Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Aminocapronsäure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing hexamethylenediamine key intermediate 6-aminocapronitrile by continuous gas-phase two-step method

ActiveCN111574401AReduced Catalytic PolymerizationReduce polymerizationOrganic compound preparationCarboxylic acid amides preparationAminocapronsäurePtru catalyst

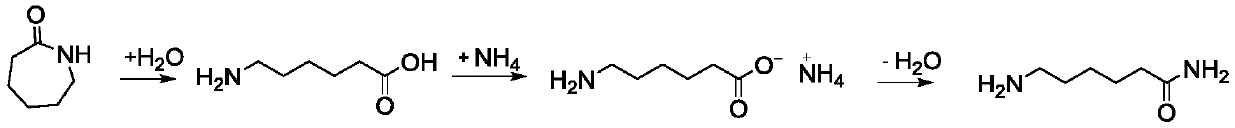

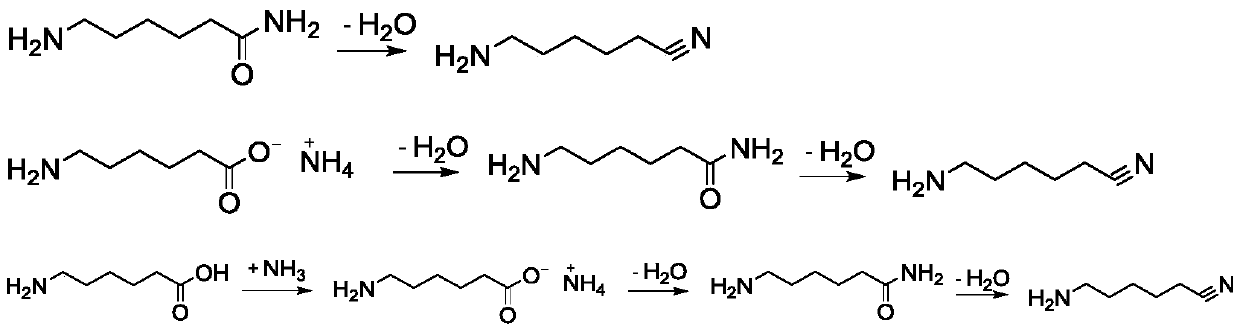

The invention provides a method for producing a hexamethylenediamine key intermediate 6-aminocapronitrile by a continuous gas-phase two-step method. The method comprises the following steps: S1, mixing caprolactam and water in a gas phase state to carry out continuous hydrolysis or mixing caprolactam and ammonia water in a gas phase state to carry out continuous hydrolysis ammoniation reaction toobtain a first product system containing 6-aminocaproic acid, 6-aminocaproic acid ammonium salt and / or 6-aminocaproamide; and S2, carrying out continuous gas-phase catalytic ammoniation and dehydration reaction on the first product system and ammonia gas to obtain a second product system containing 6-aminocapronitrile. According to the patent of the invention, the problem that water generated by reaction in a one-step process promotes polymerization reaction of the raw material caprolactam is reduced from the source, and the selectivity of aminocapronitrile is improved; and the problems of catalyst deactivation and pressure drop rise caused by polymerization and coking of caprolactam in the reactor are effectively reduced, the stability of the device is improved, and the service life of the catalyst is prolonged.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Polyester resin for low-gloss TGIC system powder coating and preparation method and application thereof

InactiveCN109320705AExcellent flatness and smoothnessImprove stabilityPowdery paintsPolyester coatingsEthylenediamineAntioxidant

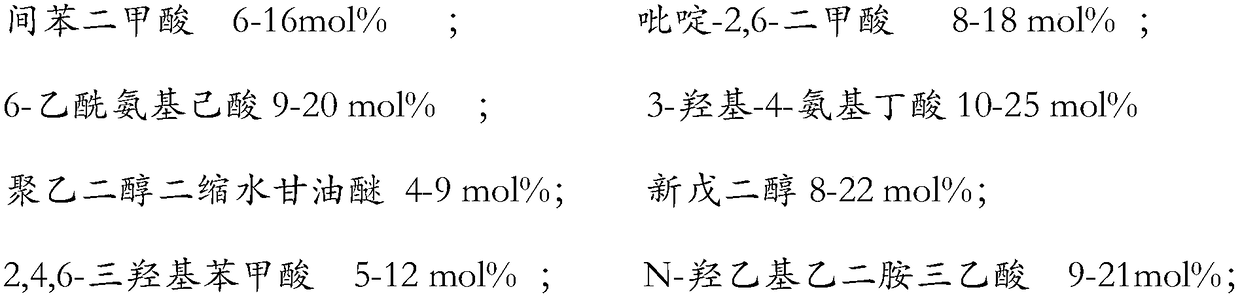

The invention belongs to the technical field of resin production, and specifically relates to polyester resin for low-gloss TGIC system powder coating, a preparation method of the polyester resin, andapplication of the polyester resin. The polyester resin is mainly prepared from isophthalic acid, pyridine-2,6-dicarboxylic acid, 6-acetylaminocaproic acid, 3-hydroxy-4-aminobutyric acid, polyethylene glycol diglycidyl ether, neopentyl glycol, 2,4,6-trihydroxybenzoic acid, N-hydroxyethyl ethylenediamine tri-acetic acid, an esterification catalyst and an antioxidant. The molecules of the polyesterresin prepared by the method disclosed by the invention simultaneously contain active amino groups, hydroxyl groups and carboxyl groups, difference between the three kinds of base groups and epoxidegroups in TGIC molecules in curing reaction rate can be used for preparing low-gloss powder coating (gloss<20%), and the film coating properties can completely reach various requirements of powder coating.

Owner:周鹤洋

Composite material containing microelement for hard tissue repair and reconstruction and preparation method thereof

The invention relates to a composite material containing microelement for hard tissue repair and reconstruction and a preparation method thereof. The composite material further contains at least one of three microelements of strontium, zinc and copper acceptable in human body with the calcium mole ratio of 0.01-0.5% in ceramic component of calcium phosphate in the ceramic component containing the calcium phosphate and the substrate material of multi-amino acid polymer, wherein the mass ratio of the ceramic component of calcium phosphate is 30-65%, and the balance of multi-amino acid polymer polymerized by epsilon-aminocaproic acid and other amino acids. The process for preparing the calcium phosphate ceramic comprises the following steps of: adding microelement, then mixing the amino acid components evenly, removing water of various forms in the mixture at a temperature lower than or equal to 200 DEG C under the protection of inert gas, then composing in situ polymerization under the condition of 210-250 DEG C and pH of 6.5-7.5. The composite material is a bionic biomedical and tissue engineering material which has controllable degradation speed, good bioactivity and compatibility and overcomes deficiencies and problems of similar repair materials at present.

Owner:SICHUAN GUONA TECH

Method for preparing chloromycetin artificial antigen

InactiveCN1996016AQuick checkSimple and fast operationBiological testingAntibody medical ingredientsProtein insertionAminocaproic acid

The alficetin artificial antigen is made by solving the alficetin into pyridomycin with succinic anhydride to have carboxy group in the alficetin molecule, adding EDAC and acepramin, making the carboxy group of the alficetin derivative condensing with the amidol of the acepramin, extending the carbon chain, getting the alficetin-carbon chain-carrier protein compound through carrier protein coupling. It is easy in application, and can be used for immune inspecting of the alficetin residue of zoonite with improved inspection level.

