Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Fiber elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

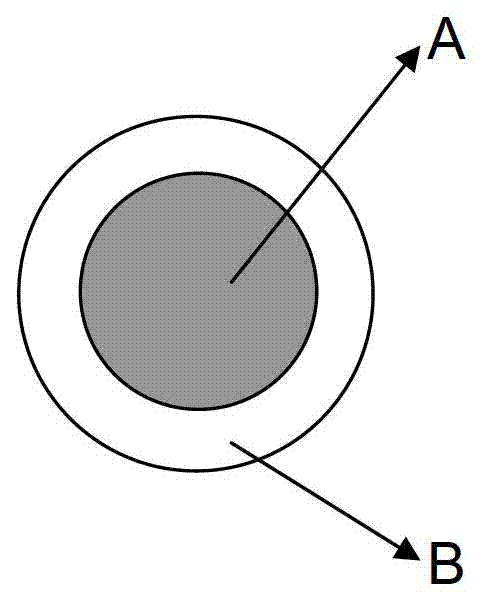

Skin core composite fiber, manufacturing method thereof and fabric

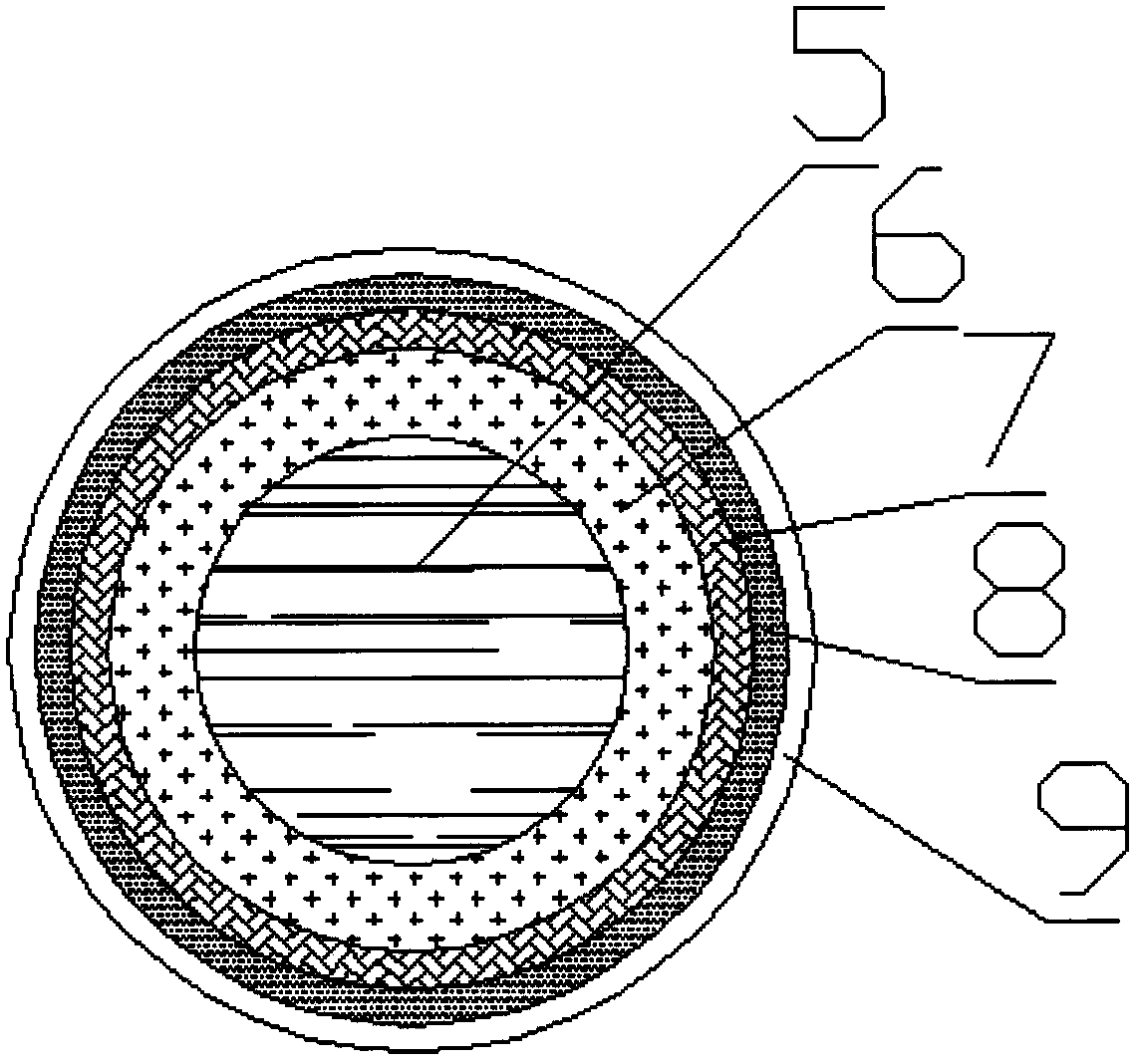

The invention provides a skin core composite fiber, a manufacturing method thereof and a fabric. The skin core composite fiber is formed by composing a skin layer made of polyamide and a core layer made of polyester and satisfies the following properties: (1) 0.6g / d <fiber fracture strength <2.5g / d; (2) 15% <fiber fracture elongation rate <50%; (3) 6g / d <fiber modulus 0-5% (Mod0-5%) <40g / d; wherein Mod0-5% = (strength at fiber elongation 5%) / (0.05).

Owner:SHINKONG SYNTHETIC FIBERS

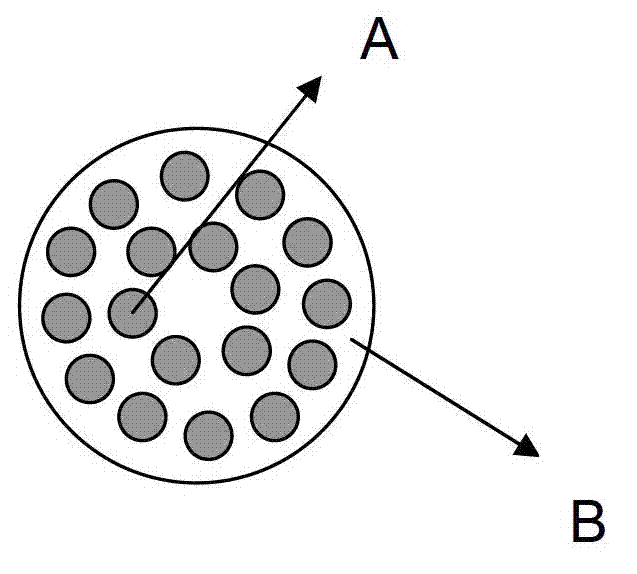

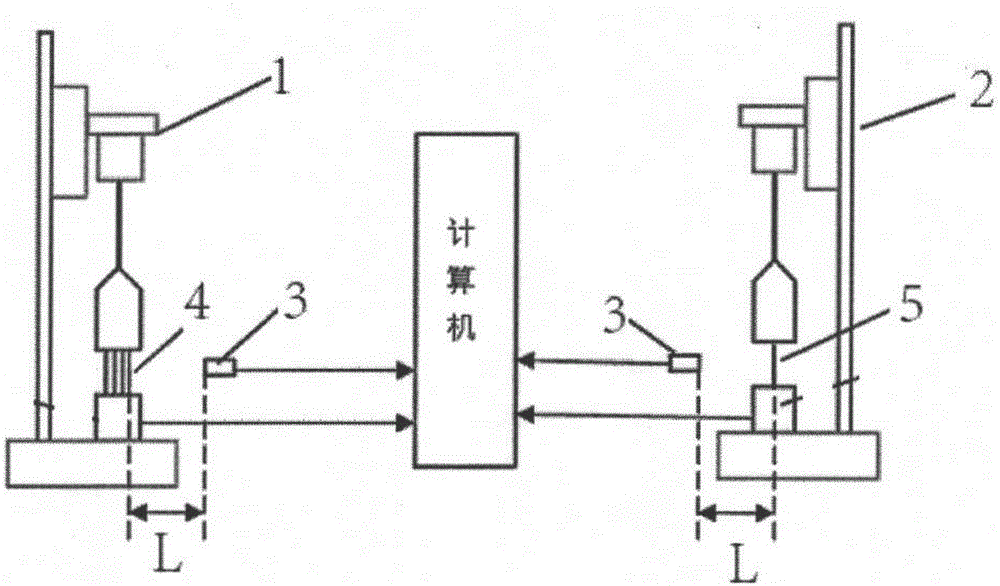

Wood bundle fiber elongation distribution and break strength distribution testing method

InactiveCN106840870AAccurate measurementMaterial strength using tensile/compressive forcesBreaking strengthAcoustic emission

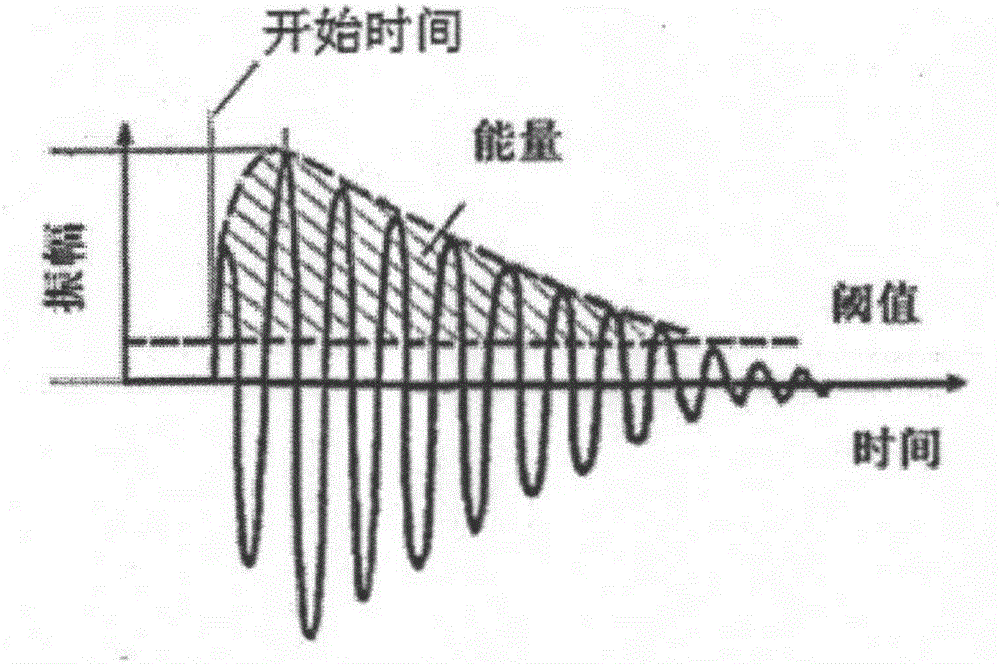

The invention provides a wood bundle fiber elongation distribution and break strength distribution testing method based on the principle of acoustic emission. A bundle fiber strength tester, a single fiber strength tester, a computer with an acoustic card and two microphones of same specification are used, both the bundle fiber strength tester and the single fiber strength tester provide constant speed elongation, the microphones are fixed to the bundle fiber strength tester and the single fiber strength tester and are L mm away from bundle fibers or a single fiber under tension. The method according to the invention has the advantage that elongation distribution and break strength distribution of each single fiber are measured accurately during bundle fiber tensioning based on acoustic emission measurement technique.

Owner:DONGHUA UNIV

Production technique of fibre for high-strength low-extention polypropylene rope

InactiveCN101177823AHigh strengthOvercoming large elongationArtificial filament physical treatmentMelt spinning methodsExtensibilityPolymer science

The invention relates to the production process of the fiber used for high-strength and low-extension polypropylene rope, which is mainly applied in the aspects of preparing high-strength ropes, project reinforcement, etc. The invention is a high-strength and low-extension modified polypropylene fiber, comprising interpolymer modified from polypropylene raw material, the adjusting screw of a twin screw extruding machine, the length-diameter ratio of which is increased, a mixing device added at the plasticizing section of the screw and a high pressure spray; after having been sprayed under high pressure, shockchilling is carried out immediately to enhance the monofilament crystallinity of the fiber; a high-temperature oil bath stretching leads the fiber molecular chain to be extended in symmetrical arrangement; a high-temperature steam stretching leads the polypropylene fiber molecular chain to be stretched fully and arranged evenly with high-strength and low-extension; the synnema of a multifilament twisting is encircled as the product fiber. The total denier of the gained high-strength and low-extension polypropylene twisting fiber of the invention is of 5000 deniers to 30000 deniers differently, the fiber strength is 8g / denier to 15 g / denier, and the fiber extensibility is 5% to 8%.

