Reusable nylon material for engineering machinery

A technology of construction machinery and nylon, which is applied in the field of construction machinery nylon materials, can solve the problems of poor flame retardancy, poor reusability, and poor dimensional stability, and achieve the effects of increasing mechanical properties, good flame retardancy and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

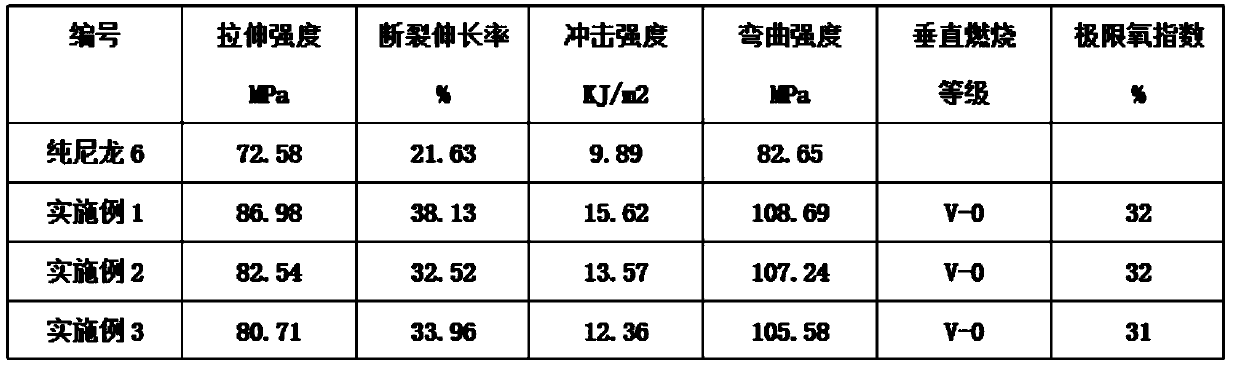

Examples

Embodiment 1

[0020] A kind of reusable engineering machinery nylon material, its raw material is made up of the following components by weight:

[0021] 100 parts of caprolactam, 10 parts of 6-aminocaproic acid, 1 part of 2,3,3',4'-biphenyltetracarboxylic dianhydride, 0.25 parts of nano mica powder.

[0022] Wherein, the preparation method of the above-mentioned reusable engineering machinery nylon material is as follows:

[0023] S1. Weigh caprolactam and 6-aminocaproic acid according to the amount and add them to the flask after vacuum drying, and pass through helium gas to remove the air, raise the temperature to 100°C under the protection of helium gas, and stir for 20 minutes to obtain the mixture A ; Wherein, the mass ratio of caprolactam to 6-aminocaproic acid is 100:10;

[0024] S2. Add 2,3,3',4'-biphenyltetracarboxylic dianhydride to the mixture A and stir evenly, raise the temperature by 10°C every 10min, stop the temperature rise when the temperature reaches 200°C and keep stir...

Embodiment 2

[0028] A kind of reusable engineering machinery nylon material, its raw material is made up of the following components by weight:

[0029] 100 parts of caprolactam, 8-12 parts of 6-aminocaproic acid, 0.5 parts of 2,3,3',4'-biphenyltetracarboxylic dianhydride, and 0.05 parts of nano mica powder.

[0030] Wherein, the preparation method of the above-mentioned reusable engineering machinery nylon material is as follows:

[0031] S1. Weigh caprolactam and 6-aminocaproic acid according to the amount and add them to the flask after vacuum drying, and pass through helium gas to remove the air, raise the temperature to 100°C under the protection of helium gas, and stir for 20 minutes to obtain the mixture A ; Wherein, the mass ratio of caprolactam to 6-aminocaproic acid is 100:8;

[0032] S2. Add 2,3,3',4'-biphenyltetracarboxylic dianhydride to the mixture A and stir evenly, raise the temperature by 10°C every 10min, stop the temperature rise when the temperature reaches 200°C and k...

Embodiment 3

[0036] A kind of reusable engineering machinery nylon material, its raw material is made up of the following components by weight:

[0037] 100 parts of caprolactam, 12 parts of 6-aminocaproic acid, 2 parts of 2,3,3',4'-biphenyltetracarboxylic dianhydride, 0.5 parts of nano mica powder.

[0038] Wherein, the preparation method of the above-mentioned reusable engineering machinery nylon material is as follows:

[0039] S1. Weigh caprolactam and 6-aminocaproic acid according to the amount and add them to the flask after vacuum drying, and pass through helium gas to remove the air, raise the temperature to 100°C under the protection of helium gas, and stir for 20 minutes to obtain the mixture A ; Wherein, the mass ratio of caprolactam to 6-aminocaproic acid is 100:12;

[0040] S2. Add 2,3,3',4'-biphenyltetracarboxylic dianhydride to the mixture A and stir evenly, raise the temperature by 10°C every 10min, stop the temperature rise when the temperature reaches 200°C and keep stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com