Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Improve anti-corrosion and anti-bacterial ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

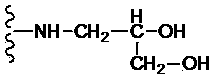

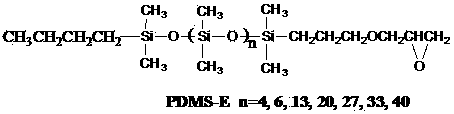

Polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and preparation method

ActiveCN103436167AImprove anti-corrosion and anti-bacterial abilitySpecific performanceAntifouling/underwater paintsFibre treatmentActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding epoxy quaternary ammonium salt into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding glycidol into a second reaction flask to obtain solution 2; adding a surfactant into a third reaction flask, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 3; mixing the solution 1, the solution 2 and the solution 3 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or three or four of ethanol, tetrahydrofuran, acetone and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the multifunctional gelatin leather finishing agent. The finishing agent has the characteristics of strong hydrophobicity, flexible film, antibacterial property, high heat stability, organic solvent resistance, wet scrubbing resistance and the like.

Owner:山东山科美谷科技发展有限公司

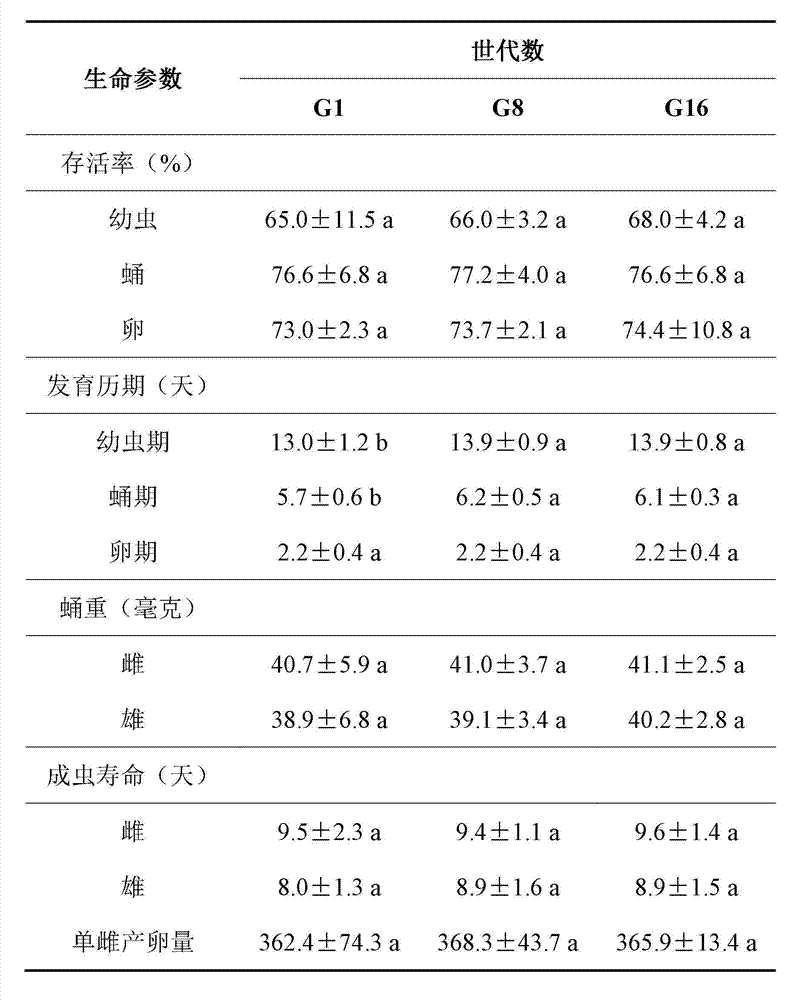

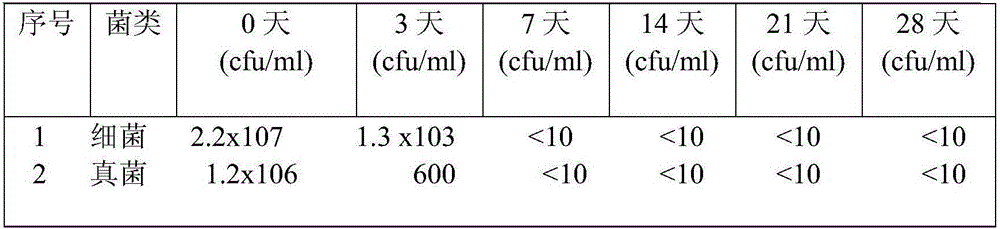

Bean pod borer artificial feed and preparation method thereof

The invention discloses bean pod borer artificial feed and a preparation method thereof. The bean pod borer artificial feed comprises, by weight, 62.5-70% of water, 2.5-3.0% of agar, 15.0-20.0% of cooked soybean meal, 4.0-6.0% of cooked wheat embryo powder, 1.0-2.0% of cane sugar, 1.0-1.5% of yeast powder and 3.0-5.0% of auxiliary materials. The auxiliary materials comprise ascorbic acid, choline chloride, methyl parahydroxybenzoate, potassium sorbate, formaldehyde, salt and vitamin complex. The bean pod borer artificial feed is simple in formula, low in price and affordable, raw materials are all common substances and are easy to obtain, a problem of shortage of natural hosts such as cowpea and hyacinth bean limited by seasons is solved, and massive and subculture feeding of indoor bean pod borer standard worm source is achieved.

Owner:HUAZHONG AGRI UNIV

Method for preparing aqueous ink special for cartons

InactiveCN101585983AImprove anti-corrosion and anti-bacterial abilityQuality improvementInksMethanolChemistry

The invention relates to a method for preparing aqueous ink special for cartons, which comprises the following steps: adding 100 portions by weight of water into a stirring kettle and then heating the water, adding 2 portions by weight of methanol into the water when the temperature of the water rises to 65 DEG C, then slowly adding 50 portions by weight of rosin resin into the mixture under stirring, stirring the mixture again when the temperature of the water rises to 75 to 80 DEG C, adding 6 portions by weight of ethanolamine into the mixture to be stirred, adding a mixture of 1 portion by weight of the methanol and 6 portions by weight of ammonia water into the mixture when the temperature is reduced to be below 70 DEG C, and continuously stirring the mixture to achieve the pH value of 8.5 to 9 and obtain rosin oil; mixing 100 portions of the rosin oil, 35 portions of pigment, 10 to 15 portions of emulsifying oil, 1 portion of antifoaming agent and 100 to 300 portions of water by weight portion, and then grinding the mixture into color paste; and adding 40 to 50 portions of the rosin oil, 3 portions of the emulsifying oil, 0.2 portion of the antifoaming agent, 0.5 portion of the ethanolamine, 3 portions of antimicrobial Nipagin esters and 10 to 100 portions of the water by weight portion into 100 portions by weight of the color paste, and mixing and stirring the mixture at normal temperature to obtain the aqueous ink. The preparation method has simple process; and the prepared aqueous ink has the advantages of bacteria and mildew resistance, good water resisting property, decoloring resistance and low cost, and can be widely applied to external packing cartons of food and the like.

