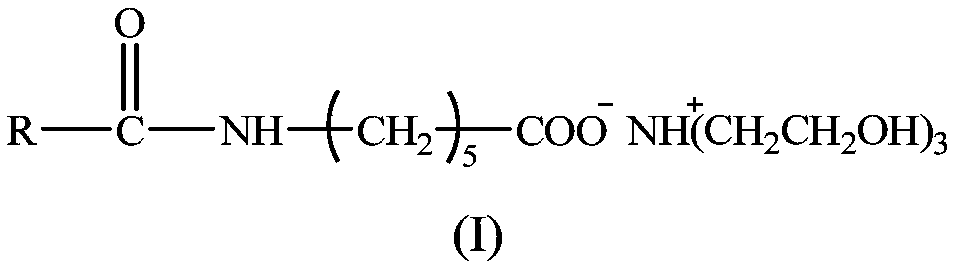

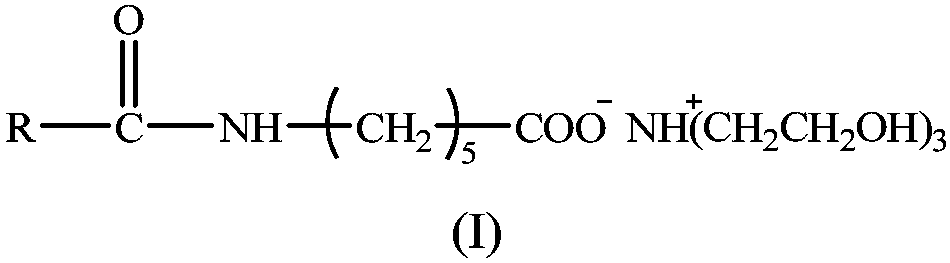

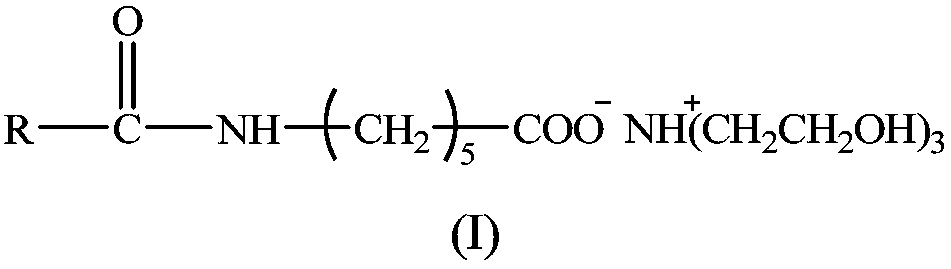

Water-soluble antirust agent as well as preparation method and application thereof

A rust inhibitor and water-soluble technology, applied in the field of water-soluble N-fatty acylaminocaproic acid triethanolamine salt and its preparation, can solve the problems of rust prevention performance evaluation and the like, and achieve good rust prevention performance, easy availability of raw materials, and reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Take 1 mol of caprolactam, 2.5 mol of sodium hydroxide, and 30 mol of water, mix evenly, stir and reflux until the caprolactam is completely hydrolyzed. The temperature of the system was lowered to 0° C., and 0.9 mol of isononanoyl chloride was slowly added dropwise therein, and the temperature of the system was controlled at 0° C. during the whole dropping process. After the addition of isononanoyl chloride was completed, the temperature was raised to 90°C for 4 hours. Cool down to room temperature, add hydrochloric acid to acidify to pH 2. The upper oil layer of the reaction solution was separated, and washed with hot distilled water until the chloride ion concentration was lower than 200ppm to obtain N-isononanoylaminocaproic acid. React it with triethanolamine at a molar ratio of 1:2 for 4 hours, and cool to room temperature to obtain a water-soluble N-isononanoylaminocaproic acid triethanolamine salt rust inhibitor.

[0062] The above-mentioned N-isononanoylamino...

Embodiment 2

[0068] Take 1 mol of caprolactam, 1 mol of sodium hydroxide, and 10 mol of water, mix evenly, stir and reflux until the caprolactam is completely hydrolyzed. The temperature of the system was lowered to -5°C, and 0.6 mol of isooctanoyl chloride was slowly added dropwise thereto, and the temperature of the system was controlled at -5°C during the entire dropping process. After the addition of isooctanoyl chloride was completed, the temperature was raised to 60° C. for 2 h. Cool down to room temperature, add hydrochloric acid to acidify to pH 1. The upper oil layer of the reaction solution was separated, and washed with hot distilled water until the chloride ion concentration was lower than 200ppm to obtain N-isooctanoylaminocaproic acid. React it with triethanolamine at a molar ratio of 1:1 for 4 hours, and cool to room temperature to obtain a water-soluble N-isooctanoylaminocaproic acid triethanolamine salt rust inhibitor.

[0069] The above-mentioned N-isooctanoylaminocapro...

Embodiment 3

[0075] Take 1 mol of caprolactam, 4 mol of sodium hydroxide, and 40 mol of water, mix evenly, stir and reflux until the caprolactam is completely hydrolyzed. The temperature of the system was lowered to 5°C, and 1.2 mol of decanoyl chloride was slowly added dropwise therein, and the temperature of the system was controlled at 5°C during the whole dropping process. After the addition of decanoyl chloride was completed, the temperature was raised to 100°C for 6 hours. Cool down to room temperature, add hydrochloric acid to acidify to pH 3. The upper oil layer of the reaction solution was separated, and washed with hot distilled water until the chloride ion concentration was lower than 200ppm to obtain N-decanoylaminocaproic acid. React it with triethanolamine at a molar ratio of 1:3 for 4 hours, and cool to room temperature to obtain a water-soluble N-decanoylaminocaproic acid triethanolamine salt rust inhibitor.

[0076] The above-mentioned N-decanoylaminocaproic acid trietha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com