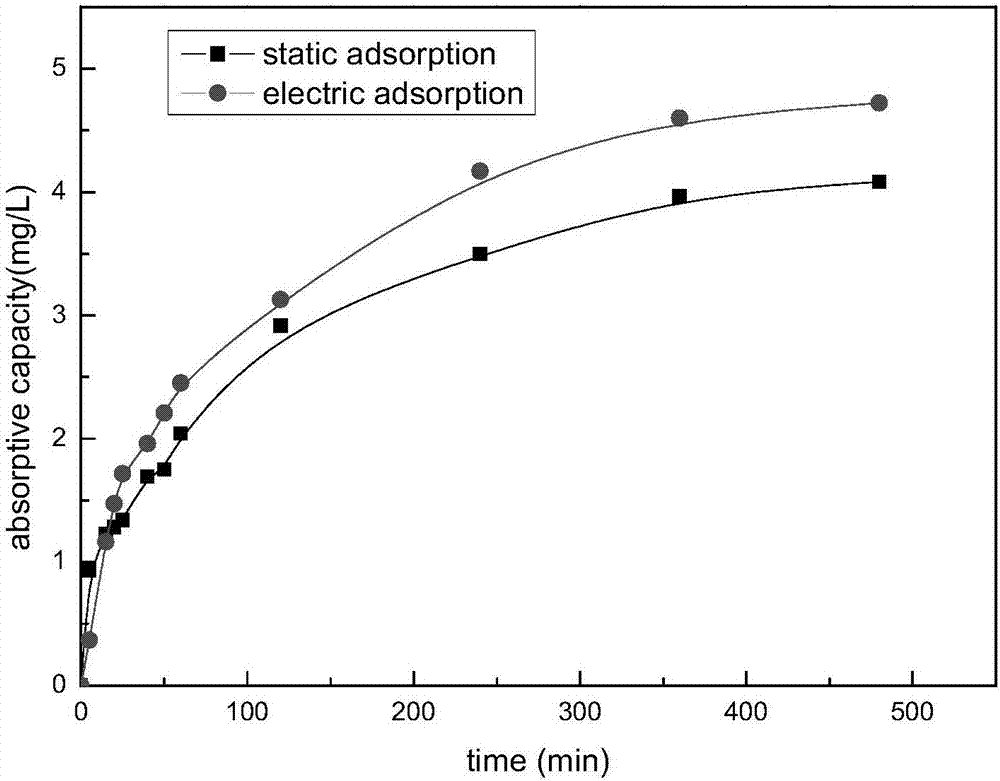

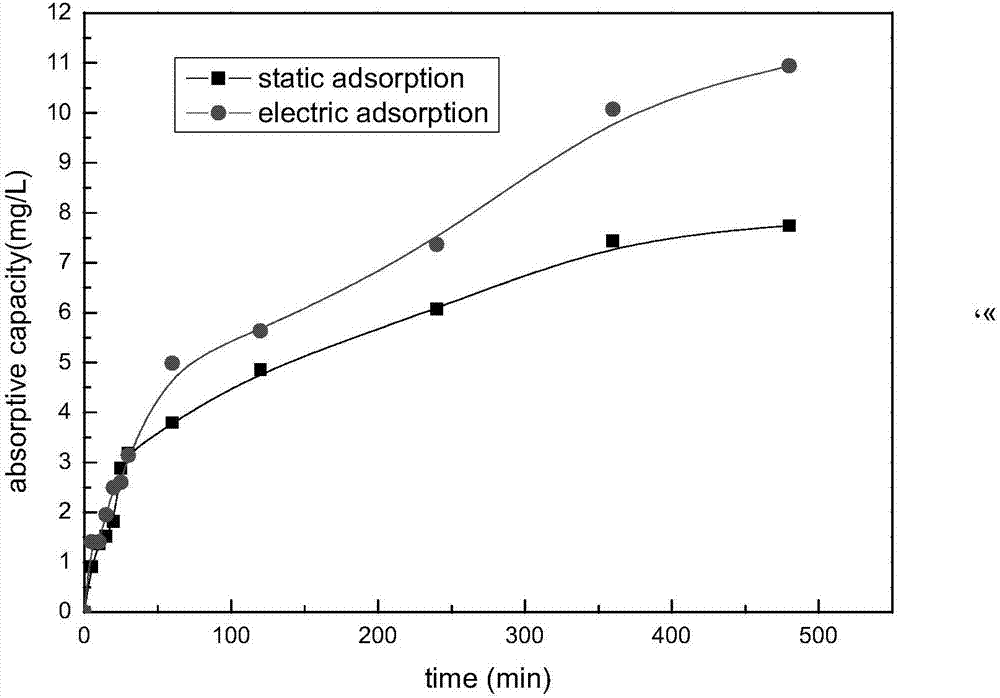

Making method of fish bone charcoal fluoride removal electrode

ActiveCN107324459AEfficient removalWater contaminantsDispersed particle separationIon exchangeDissolution precipitation

The invention discloses a making method of a fish bone charcoal fluoride removal electrode. According to the method, fish bone is cleaned and dried, is subjected to primary pulverization, and is put into a grinding machine to be ground into fish bone powder; the fish bone powder is put into a vacuum tubular furnace to be carbonized to obtain fish bone charcoal; the fish bone charcoal, PVDF and carbon black are taken and are uniformly stirred so that the materials are fully mixed to obtain a mixture; N,N-dimethylacetamide is added into the obtained mixture while the stirring is performed till slurry is obtained; the slurry is stirred and mixed for 2 to 4h; the stirred slurry is uniformly coated on an electrode plate; the electrode plate coated with the slurry is put into a drying oven to be dried; the fish bone charcoal fluoride removal electrode is obtained. The major ingredient of the fish bone charcoal is hydroxyapatite; a porous structure is realized; the fluoride can be removed in modes of in exchange, adsorption, dissolution precipitation and the like. The fish bone charcoal fluoride removal electrode can effectively remove fluoride ions under the condition of low energy consumption. Therefore the fish bone charcoal fluoride removal electrode has the promotion value in the fluoride-containing sewage treatment aspect.