Owner:QINGDAO UNIV

Preparation method of sorbitan octoate

InactiveCN105859661ALight colorImproved antiseptic and antibacterial effectOrganic chemistrySorbitan olivateDistillation

The invention relates to a preparation method of sorbitan octoate. The preparation method includes: adding a dehydration catalyst into sorbitol for dehydration at 150-175 DEG C under nitrogen protection for a certain period of time, adding caprylic acid and an esterification catalyst, rising the temperature to 190-210 DEG C, and continuing the stirring reaction under the pressure of 4000-5000pa until the acid value and the saponification value meet the requirements; performing further molecular distillation to obtain the sorbitan octoate. The obtained sorbitan octoate is high in content and light in color, and tests prove that the sorbitan octoate is suitable for being used as the multifunctional additives of daily chemical products.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Anticorrosive and antibacterial medium-density fiber plate and manufacturing process thereof

InactiveCN108687902ATaking into account anti-corrosion and anti-bacterial propertiesTaking into account the mechanical performance requirementsWood treatment detailsPressure impregnationFiberAdhesive

The invention belongs to the technical field of artificial plates, relates to a medium-density fiber plate, in particular to an anticorrosive and antibacterial medium-density fiber plate. The anticorrosive and antibacterial medium-density fiber plate is composed of 100% of completely-dried wood fibers, 8-12% of an adhesive, 0.25-1% of an antiseptic and antibiotic agent A, 0.25-0.5% of an antiseptic and antibiotic agent B and 1-2% of paraffin. The invention further discloses a process for manufacturing the anticorrosive and antibacterial medium-density fiber plate. The process comprises the steps of preparation of the antiseptic and antibiotic agents, material preparation, antiseptic treatment of poplar wood pieces, hot grinding, gluing, drying, hot pressing and cooling, classification andpackaging. The manufacturing process is simple, gingko wood and poplar wood serve as the wood materials, the gingko wood has a natural antiseptic effect, three substances including a boric acid, copper chelate and didecyl dimethyl ammonium chloride are selected to serve as the antiseptic and antibiotic agents, the application manners are different, the anticorrosive and antibacterial effects of the fiber plate are improved, and influences on the physical and mechanical properties of the plate are quite small.

Owner:DARE WOOD BASED PANEL GRP

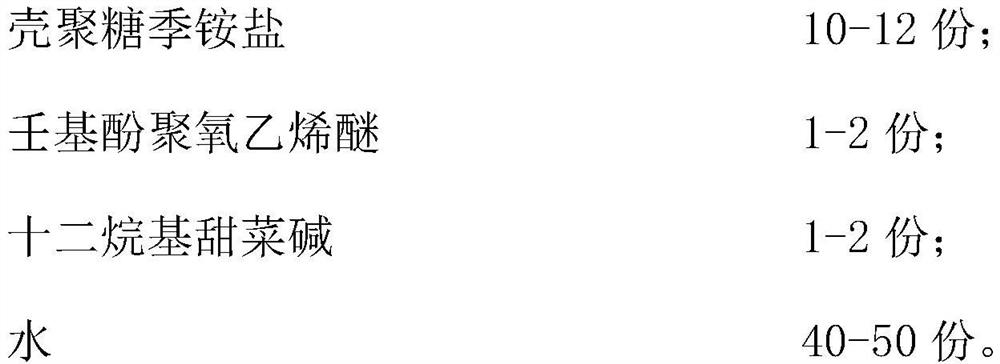

Passion fruit fresh-keeping agent and preparation method thereof

InactiveCN107361133AImprove anti-corrosion and anti-bacterial abilityStrong slow release functionFruits/vegetable preservation by coatingFood ingredient for microbe protectionSucroseAdditive ingredient

The invention discloses a passion fruit fresh-keeping agent and a preparation method thereof, and relates to the technical field of fresh keeping of passion fruits. The fresh-keeping agent comprises the following raw materials in parts by weight: 40-50 parts of modified sodium alginate, 9-15 parts of calcium chloride, 3-7 parts of sodium dehydroacetate, 6-9 parts of plant essential oil, 0.9-1.5 parts of sucrose fatty acid ester, and 100-150 parts of water. The fresh-keeping agent disclosed by the invention has high slow-release regulating and controlling capacity after film forming, and can reduce the release speed of antibacterial components in the fresh-keeping agent, so that the antibacterial capacity is durable, and the fresh-keeping time is prolonged.

Owner:平南县正达农业发展有限公司

Antibacterial anticorrosive coating for building exterior wall and preparation method thereof

InactiveCN111944369AImprove compactnessImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesCelluloseChlorinated paraffins

The invention discloses antibacterial anticorrosive coating for a building external wall. The coating is prepared from the following raw materials in parts by weight: 55-65 parts of silicone acrylic emulsion, 9-12 parts of perfluorosiloxane resin, 3-4 parts of an antibacterial agent, 2-3 parts of hydroxyethyl cellulose, 0.5-0.7 part of chlorinated paraffin, 0.3-0.4 part of ammonium trimolybdate and 0.8-1 part of an auxiliary agent. The invention also discloses a preparation method of the antibacterial anticorrosive coating. According to the invention, the silicone acrylic emulsion and the perfluorosiloxane resin are used as film-forming substances of the coating, so that the coating has good waterproof performance; the self-made antibacterial agent is added into the coating, has multiple and efficient antibacterial properties, has good compatibility with a coating matrix and can be uniformly dispersed in the coating; nano particles can block pores of a coating to a certain extent, thecompactness and hydrophobicity of the coating layer are improved, and the corrosion resistance and antibacterial property of the coating are improved. The waterproof coating with antibacterial and anticorrosive properties is prepared and is suitable for coating of building exterior walls.

