Production method of iron and aluminium compound bone char fluorine removal agent and produced fluorine removal agent

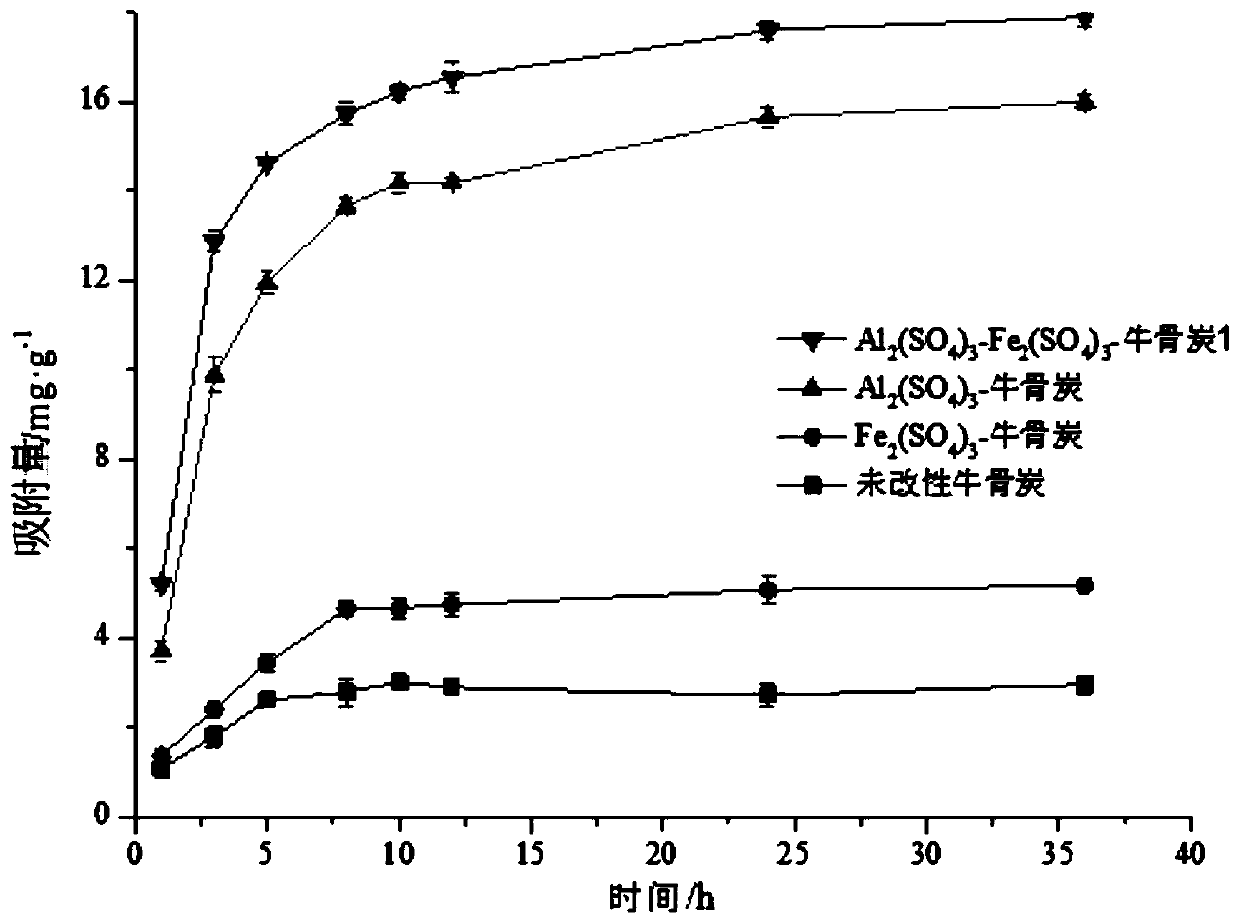

A technology of defluoridation agent and bone charcoal, which is applied in chemical instruments and methods, contaminated groundwater/leachate treatment, special treatment targets, etc., can solve the problem of small adsorption capacity of bone charcoal defluoridation agent, and achieve high recyclability, Effect of enhanced fluoride removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put 900 g of the cleaned bovine bone into a muffle furnace (box-type resistance furnace SX-5-12, Tianjin Test Co., Ltd.), and carbonize at 450 ° C for 2 h to obtain bone char. After cooling the bone charcoal to room temperature, use a grinder (Tianjin Tester, FW100 grinder) to grind it through a sieve with a mesh number of 80 (particle size about 0.2mm), then wash it with deionized water until the water is clear, and then Bone charcoal pellets (unmodified bone charcoal) were obtained by drying in an oven at 100°C (Shanghai Jinghong, DHG-9030A 9070A, electric constant temperature blast drying oven, the same below).

[0020] Add 50g of bone charcoal particles (unmodified bone charcoal) to 250ml of Fe with a concentration of 4% by mass 2 (SO 4 ) 3 Soak in the solution for 0.5h, wash with deionized water until the pH is neutral, and dry in an oven at 100°C to obtain Fe 2 (SO 4 ) 3 Modified beef bone charcoal. Then Fe 2 (SO 4 ) 3 50g of modified bovine charcoal is a...

Embodiment 2

[0022] Put 900g of the cleaned bovine bone into a muffle furnace and carbonize at 450°C for 2h to obtain bone char. After cooling the bone charcoal, use a grinder to grind it through a sieve with a mesh number of 80 mesh (particle size about 0.2mm), then wash it with deionized water until the water is clear, and dry it in an oven at 100°C to obtain bone charcoal particles (unmodified sexual bone char).

[0023] Add 50g of bone charcoal particles (unmodified bone charcoal) to 150ml of Fe with a concentration of 8% by mass 2 (SO 4 ) 3 Soak in the solution for 0.3h, wash with deionized water until the pH is neutral, and dry in an oven at 100°C to obtain Fe 2 (SO 4 ) 3 Modified beef bone charcoal. Then Fe 2 (SO 4 ) 3 50g of modified bovine charcoal is added with 200ml of Al with a mass percentage concentration of 10%. 2 (SO 4 ) 3 Soak in the solution for 0.5h, wash with deionized water until the pH becomes neutral, and dry in an oven at 100°C to obtain Al 2 (SO 4 ) ...

Embodiment 3

[0025] Put 900g of the cleaned bovine bone into a muffle furnace and carbonize at 450°C for 2h to obtain bone char. After cooling the bone charcoal, use a grinder to grind it through a sieve with a mesh number of 10 mesh (particle size about 2mm), then wash it with deionized water until the water is clear, and dry it in an oven at 100°C to obtain bone charcoal particles (unmodified bone char).

[0026] Add 50g of bone charcoal particles (unmodified bone charcoal) to 450ml of Fe with a concentration of 2% by mass 2 (SO 4 ) 3 Soak in the solution for 0.7h, wash with deionized water until the pH is neutral, and dry in an oven at 100°C to obtain Fe 2 (SO 4 ) 3 Modified beef bone charcoal. Then Fe 2 (SO 4 ) 3 50g of modified beef bone charcoal is added with 350ml of Al with a mass percentage concentration of 3%. 2 (SO 4 ) 3 Soak in the solution for 1.5h, wash with deionized water until the pH becomes neutral, and dry in an oven at 100°C to obtain Al 2 (SO 4 ) 3 -Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com