Owner:WUHAN UNIV OF TECH

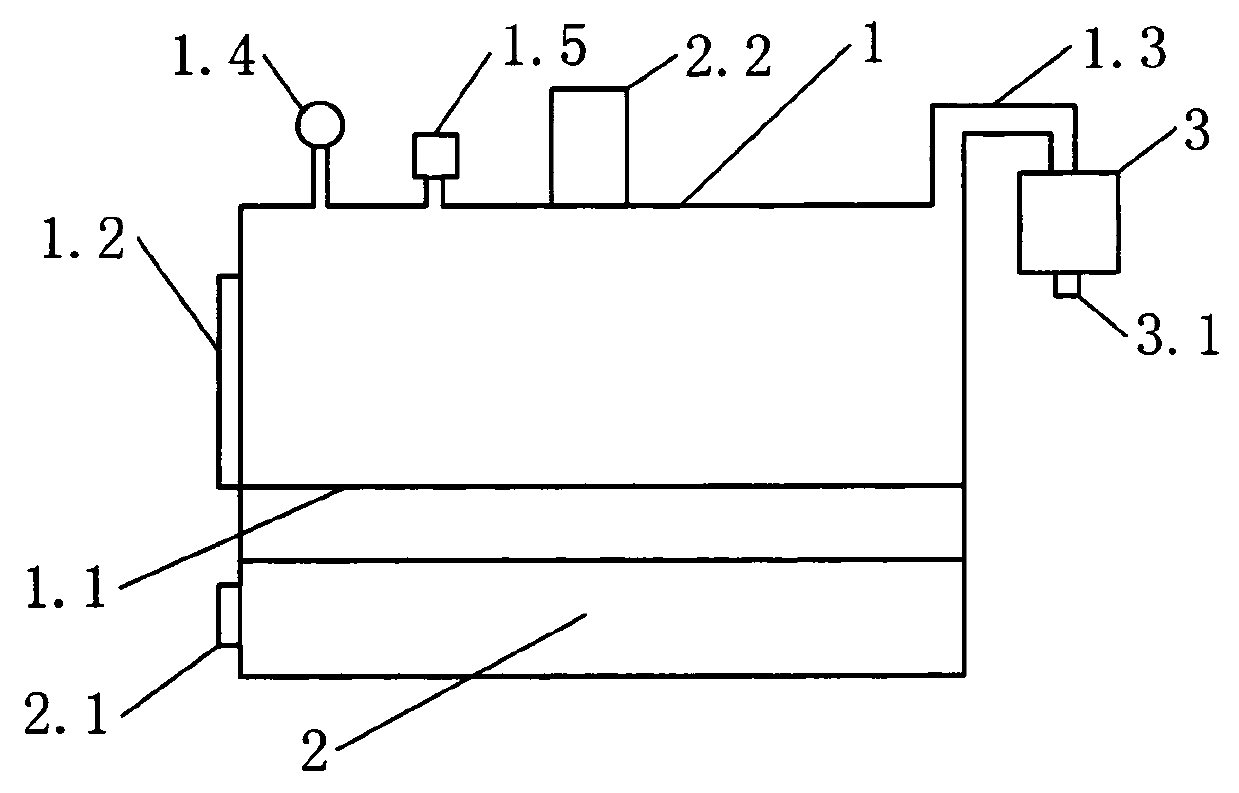

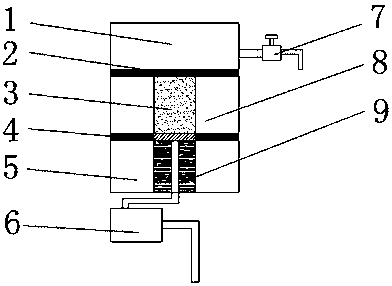

Rural small well water defluorination device and application method thereof

PendingCN107902792APrevent dental cariesLow priceWater contaminantsTreatment involving filtrationEngineeringWater fluoride

The invention relates to a small-scale rural well water defluorination device and an application method thereof, belonging to the technical field of water treatment. The present invention is placed at the wellhead, and the well water is connected with a small electric pump through a pipeline, and the small electric pump pumps the well water into the defluoridation pretreatment part, and the well water is filtered through a filter net after being treated by the pretreatment filter element and enters the defluorination part, and the well In the defluoridation part, the water is treated by the defluoridation filter element to remove fluoride, and then filtered through the filter screen into the water storage tank, and finally discharged from the faucet. The device of the invention is simple in structure, and the only energy consumption is a small electric pump, so that it can be applied in remote areas, easy to operate, and does not need human control. When water is needed, the electric pump can be turned on. The materials used in the invention are mainly activated alumina and bone charcoal. These two materials are low in price and have a good defluorination effect. They are also easy to obtain in remote rural areas. Even in remote areas, the materials in the device can be replaced, which expands the scope of the present invention. application range.