Owner:NINGBO DACHENG ADVANCED MATERIAL

Method for producing Nano fire resistant and fire retardant fiber

InactiveCN1540047AControl the rate of volatilization formationPlay the role of shielding the flameFlame-proof filament manufactureRefractoryLimiting oxygen index

A fire-retarding refractory nano fibre is prepared through preparing nano additive from SiO2 and Al2O3, mixing it with cellulose, preparing spinning dope, and spinning. Its advantages are high strength and elongation, low moisture regain, and high refractory effect (1300 deg.C).

Owner:冷纯廷

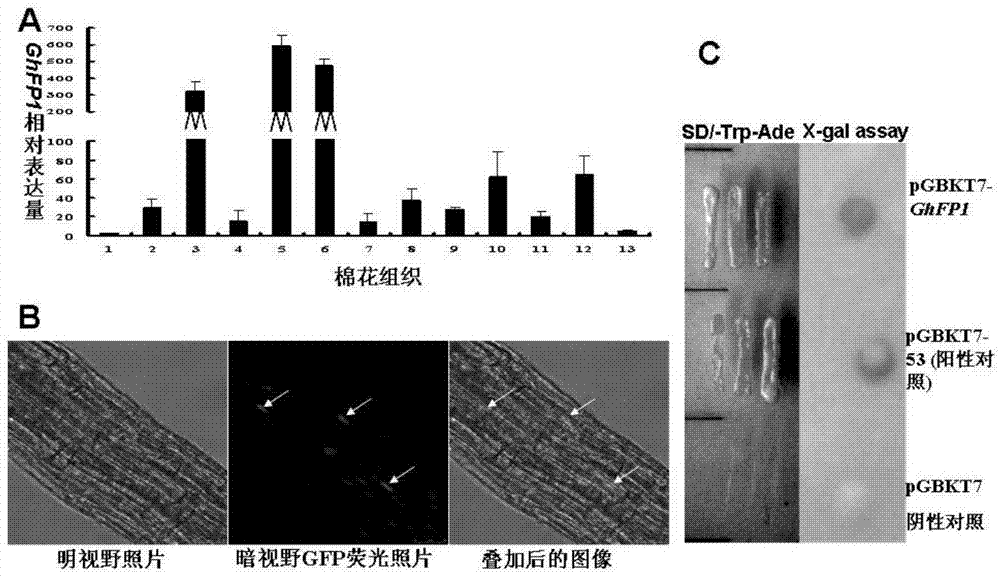

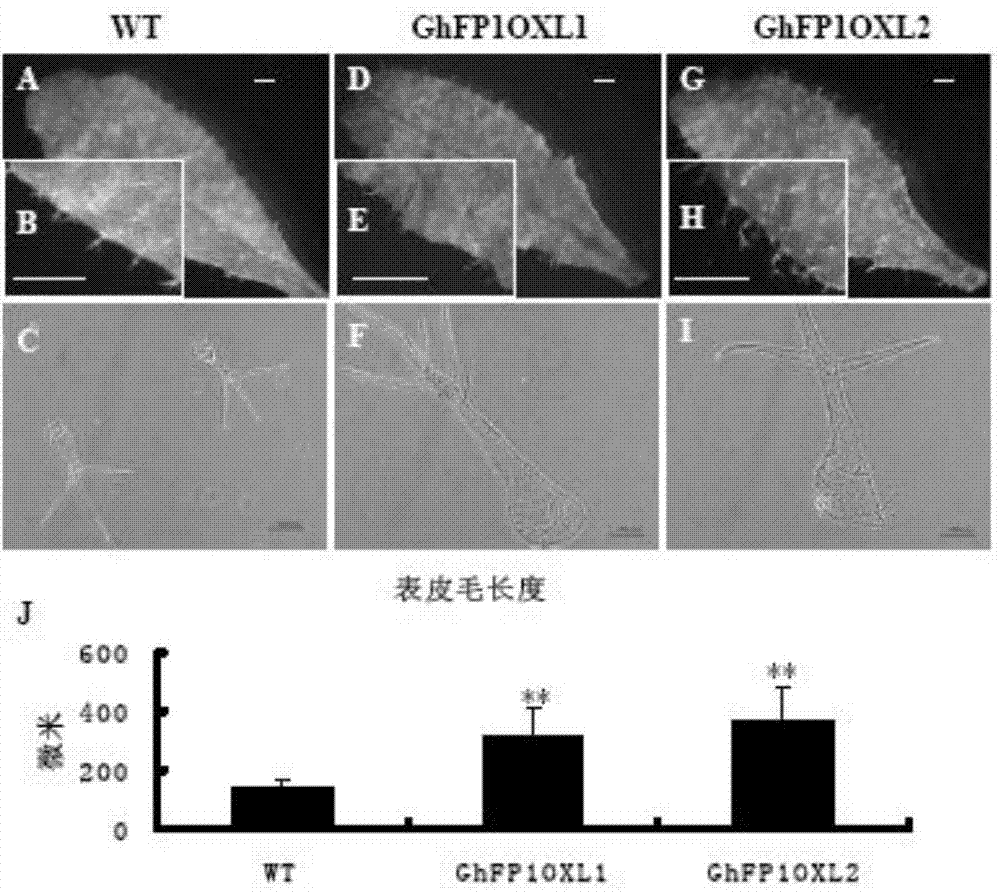

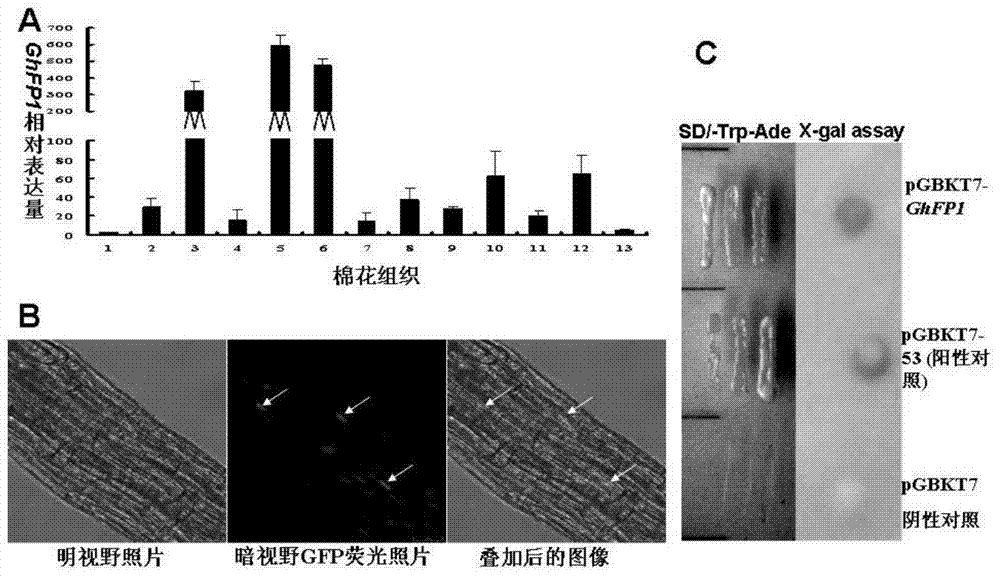

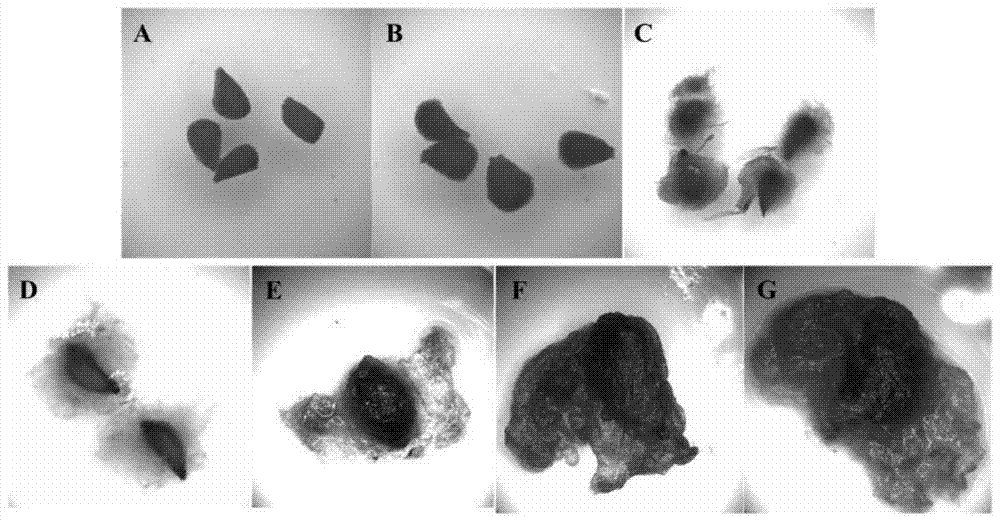

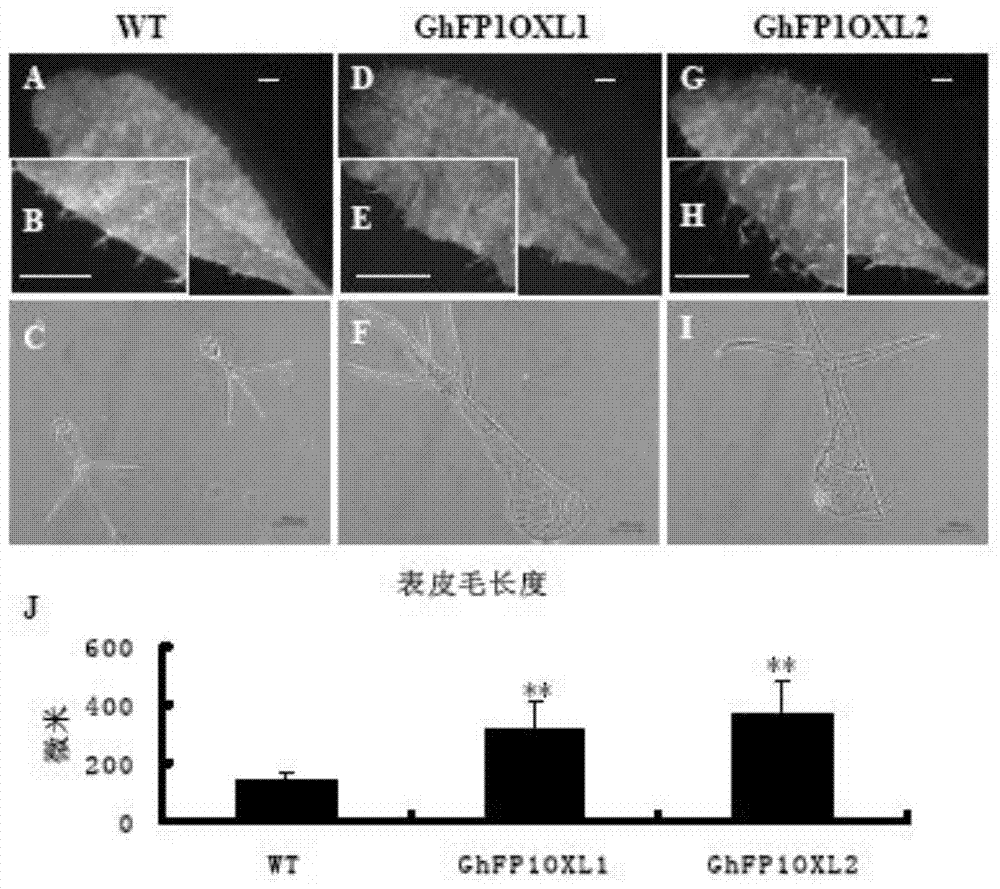

Identification and application of cotton bHLH transcription factor gene GhFP1 and promoter thereof

ActiveCN104711266AHigh specific expression activityHigh elongationMicrobiological testing/measurementPlant peptidesAgricultural sciencePromoter activity

The invention relates to a cotton GhFP1 gene which belongs to a member of a bHLH transcription factor gene family, the cDNA (complementary deoxyribonucleic acid) full length is 1262bp, and the cotton GhFP1 gene can code a bHLH protein containing 355 amino acids. GhFP1 is respectively expressed in various tissues of cotton, and is highly expressed in the fiber development premetaphase. The GhFP1 promoter segment with the length of 1061bp is separated and cloned. The analysis on the activity of the promoter by using the GUS report gene indicates that the promoter has higher specific expression activity in cotton fibers. The experiment indicates that the overexpression of GhFP1 in Arabidopsis thaliana results in increase of leaf epidermal hair; and the overexpression of GhFP1 in cotton results in enhancement of expression of related genes of cotton fibrocyte brassinolide and increase of ripe cotton fiber length. The result proves that the GhFP1 protein performs positive regulating actions and promotes elongation of fibrocytes in the cotton fiber elongation process, and thus, possibly has important application value in improving the cotton fiber quality and increasing the cotton yield.