Owner:马鞍山市金韩防水保温工程股份有限公司

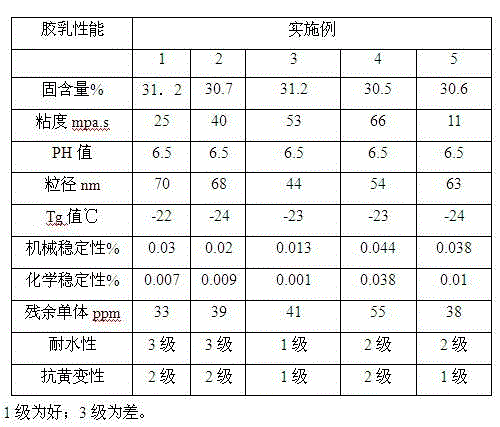

Special waterborne acrylic resin for wallpaper as well as preparation method of special waterborne acrylic resin

InactiveCN104558384AHigh molecular weightImprove heat resistancePaper coatingCoatingsSoftened waterPhosphate

The invention belongs to the technical field of chemical engineering and particularly relates to special waterborne acrylic resin for wallpaper as well as a preparation method of the special waterborne acrylic resin. The special waterborne acrylic resin for wallpaper is prepared from the following raw materials in parts by weight: 100 parts of a monomer, 0.3-3 parts of an anionic emulsifier, 0.1-1.5 parts of a nonionic emulsifier, 0.1-5 parts of an initiator, 0.1-5 parts of a pH value adjustor, 150-300 parts of softened water and 0.1-0.2 part of aluminum dihydrogen phosphate. The waterborne acrylic resin produced by a low-temperature polymerization method thoroughly solves the problem that the existing acrylic emulsion for wallpaper is sticky when the TG value is -20 DEG C and the roller is sticky in the coating process of the wallpaper, so that latex is not sticky to the roller in the production application process. Wallpaper is mostly used for home decoration with considerably important environmental requirements. The wallpaper latex prepared is free of VOC and is environmental-friendly as compared with currently used formaldehyde-phenolic resin, urea resin, modified starch glue and styrene-butadiene latex.

Owner:RIZHAO GUANGDA BUILDING MATERIALS

Fresh keeping method for longan

InactiveCN107494717ABacteriostaticHas inhibitory effectFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingFilm-coated tabletFilm coating

The invention discloses a fresh keeping method for longan and relates to the technical field of fresh keeping of agricultural products. The method includes the steps of screening, disinfection, film coating, packaging and storage. In the method, sodium alginate is modified to improve antibacterial capability and sustained release performance thereof; after the longan is picked, the surface of the fruit is sterilized and then is coated with a film by means of the modified sodium alginate; finally the longan is stored under low-temperature regulation and control. By combination of the mentioned methods, fresh keeping time of longan is prolonged and quality of the longan is maintained.

Owner:平南县正达农业发展有限公司

Environment-friendly water-based ink, and environment-friendly high-strength compression-resistant color box and manufacturing method thereof

The invention discloses environment-friendly water-based ink, and an an environment-friendly high-strength compression-resistant color box and a manufacturing method thereof. The environment-friendlywater-based ink is prepared from the following raw materials in parts by weight: 25-35 parts of epoxy acrylic resin, 10-15 parts of fluorosilicone modified acrylate emulsion, 5-8 parts of hydroxy cellulose, 10-30 parts of colorant, 5-20 parts of nano calcium carbonate, 1-3 parts of cerium dioxide, 0-11 parts of butyl cellosolve, 5-10 parts of triethanolamine, 0.5-0.8 part of defoamer, 0.5-1.0 partof sodium hexametaphosphate, 0.5-1.1 parts of trimethoprim, 0.5-1.5 parts of an auxiliary agent, 15-25 parts of deionized water and 3-5 parts of isopropanol. According to the invention, the corrugated paper of the middle layer of the color box is folded into a corrugated structure, so that the stability of the structure of the middle layer is improved, and the situation that the corrugated paperis impacted and deformed, and consequently the corrugated structure in the corrugated paper is damaged is reduced.

Owner:晋江市顺力纸箱有限公司

Anticorrosive and antibacterial fishing net

InactiveCN105504438ASimple processing technologyLow priceFishing netsConjugated synthetic polymer artificial filamentsEpoxyFiber

The invention discloses an anticorrosive and antibacterial fishing net. The anticorrosive and antibacterial fishing net is prepared from following components: polyethylene fibers, bamboo powder, waste PCB powder, an epoxy resin adhesive film, calcium carbonate powder, dibutyl phthalate and calcium stearate. According to the prepared fishing net, a processing technology is simple, the polyethylene fibers are taken as the raw material for processing, the cost of the fishing net is reduced greatly, the performance of the prepared fishing net is improved greatly through modification processing performed on the polyethylene fibers in advance, the anticorrosive and antibacterial capacity of the fishing net can be improved greatly through adoption of the waste PCB powder and the bamboo powder, and the service life of the fishing net is prolonged accordingly; with addition of the processed epoxy resin adhesive film, the compatibility of the components can be improved, and the combination property of the fishing net can be enhanced; the fishing net has excellent tensile strength and wear resistance.

Owner:巢湖市瑞强渔具有限责任公司

Surface treating agent for smooth foamless aluminum alloy

InactiveCN104099592ACoating film is smooth without bubblesStrong compactnessMetallic material coating processesEthylic acidDioctyl sebacate

The invention discloses a surface treating agent for smooth foamless aluminum alloy. The surface treating agent comprises the following raw materials in parts by weight: 0.8-2 parts of hydroxyethyl oleic imidazoline betaine, 1-2 parts of locust bean gum, 0.1-0.2 part of neodymium acetate, 1-2 parts of ethylene diamine tetraacetic acid, 0.3-1 part of antimony oxide, 1-2 parts of sodium tungstate, 2-3 parts of magnesium nitrate, 0.3-1 part of graphite powder, 0.1-0.2 part of dioctyl sebacate, 2-3 parts of 1, 4-cyclohexanedimethanol, 2-3 parts of a coalescing agent, 8-12 parts of 3-amino propyl trimethoxy silane, 6-10 parts of silane coupling agent KH570, and 110-140 parts of de-ionized water. The surface treating agent can form a stable and even coating film on the surface of the aluminum alloy; and the coating film is foamless and smooth, and has the advantages of strong compactness, good leakage resistance, strong corrosion and bacterial resistance and good easy cleanness.