Owner:常州水精灵环保设备有限公司

Graphene anion bone shell porcelain tea set and preparation method thereof

InactiveCN108675766AImprove toughnessSmooth textureDrinking vesselsCeramic materials productionPyrophylliteHazardous substance

The invention discloses a graphene anion bone shell porcelain tea set. A preform body of the tea set is prepared from the following components in parts by weight: 1 to 20 parts of graphene, 1 to 30 parts of carbon nano tube, 1 to 200 parts of kieselguhr, 400 to 600 parts of kaoline, 50 to 100 parts of feldspar, 20 to 400 parts of bone black, 1 to 50 parts of spodumene, 1 to 80 parts of pyrophyllite, 1 to 400 parts of deep sea shell powder, 1 to 100 parts of quartz, and 1 to 40 parts of silicon nitride. By adopting the technical scheme, the graphene anion bone shell porcelain tea set has good heat resistance and cold resistance and is not afraid of quick-heating or snap-chilling; a tea cup is fine and smooth in texture, better in toughness, not easy to break, and not easy to fracture when falling down; in addition, the tea set can release negative ions and does not contain hazardous substances such as lead, cadmium, arsenic and mercury; the contents of negative oxygen ions released by the tea set and negative ions of hydroxide radical in tea soup are more, so that a health care effect is achieved on a human body.