Owner:ZHEJIANG UNIV

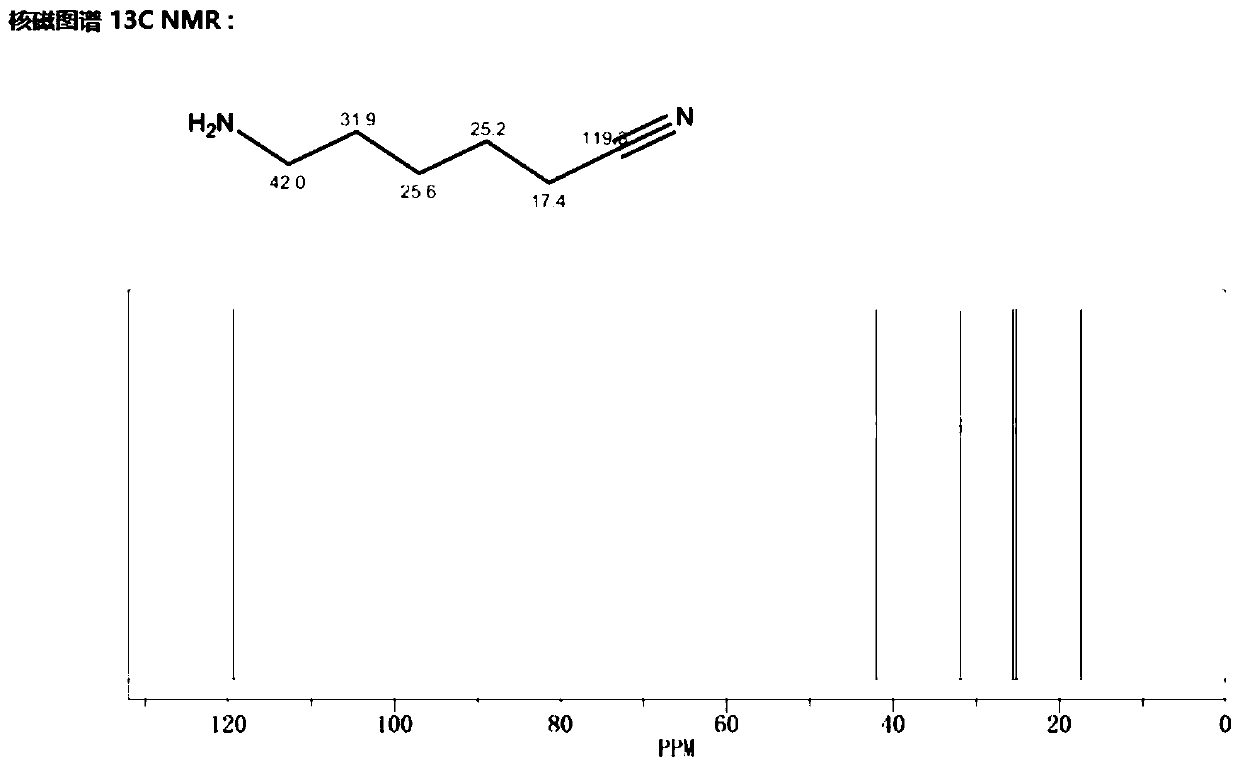

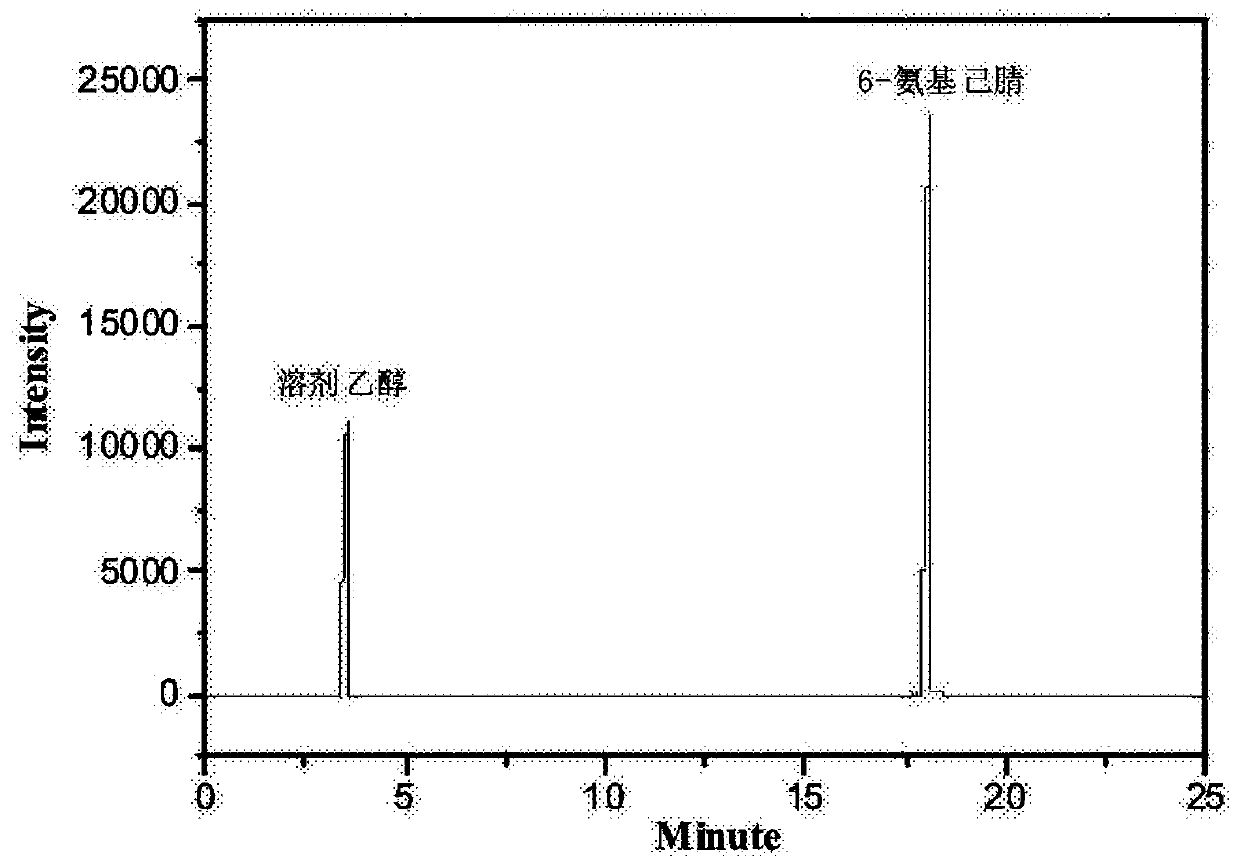

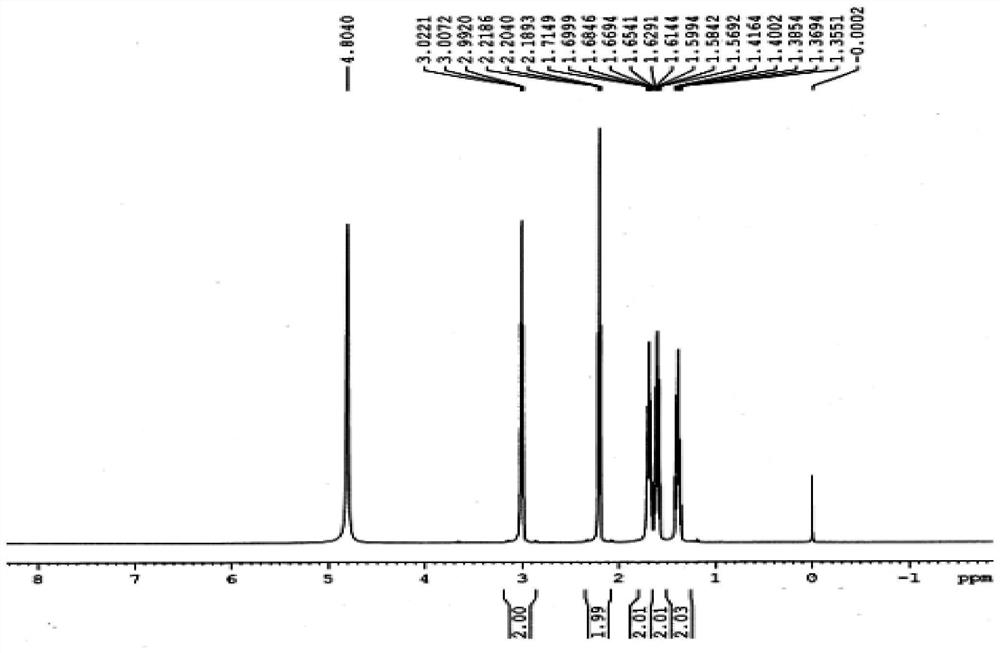

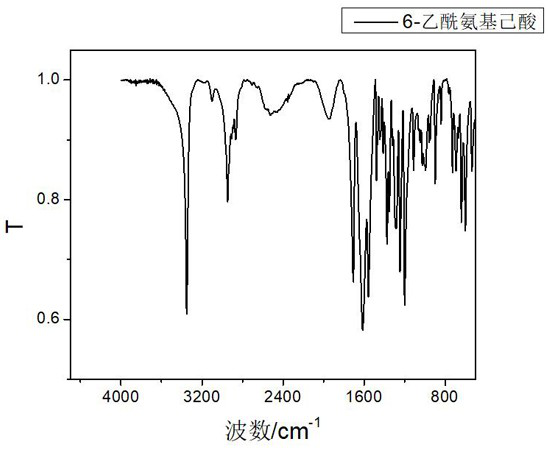

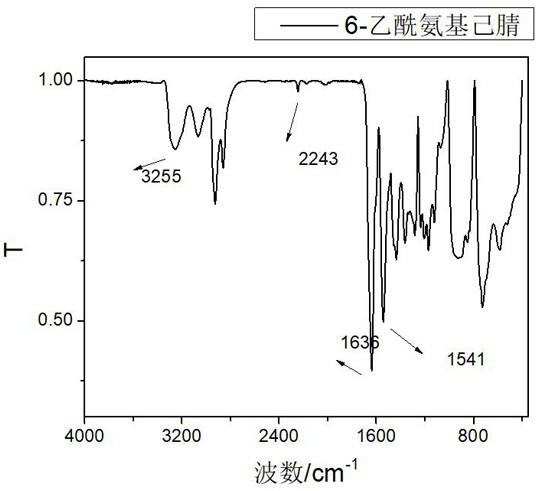

Method for preparing 6-aminocapronitrile product

ActiveCN111233704AReduce pollutionLow reaction temperatureOrganic compound preparationAmino-carboxyl compound preparationAminocapronsäureAlcohol

The invention relates to a method for preparing a 6-aminocapronitrile product. The method comprises the following steps: A, uniformly mixing caprolactam, an acidic solution and the like according to acertain ratio, then adding the mixture into a reaction kettle, heating and stirring the mixture and carrying out a reaction; B, after the caprolactam reaction in the step A is completed, removing low-boiling-point substances under reduced pressure, and recrystallizing the reaction product to obtain 6-aminocaproate; C, uniformly mixing the 6-aminocaproate obtained in the step B, alcohol, an ammoniating agent, a dehydrating agent and the like according to a certain ratio, adding the mixture into a reaction kettle, and heating and stirring the mixture and carrying out a reaction; and D, rectifying the reaction liquid obtained in the step C, and separating and purifying the reaction liquid to obtain 6-aminocapronitrile. According to the method for preparing the 6-aminocapronitrile product, the reaction conversion rate is high, the purity of the 6-aminocapronitrile product can reach 98% or above, the reaction conditions are mild, and the preparation process is relatively simple.

Owner:湖北三宁碳磷基新材料产业技术研究院有限公司 +1

Hard-water-resistant anti-freezing cooling liquid composition

The invention relates a hard-water-resistant anti-freezing cooling liquid composition, and provides a hard-water-resistant anti-freezing cooling liquid having the anti-boiling and anti-corrosive functions in order to overcome the conventional technical shortages. The hard-water-resistant anti-freezing cooling liquid composition is composed of glycol, sodium triazinyltriaminohexanoate, N-caprylyl sodium glutamate, a copper aluminum corrosion inhibitor, a mildew inhibitor, an antifoaming agent, fluorescein, and water.

Owner:张亚利

Use of decamethylene diamine in preparing copolyamide hot sol

The invention relates the diamine product used to produce copolyamide hot melt adhesive. The method comprises the following steps: 1. using decanamine to prepare hot melt adhesive; 2. the copolymerization hot melt adhesive being ternary or polyvalent; 3. the copolymerization hot melt adhesive comprising a, b elementary units, a: two or many C6-13 diamine or two or many C6-13 dibasic acid, b: aminocaprolactam or aminoadipic acid; 4. 60-80% a and 20-40% b. The decanamine belongs to a. The invention has the advantages of simple technology, low cost, and easy operation.

Owner:WUXI YINDA NYLON

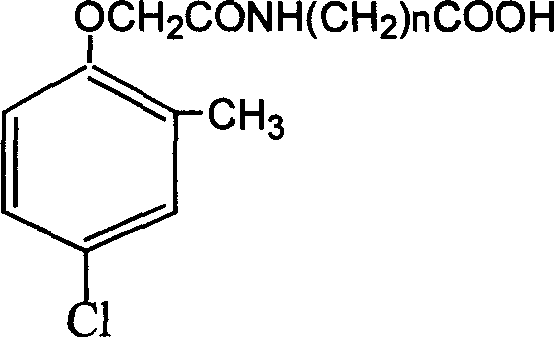

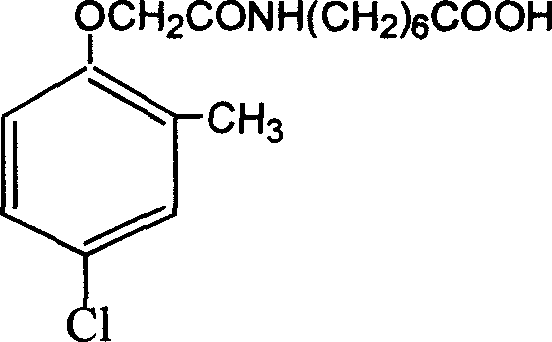

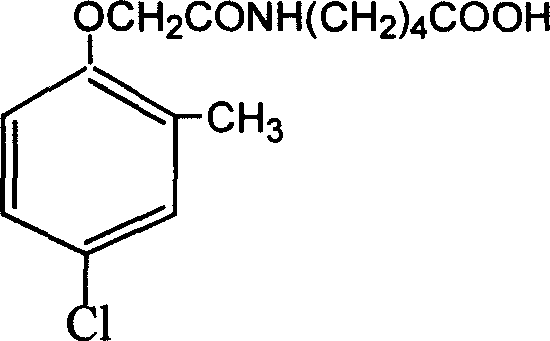

Method for preparing 2 metho 4 chlorine artificial half antigen, artificial antigen, specific antibody and application

InactiveCN1562963AFast and accurate analysis and detectionEasy to handleImmunoglobulinsCarrier-bound/immobilised peptidesCarboxylic acidSpecific antibody

Raw material-2-methyl-4-chlorophenoxy carboxylic acid (2-ME-4-CHL) is acrylated by sulfoxide chloride, then reacting with amino-butyric and amino-caproic acid respectively, to prepare half antigens: 4-(2-methyl-4-chlorophenoxyacetyl) amino butyric acid and 6-(2-methyl-4-chlorophenoxyacetyl) amino caproic acid (MB and MC for short, resp). And 2-ME-A-CHL itself can be half-antigen (M for short). Halfantigens M, MB and MC are coupled with protein to produce immune antigen and envelope antigen by carbodi-imide and mixed acid anhydride methods. Immue antigen immune animals are used to produce special antibody with high avidity to 2-ME-4-CHL. This antibody does not react with other compounds. Enzyme-linked immunosorbant assay established with said antibody can test trace ammount of 2-ME-4-CHL residues quickly and conveniently.