Owner:HUAZHONG NORMAL UNIV

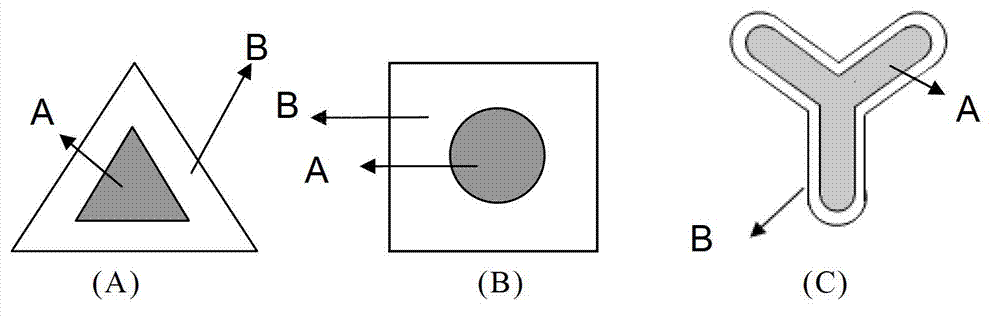

Elastic composite fiber and preparation method thereof

PendingCN111206300AGood water absorption and quick drying performanceSoft touchFilament/thread formingConjugated synthetic polymer artificial filamentsFiberBreaking strength

The invention discloses an elastic composite fiber. The elastic composite fiber has a parallel composite structure in the cross section, which is compounded after separately extruding water-absorbingmodified PET and PTT at a mass ratio of 48 to 52 to 52 to 48. The elastic composite fiber disclosed by the invention has an excellent water absorption and quick drying performance and a soft touch; the groove formed between the two components along the fiber elongation direction makes the parallel composite fiber have good moisture conductivity and quick drying performance; the breaking strength is greater than or equal to 2.8cN / dtex, and the elongation at break is 24% to 30%; the composite elastic fiber has a high degree of curling and fluffiness similar to wool, which is suitable for the application of close-fitting clothing, and expands the use of the elastic composite fiber; and the shrinkage rate is 40% to 45%. The elastic elongation of the fabric is greater than or equal to 25%, theelastic recovery rate is greater than or equal to 98%, the water absorption is that the dripping diffusion time is less than 1s, the diffusive residual moisture rate is 10%, and the required time is less than or equal to 50min.