Owner:RUIZHAN TONGLING TECH

MXene/polyaniline nano-composite anticorrosive and antibacterial coating and preparation method thereof

PendingCN113122106AGood electrical conductivity and antibacterial propertiesExcellent anti-corrosion and anti-bacterial propertiesAntifouling/underwater paintsPaints with biocidesPolyaniline compositeNanocomposite coating

The invention provides an MXene / polyaniline nano-composite anticorrosive and antibacterial coating and a preparation method thereof, and the MXene / polyaniline nano-composite anticorrosive and antibacterial coating comprises the following components in parts by weight: 40-70 parts of epoxy resin, 1-5 parts of an MXene / polyaniline composite material, 1-2 parts of a defoaming agent, 1-2 parts of a leveling agent and 10-30 parts of a curing agent. The MXene and polyaniline in the prepared coating have a synergistic effect, so that the nano composite coating not only has conductivity, but also has antibacterial property, and also provides chemical corrosion prevention and physical barrier effects. The preparation method of the nano-composite coating is simple, the anti-corrosion and antibacterial properties are good, and large-scale industrial production is easy.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Nylon antiseptic antibacterial type cooling coating

InactiveCN103756554AHigh surface hardnessNo shrinkage cavityPolyamide coatingsMethyl carbonatePhthalate

The invention discloses a nylon antiseptic antibacterial type cooling coating which is composed of the following raw materials in parts by weight: 84-90 parts of nylonTR90, 1-2 parts of vinyl acetate, 3-4 parts of dicapryl phthalate, 1-2 parts of lithium silicate, 1-2 parts of disodium octaborate tetrahydrate, 1-2 parts of 2,2-dibromo-3-cyanoacetamide, 2-3 parts of dimethyl carbonate, 1-2 parts of pine tar, 0.2-0.4 part of fenbendazole, 0.1-0.2 part of dimethyl isooctyl thioglycolate tin, 2-3 parts of medical stone powder, 4-6 parts of gibbsite and 6-10 parts of modified filler. The powder coating is high in surface hardness, good in levelling property, strong in coating stability, good in weather resistance, good in antiseptic antibacterial property and long in service life and does not have contraction cavity.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Coffee beans automatic drying and screening device

InactiveCN107495429ADry fastPrevent leakageSievingGas current separationPulp and paper industryHot blast

The present invention provides a coffee bean automatic drying and screening device. The coffee bean automatic drying and screening device comprises a roller, and a transmission mechanism and a bracket part connected with an outer surface of the roller. A material inlet is connected with a left side of the roller, a material outlet is connected with a right side of the roller, a hot blast stove is connected with the right side of the roller via an air guide pipe, two dust removers are connected with two sides of the roller and both connected with a variable frequency fan, a screening box is arranged right below the material outlet, a dust collection box is arranged at a left side of the screening box, and a material loading box is arranged at a right side of the screening box. By using the hot blast stove to blow air into the roller, a purpose of drying coffee beans is achieved and the hot air can also carry away dust, so that air in the roller circulates, the drying of the coffee beans is accelerated and a dust concentration within the roller is also reduced. The coffee bean automatic drying and screening device ensures a smooth operation of the roller, can also conduct the automatic screening after the drying is completed, reduces labor costs and improves a use value.

Owner:兰溪市奥而特农业科技有限公司

Efficient dryer facilitating fertilizer forming

InactiveCN107677070ADry fastAvoid cloggingSievingManure dryingFrequency conversionAgricultural engineering

The invention provides an efficient dryer facilitating fertilizer forming. The efficient dryer facilitating fertilizer forming comprises an obliquely arranged roller, a transmission mechanism connected with the outer surface of the roller and a bracket part. A feeding port is connected with the left side of the roller, a discharging port is connected with the right side of the roller, a hot blastheater is connected with the right side of the roller through a wind guide pipe, and dust removers are connected with the two sides of the roller; and the dust removers are both connected with a frequency conversion fan, a screening box is arranged over the discharging port, a dust collecting box is arranged on the left side of the screening box, and a charging box is arranged on the right side ofthe screening box. According to the efficient dryer facilitating fertilizer forming, the drying effect is good, fertilizer drying is even, dust removing can be conducted in the drying process and after drying is conducted, the fertilizer quality is obviously improved, cooling screening can be integrally achieved after drying is completed, the labor cost is reduced, and the market prospect of thedryer is promoted.

Owner:浦江县元寿农业科技有限公司

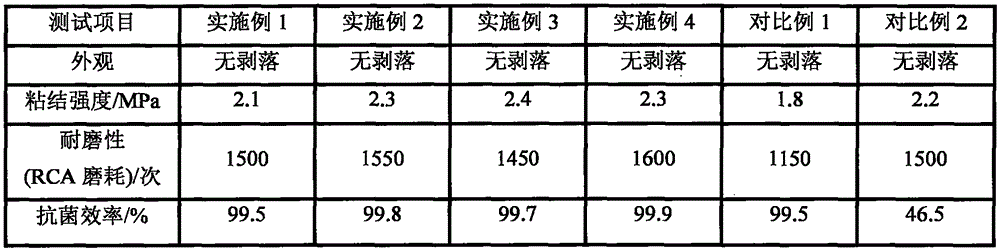

Photocuring abrasion-resistant coating having antibacterial performance and preparation method thereof

ActiveCN105400385AHas antibacterial propertiesImprove surface abrasionAntifouling/underwater paintsPaints with biocidesCelluloseOligomer

The invention provides a photocuring abrasion-resistant coating having an antibacterial performance. The photocuring abrasion-resistant coating comprises, by mass parts, 50-60 parts of oligomer, 5-6 parts of crosslinking agent, 10-15 parts of reactive diluent, 6-8 parts of photoinitiator, 0.8-1.5 parts of antifoaming agent, 1-1.5 parts of flatting agent, 1-1.2 parts of matting agent, 0.5-1 part of slip agent, 0.8-1.2 parts of wetting agent, 10-15 parts of solvent, 0.5-1 part of cellulose, 3-5 parts of abrasion-resistant additive, 3-5 parts of antibacterial agent and 0.8-1 part of preservative, wherein the oligomer is mixed solution of polysilicone emulsion and epoxy acrylate.

