Making method of fish bone charcoal fluoride removal electrode

A production method and technology of fishbone charcoal, applied in the field of environmental engineering, can solve the problems of small bone charcoal particle size, increased water head loss of adsorption column, and unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

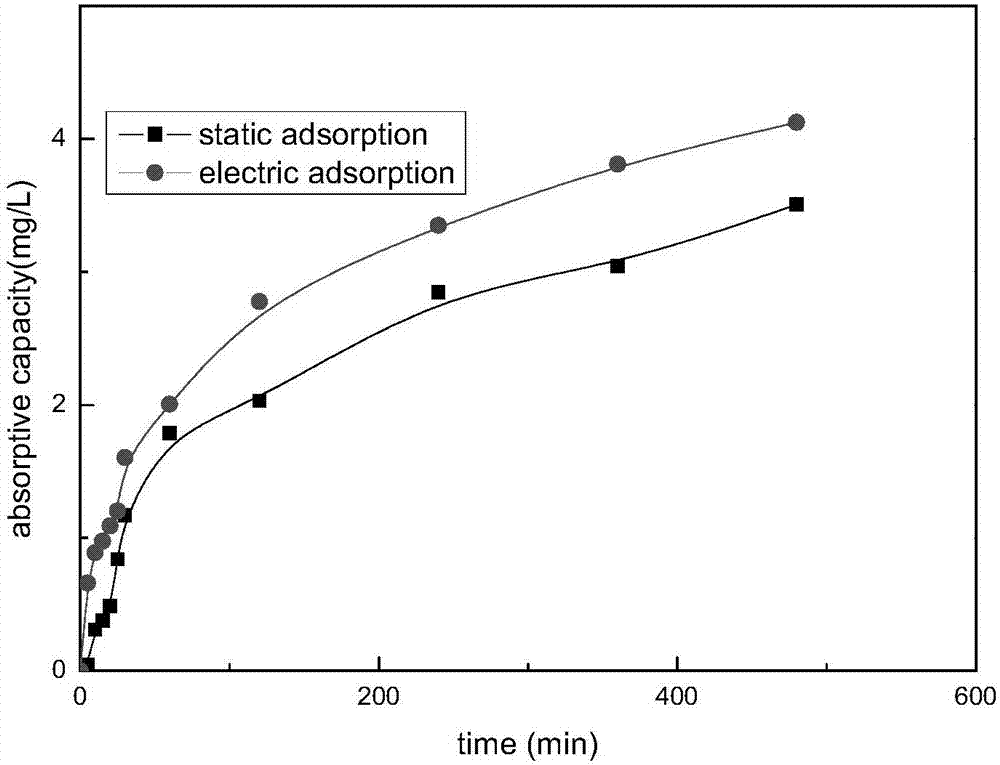

Embodiment 1

[0023] Preparation of herringbone carbon electrodes:

[0024] (1) Wash, dry and preliminarily crush the fish bones, and place them in a planetary grinder for 4 times of grinding at 400rad / min, each time for 10 minutes, with an interval of 5 minutes between two grindings, that is, a total of 40 minutes of grinding to obtain fish bone meal .

[0025] (2) The obtained fish bone meal was carbonized in a tube furnace with nitrogen as the protective gas at a heating rate of 5 °C / min to 500 °C, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature to obtain fish bone charcoal.

[0026] (3) Separately weigh 2.400g, 0.450g, and 0.150g of herringbone charcoal, PVDF, and carbon black (that is, the mass ratio is 16:3:1) in a beaker, stir evenly and make it fully mixed to obtain a mixture;

[0027] (4) Slowly add N,N-dimethylacetamide to the mixture in 3) while stirring until a slurry with a total volume of about 25ml is obtained, and put the slurry in t...