Owner:ZHEJIANG UNIV

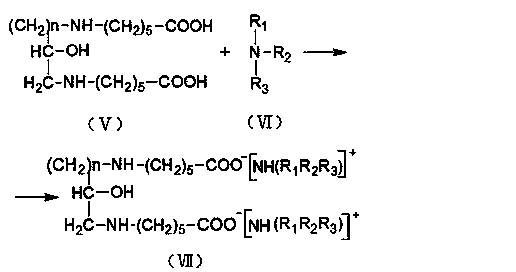

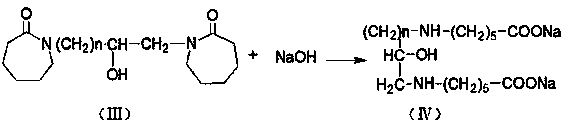

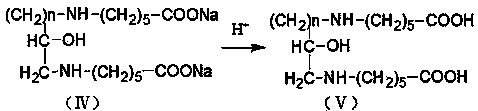

Synthesis method of hydroxyalkyl tertiary ammonium beta-hydroxyalkyldienediaminocaproate

ActiveCN104109099AStrong rust resistanceAnti-wear and anti-frictionOrganic compound preparationAmino-carboxyl compound preparationAminocapronsäureAlkane

The invention discloses a synthesis method of hydroxyalkyl tertiary ammonium beta-hydroxyalkyldienediaminocaproate. The synthesis method comprises that chloroepoxyalkane and a caprolactam group undergoes a heating backflow reaction with stirring in the presence of benzene as a solvent and zinc chloride and zinc hydroxide as catalysts to produce dicaprolactam-2-ol, a sodium hydroxide solution is added into the reaction mixture, a lower layer is separated so that a sodium beta-hydroxyalkyldienediaminocaproate solution is obtained, an acid solution is slowly added into the sodium beta-hydroxyalkyldienediaminocaproate solution, a PH value of the mixed solution is adjusted to about 1.0, and the separated beta-hydroxyalkyldienediaminocaproic acid is added into the hydroxyalkyl tertiary amine so that the hydroxyalkyl tertiary ammonium beta-hydroxyalkyldienediaminocaproate is obtained. The hydroxyalkyl tertiary ammonium beta-hydroxyalkyldienediaminocaproate has multiple active adsorption centers, can improve anodic polarization performances and has corrosion inhibition effects. The hydroxyalkyl tertiary ammonium beta-hydroxyalkyldienediaminocaproate has combined characteristics of two amido groups, two carboxyl groups and metals, and has strong antirust effects and antiwear and antifriction effects.

Owner:山东蓝盟防腐科技股份有限公司

Formula and preparation method for producing low melting point and high decomposition temperature ternary copolyamide without ring-opening agent

The present invention relates to a polymer material, more particularly to a low melting point and high decomposition temperature ternary copolyamide produced without a ring-opening agent. According to the present invention, the problem that the caprolactam polymerization process is limited by the ring-opening agent (the conventional polymerization reaction usually adopts water and aminocaproic acid as ring-opening agents) is solved, wherein in order to ensure the ring-opening reaction rate, a lot of water is required to be added at the reaction early stage so as to cause problems such as water removing difficulty at the reaction later stage, high energy consumption, and influence of not complete water removing on the product quality; the low molecular weight extractable product content of the polyamide 6 prepared through the conventional polymerization is more than 9%, the extraction and re-drying process is required before the processing so as to provide the long process and increase the product cost, the low molecular weight extractable product content of the product of the present invention is only 1-5% so as to eliminate the extraction re-drying and monomer recovery process, and the caprolactam conversion rate is substantially improved so as to save the cost; and the problems of high melting point and difficult processing of polyamide are solved, and the shortcomings of the prior art are overcome.

Owner:HUNAN NORMAL UNIVERSITY

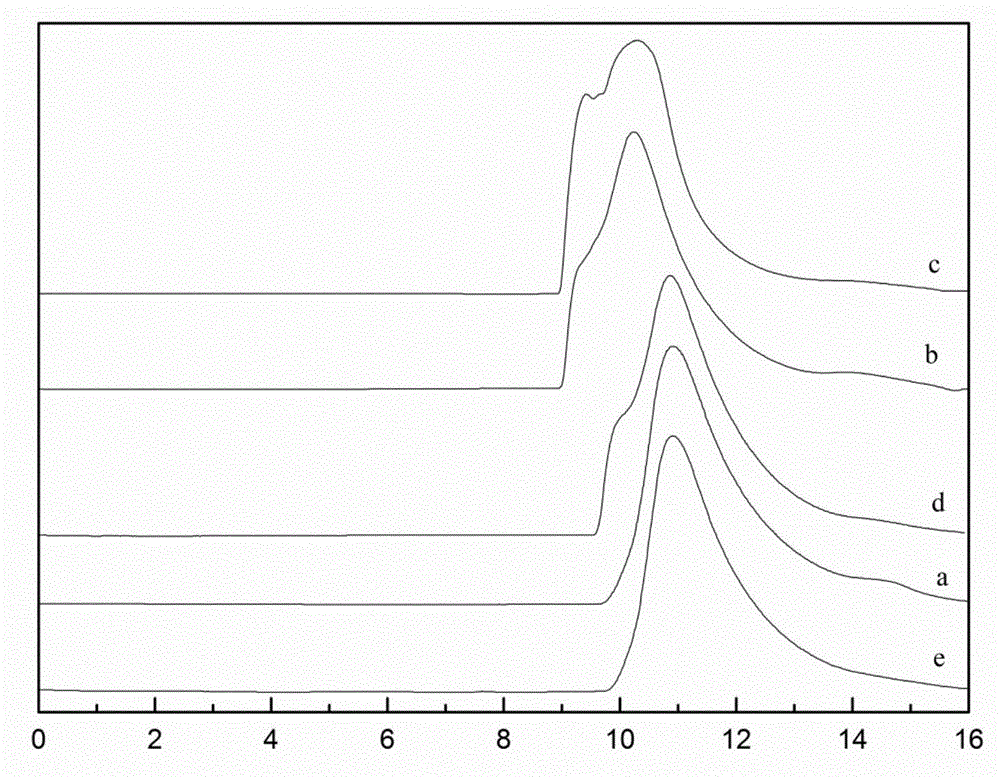

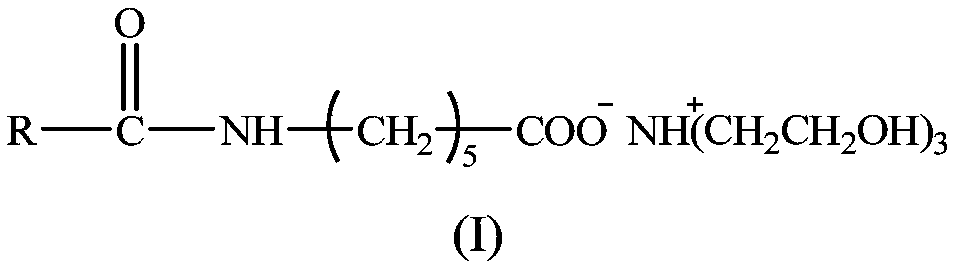

Water-soluble antirust agent as well as preparation method and application thereof

InactiveCN111039820AEasy to degradeImprove rust resistanceOrganic compound preparationCarboxylic acid amides preparationAminocapronsäureDistilled water

The invention relates to a water-soluble antirust agent, and also relates to a preparation method of the water-soluble antirust agent. The method comprises the following steps: (1) adding caprolactaminto a strong alkali aqueous solution, and carrying out reflux hydrolysis to form an aminocaproate aqueous solution; (2) cooling the aminocaproate aqueous solution to -5 to 5 DEG C, slowly dropwise adding fatty acyl chloride into the aminocaproate aqueous solution, and keeping the temperature of the reaction system at -5 to 5 DEG C in the whole dropwise adding process; (3) after addition of the fatty acyl chloride is finished, slowly heating, and continuously reacting; (4) cooling the reaction system in the step (3) to room temperature, adding hydrochloric acid for acidification, standing forlayering, and taking an upper organic phase to obtain an intermediate of the water-soluble antirust agent; and (5) washing the intermediate with hot distilled water until the chloride ion concentration is lower than 200 ppm, and reacting with triethanolamine to obtain the water-soluble antirust agent. The invention also relates to application of the water-soluble antirust agent in antirust additives of water-based metal machining fluids and water-based hydraulic fluids.

Owner:PETROCHINA CO LTD

Flame-retardant nylon 6 fiber and preparation method thereof

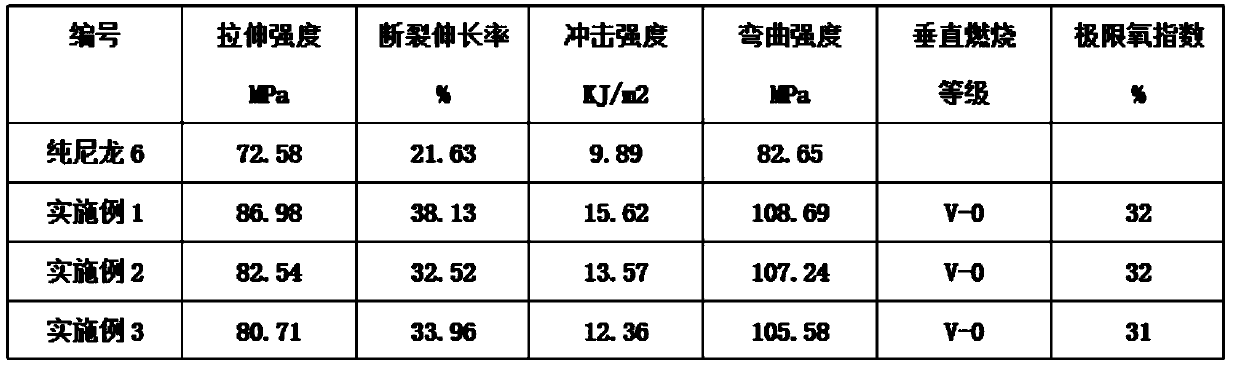

PendingCN113666880AImprove flame retardant performanceDoes not affect normal useOrganic chemistryFlame-proof filament manufactureAminocapronsäurePolymer science

The invention discloses a flame-retardant nylon 6 fiber and a preparation method thereof, and belongs to the technical field of functional fibers. The preparation method of the flame-retardant nylon 6 fiber comprises the steps: 1, reacting caprolactam, a flame retardant represented by the formula I, deionized water and 6-aminocaproic acid in a reaction device, to obtain flame-retardant nylon 6; and 2, drying the flame-retardant nylon 6, and performing melt spinning to obtain flame-retardant nylon 6 fiber, wherein the formula I is described in the specification. According to the preparation method disclosed by the invention, the caprolactam and the flame retardant represented by the formula I are subjected to in-situ polymerization to obtain the flame-retardant nylon 6, so that the flame retardant can be uniformly dispersed in the flame-retardant nylon 6, and the spinnability, the flame retardance, the thermal stability, the mechanical property and the hygroscopicity of the flame-retardant nylon 6 are improved.