Owner:JIANGSU HIMONIA TECH

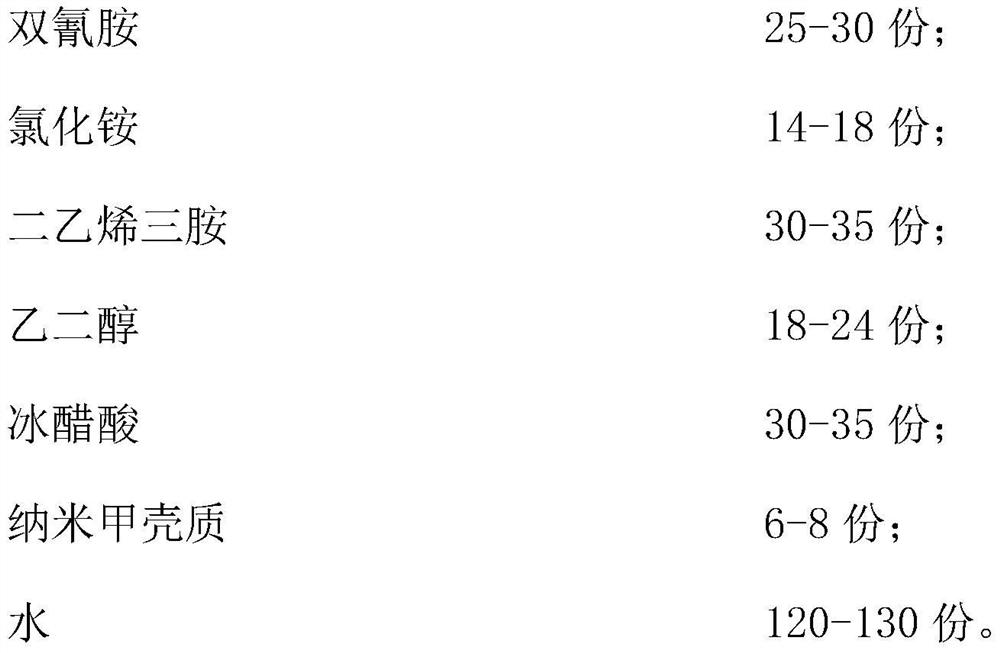

Color fixing agent and cotton cloth pad dyeing process using color fixing agent

ActiveCN113026396ADelay fadingImprove washabilityGrip property fibresDyeing processChitinCotton cloth

The invention relates to the field of cloth dyeing, in particular to a color fixing agent and a cotton cloth pad dyeing process using the color fixing agent. The color fixing agent is prepared from the following raw materials in parts by weight: 25-30 parts of dicyandiamide; 14-18 parts of ammonium chloride; 30-35 parts of diethylenetriamine; 18-24 parts of ethylene glycol; 30-35 parts of glacial acetic acid; 6-8 parts of nano chitin; and 120-130 parts of water. The cotton cloth pad dyeing process using the color fixing agent specifically includes the following process steps: S1, pretreatment; S2, dyeing; S3, washing with water; S4, finishing; and S5, shaping. The color fixing agent has the advantage of enhancing the color fixing effect.

Owner:绍兴盛鑫印染有限公司

Natural plant extract composition and application in cosmetic

InactiveCN107823023AReduce the rate of allergiesImprove anti-corrosion and anti-bacterial abilityCosmetic preparationsToilet preparationsHelichrysum italicum flowerMass ratio

The invention discloses a natural plant extract composition preservative, which is formed by mixing the following raw materials: Anacardium occidentale extract, glycine soja sprout extract and Helichrysum Italicum flower oil. The mass ratio of Anacardium occidentale extract to glycine soja sprout extract to Helichrysum Italicum flower oil is 1-3: 1-3: 1-3. In comparison with the prior art, the invention has the following beneficial effects: the natural plant extract composition preservative adopts natural plant raw materials, replaces a traditional preservative, provides excellent anticorrosive and antibacterial properties for a cosmetic product, and avoids the skin irritation possibility of a traditional preservative so as to greatly reduce use irritability of cosmetics.

Owner:李冬梅

Environment-friendly non-toxic metal surface treatment agent

InactiveCN104928662APrevent metal corrosionSlow down the electrode reactionMetallic material coating processesYttriumChemistry

The invention discloses an environment-friendly non-toxic metal surface treatment agent which is prepared from the following raw materials in parts by weight: 4-6 parts of alkenyl succinate, 0.1-0.2 part of tetramethyl glutaric acid, 0.8-2 parts of alpha-olefin sulfonate, 1-2 parts of sodium polycarboxylic acid, 0.6-1 part of N,N-diethylaniline, 0.2-0.3 part of tetraethylammonium tetrafluoroborate, 0.1-0.2 part of sodium diacetate, 0.7-1 part of pyrrolidone hydroxy acid sodium, 2-3 parts of diethanol amine, 4-5 parts of triethanolamine borate, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550 and 150-200 parts of water. The metal surface treatment agent has the advantages of being non-toxic and pollution-free, good in environment-friendly property, good in anticorrosive and antibacterial properties, good in storage stability and long in service life.

Owner:BENGBU TIMES ELECTRONICS

Sucrose-free bread with long shelf life and preparation method thereof

PendingCN114391564AImprove antiseptic and antibacterial effectReduce inhibitionDough treatmentClimate change adaptationSodium dehydroacetateChemical preservatives

The invention relates to the field of sucrose-free bread, in particular to sucrose-free bread with a long shelf life and a preparation method of the sucrose-free bread, and the sucrose-free bread is prepared from the following raw materials in parts by weight: 40-60 parts of flour, 8-15 parts of a sucrose-free sweetening agent, 10-13 parts of egg liquid, 15-18 parts of water, 0.4-0.6 part of a humectant, 0.012-0.016 part of a bread improver, 0.4-0.6 part of emulsifying paste, 0.9-1 part of yeast, 0.4-0.6 part of salt and 0.07-0.11 part of a preservative. The preservative comprises a chemical preservative, and the chemical preservative is composed of sodium dehydroacetate and calcium propionate according to the mass ratio of (0.02-0.04): (0.05-0.07). The method has the advantage of prolonging the shelf life of the 0-sucrose bread.