Owner:厦门翔鹭化纤股份有限公司

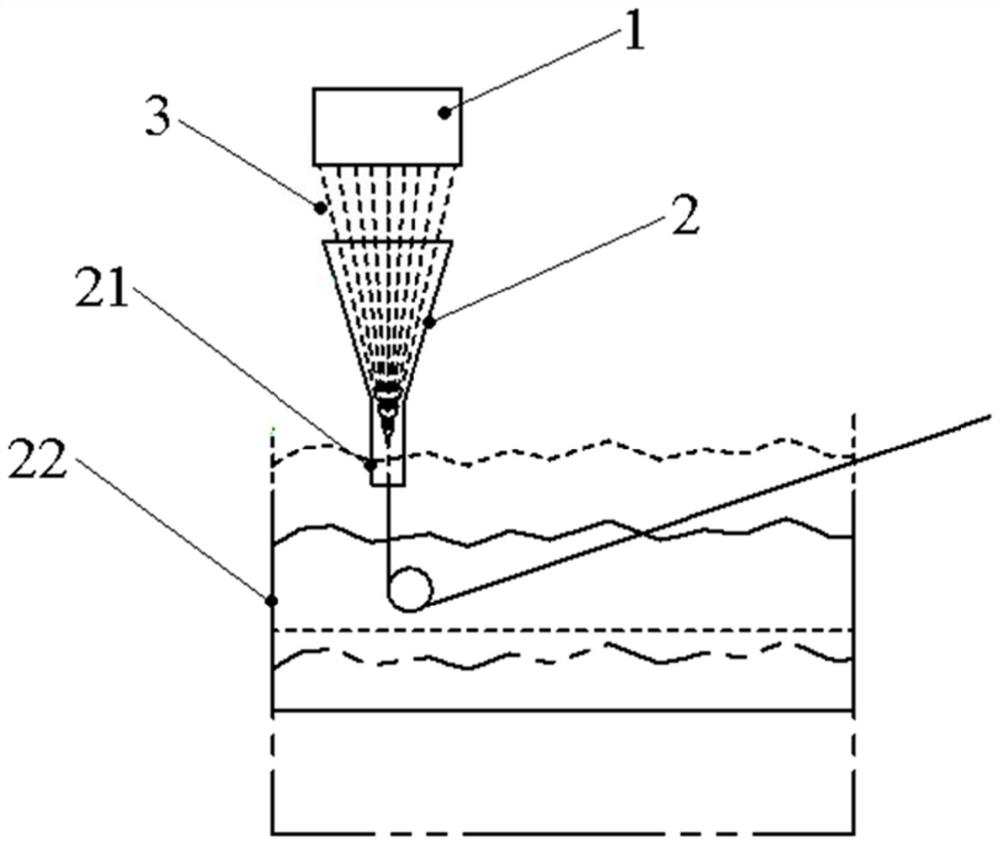

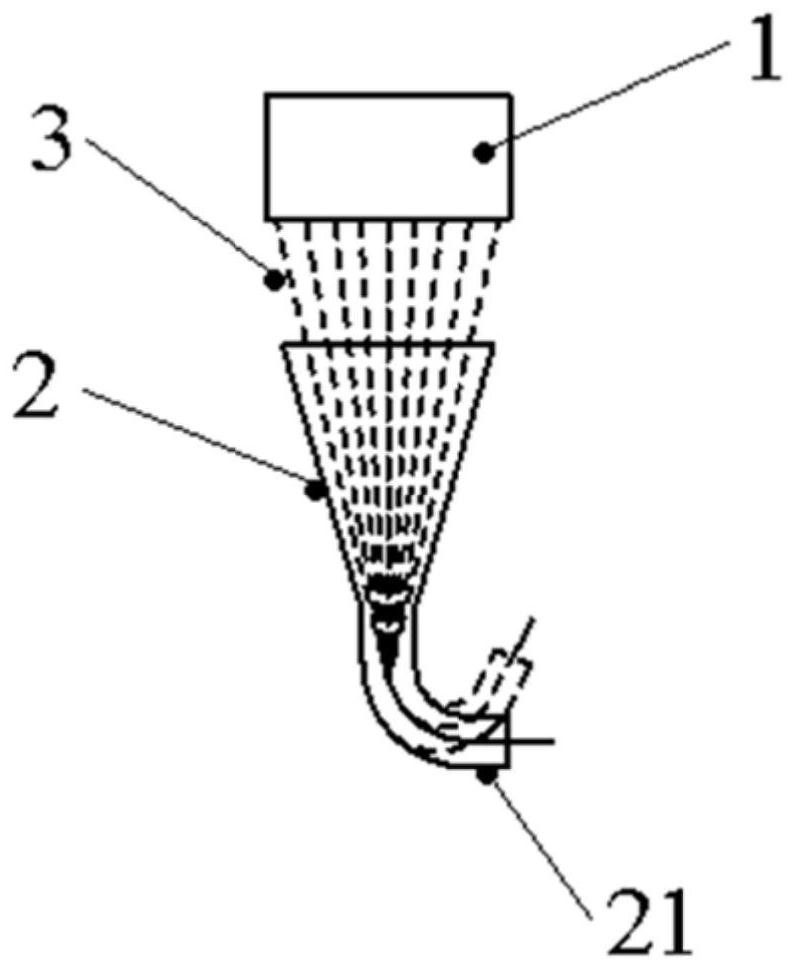

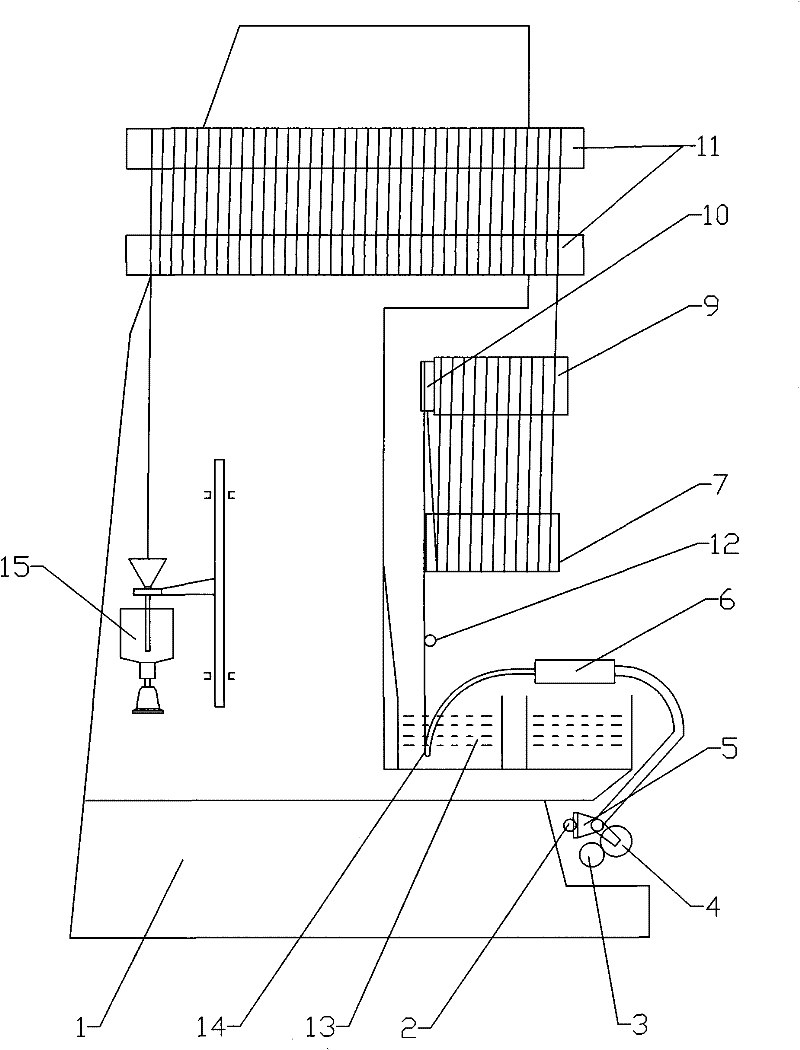

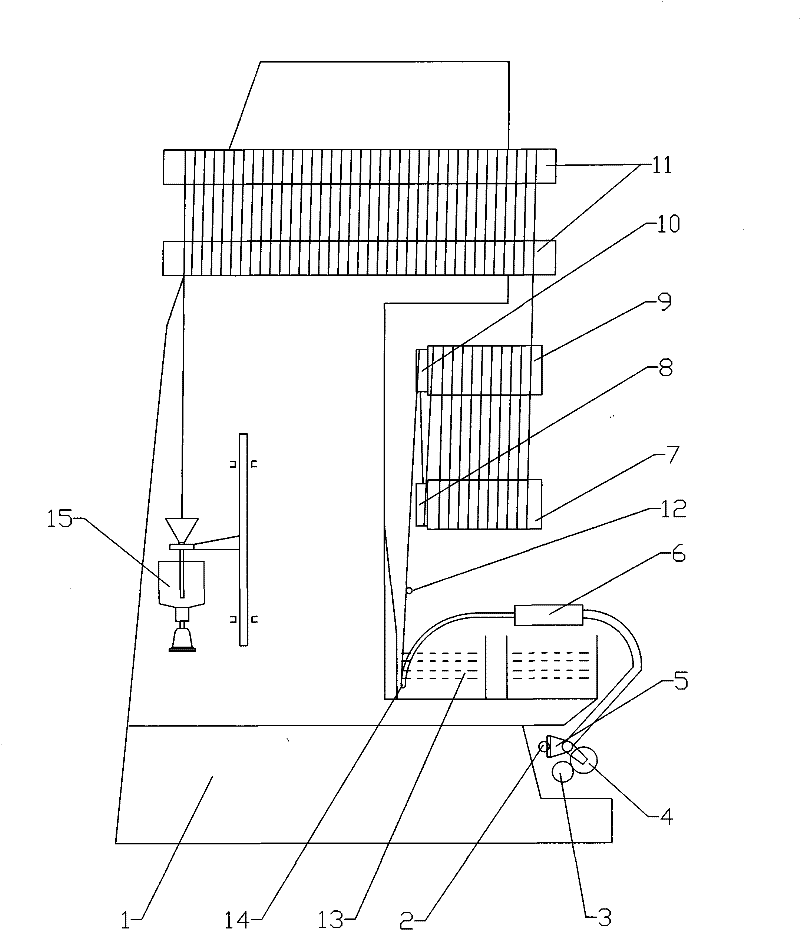

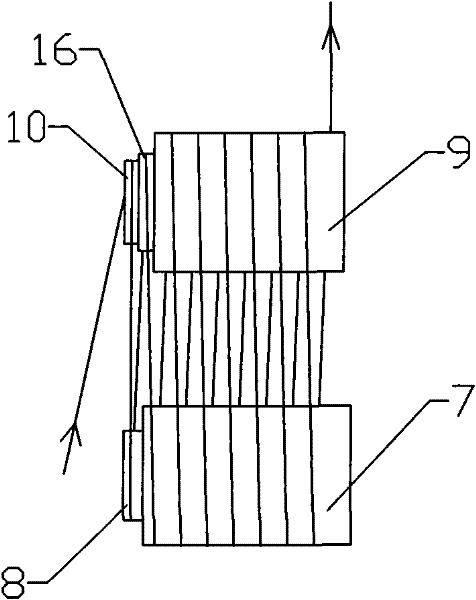

Viscose filament yarn semi-continuous spinning machine and spinning process thereof

ActiveCN101824663AAvoid damageLow elongationNew-spun product collectionArtificial thread manufacturing machinesEngineeringUltimate tensile strength

The invention relates to a viscose filament yarn semi-continuous spinning machine and a spinning process thereof. The viscose filament yarn semi-continuous spinning machine comprises a frame. A glue spray device, a lower solidifying roller and an upper solidifying roller are arranged on the frame. An upper drafting disc is coaxially arranged at the end part of the upper solidifying roller and a lower drafting disc is coaxially arranged on the lower solidifying roller. Since the upper drafting disc and the lower drafting disc are arranged for drafting nascent filaments to break down a large draft multiple into a plurality of small draft multiples for times of drafting, the invention has the advantages that the one-step large-multiple drafting is avoided, the situation that the fiber elongation is reduced because the filaments are damaged is avoided, viscose filament yarns with high strength and elongation which satisfies process requirements can be spun, the strength of the viscose filament yarns can reach above 2.5CN / dtex and the viscose filament yarns can be used as both the warps and the wefts of fabrics.

Owner:潍坊欣龙生物材料有限公司

Process for producing bamboo charcoal polypropylene composite fibers

InactiveCN103014896AWith adsorptionAdsorptiveMonocomponent polyolefin artificial filamentArtifical filament manufacturePolypropylene compositesExtensibility

The invention discloses a process for producing bamboo charcoal polypropylene composite fibers. The process comprises the steps of mixing bamboo charcoal micro-powder with polypropylene slices to ensure that the bamboo charcoal micro-powder is uniformly dispersed in the polypropylene slices; extruding the mixture by using a twin-screw extruder to obtain bamboo charcoal master batches; mixing the bamboo charcoal master batches with polypropylene slices; heating and drying the mixture under the protection of an inert gas; spinning the mixture through a melt spinning machine; and applying oil, and molding by coiling, thus obtaining the bamboo charcoal polypropylene composite fibers. Therefore, by adopting the process for producing the bamboo charcoal polypropylene composite fibers, the prepared fibers has high extensibility, small difference of wet strength and dry strength, high strength, good shaping stability and capability of improving the durability of a fabric; the fabric has high sunlight resistance and high fluffiness, and the added bamboo charcoal has the functional characteristics of adsorbability, antibiosis and the like, so that the process is simple for preparation, reduces the production cost, and is suitable for large-scale batch industrialized production.