Owner:RUINAI COMPOSITE MATERIAL

Water-soluble polymer sterilizing agent and preparation method thereof

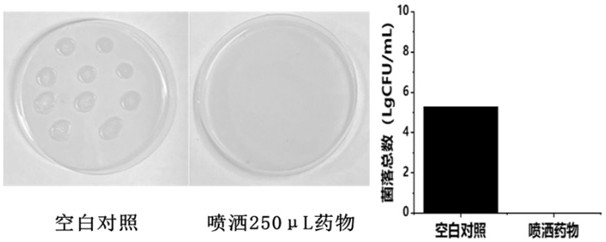

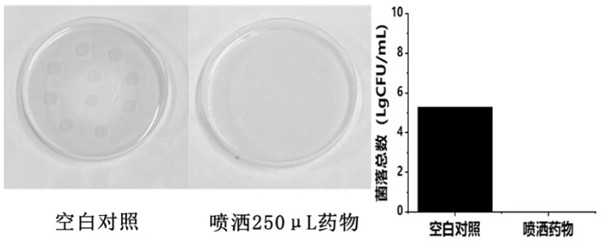

PendingCN113545355ADisinfect quicklyEfficient and non-freezingBiocideDisinfectantsAminocapronsäureCold chain

The invention discloses a water-soluble polymer sterilizing agent and a preparation method thereof, which belong to the technical field of food safety. The preparation method comprises the following steps of carrying out a cross-linking polymerization reaction on cationic glucan, 2, 6-diaminocaproic acid and epoxy chloropropane under an alkaline condition, carrying out rotary evaporation drying to obtain an agent A, and dissolving the agent A in water to obtain an effective component agent A solution, dissolving magnesium chloride with water to obtain a magnesium chloride solution, and mixing the magnesium chloride solution with absolute ethyl alcohol to obtain a low-temperature anticoagulant B solution, and mixing the effective component A solution with the low-temperature anticoagulant B solution to obtain the water-soluble polymer sterilizing agent. The sterilizing agent is suitable for being used in an environment of -20 DEG C to 40 DEG C in a spraying manner, has the advantages of high efficiency and no freezing under a low-temperature condition, and can be used for sterilizing bacteria on cold chains, refrigeration houses and food outer packages.

Owner:FUZHOU UNIV

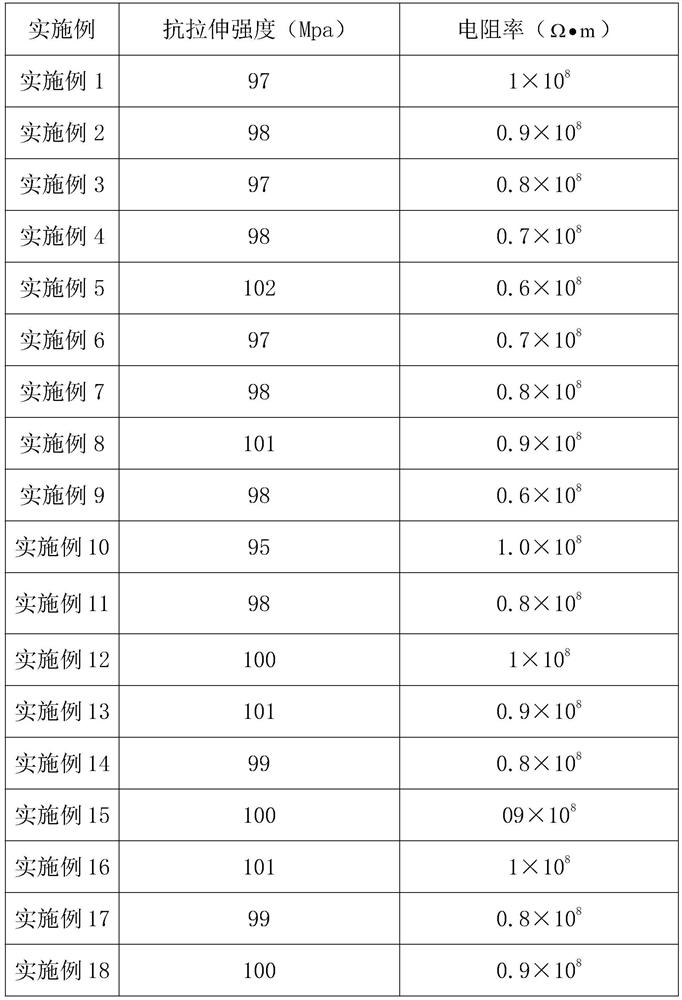

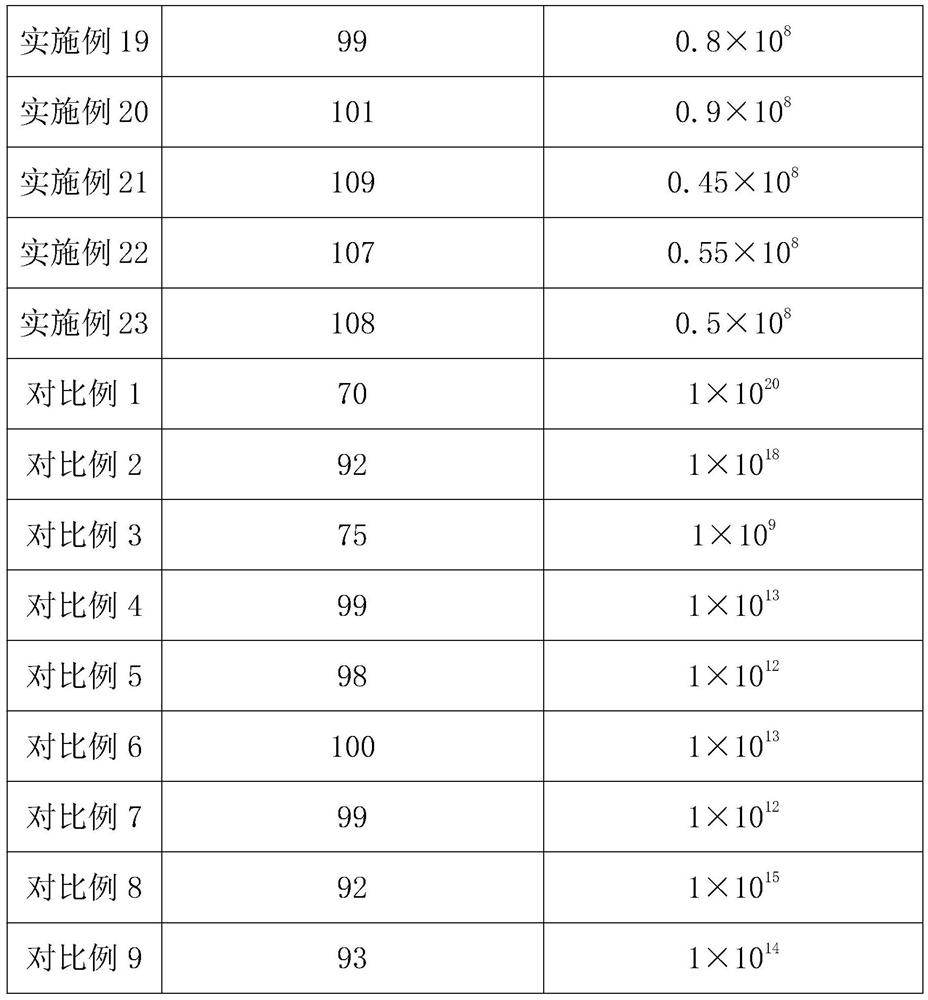

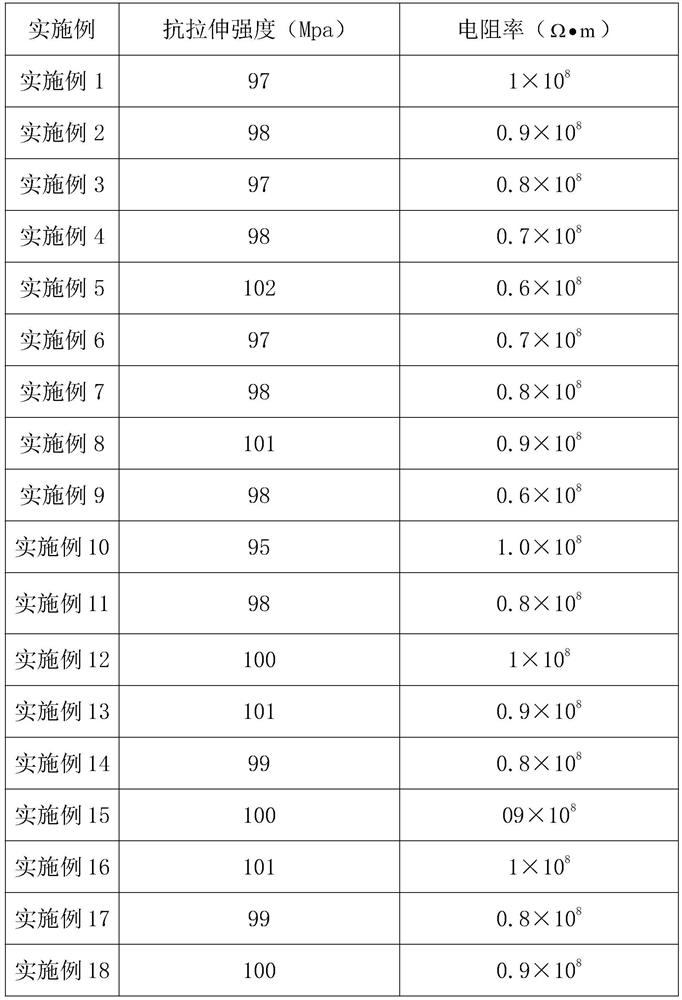

Antistatic polymer film and preparation method thereof

ActiveCN112341660AExtended service lifeDoes not affect structuralPolyamide coatingsElectrically-conductive paintsAminocapronsäureSulfonate

The invention relates to the field of polymer films, and particularly discloses an antistatic polymer film and a preparation method thereof. The antistatic polymer film is prepared from, by weight, 20-40 parts of a polymer material, 4-15 parts of carbon nanotubes and 1-6 parts of an antistatic agent, wherein the antistatic agent is prepared from, by weight, 2-8 parts of 1,6-caprolactam, 1-6 partsof alkyl sodium sulfonate and 2-7 parts of 6-aminocaproic acid. According to the invention, the antistatic performance of the antistatic polymer film is improved, and the influence on the mechanical properties of the antistatic polymer film is reduced.