Owner:浙江纳巍健康科技有限公司

Nanometer negative ion health bone china production process

The invention relates to a nanometer negative ion health bone china production process, particularly to the technical field of daily life china. The nanometer negative ion health bone china production process comprises: crushing and stirring on 5-15% of quartz, 5-15% of feldspar, 5-15% of Longyan clay, 1-10% of Beihai clay, 35-46% of animal bone char and 19-30% of a ceramic raw material through a ball mill to prepare an embryonic form blank, loading the blank into a special kiln, carrying out primary firing to obtain the bisque, spraying the original lead-free bone china glaze on the bisque, firing the glaze surface for a plurality of hours at a temperature of 1121-1139 DEG C, sticking lead-free pattern paper with the required pattern according to the requirement, placing into the kiln, and firing. According to the present invention, the rare earth raw material is added to the traditional ceramic, such that the domestic bone china can release the trace elements beneficial to humans, and the use value of the bone china can be well improved.

Owner:赵学东

Preparation method of high-color-fixation bone coal powder for preparing bone china

InactiveCN105732039AUniform textureSolve the problem of poor color fixationSaline waterCetylpyridinium chloride

A preparation method of bone charcoal powder with strong color fixation for preparing bone china, which relates to the technical field of bone charcoal powder production. The bone charcoal powder is preliminarily crushed, then degreased and degummed, and then the color is locked by salt water, and the color is fixed by the color fixing solution. It is obtained after washing, drying and grinding. The beneficial effects of the present invention are: the technological process of the present invention is simple, the technical method is reasonable and standardized, not only can normally prepare high-purity bone charcoal powder, but also ensures the blockage of its own chromaticity through immersion in salt water, and through cetyl chloride The mixture of pyridine, cetylpyridinium bromide and water is used to fix the color, which ensures a more balanced texture of the prepared bone charcoal powder, ensures a good raw material for the preparation of bone china, and solves the problem of poor color fixation of the traditionally prepared bone charcoal powder The problem is to ensure the whiteness of bone china, thereby enhancing the fineness and self-value of bone china.

Owner:安徽省淮河制胶有限公司

Mud glaze formula for high-temperature firing of bone daily-use porcelain

PendingCN112552019ALow lead and cadmium dissolutionImprove thermal shock resistanceCeramic materials productionClaywaresPhysical chemistryEngineering

The invention relates to a mud glaze formula for high-temperature firing of bone daily porcelain, and belongs to the technical field of ceramic products. The pug and the glaze are prepared from the following formula components in parts by weight: pug: 70-80 parts of talc, 3-4 parts of bone charcoal powder, 3-6 parts of feldspar, 4-7 parts of bentonite, 91-3 parts of Datong soil and 0.2-0.5 part ofsodium humate; glaze: 55-62 parts of potassium feldspar, 9-12 parts of quartz, 9-11 parts of Longyan clay, 3-4 parts of lepidolite, 3-5 parts of zinc oxide, 9-10 parts of waste porcelain powder and 2-3 parts of bone black powder. With performance of pug and glaze preparation, molding, drying, glazing and high-temperature firing, the product is obtained, the firing time is 8-12 hours, and the highest firing temperature is 1280-1320 DEG C. The novel bone daily-use porcelain fired by the method is good in transparency, strength and whiteness, smooth and clean, and high in ornamental value, so that the novel bone daily-use porcelain has a wide application prospect.

Owner:江西省金海利陶瓷有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com