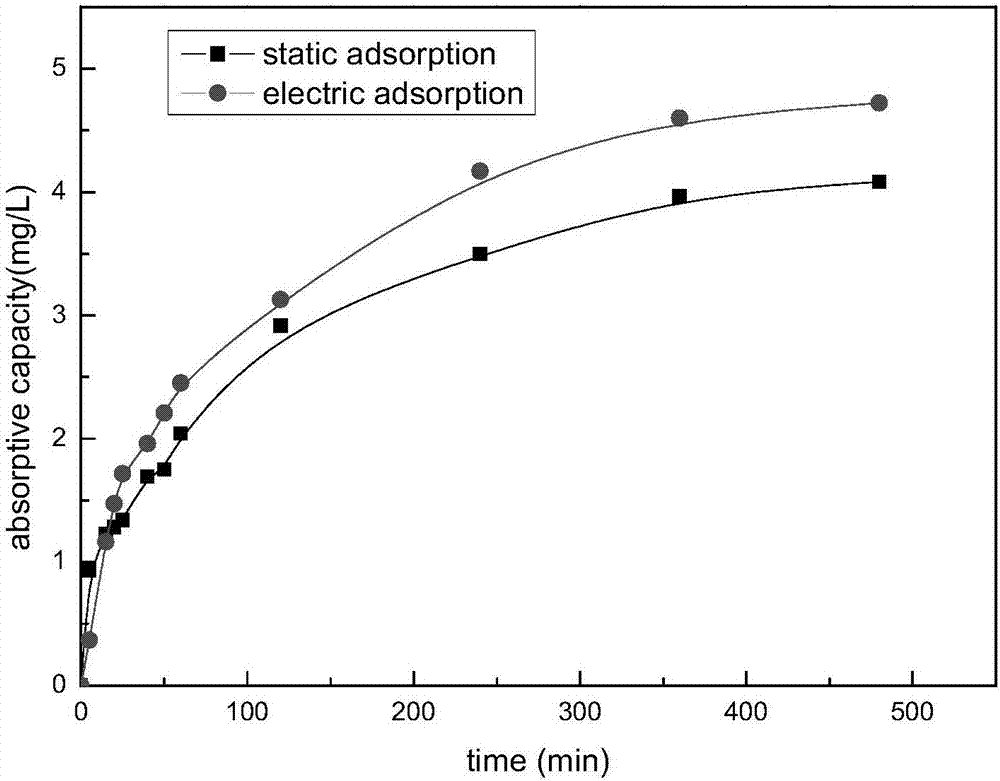

Embodiment 2

[0036] Preparation of Herringbone Carbon Electrode

[0037] (1) Wash, dry and preliminarily crush the fish bones, and place them in a planetary grinder for 4 times of grinding at 400rad / min, each time for 10 minutes, with an interval of 5 minutes between two grindings, that is, a total of 40 minutes of grinding to obtain fish bone meal .

[0038] (2) The obtained fish bone meal was carbonized in a tube furnace with nitrogen as the protective gas at a heating rate of 5 °C / min to 500 °C, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature to obtain fish bone charcoal.

[0039] (3) Separately weigh 2.400g, 0.450g, and 0.150g of herringbone charcoal, PVDF, and carbon black (that is, the mass ratio is 16:3:1) in a beaker, stir evenly and make it fully mixed to obtain a mixture;

[0040] (4) Slowly add N,N-dimethylacetamide to the mixture in 3) while stirring until a slurry with a total volume of about 25ml is obtained, and put the slurry in the...

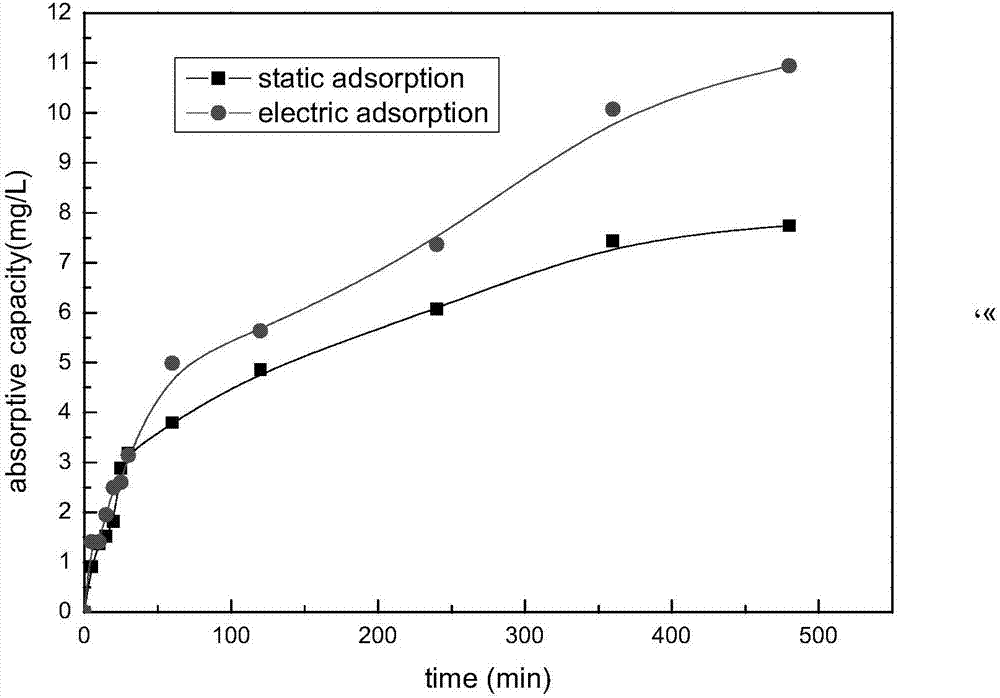

Embodiment 3

[0049] Preparation of Herringbone Carbon Electrode

[0050] (1) The fish bones were cleaned, dried, preliminarily crushed, and ground in a planetary grinder at 400rad / min for 4 times, each time for 10 minutes, with an interval of 5 minutes between two grindings, for a total of 40 minutes to obtain fish bone meal.

[0051] (2) The obtained fish bone meal was carbonized in a tube furnace with nitrogen as the protective gas at a heating rate of 5 °C / min to 500 °C, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature to obtain fish bone charcoal.

[0052] (3) Separately weigh 2.400g, 0.450g, and 0.150g of herringbone charcoal, PVDF, and carbon black (that is, the mass ratio is 16:3:1) in a beaker, stir evenly and make it fully mixed to obtain a mixture;

[0053] (4) Slowly add N,N-dimethylacetamide to the mixture in 3) while stirring until a slurry with a total volume of about 25ml is obtained, and put the slurry in the stirrer at a speed of 300ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com