Flame-retardant nylon 6 fiber and preparation method thereof

A flame-retardant nylon and fiber technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyamide rayon, and single-component copolyamide rayon, etc. Problems such as melting and dripping, to achieve the effect of high Young's modulus, high hygroscopicity, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

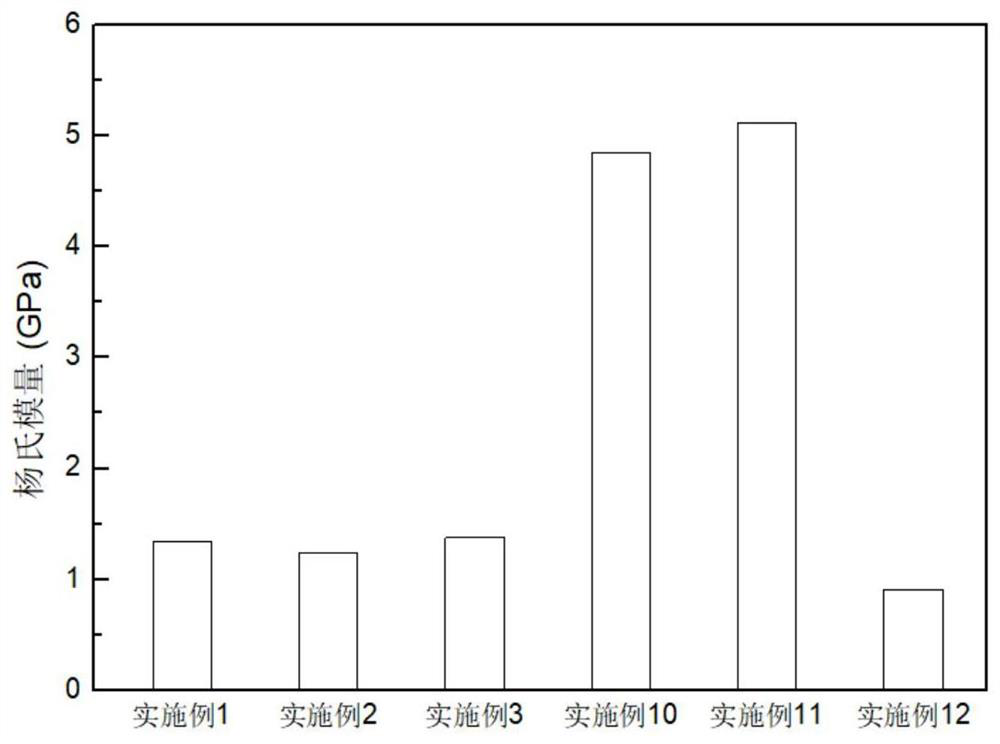

Embodiment 1

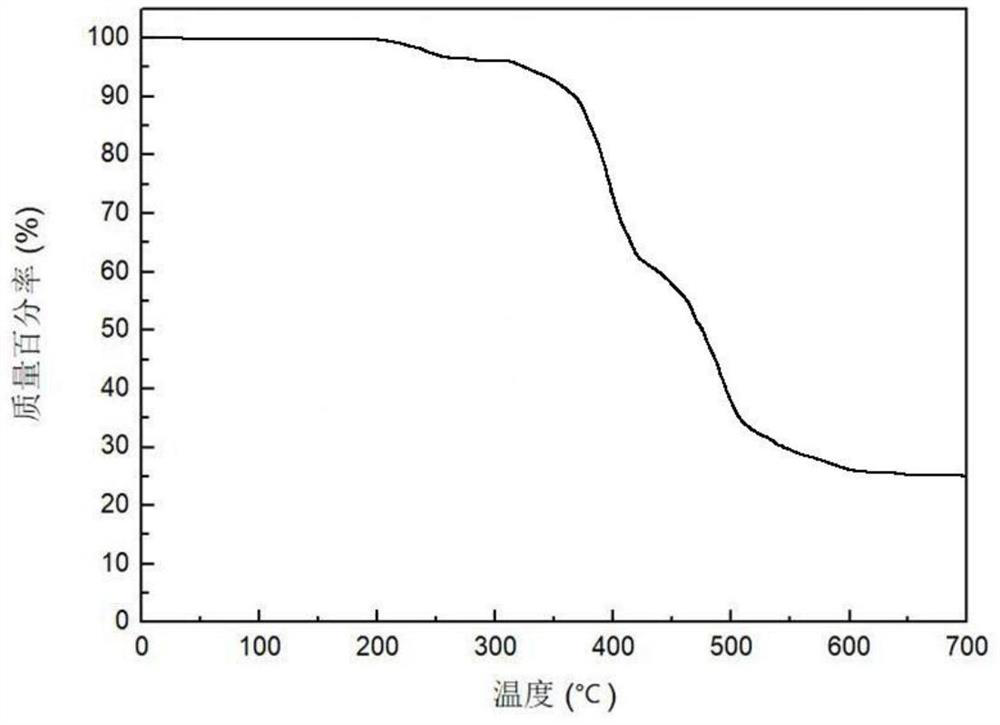

[0064] A preparation method of flame retardant shown in formula I, comprising,

[0065] Add cyanuric chloride and sulfallic acid to petroleum ether at 78°C at the same rate, the dosage ratio of cyanuric chloride, sulfallic acid and petroleum ether is 1mol:3.4mol:150mL, continue to react to the pH value after the dropwise addition Keep the pH at 9 during the reaction, cool, concentrate under reduced pressure, add 8 times the volume of absolute ethanol, filter with suction, wash the filter cake with a methanol / chloroform mixture with a volume ratio of 1:0.8, and dry it to obtain Flame retardant shown in formula I, productive rate is 86.37%.

[0066] Formula I