Owner:多麦(福建)食品有限公司

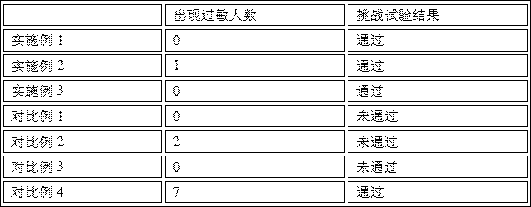

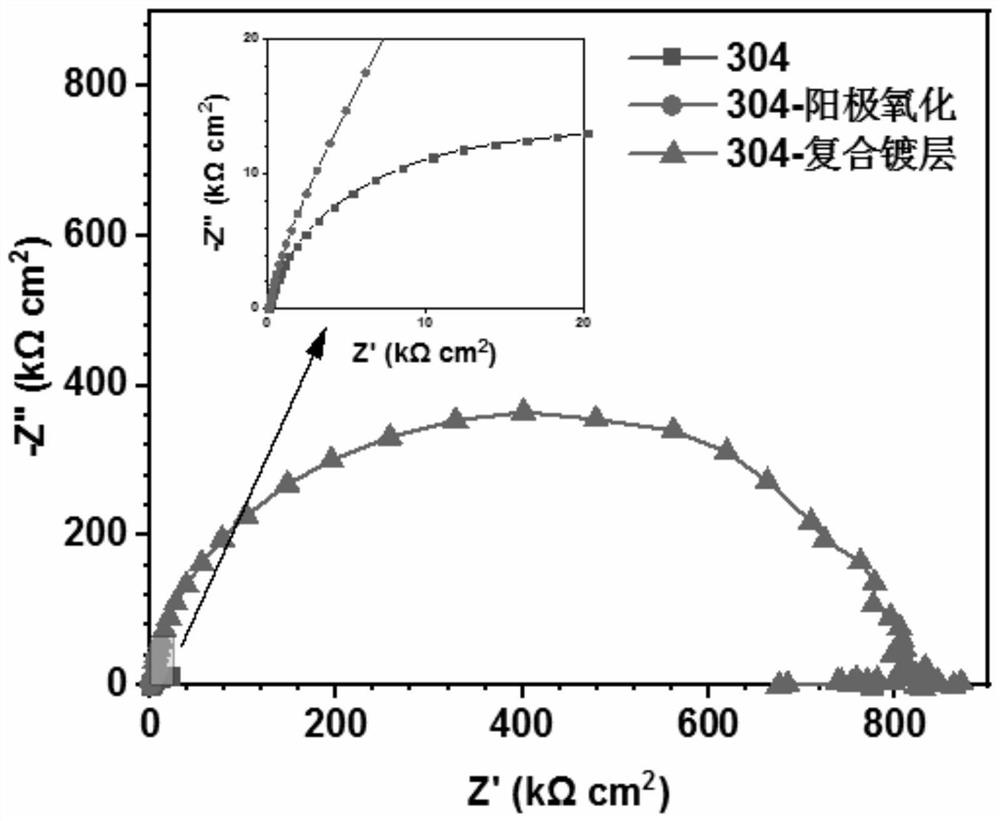

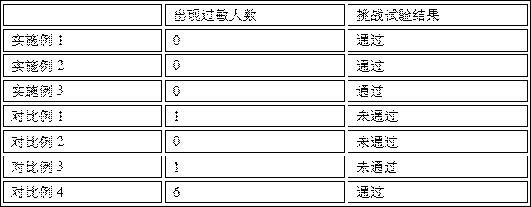

Anticorrosion and antibacterial surface treatment method for stainless steel

PendingCN114232053AAnti-corrosion functionWith bactericidal functionAnodisationElectrolytic organic material coatingMicrobial corrosionAntimicrobial surface

The invention belongs to the field of metal corrosion prevention, and particularly relates to a stainless steel anti-corrosion and antibacterial surface treatment method. According to the method, firstly, a nanopore array is prepared on the surface of stainless steel through an anodic oxidation method, and then a composite zinc coating loaded with an organic antifouling agent is prepared on the surface of the nanopore array through a constant-current polarization method. According to the invention, the binding force between the composite zinc coating and the matrix can be improved, the load capacity of the antifouling agent is increased, the microbial corrosion protection capability of the composite zinc coating is improved, and the composite zinc coating can be applied to the stainless steel surface, so that the stainless steel surface has anticorrosive and antibacterial properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite plant extract and application thereof to cosmetic preservative

InactiveCN107802565AReduce the rate of allergiesImprove anti-corrosion and anti-bacterial abilityCosmetic preparationsToilet preparationsMass ratioPreservative

The invention discloses a composite plant extract cosmetic preservative. The composite plant extract cosmetic preservative is prepared by mixing the following raw materials: rosa centifolia flower extract, fragaria vesca leaf extract and prunus pseudocerasus leaf extract, wherein the mass ratio of the rosa centifolia flower extract to the fragaria vesca leaf extract to the prunus pseudocerasus leaf extract is (1 to 3) to (1 to 5) to (1 to 10). Compared with the prior art, the composite plant extract cosmetic preservative disclosed by the invention has the beneficial effects that natural plantsourced raw material components are used for replacing a traditional preservative; excellent anti-corrosion and antibacterial performance is provided for a cosmetic product; meanwhile, the possibilityof stimulating skin by the traditional preservative is avoided, so that the rate of allergy of using cosmetics is greatly reduced.