Owner:WUJIANG CHAOWEI TEXTILE

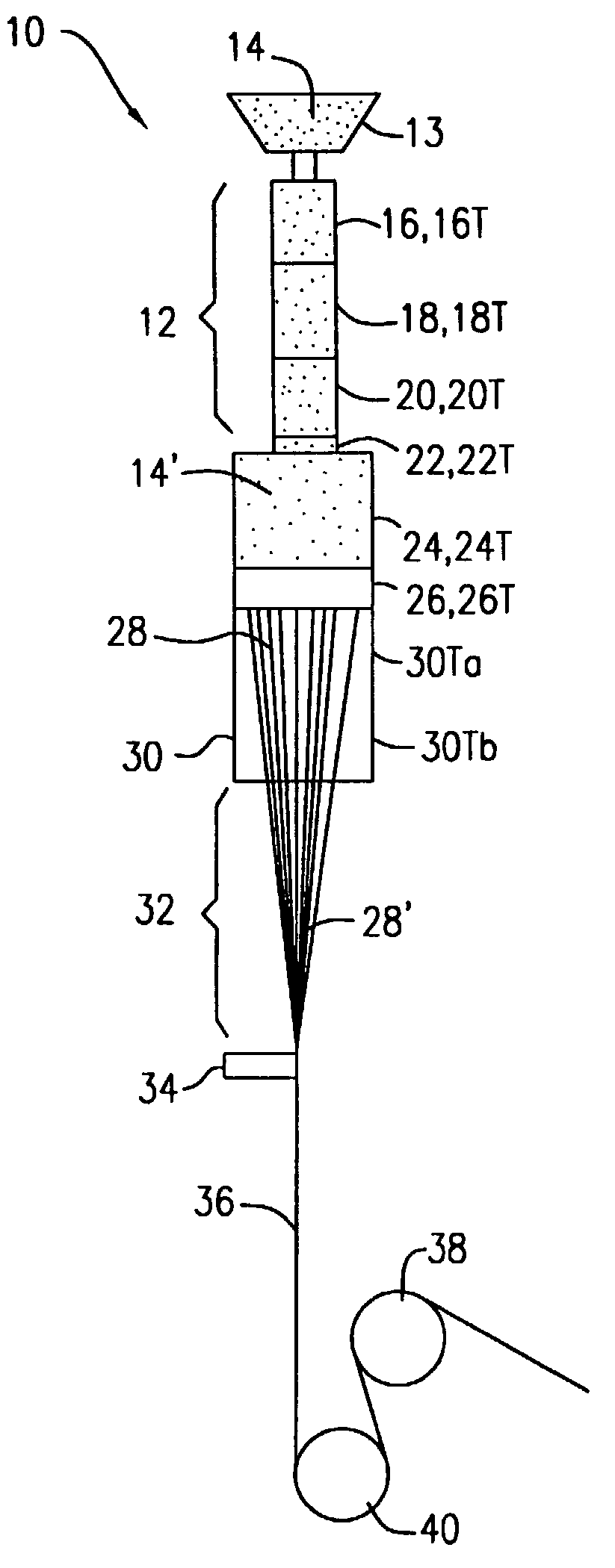

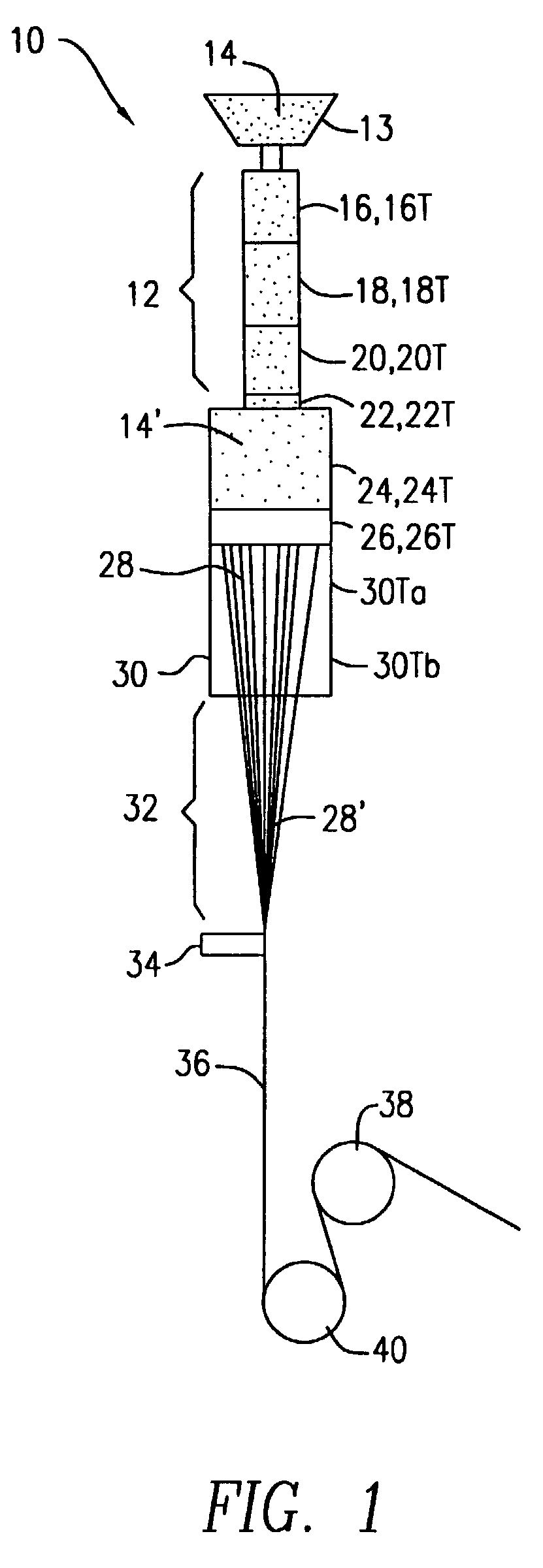

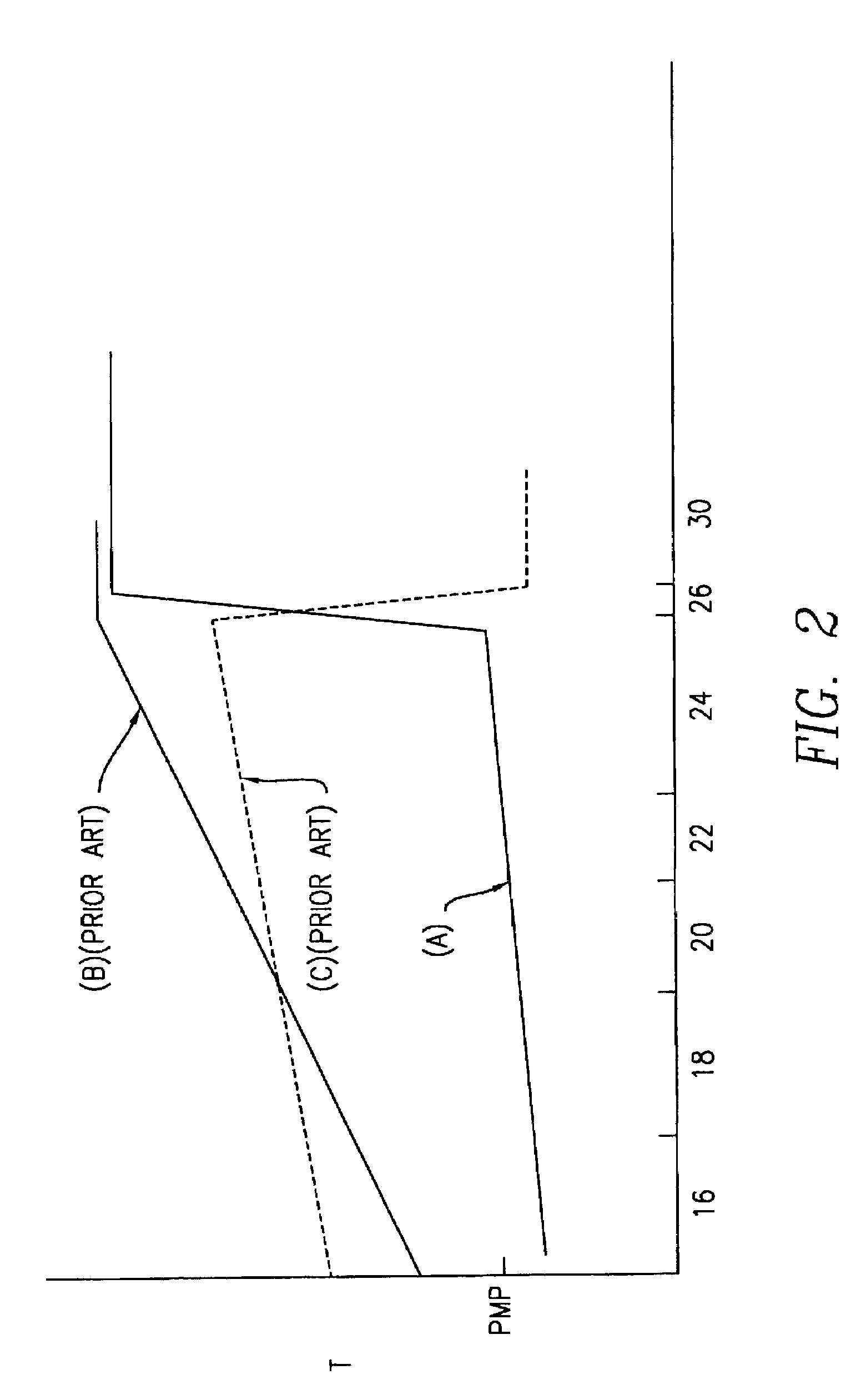

Process for the formation of high strength bio-absorbable suture fibers

A PGA / PLA copolymer suture fiber having a fiber tenacity of between approximately 7.2 to 8.0 grams per denier and a fiber elongation between approximately 22% and 35% is produced by a process that utilizes extruder apparatus having at least one heated zone that is maintained at a temperature of from about 20° C. below the copolymer melting point to about 5° C. above the copolymer melting point, a metering pump and a heated block that are maintained at a temperature of no more than about 40° C. above the copolymer melting point, a spinneret that is maintained at a temperature of from about 40° C. to about 60° C. above the copolymer melting point, and an elongated heated sleeve extending between six and twenty inches from the spinneret that is maintained at a temperature of at least about 60° C. above the copolymer melting point.

Owner:ETHICON INC

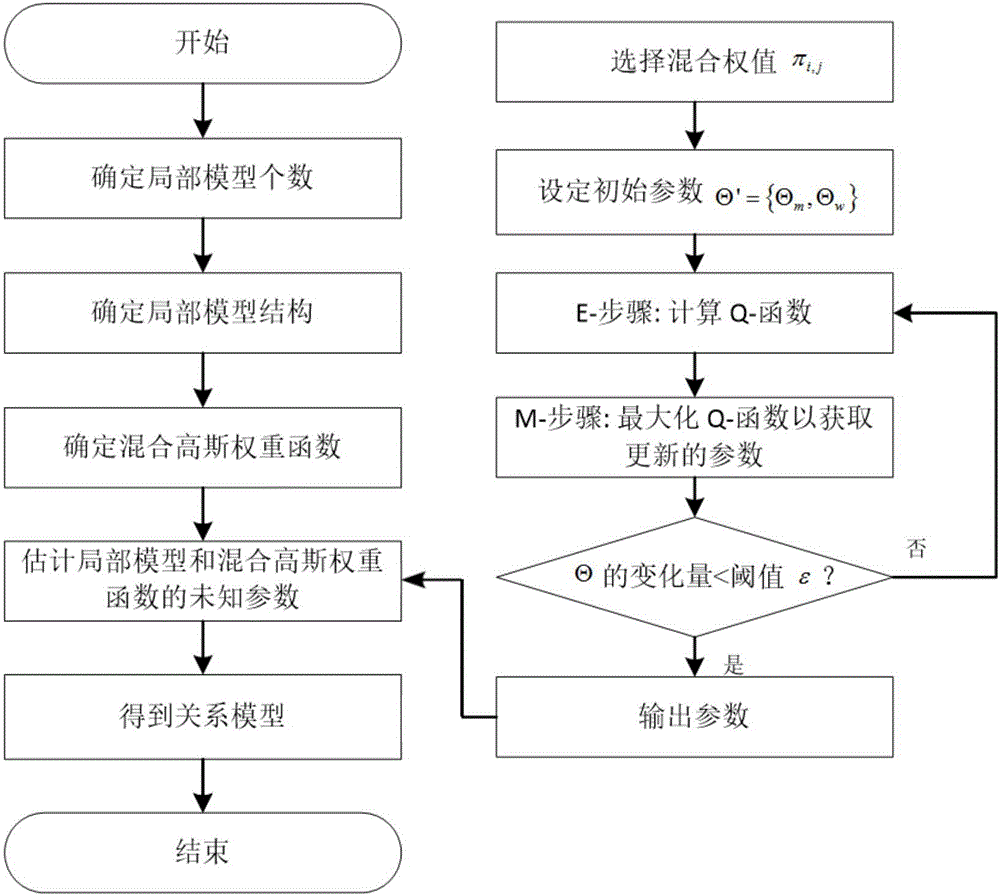

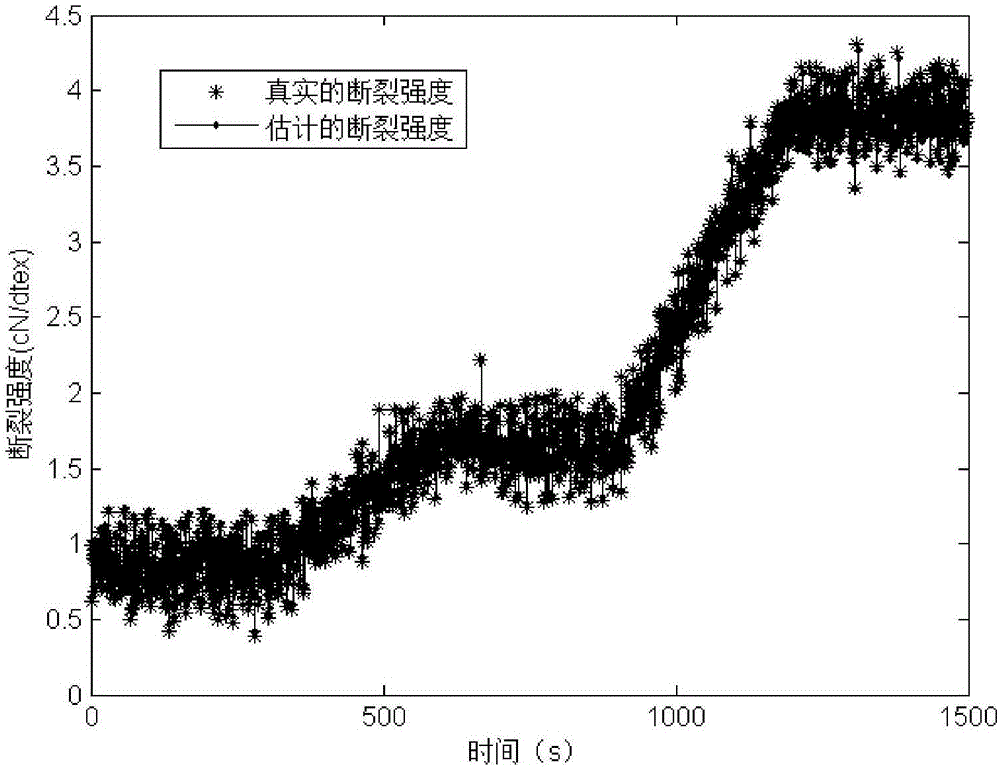

FDY (fully drawn yarn) spinning technology for optimizing multi-model method based on mixture Gaussian weighting function

ActiveCN106599431AOptimizing Process ParametersImprove acceleration performanceDesign optimisation/simulationSpecial data processing applicationsFiberBreaking strength

The invention discloses an FDY (fully drawn yarn) spinning technology for optimizing a multi-model method based on a mixture Gaussian weighting function. The relation models between the breaking strength and orientation degree of a FDY as well as between the crystalline degree and the fiber elongation rate of the FDY are firstly established, meanwhile the relation function between the temperatures and speeds of GR1 and GR2 and the orientation degree and the crystalline degree of the FDY is established, then a database is established, finally the temperatures and speeds of the GR1 and GR2 are calculated according to the relation function by selecting the breaking strength, and the spinning technology is adjusted. The establishment of the relation model comprises the following steps: 1) determining the number of local models; 2) determining the structures of the local models; 3) determining the mixture Gaussian weighting function; 4) estimating unknown parameters in the local models and the mixture Gaussian weighting function; and 5) obtaining the relation model. The model established in the invention has the characteristics of high accuracy and high reliability, and the spinning technology in the invention is beneficial for preparing fibers with excellent mechanical property.

Owner:DONGHUA UNIV

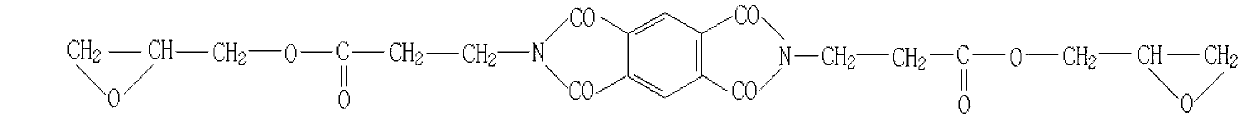

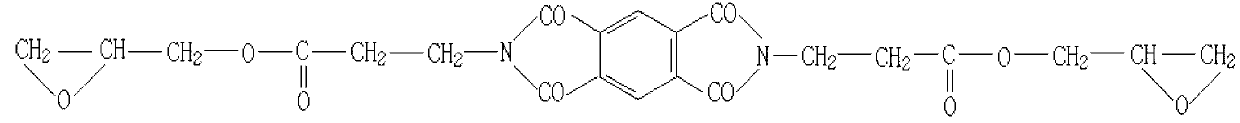

Production technology for anti-ultraviolet finishing liquid for elastic worsted fabric

InactiveCN105951440AImprove mechanical propertiesSuitable tensile strengthLight resistant fibresFiberCarboxymethyl cellulose

The invention discloses a production technology for an anti-ultraviolet finishing liquid for elastic worsted fabric. The production technology comprises the steps of preparing a wool keratin solution, preparing a sodium carboxymethyl cellulose solution and preparing the finishing liquid. The anti-ultraviolet finishing liquid for the elastic worsted fabric can form a uniform and elastic film on the fiber surface of the fabric, is good in mechanical property, proper in tensile strength and higher in elongation at break and can be matched with the elastic worsted fabric, influence on the film forming adhesion due to fiber elongation caused by elastic deformation of the fabric is avoided, and long-time anti-ultraviolet performance of the fabric can be maintained.