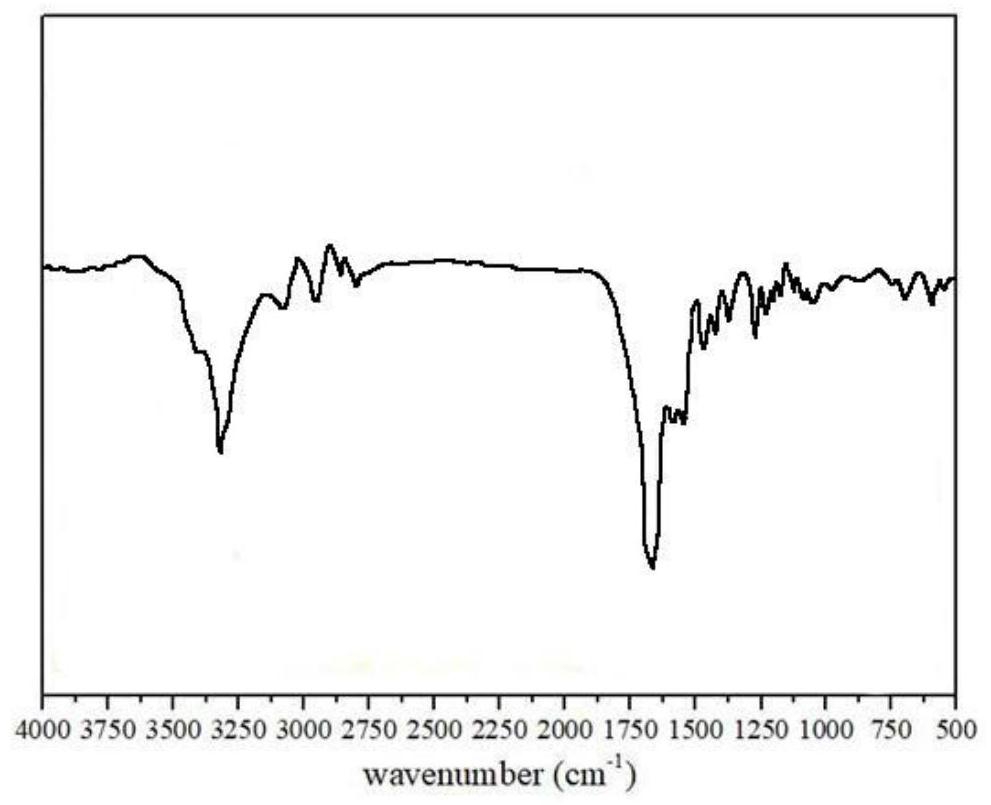

[0067] The flame retardant shown in formula I is characterized by proton nuclear magnetic resonance spectrum, 1 H-NMR (300MHz, DMSO-d 6 ) δ: 11.34(s, 3H, COOH), 7.53-8.49 (s, 9H, Ph-H), 4.18(d, 6H, Ph-CH 2 ), 1.86(s, 3H,S-OH).

[0068] A preparation method of flame-retardant nylon 6 fiber, comprising,

[0069] Ste...

Embodiment 2

[0077] A preparation method of a flame retardant shown in formula I is the same as in Example 1.

[0078] A kind of preparation method of flame-retardant nylon 6 fiber, the difference with embodiment 1 is:

[0079] The dosage ratio of caprolactam, flame retardant shown in formula I, deionized water and 6-aminocaproic acid is 100g:0.6g:7.8g:0.78g.

Embodiment 3

[0081] A preparation method of a flame retardant shown in formula I is the same as in Example 1.

[0082] A kind of preparation method of flame-retardant nylon 6 fiber, the difference with embodiment 1 is:

[0083] The dosage ratio of caprolactam, flame retardant shown in formula I, deionized water and 6-aminocaproic acid is 100g:2.5g:7.8g:0.78g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com