Owner:HEBEI KELUN PLASTIC TECH

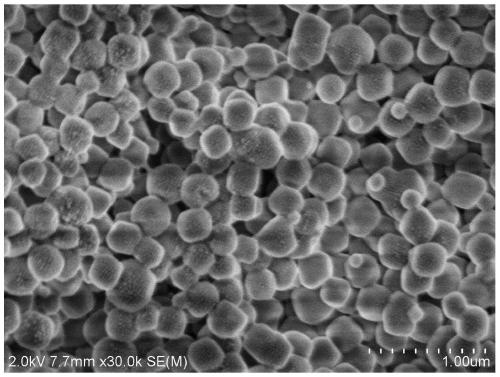

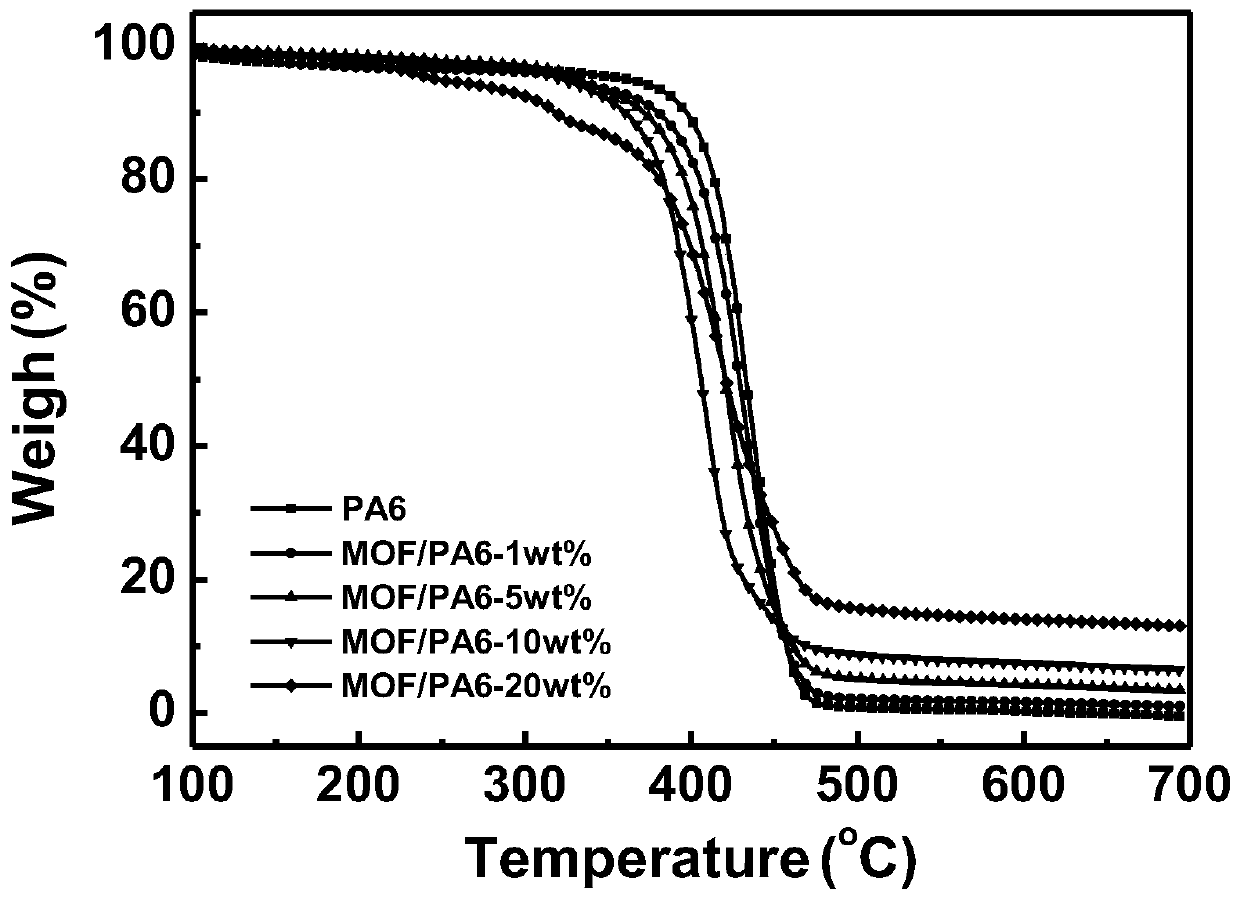

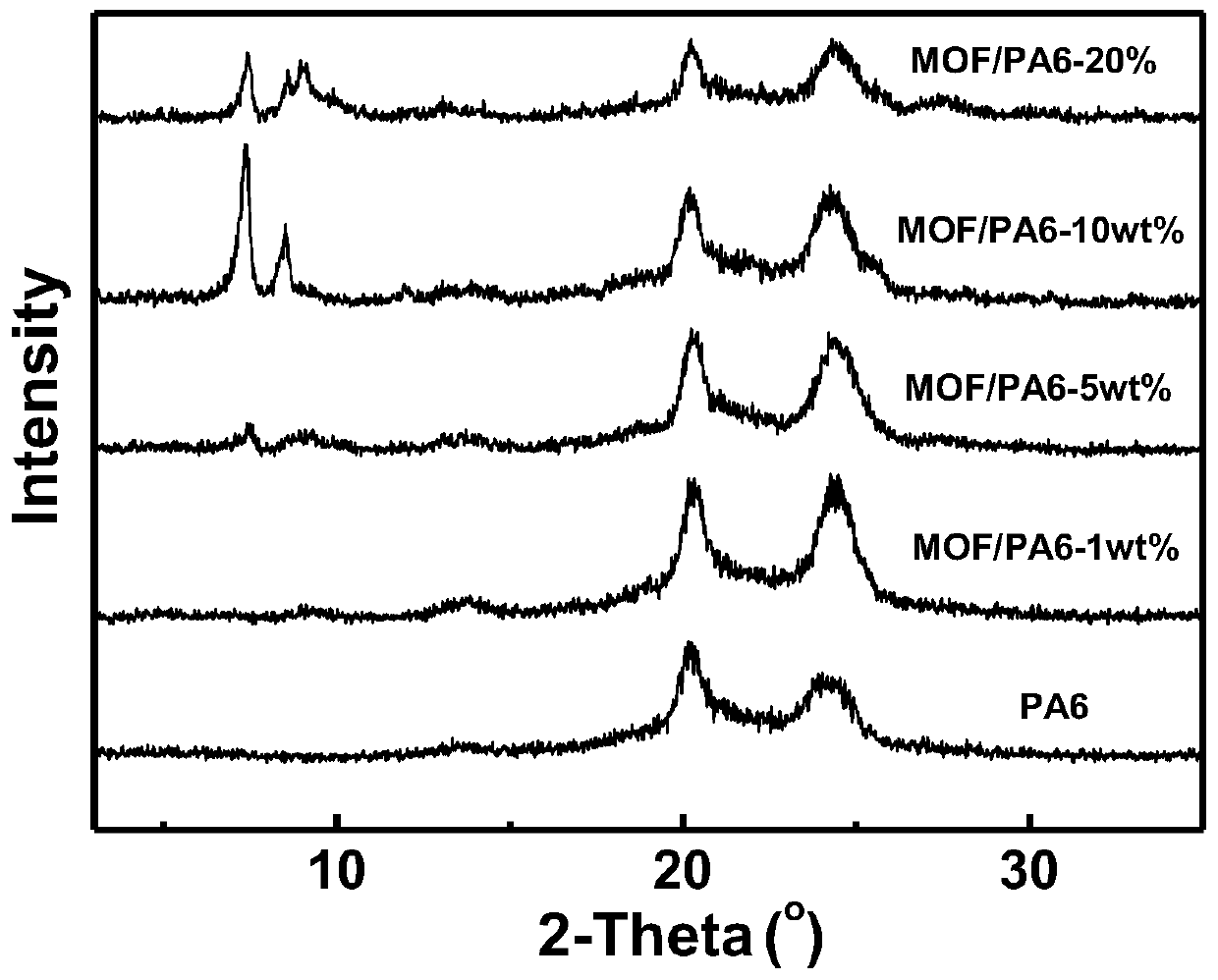

The preparation method of MOF/nylon 6 composite material

The invention relates to modified nylon 6 resin, and a preparation method and an application thereof. The modified nylon 6 resin provided by the invention is prepared by addition of metal-organic framework (MOF) nanoparticles. The preparation method comprises the following steps: (1) dissolving a metal salt and an organic ligand used as MOF precursors, and a polymer monomer namely caprolactam intoa mixed solution composed of water and a polar organic solvent, and carrying out a reaction under heating at a certain temperature for a period of time so as to obtain a nanometer MOF dispersion; (2)carrying out evaporation so as to remove the polar organic solvent in the nanometer MOF dispersion obtained in the step (1), adding 6-aminocaproic acid into residues, and carrying out a polymerization reaction so as to obtain MOF nanoparticle modified nylon 6 resin masterbatches; and (3) subjecting the modified nylon 6 resin masterbatches obtained in the step (2) and nylon 6 (a market product) tomelt blending so as to obtain MOF nanoparticle modified nylon 6 resin. According to the invention, the MOF nanoparticles are used as a modifying agent in the process of polymerization, and the modifying agent can significantly improve crystallization properties of the modified nylon 6 resin provided by the invention.

Owner:常州锦弘新材料有限公司

High-elasticity adult diaper convenient to wear

ActiveCN114209498ASoft touchIncrease elasticityMonocomponent synthetic polymer artificial filamentArtifical filament manufactureAminocapronsäureFiber

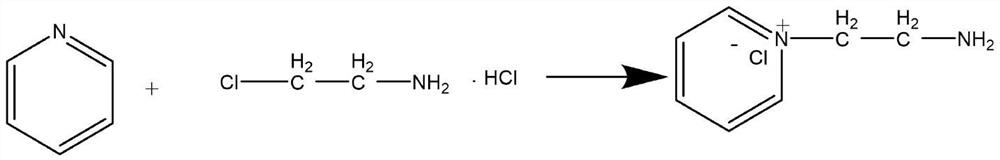

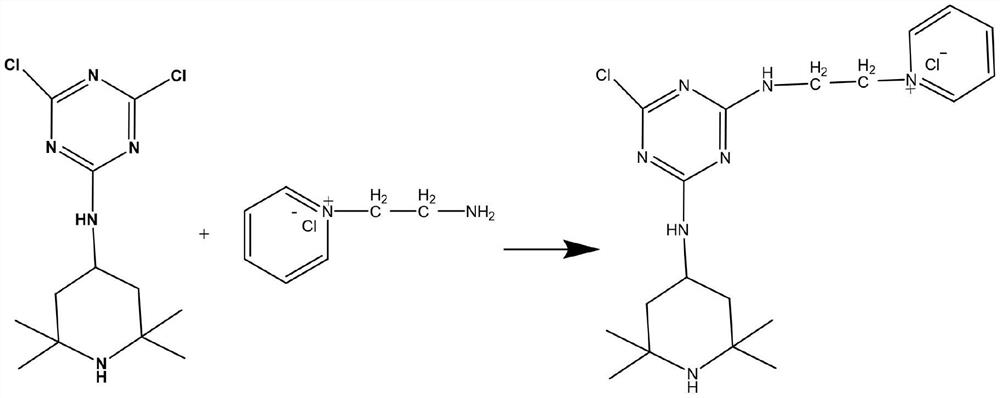

The high-elasticity adult diaper convenient to wear comprises a diaper body, the diaper body is provided with a surface layer, a flow guide layer, an absorption core layer and a back layer from top to bottom, and the surface layer is made of modified fibers; the preparation process of the modified fiber comprises the following steps: firstly, reacting chloroethylamine hydrochloride with pyridine to produce an intermediate 1, and then substituting a chlorine atom on cyanuric chloride with 2, 2, 6, 6-tetramethyl piperidylamine to obtain an intermediate 2; finally, the intermediate 1 is used for replacing another chlorine atom on cyanuric chloride, an intermediate 3 is prepared, and the intermediate 3 has good antibacterial performance; then, the intermediate 3 reacts with caprolactam to replace the last chlorine atom, and an intermediate 4 is obtained; preparing a polyether amide polymer from the intermediate 4, sebacic acid, 6-aminocaproic acid and polyethylene glycol through a one-step method; the adult diaper prepared by the invention has good antibacterial performance.

Owner:安徽舒源妇幼用品有限公司

Process to continuously prepare aqueous mixture of epsi-caprolacta and epsi caprolactam precursors

InactiveCN1142907CImprove initial activityImprove selectivityLactams preparationOrganic compound preparationSolventAminocaproic acid

The present invention provides a process for preparing an aqueous mixture of epsilon -caprolactam and 6-aminocaproic acid and or 6-aminocaproamide which involves, as the reductive amination step, contacting 5-formylvaleric acid and / or an alkyl 5-formylvalerate in water as solvent with hydrogen and an excess of ammonia in the presence of a ruthenium on carrier, as a catalyst, wherein the carrier is titanium oxide, zirconium oxide, graphite or carbon and the catalyst also contains at least one of the metals of group 8-11, or a compound of these metals. The aqueous mixture can be used to prepare epsilon -caprolactam.