Owner:李冬梅

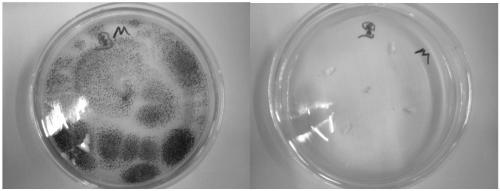

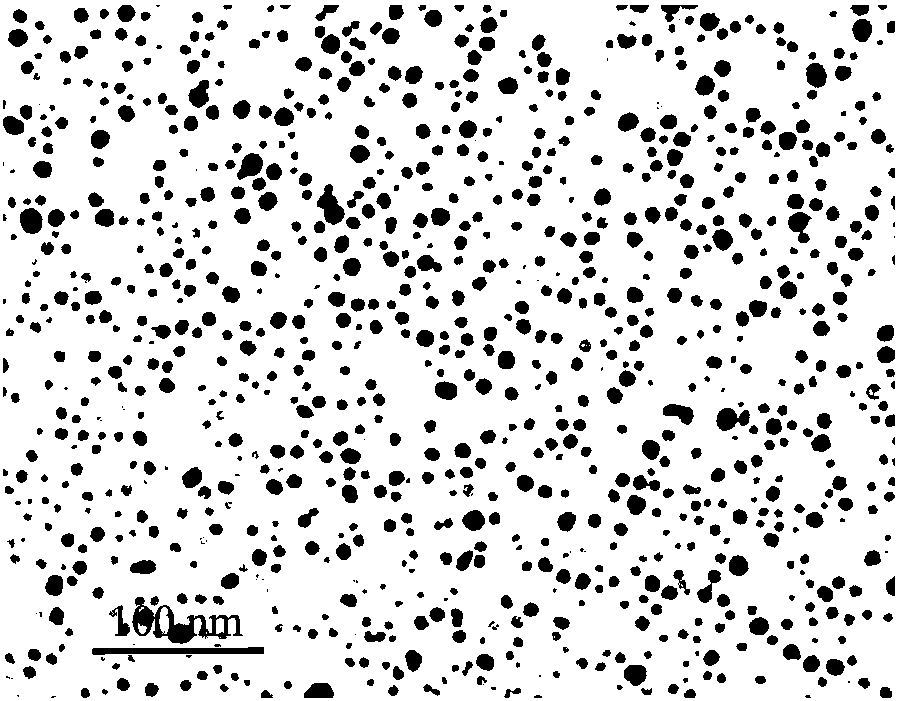

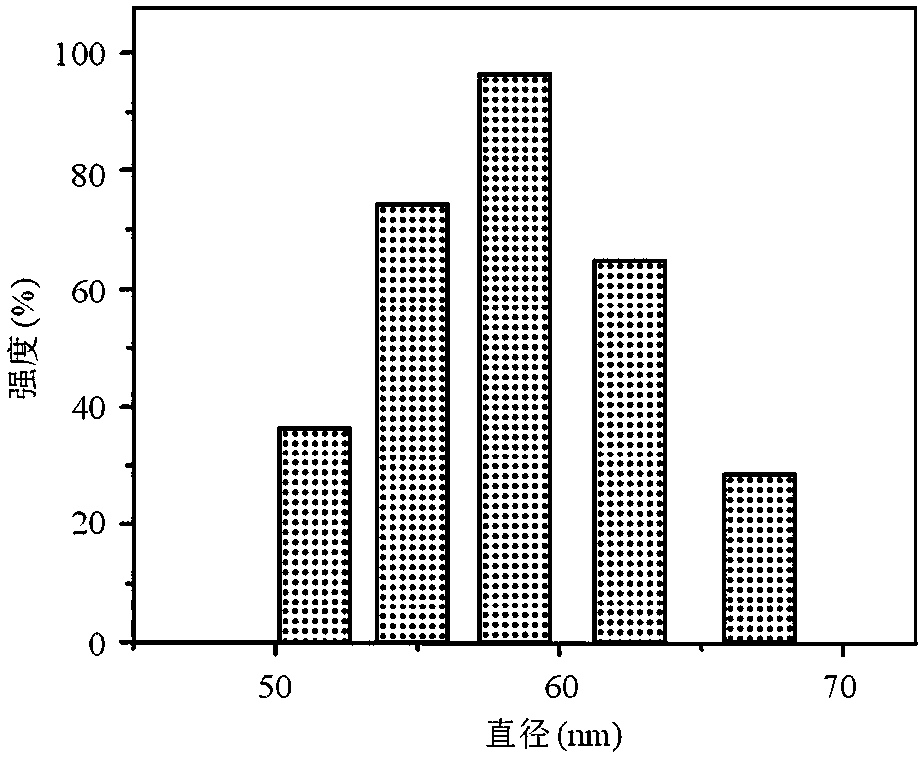

Composite anticorrosive and antibacterial sustained-release thin film and preparation method thereof

InactiveCN109021517AEffectively control the release rateControlled release rateEnvironmental resistanceGallic acid ester

The invention discloses a composite anticorrosive and antibacterial sustained-release thin film comprising the following raw material ingredients in parts by weight: 2-20 parts of gallic acid, 5-40 parts of an argy wormwood extract, 5-40 parts of a calamus extract and 20-88 parts of polycaprolactone. The three selected anticorrosive and antibacterial active components of gallic acid, the argy wormwood extract and the calamus extract are all natural plant extracts, and polycaprolactone has biodegradable properties. Therefore, the composite anticorrosive and antibacterial sustained-release thinfilm can be gradually degraded in the environment after use, can be absorbed or decomposed by the environment, has no material residue, has no post-treatment problem, and cannot pollute the surrounding environment. The method of hot pressing, 3D printing or melting blow moulding is green and environmentally friendly. The process is simple and reliable, no organic solvents or other additives are added in use, and no environmental pollution or other problems exist.

Owner:车宏伟 +1

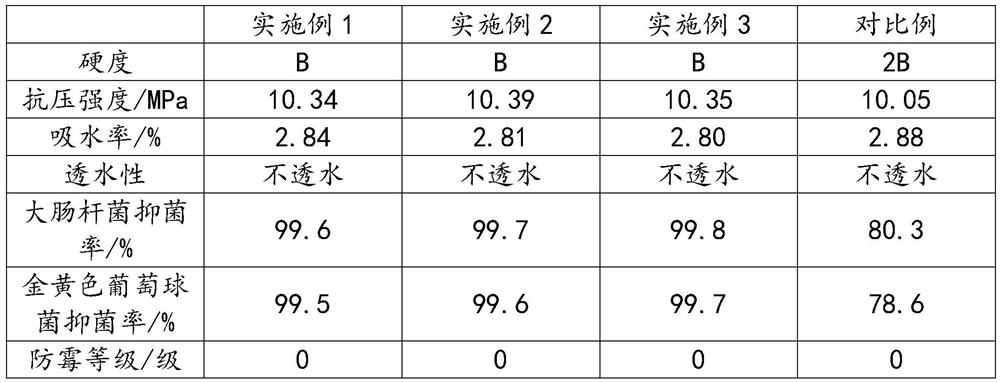

Anticorrosion and antibacterial tile seam filling and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to an anticorrosion and antibacterial tile seam filling and a preparation method thereof. The tile seam filling comprises, by weight, 42-67 parts of coal gangue, 32-40 parts of limestone, 15-28 parts of low-melting-point glass powder, 6-15 parts of nano-titanium dioxide, 5-15 parts of inorganic fillers, 2-7 parts of mildew-proof agents, 22-25 parts of composite adhesives and 80-110 parts of water. According to the tile seam filling, the coal gangue is modified through the low-melting-point glass powder, compactness of the coal gangue is improved when the coal gangue serves as a component of the tile seam filling, surface roughness of the coal gangue is reduced, tile seams filled with the filling are easily cleaned, smudginess is not easily concentrated, water absorption of the tile seam filling and nutrient enrichment are prevented, breeding places of bacterial microorganisms are avoided, and good anticorrosion and antibacterial capability of the tile seam filling is ensured.