Owner:JIANGSU SUNSHINE

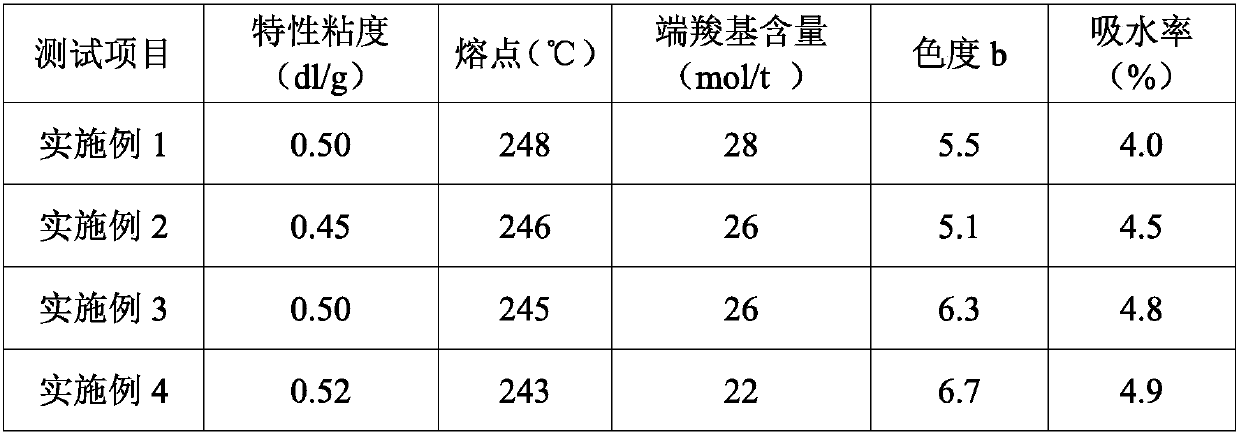

Improved PBT (polybutylene terephthalate) fiber spinning technology

InactiveCN107354531AIncreased flexural modulusHigh tensile strengthFilament/thread formingFilament-forming treatmentGlass fiberMasterbatch

The invention discloses an improved PBT (polybutylene terephthalate) fiber spinning technology adopting a POY technology. The spinning technology comprises the steps as follows: modified PBT masterbatch is obtained through copolymerization of ethylene terephthalate, 1,3-butanediol and 5-sodium sulfonate-1,3-glycol isophthalate, the dried modified PBT masterbatch, glass fiber and titanium dioxide particles are extruded and mixed at a certain temperature, a spinning melt is prepared, spinning is performed in a spinning box after prefiltration, nascent fiber is obtained and cooled by a circular blowing cooling system, cooled tows are oiled and guided by a guide system, and the prepared modified PBT fiber is easy to deeply dye at the normal temperature, has the color fastness up to 4-4.5 grade, the breaking strength of 2.3-3.0 cN / dtex and the elongation at break of 90%-110%. A hydrophilic group is introduced into the modified PBT fiber, so that the modified PBT fiber is easy to dye at the normal temperature, the strength of the fiber can be improved after the fiber is blended with the glass fiber and the titanium dioxide particles, the fiber has an ultraviolet-proof function, and the prepared fiber has higher elongation and is easy to further draw and process later.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

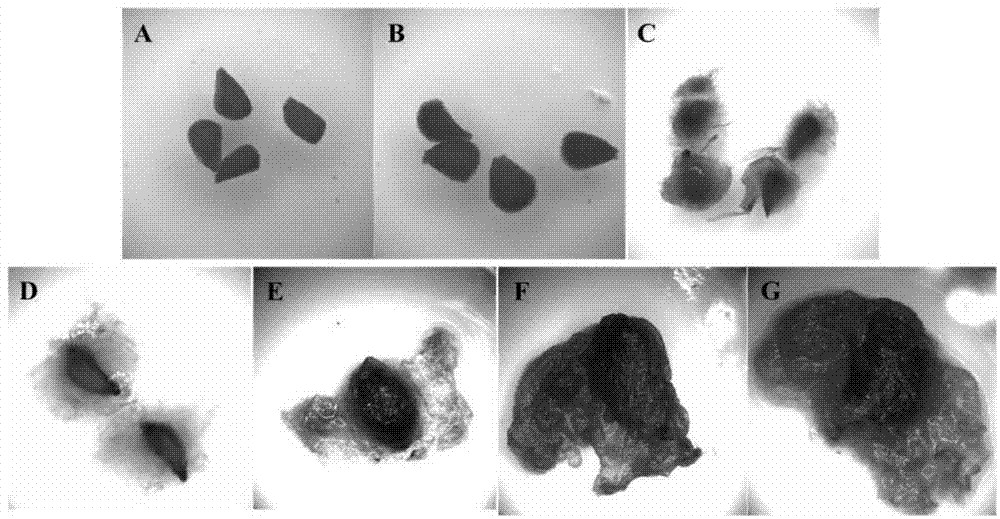

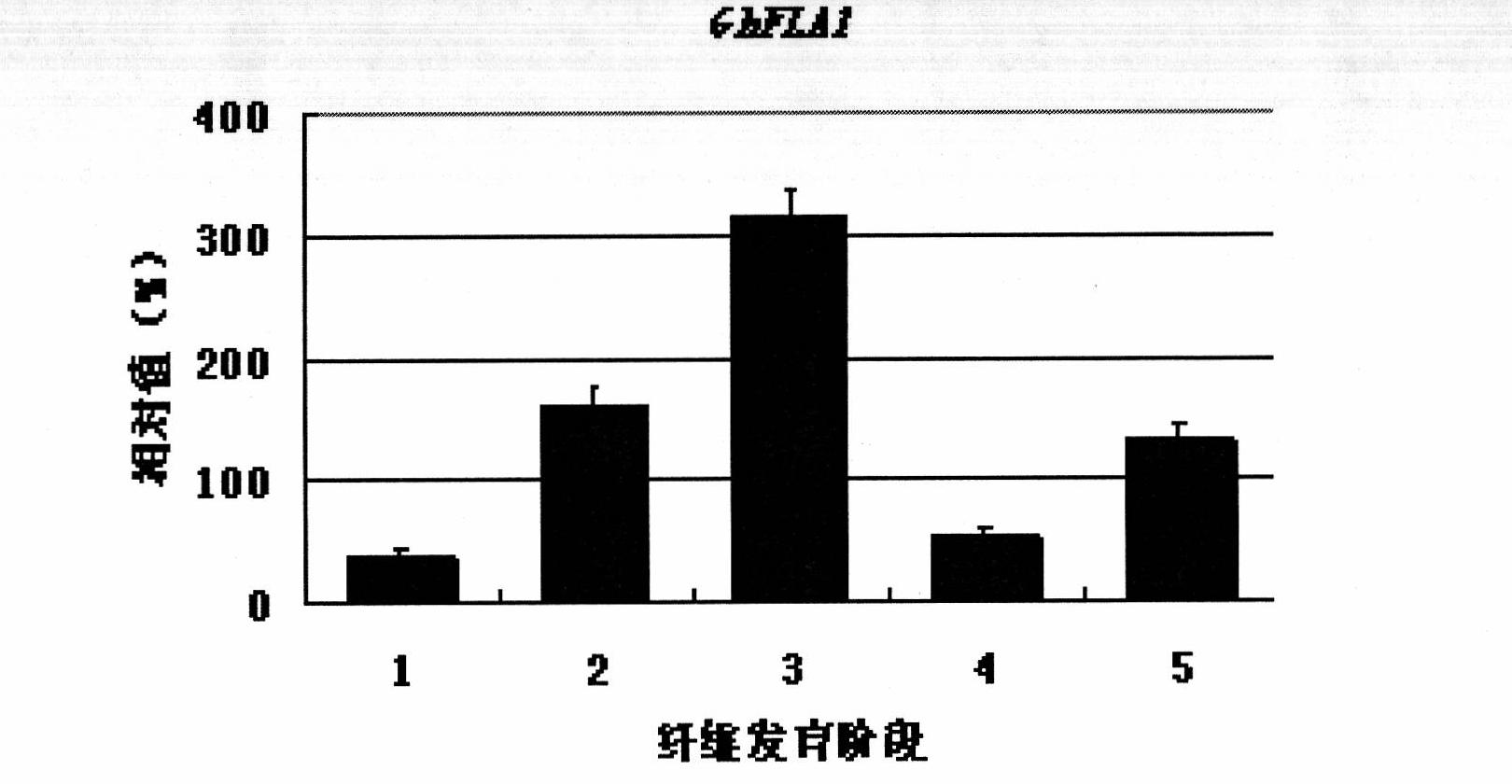

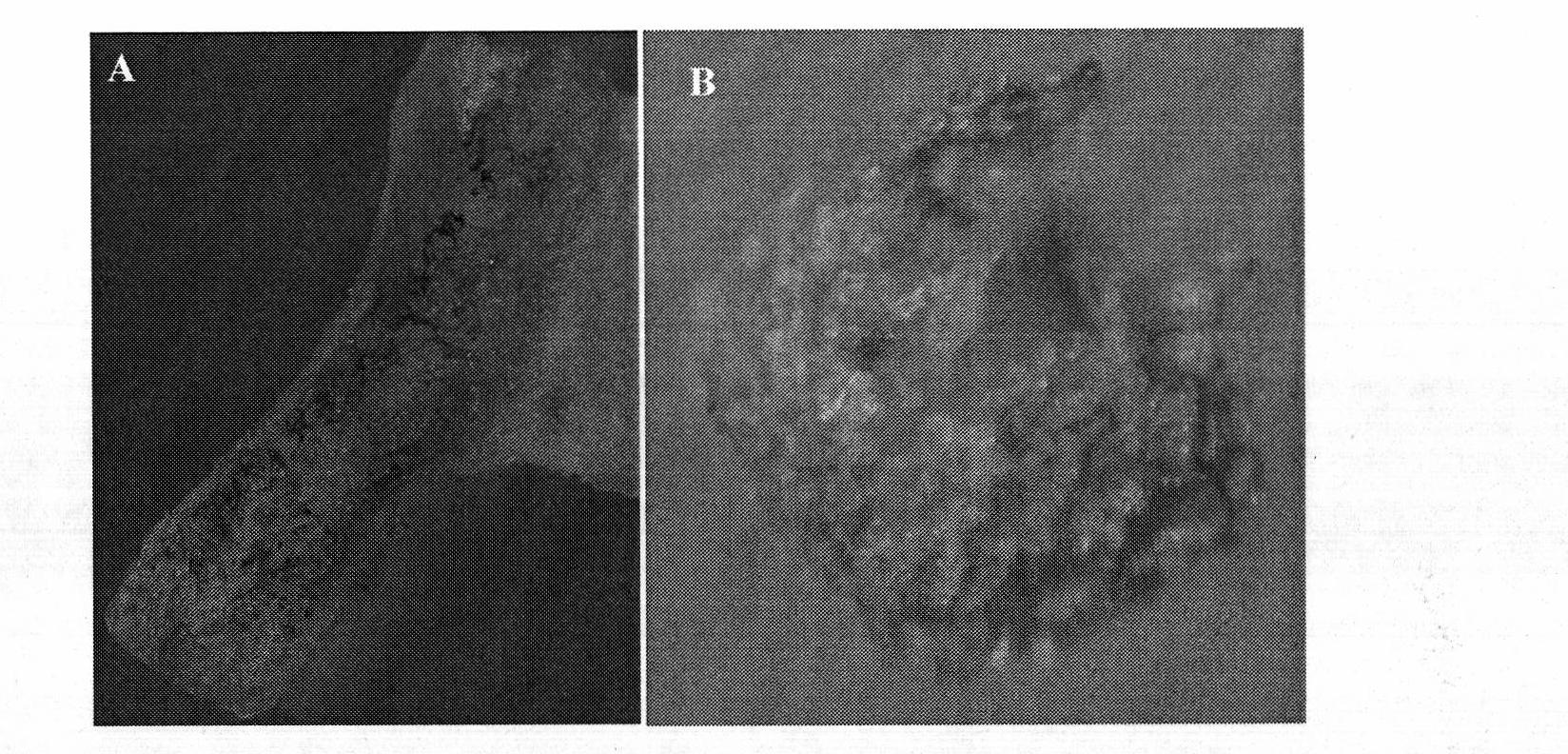

Identification of cotton fiber specificity promoter GhFLA1

The invention discloses a cotton fiber specificity promoter GhFLA1 and a gene complete sequence thereof, relating to an important regulatory element related to cotton fiber development. The FLA1 gene complete sequence has totally 1920bp and comprises a 5' end promoter and a gene coding sequence. The gene does not contain an intron and encodes an arabinogalactan protein (AGP). The cotton fiber contains a great amount of the AGP protein, and that AGP irreversible inhibitor can inhibit fiber elongation shows that the protein has an important role for cotton fiber development. That the FLA1 gene mRNA has a great amount of specificity accumulation in the process of cotton fiber cell development shows that the gene promoter plays an important role in the regulation of fiber specificity expression. Experiments also show that the promoter has strong expression activity in tobacco leaf epidermal hair, which further proves that the promoter is the specificity regulatory element of the cotton fiber. The promoter can be used as a gene cis-regulatory element to be applied to cotton molecular breeding research so as to improve the cotton fiber quality and to enhance the cotton yield.