Owner:INVISTA TECHNOLOG IES S A R L

Engineered trans-enoyl COA reductases and methods of making and using same

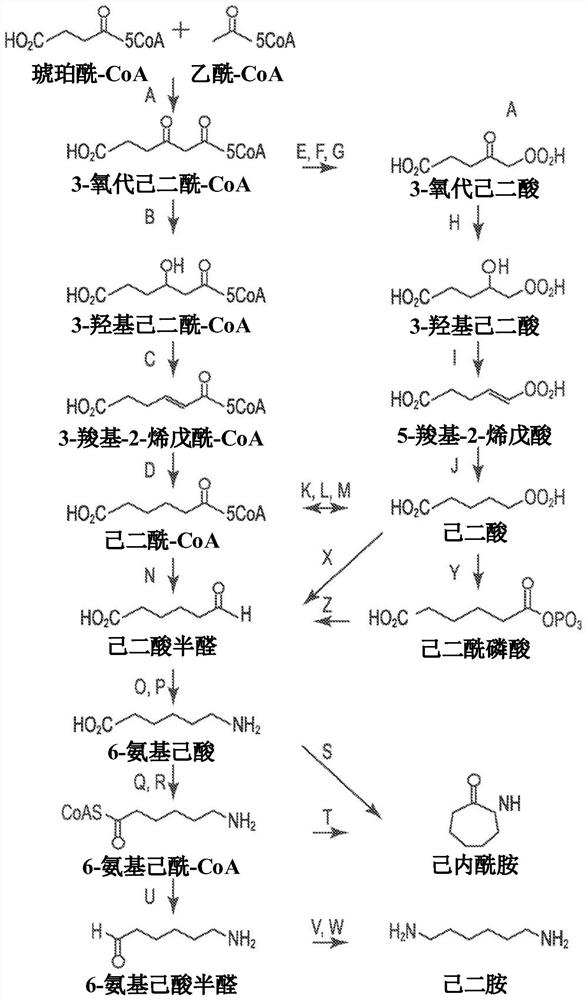

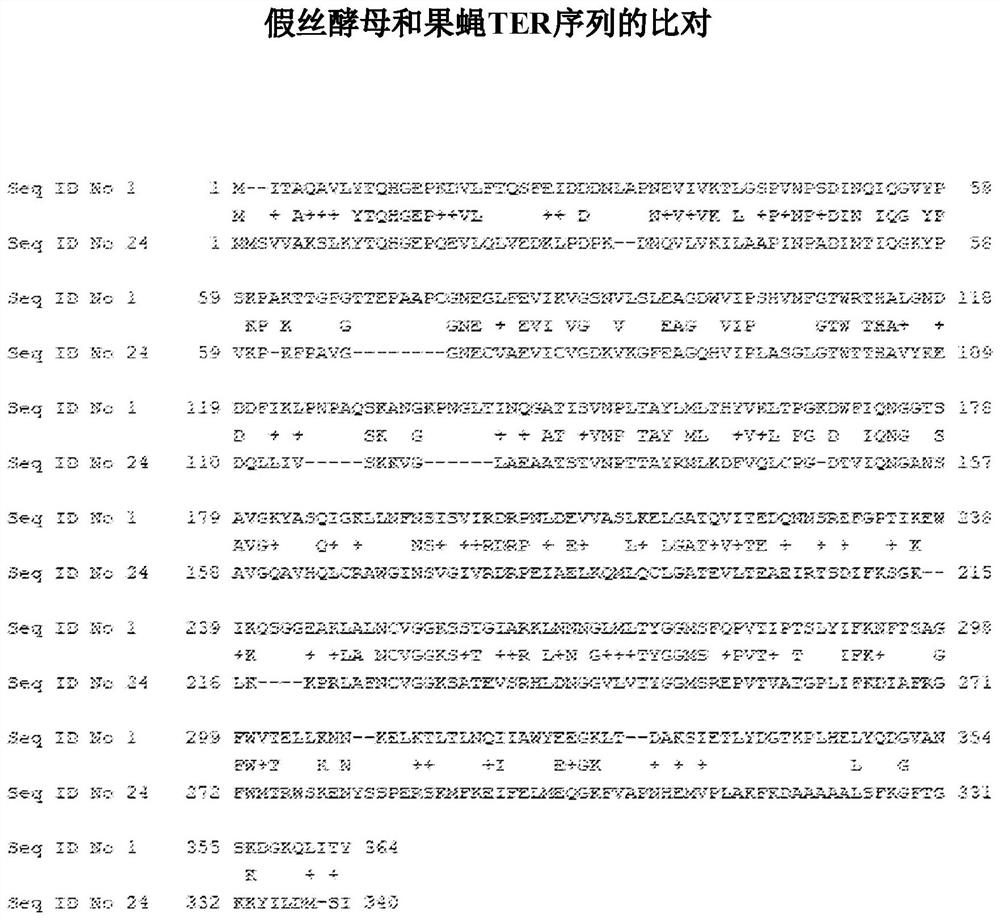

Trans-enoyl CoA reductase (TER) enzymes and nucleic acids encoding the same are disclosed. In some cases, the TER enzyme is a non-natural engineered trans-enoyl CoA reductase. Also disclosed are biosynthetic methods and engineered microorganisms that enhance or improve the biosynthesis of 6-aminocaproic acid, hexamethylenediamine, caproic acid, caprolactone, or caprolactam. The engineered microbial organisms include an exogenous TER, and in some cases also include an engineered TER.

Owner:GENOMATICA INC

Preparation method of 6-aminocaproic acid

ActiveCN112500304AInhibitionShorten the hydrolysis timeGeneral water supply conservationOrganic compound preparationAminocapronsäurePhysical chemistry

The invention discloses a preparation method of 6-aminocaproic acid, which comprises the following steps: by using caprolactam as a raw material, carrying out alkaline hydrolysis, neutralization treatment, desalination treatment and refining treatment to obtain the 6-aminocaproic acid, wherein the alkaline hydrolysis is carried out on caprolactam, sodium hydroxide and water at a certain temperature and under a certain pressure, a certain temperature is 115-125 DEG C, a certain pressure is 0.15-0.3 MPa, and the reaction time of alkaline hydrolysis does not exceed 1.5 hours. According to the alkaline hydrolysis method disclosed by the invention, the hydrolysis time is shortened through pressurization, so that the generation of by-products can be effectively inhibited under the condition of ensuring complete hydrolysis, and therefore, the alkaline hydrolysis method not only has relatively high reaction yield, but also has relatively high product purity.

Owner:CHANGZHOU LANLING PHARMA

A kind of antistatic polymer film and preparation method thereof

ActiveCN112341660BExtended service lifeDoes not affect structuralPolyamide coatingsElectrically-conductive paintsAminocapronsäurePolymer science

This application relates to the field of polymer films, and specifically discloses an antistatic polymer film and a preparation method thereof. The raw materials of the antistatic polymer film include the following components in parts by weight: 20-40 parts of polymer materials, carbon nano 4-15 parts of tube, 1-6 parts of antistatic agent, said antistatic agent includes the following components by weight: 1,6-caprolactam 2-8 parts, 1-6 parts of sodium alkylsulfonate, 6-amino 2‑7 parts of hexanoic acid. The present application improves the antistatic performance of the antistatic polymer film and at the same time reduces the influence of the mechanical properties of the antistatic polymer film itself.

Owner:HEBEI KELUN PLASTIC TECH

Method for preparing 6-aminocaproic acid

PendingCN114163344AAvoid pollutionHigh purityOrganic compound preparationAmino-carboxyl compound preparationAminocapronsäureOrganic acid

The invention relates to a method for preparing aminocaproic acid, which comprises the following steps: S1, adding organic acid into caprolactam waste liquid, and carrying out reflux reaction to obtain a first product; s2, dehydrating the first product under reduced pressure, and adding the dehydrated first product into an alcohol solvent for dissolving to obtain a second product; performing first filtration on the second product to obtain first filtrate; s3, adding organic amine or introducing ammonia gas into the first filtrate, adjusting the pH value of the first filtrate to 7-8, and then carrying out second filtration to obtain crude aminocaproic acid; wherein the waste liquid of caprolactam prepared by the rearrangement method is selected from at least one of waste liquid of caprolactam prepared by a sulfuric acid liquid-phase rearrangement method and waste liquid of caprolactam prepared by a sulfuric acid gas-phase rearrangement method. According to the method, the problem of environmental pollution caused by the waste liquid is solved, valuable components are extracted and converted into the high-added-value product aminocaproic acid, and the adverse effect of hydrochloric acid serving as a catalyst on the product is solved.

Owner:昌德新材科技股份有限公司

Low-elongation polyamide fishing line and preparation method thereof

PendingCN114808177AHigh strengthReduce toughnessMelt spinning methodsArtifical filament manufactureAminocapronsäureElastomer

The invention relates to the technical field of polyamide fishing lines, and discloses a low-elongation polyamide fishing line and a preparation method thereof.The low-elongation polyamide fishing line comprises a polycaprolactam oligomer and a thermoplastic elastomer, and the polycaprolactam oligomer is prepared from, by weight, 1-1.4 parts of caprolactam, 0.5-0.8 part of 6-aminocaproic acid, 6-0.9 part of adipic acid and 10-15 parts of water; the reinforcing body is prepared from the following raw materials in parts by weight: 0, 3 to 0.7 part of polyethylene glycol, 0.7 to 0.99 part of tetrabutyl titanate, 0.2 to 0.6 part of pentaerythritol, 0.4 to 0.8 part of m-phenyl bisoxazoline, 0.1 to 0, 3 parts of an antioxidant 168 and 0.2 to 0.4 part of an antioxidant 1010. According to the fishing line, the polyethylene glycol, the tetrabutyl titanate, the pentaerythritol, the m-phenyl bisoxazoline, the antioxidant 168 and the antioxidant 1010 are added into the polycaprolactam oligomer, so that the strength of the polyamide is improved, the toughness of the polyamide is reduced, and the situations that the fishing line is pulled, the fishing line is extended and the strength of the fishing line is reduced in the using process of the fishing line are avoided.

