Anticorrosion and antibacterial surface treatment method for stainless steel

An anti-corrosion, anti-bacterial and surface treatment technology, applied in anodizing, electrolytic organic material coating, etc., can solve problems such as environmental pollution, poor long-term protection performance of nano-anti-fouling coating on micro-arc oxidation surface, and weak matrix adhesion. , to ensure the service life, excellent anti-corrosion and antibacterial properties, and prolong the protection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, the preparation process of the surface nanohole array is as follows:

[0033] (1) Use a measuring cylinder to measure 50ml of perchloric acid with a mass concentration of 71-73% and dissolve it in 960ml of ethylene glycol solution. After it is completely dissolved, oscillate ultrasonically for 5 minutes to ensure uniform dissolution.

[0034] (2) Use SiC sandpaper to grind the 304 stainless steel sheet step by step to 2000# for later use. Before use, ultrasonically clean it in anhydrous ethanol for 5 minutes to completely wash off the surface oil and impurities. Take it out and dry it. Solder the wire on one side and seal it with epoxy resin , only keep the work surface to be processed.

[0035] (3) The temperature of the solution is set to 5°C, and the rotor speed is set to gear 1 (DF1 collector heating stirrer). After the temperature in the beaker is constant, use the TPN-F2011D regulated power supply to adjust to the constant voltage mode, and adjust...

Embodiment 2

[0038] In this embodiment, the preparation process of the composite galvanized layer on the surface of the nanohole array is as follows:

[0039] (1) Weigh 250g ZnSO with a balance with an accuracy of 0.0001g 4 7H 2 O, 80g Na 2 SO 4 , 26g H 3 BO 3 and 40g Al 2 (SO 4 ) 3 18H 2 O, completely dissolved in pure water to make 1L of galvanizing solution.

[0040] (2) Weigh 0.29g of 4,5-dichloro-N-octyl-4-isothiazolin-3-one (DCOIT) with a balance with an accuracy of 0.0001g, and dissolve it in the galvanizing solution of step (1) .

[0041] (3) Use the TPN-F2011D regulated power supply, adjust to constant current mode, use pure zinc sheet as the anode, and prepare the 304 stainless steel sample to be plated in Example 1 (with a nanopore array on the surface) as the cathode, at 7.5mA / cm 2 At a constant current density, the electrodeposition activation time is 2 hours, and the galvanized layer (composite galvanized layer) loaded with the fungicide DCOIT can be prepared, an...

Embodiment 3

[0045] In the present embodiment, the anti-microbial corrosion performance of the composite galvanized layer is as follows:

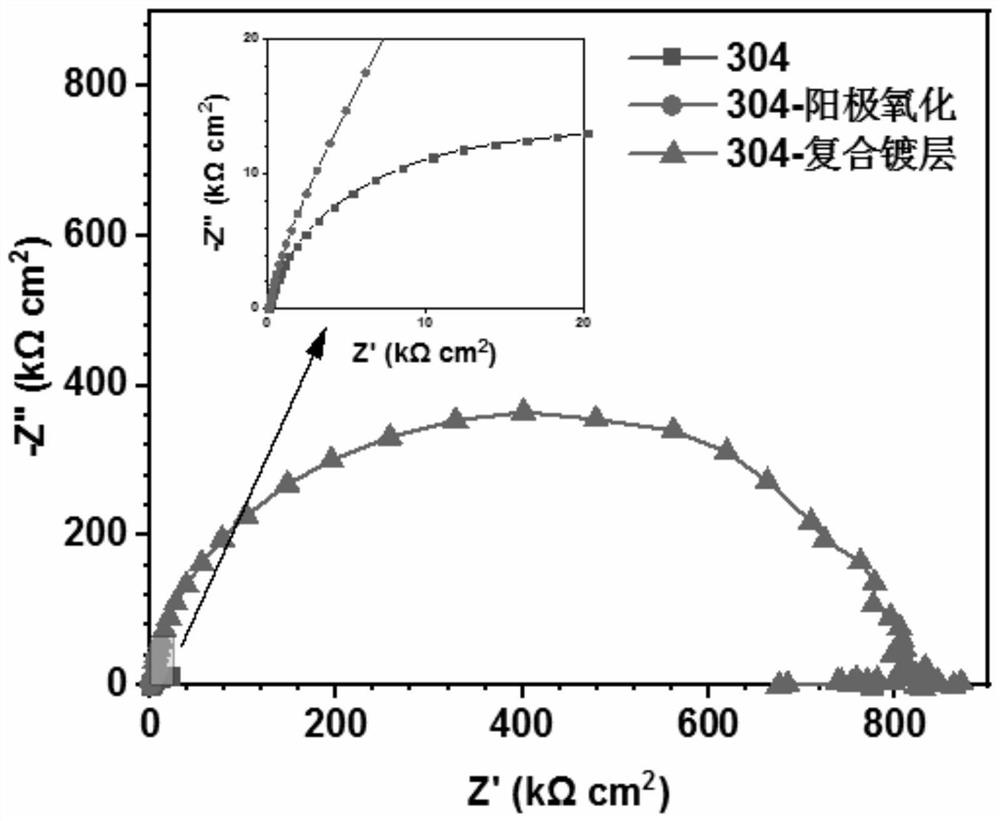

[0046] The 304 stainless steel base material, the 304 stainless steel with nanopore array on the surface prepared in embodiment 1 and the composite galvanized layer prepared in embodiment 2 were soaked in the salt solution containing marine corrosive microorganism sulfate reducing bacteria (SRB) for 48 hours, Electrochemical impedance spectroscopy was used to evaluate the SRB corrosion resistance of the three materials, and the results were as follows image 3 As shown, it can be seen from the figure that the capacitive arc radius of the composite galvanized layer is significantly larger than that of the other two materials, indicating that the composite galvanized layer can well inhibit the corrosion of SRB on the 304 stainless steel substrate.

[0047] The results of the examples show that the present invention can improve the binding force between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com