Owner:HUAZHONG NORMAL UNIV

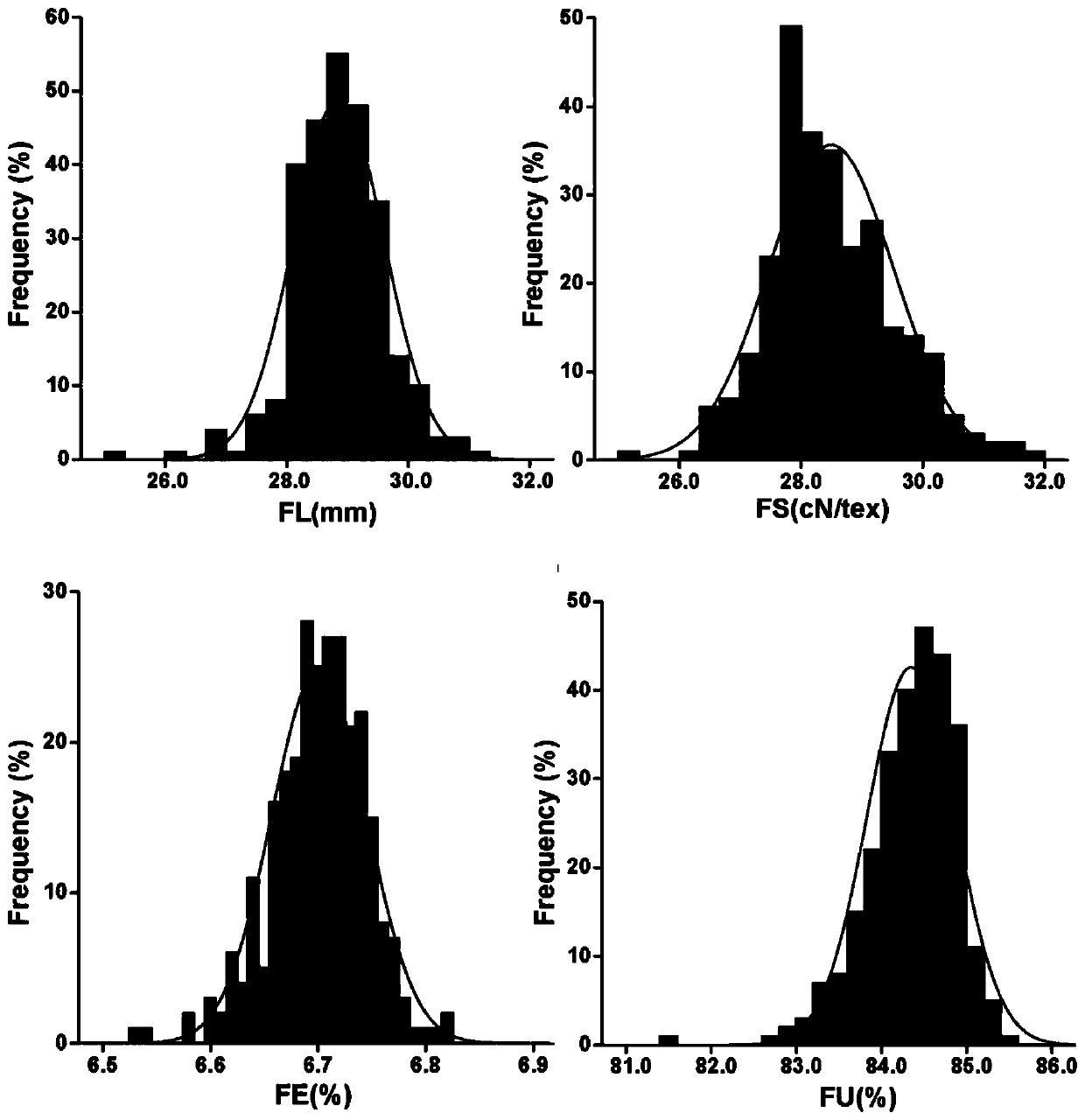

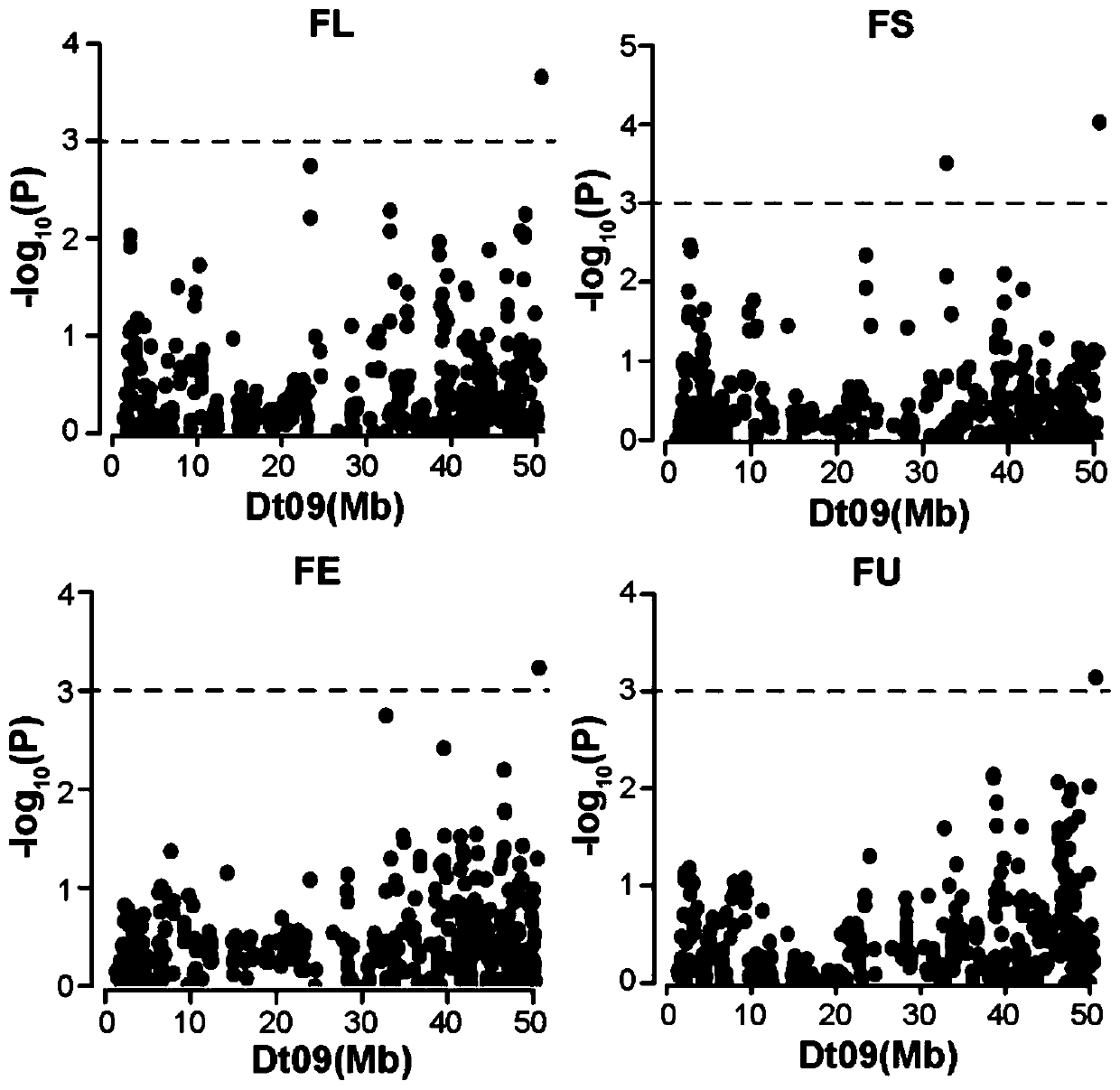

GhJMJ12 gene SNP marker related to cotton fiber quality, and application of same

ActiveCN111218524AEfficient prediction of fiber qualityEarly screeningMicrobiological testing/measurementPlant genotype modificationBiotechnologyFiber

The invention relates to the technical field of quality breeding of cotton fibers and specifically relates to a GhJMJ12 gene SNP marker related to cotton fiber quality and application of the same. TheGhJMJ12 gene SNP marker related to cotton fiber quality is located at the 7215bp locus of a GhJMJ12 gene of a Dt09 chromosome of cotton, the SNP marker is a base A or C, and the GhJMJ12 gene has a nucleotide sequence shown by SEQ ID NO:1. According to the invention, 10660 SNP markers are used for whole genome association study of quality characters of the cotton fibers, and the study indicates one SNP locus on the GhJMJ12 is significantly correlated with fiber quality characters such as the fiber length, the fiber specific strength, the fiber elongation and the fiber uniformity.