Owner:江苏普乐菲新材料有限公司

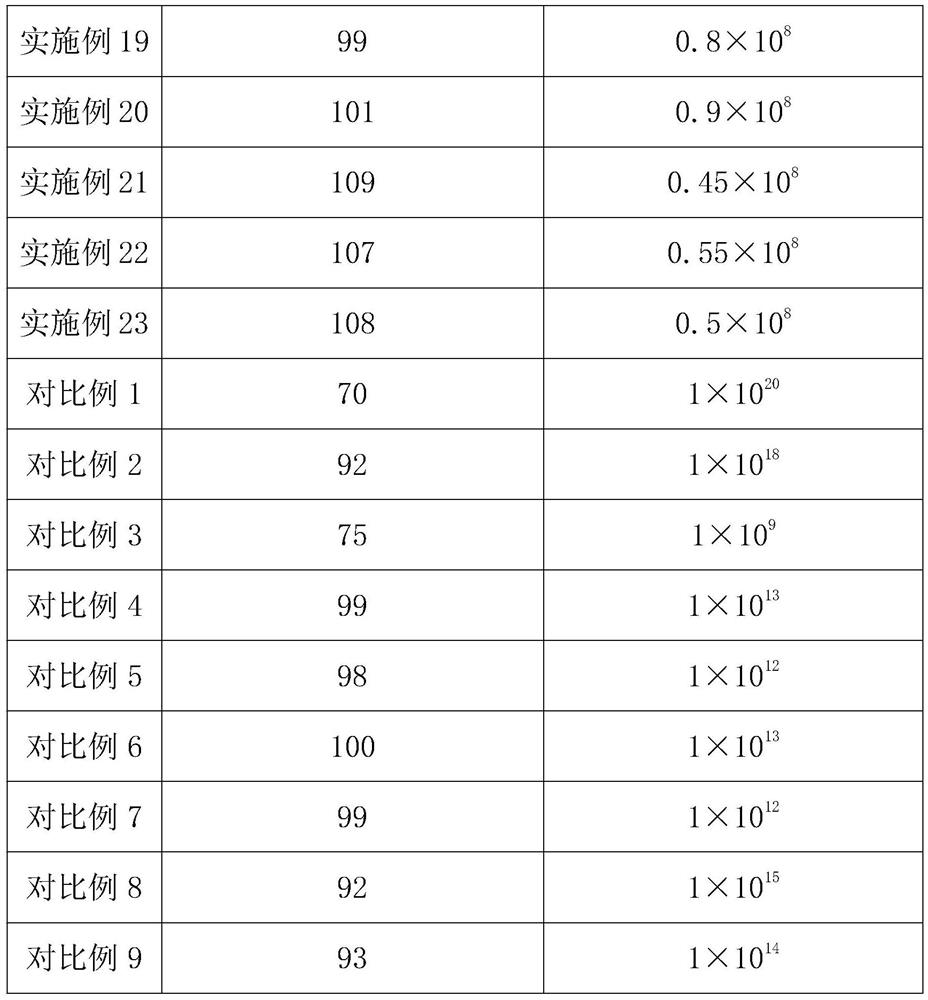

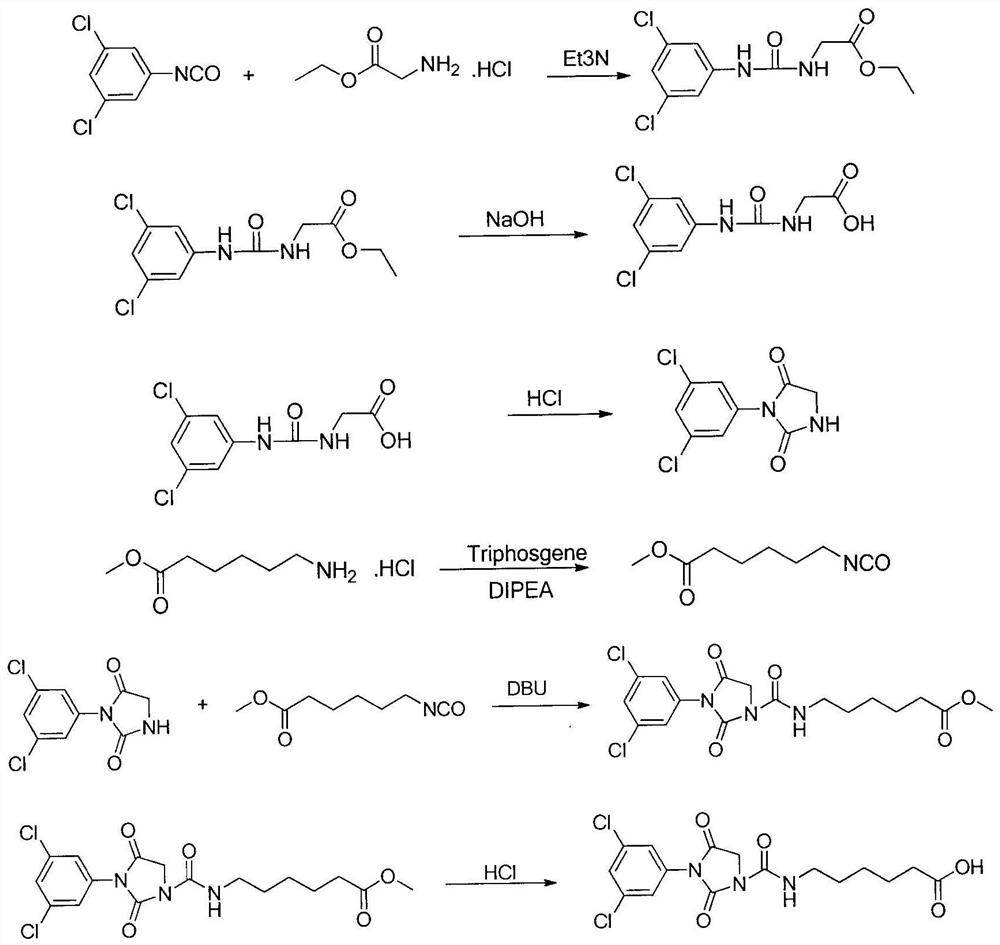

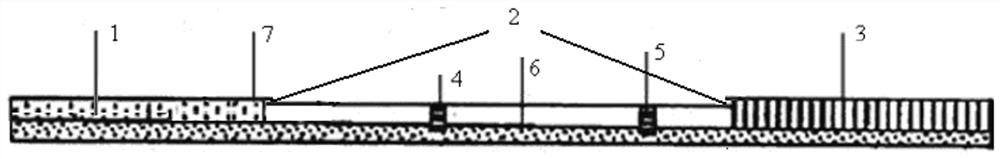

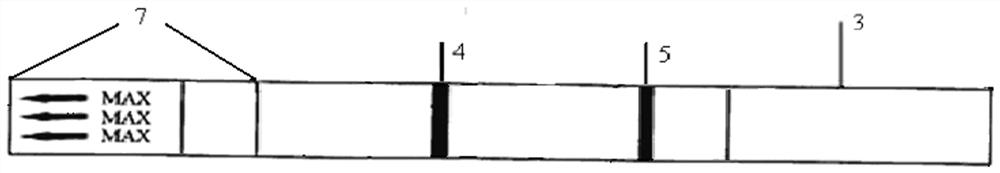

Preparation method and application of a kind of iprodione hapten and antigen

ActiveCN109265401BQuick checkStrong specificityOvalbuminSerum albuminImidazolidineMonoclonal antibody agent

A preparation method and application of an iprodione hapten and an antigen. The iprodione hapten is produced by reacting 3,5-dichlorophenylisocyanate and glycine ethyl ester hydrochloride to produce hydrolysis, and then undergoes a cyclization reaction to obtain 3- (3,5‑dichlorophenyl)‑2,4‑imidazolidinedione, reacted with 6‑isocyanatocaproic acid methyl ester obtained by reaction of 6‑aminocaproic acid methyl ester hydrochloride with triphosgene Generate 6‑(3‑(3,5‑dichlorophenyl)‑2,4‑dioximidazolidinyl‑1‑carboxamido) methyl hexanoate, which is finally obtained by hydrolysis under acidic conditions; iprodione antigen It is obtained by coupling iprodione hapten with carrier protein. The antigen prepared by the invention presents specific iprodione epitope, which makes it possible to screen highly specific iprodione monoclonal antibody. The antibody produced has high specificity and high sensitivity, and can be used for enzyme-linked immunosorbent assay and rapid assay with test paper.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

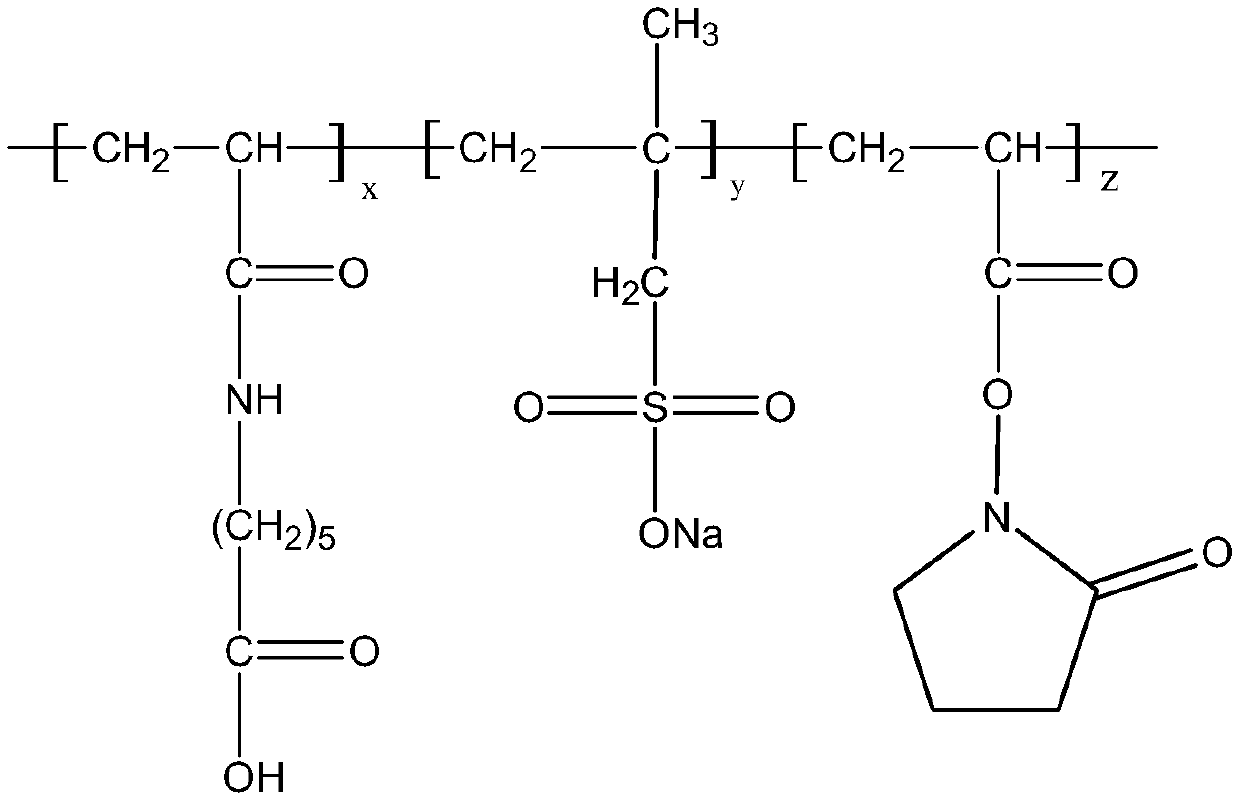

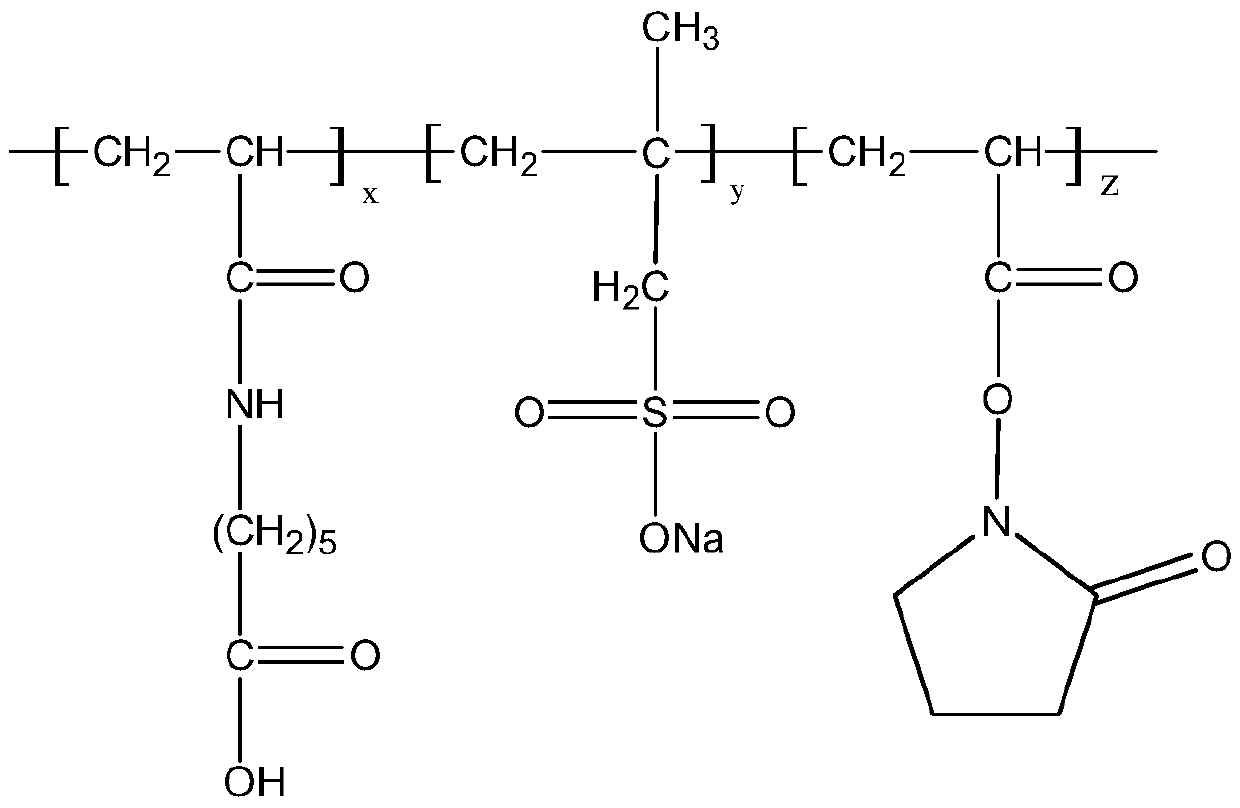

A kind of high temperature resistant foaming agent and preparation method thereof

