Preparation method of underglaze color bone ash porcelain

A technology of bone china and underglaze color, which is applied in the field of preparation of underglaze color bone china, which can solve the problems of easy cracking, poor carcass hardness, and low service life, and achieve whiteness and brightness with less energy. Loss, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

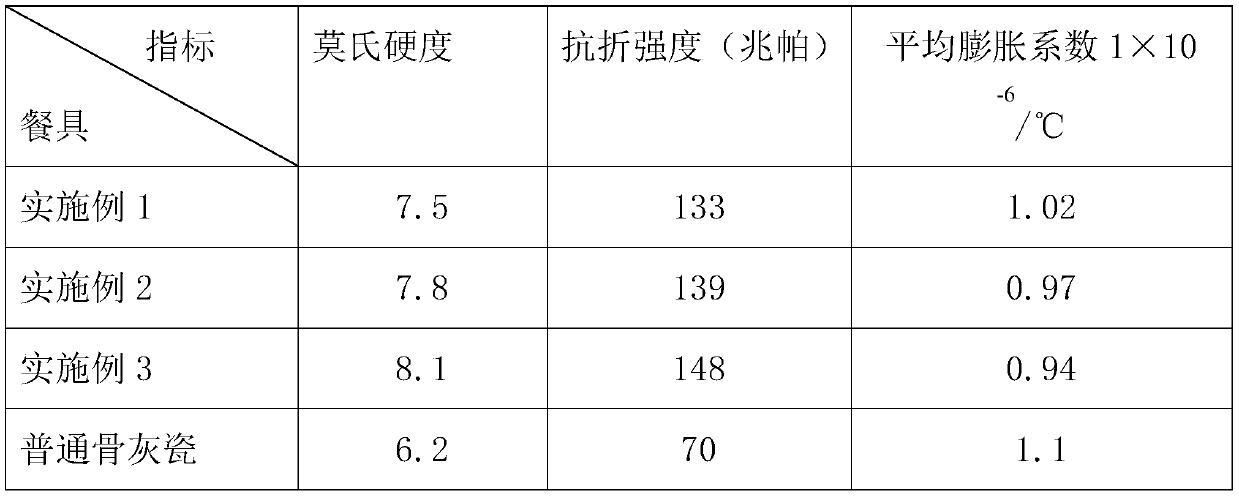

Examples

preparation example Construction

[0022] A preparation method of underglaze color bone china includes the following steps:

[0023] (1) Weigh the ingredients according to the raw material formula of the body and the glaze, and the raw materials are separately mixed, crushed, mixed, and wet-milled to prepare the slurry and the glaze;

[0024] (2) The slurry and glaze prepared in step (1) are subjected to a magnetic separator to remove iron for many times until the iron content in the slurry and glaze is less than 0.05%;

[0025] (3) The green slurry obtained in step (2) is made into a green body, which is put into a kiln and sintered at 1220-1260°C for 4-5 hours to obtain a ceramic green body;

[0026] (4) Apply the glaze produced in step (2) to the surface of the ceramic green body obtained in step (3);

[0027] (5) After the glaze on the surface of the ceramic green body is dried, it is put into the kiln, and it is fired in a reducing atmosphere at 760-800℃ for 3-4h, then it is changed to an oxidizing atmosphere, and t...

Embodiment 1

[0034] An underglaze color bone ash porcelain, comprising a bone ash body and a glaze, the body comprising the following raw materials in parts by weight: 70 parts of bone charcoal, 35 parts of anorthite, 30 parts of quartz, 30 parts of kaolin, 10 parts of sepiolite, 20 parts of evening stone, 5 parts of vermiculite, 3 parts of diatomaceous earth, 8 parts of alumina, and 6 parts of magnesium oxide.

[0035] The glaze includes the following raw materials by weight: 20 parts of dolomite, 30 parts of cooked talc, 15 parts of anorthite, 10 parts of quartz, 12 parts of zirconium silicate, 6 parts of zinc oxide, 5 parts of magnesium silicate, and 1 part of barium oxide , 0.8 part of lanthanum oxide, 1 part of sodium polyacrylate.

[0036] A preparation method of underglaze color bone china includes the following steps:

[0037] (1) Weigh the ingredients according to the raw material formula of the body and the glaze, and the raw materials are separately mixed, crushed, mixed, and wet-mill...

Embodiment 2

[0048] An underglaze color bone ash china, comprising a bone ash body and a glaze. The body comprises the following raw materials in parts by weight: 80 parts of bone charcoal, 30 parts of anorthite, 40 parts of quartz, 20 parts of kaolin, 12 parts of sepiolite, 10 parts of evening stone, 10 parts of vermiculite, 5 parts of diatomaceous earth, 5 parts of alumina, 10 parts of magnesium oxide.

[0049] The glaze includes the following raw materials in parts by weight: 25 parts of dolomite, 20 parts of cooked talc, 18 parts of anorthite, 15 parts of quartz, 10 parts of zirconium silicate, 10 parts of zinc oxide, 3 parts of magnesium silicate, 3 parts of barium oxide , 0.5 parts of lanthanum oxide, 2 parts of sodium polyacrylate.

[0050] A preparation method of underglaze color bone china includes the following steps:

[0051] (1) Weigh the ingredients according to the raw material formula of the body and the glaze, and the raw materials are separately mixed, crushed, mixed, and wet-mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com