Owner:佛山市卡茵建材有限公司

Preparation method of disposable antibacterial paper bowl

InactiveCN109354894AImprove wettabilityLower contact angleAntifouling/underwater paintsPaints with biocidesFiberAdhesive

The invention relates to a preparation method of a disposable antibacterial paper bowl. The preparation method of the disposable antibacterial paper bowl comprises the following steps of soaking raw fiber in sodium hydroxide solution into mixed fiber powder; mixing and pounding Chinese herb residues, and then boiling the pounded residues in ethanol solution into paste obtain a herb residue paste;uniformly mixing coagulated polysaccharides, sodium alginate and methylcellulose with water, keeping temperature in water bath to obtain a mixed adhesive; preparing and mixing chitosan solution and polyvinyl alcohol solution of a certain concentration, then adding in lactic streptococci nicin to obtain an antibacterial oil-proofing agent; uniformly mixing the mixed fiber powder, the herb residue paste and the mixed adhesive, and then hot-pressing the mixture into a bowl body; uniformly applying the antibacterial oil-proofing agent onto the inner surface of the bowl body, and performing dryingand cooling treatment to obtain the disposable antibacterial paper bowl. According to the preparation method of the disposable antibacterial paper bowl, the waste Chinese herb residues serve as the raw materials to produce the disposable antibacterial paper bowl to achieve high economic and ecological benefits; the prepared disposable antibacterial paper bowl is environmentally friendly and degradable and achieves excellent anti-oil and antibacterial performance.

Owner:安庆市恒原纸塑有限公司

Natural biological fresh-keeping agent and preparation method thereof

InactiveCN107853388AIncrease the range of antibacterial and bactericidal effectsImprove anti-corrosion and anti-bacterial abilityFruit and vegetables preservationAntioxidantCoconut oil

The invention discloses a natural biological fresh-keeping agent and a preparation method thereof, and relates to the technical field of fresh-keeping agents. The biological fresh-keeping agent is prepared from, by weight, 2-8 parts of Chinese bulbous onion, 4-10 parts of tea leaves, 5-9 parts of eutrema yunnanense, 3-7 parts of trichosanthes kirilowii maxim, 2-8 parts of rhizoma atractylodis macrocephalae, 4-10 parts of radix angelicae, 2-8 parts of gallnut, 0.5-3.5 parts of rosemary essential oil, 6-12 parts of wheat bran, 1-4 parts of glycerinum, 0.5-2.5 parts of tartaric acid, 10-20 partsof pullulan polysaccharide, 0.5-2.5 parts of Arabic gum, 0.2-2 parts of edible salt, 0.5-2.5 parts of calcium chloride, 0.5-3 parts of coconut oil glyceride and 60-100 parts of distilled water. Various components excellent in bacterium restraining and sterilizing effect are combined, antioxidants, film forming agents and the like are added for achieving a mutual synergistic effect, the effect of the fresh-keeping agent is improved, and the fresh-keeping time of the fresh-keeping agent for fruits and vegetables is prolonged. The fresh-keeping agent is prepared by adopting natural plant components according to a proportion and is free of toxicity and harm.

Owner:杨坚

Wood preservative preparing method

InactiveCN108189181AGood dispersionImprove stabilityWood treatment detailsWood impregnation detailsPreservativeHigh pressure

The invention discloses a wood preservative preparing method. The wood preservative preparing method comprises the following steps that firstly, TiO2 suspension liquid is subjected to high-pressure sterilization treatment, and TiO2 with photocatalytic activity is obtained; secondly, propylene glycol serves as a solvent, and TiO2 obtained in the first step is prepared into TiO2 dispersed suspensionliquid with the TiO2 mass percent content being 0.5%-2%; thirdly, nano particles are added in the TiO2 dispersed suspension liquid obtained in the second step, homogenizing is conducted, and a uniform nano particle / TiO2 / propylene glycol mixed solution is obtained; and fourthly, the nano particle / TiO2 / propylene glycol mixed solution is subjected to ultrasonic treatment, and the uniform and stablewood preservative is obtained. The wood preservative obtained through the preparing method is very good in dispersibility, very high in stability and long in storage period and has wide popularizationand application value.

Owner:贵州省林业科学研究院 +1

Method for preparing aqueous ink special for cartons

InactiveCN101585983BImprove anti-corrosion and anti-bacterial abilityQuality improvementInksMethanolDefoamer

The invention relates to a method for preparing aqueous ink special for cartons, which comprises the following steps: adding 100 portions by weight of water into a stirring kettle and then heating thewater, adding 2 portions by weight of methanol into the water when the temperature of the water rises to 65 DEG C, then slowly adding 50 portions by weight of rosin resin into the mixture under stirring, stirring the mixture again when the temperature of the water rises to 75 to 80 DEG C, adding 6 portions by weight of ethanolamine into the mixture to be stirred, adding a mixture of 1 portion byweight of the methanol and 6 portions by weight of ammonia water into the mixture when the temperature is reduced to be below 70 DEG C, and continuously stirring the mixture to achieve the pH value of8.5 to 9 and obtain rosin oil; mixing 100 portions of the rosin oil, 35 portions of pigment, 10 to 15 portions of emulsifying oil, 1 portion of antifoaming agent and 100 to 300 portions of water by weight portion, and then grinding the mixture into color paste; and adding 40 to 50 portions of the rosin oil, 3 portions of the emulsifying oil, 0.2 portion of the antifoaming agent, 0.5 portion of the ethanolamine, 3 portions of antimicrobial Nipagin esters and 10 to 100 portions of the water by weight portion into 100 portions by weight of the color paste, and mixing and stirring the mixture atnormal temperature to obtain the aqueous ink. The preparation method has simple process; and the prepared aqueous ink has the advantages of bacteria and mildew resistance, good water resisting property, decoloring resistance and low cost, and can be widely applied to external packing cartons of food and the like.

Owner:QINGDAO UNIV

A kind of preparation method of sorbitan monocaprylate

The invention relates to a preparation method of sorbitan octoate. The preparation method includes: adding a dehydration catalyst into sorbitol for dehydration at 150-175 DEG C under nitrogen protection for a certain period of time, adding caprylic acid and an esterification catalyst, rising the temperature to 190-210 DEG C, and continuing the stirring reaction under the pressure of 4000-5000pa until the acid value and the saponification value meet the requirements; performing further molecular distillation to obtain the sorbitan octoate. The obtained sorbitan octoate is high in content and light in color, and tests prove that the sorbitan octoate is suitable for being used as the multifunctional additives of daily chemical products.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com