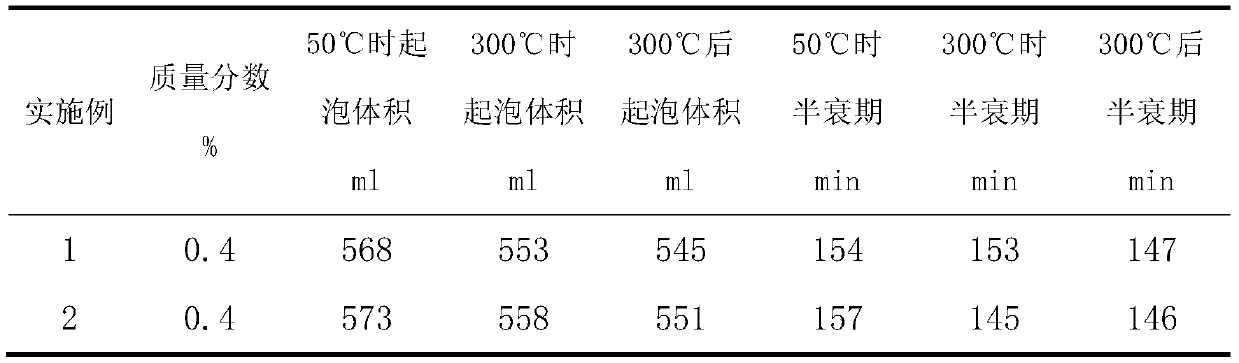

The invention provides to a high temperature resistant forming agent and a preparation method thereof, which relate to the technical field of tertiary oil recovery of an oil field. The high temperature resistant forming agent is generated through the copolymerization of 6-acrylamicarboxylic acid, sodium methallyl sulfonate and 1-acryl oxide-2-pyrrolidone. The preparation method of the high temperature resistant forming agent includes the following steps: adding the sodium methallyl sulfonate and an initiator persulfate into a flask, performing magnetic stirring, and mixing the 6-acrylamicarboxylic acid and the 1-acryl oxide-2-pyrrolidone and adding a liquid dripping pump; after the temperature rises to 30 DEG C; injecting the 6-acrylamicarboxylic acid and 1-acryl oxide-2-pyrrolidone mixture into the flask, rising the temperature to 70 DEG C, after heat preservation, and adding a quinone polymerization inhibitor and then stopping the polymerization reaction, and after the reaction is stopped for 20-60 min, cooling to room temperature, and obtaining the high temperature resistant forming agent after separation and purification. According to the invention, the oil field recovery rateis improved under the environment of hot water, steam and high temperature flue gases.

Owner:XIAMEN UNIV

Composite bone implant material and method of making thereof

ActiveUS10967099B2Provide certain mechanical strengthReduce regularityTissue regenerationCoatingsAminocapronsäureMedicine

The present invention relates to the controllable degradation, filling-type complex bone implant of multivariant amino acid polymer-organic calcium / phosphorus salts, as well as to the preparative method thereof. The complex bone implant is consisted of multivariant amino acid polymers and medically acceptable organic calcium / phosphorus salts, while the content of organic calcium / phosphorus salts is 20-90% based on the total mass of composite material; the multivariant amino acid polymer is polymerized by ε-aminocaproic acid and at least two other amino acids, in which the molar content of ε-aminocaproic acid is at least 50% of the total molar quantity of amino acid polymers, while the amounts of other amino acids are at least 0.5% of the total molar quantity of amino acid polymers.

Owner:SICHUAN GUONA TECH

Reusable nylon material for engineering machinery

InactiveCN110698668AImprove mechanical propertiesImprove flame retardant performanceAminocapronsäureNylon material

The invention relates to the field of engineering machinery, in particular to a reusable nylon material for engineering machinery. The reusable nylon material comprises the following raw materials inparts by weight: 100 parts of caprolactam, 8 to 12 parts of 6-aminocaproic acid, 0.5 to 2 parts of 2,3,3,4'-biphenyl tetracarboxylic dianhydride and 0.05 to 0.5 part of nanometer mica powder. According to the invention, the defects of poor flame retardancy and poor reusability of nylon materials on the market at present are overcome. The nylon material is modified by adding the 2,3,3,4'-biphenyl tetracarboxylic dianhydride and the nanometer mica powder, and the obtained modified nylon material has good flame retardancy and reusability on the basis of maintaining good mechanical properties.

Owner:徐州兰贵机械科技有限公司

Process for continuous purification of crude epsi-caprolactam

The invention relates to a process for the purification of crude epsilon -caprolactam, wherein crude epsilon -caprolactam prepared by cyclization of alkyl 6-aminocaproate, 6-aminocapronitrile, 6-aminocaproic acid, 6 aminocaproic amide and / or oligomers thereof, is subjected to a crystallization process.

Owner:INVISTA TECHNOLOG IES S A R L +1

Preparation method of 6-aminocaproic acid

PendingCN114478283AEasy to operateReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationAminocapronsäureOrganic acid

The invention relates to the field of organic synthesis, in particular to a preparation method of 6-aminocaproic acid. The method comprises the following steps: hydrolyzing caprolactam by using potassium salt as alkali to obtain 6-aminocaproic acid potassium salt, acidifying by using organic acid to obtain 6-aminocaproic acid and organic potassium salt, and finally recrystallizing by using the solubility difference of the organic potassium salt and 6-aminocaproic acid in an alcohol solvent to obtain high-purity, high-content and high-stability 6-aminocaproic acid. The preparation method does not need special equipment, is simple to operate, reduces the production cost, and is easy for industrial production.

Owner:ZHUHAI UNITED LAB

Preparation method of 6-aminocaproic acid

PendingCN114195663ALow costHigh purityOrganic compound preparationAmino-carboxyl compound preparationAminocapronsäureDepolymerization

The invention relates to a 6-aminocaproic acid preparation method, which comprises: S1, carrying out first dehydration on caprolactam waste liquid, and carrying out high temperature polymerization to obtain a polymer; adding an acid solution into the polymer, and carrying out reflux depolymerization to obtain a first product; s2, dehydrating the first product under reduced pressure, and adding the dehydrated first product into an alcohol solvent for dissolving to obtain a second product; performing first filtration on the second product to obtain first filtrate; and S3, adding organic amine or introducing ammonia gas into the first filtrate, adjusting the pH value of the first filtrate to 7-8, and carrying out second filtration to obtain crude 6-aminocaproic acid. According to the method disclosed by the invention, the cost of directly treating the caprolactam waste liquid as wastewater is saved, effective substances in the caprolactam waste liquid can be extracted, and aminocaproic acid is synthesized.

Owner:昌德新材科技股份有限公司

A kind of method that takes caprolactam as raw material to synthesize hexamethylene diamine

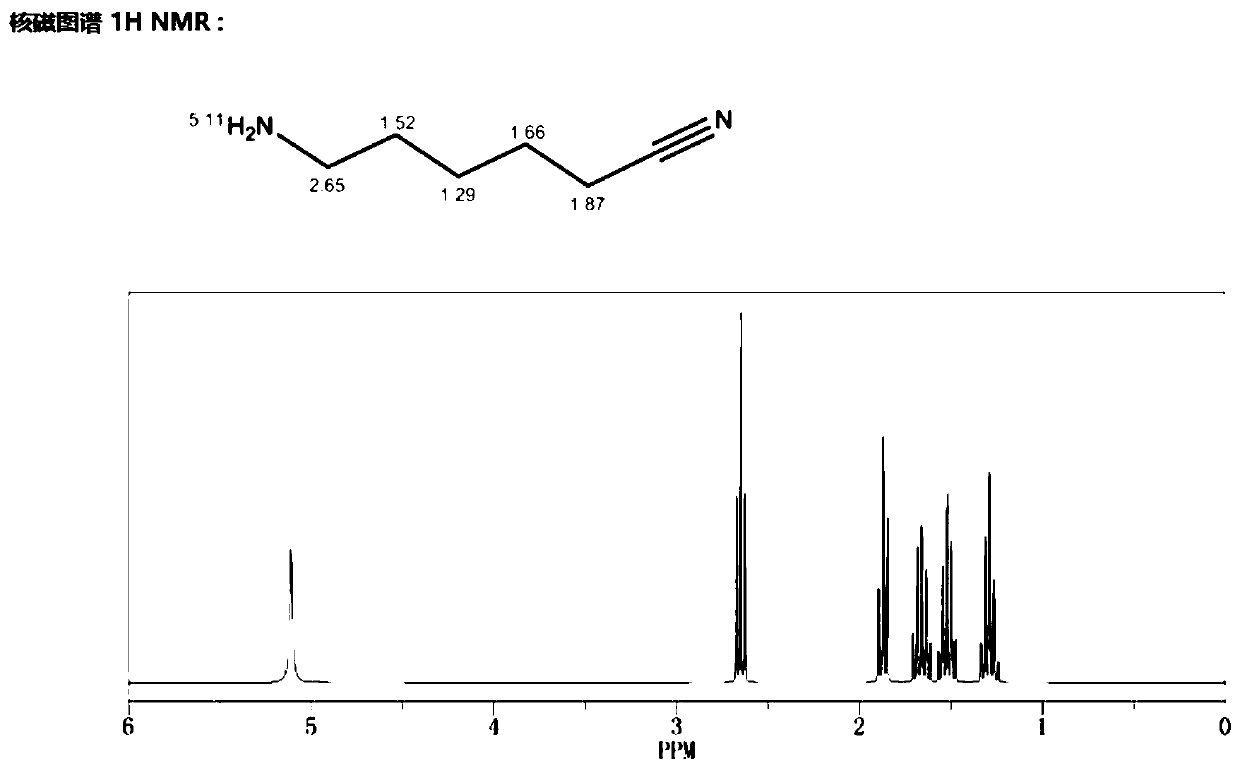

ActiveCN110423201BMild reaction conditionsEasy post-processingOrganic compound preparationCarboxylic acid amides preparationAminocapronsäurePolymer science

The invention discloses a method for synthesizing hexamethylenediamine using caprolactam as a raw material, comprising the following steps: 1) after mixing caprolactam, alkali and water, heating and refluxing to obtain 6-aminocaproate; 6-aminocaproic acid salt introduces amino protecting group to protect terminal amino group, then adds acid and neutralizes to generate aminocaproic acid with amino protecting group; 3) after drying the product obtained in step 2), add dehydration catalyst for amide And heating reaction in the presence of ammonia source converts carboxylic acid group into cyano group to obtain product nitrile; 4) The product nitrile obtained in step 3) is extracted and purified, catalytically hydrogenated to generate corresponding amine, and then the protective group is removed to obtain target product.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com