Owner:HENAN AGRICULTURAL UNIVERSITY

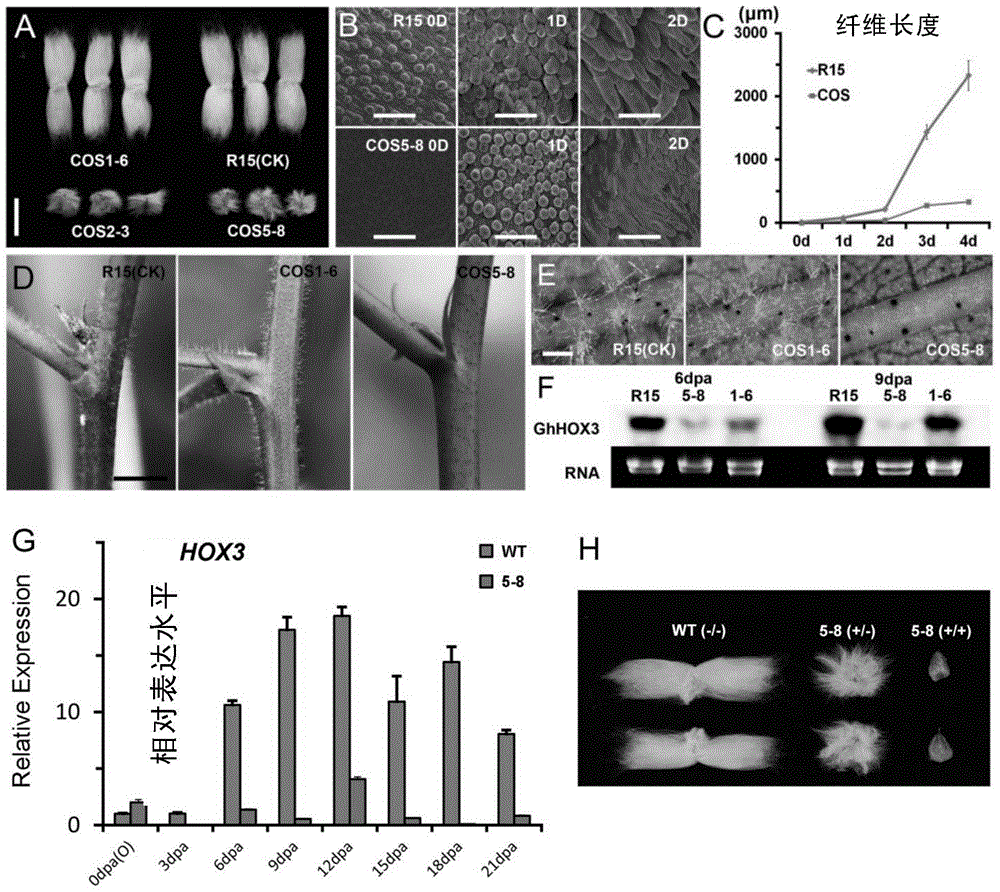

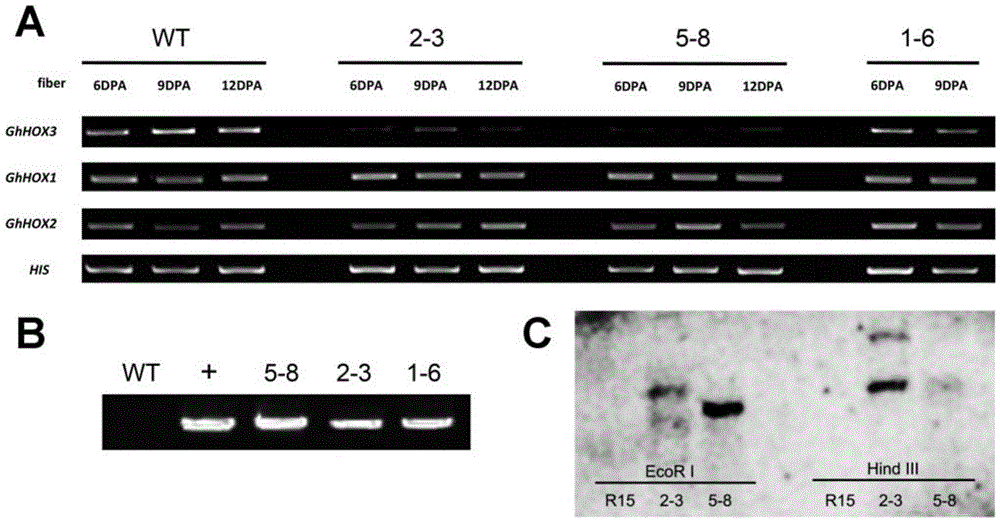

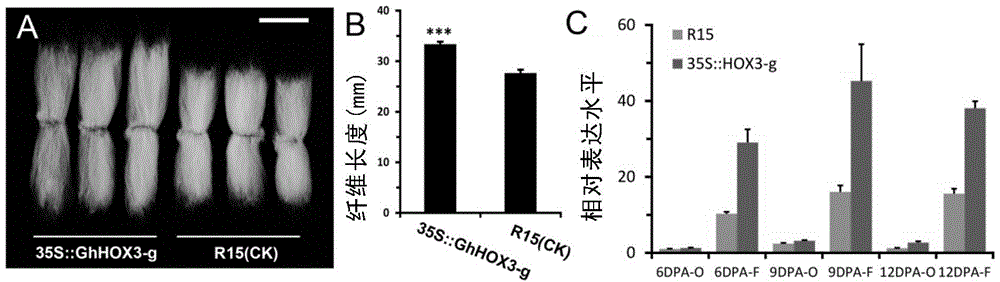

Applications of HOX3 gene in improving cotton fiber elongation property

The invention relates to applications of an HOX3 gene in improving the cotton fiber elongation property, specifically, the invention provides the applications of the cotton fiber elongation gene GhHOX3 gene of cotton and polypeptide of the cotton fiber elongation gene GhHOX3 gene in improving the cotton fiber elongation property. The experiment proves that the genomic gene of the cotton fiber elongation gene GhHOX3 can effectively and exclusively improve the cotton fiber length in the molecular level, and the synchronous improvement of the yield of the cotton fiber is realized.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

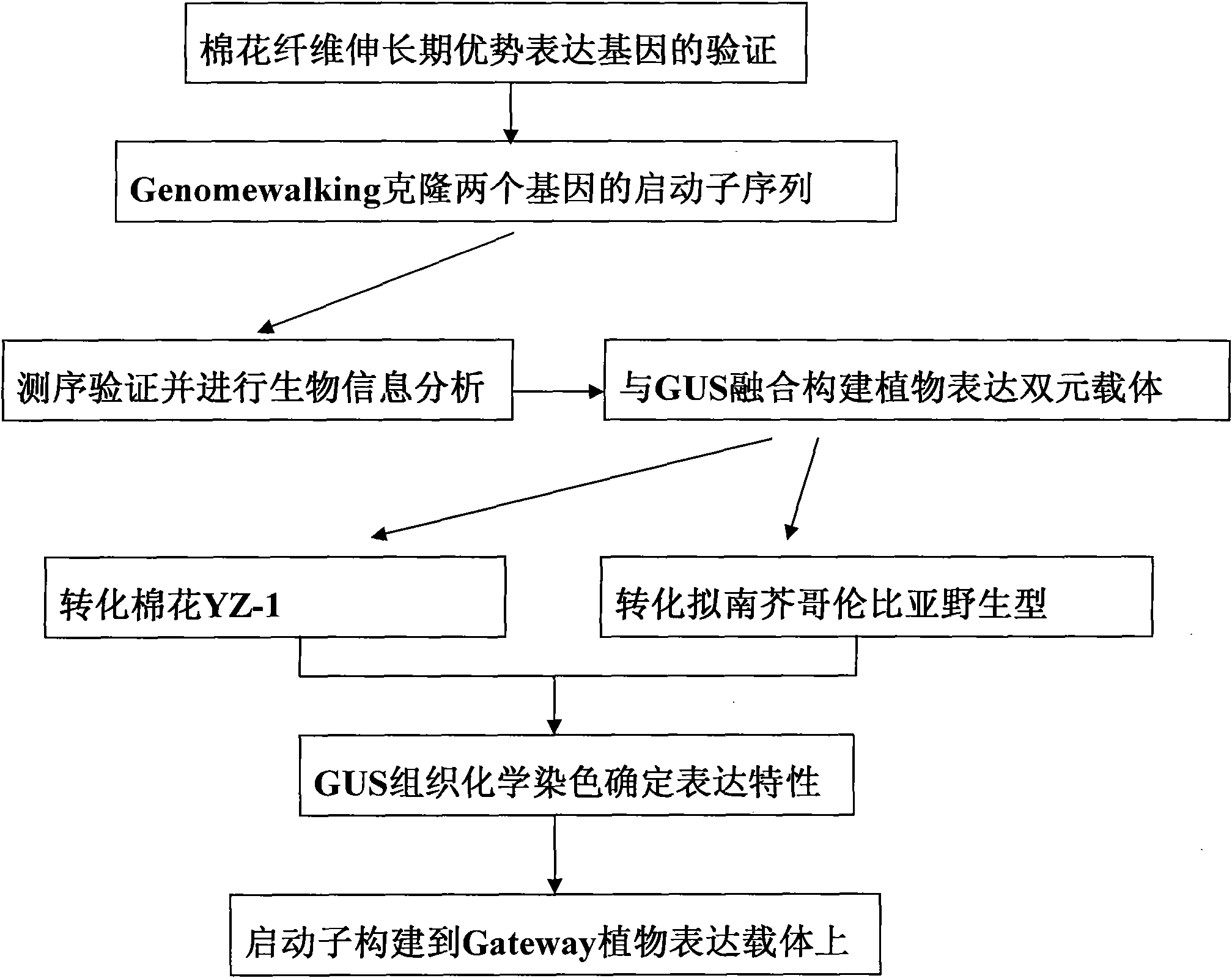

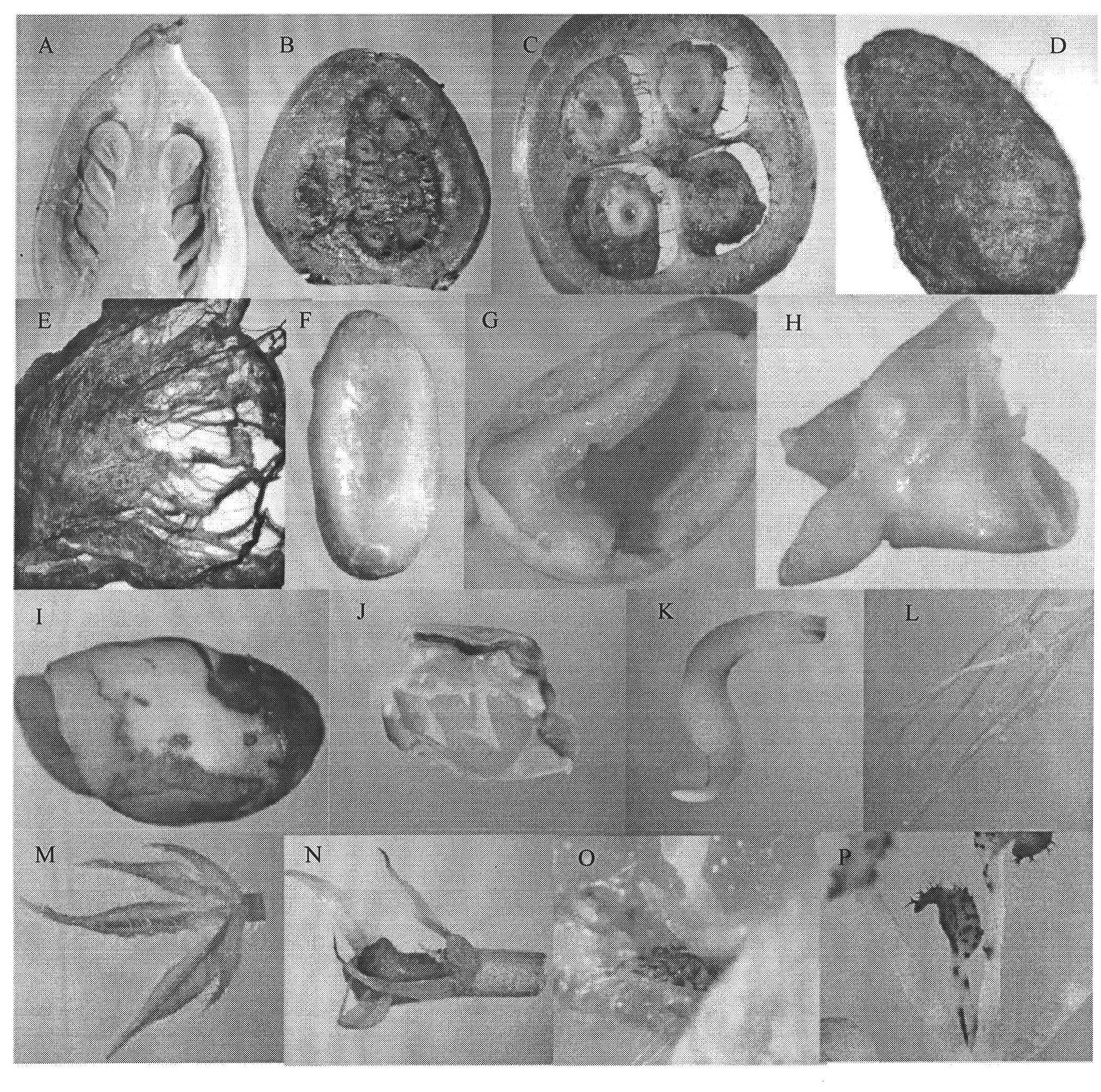

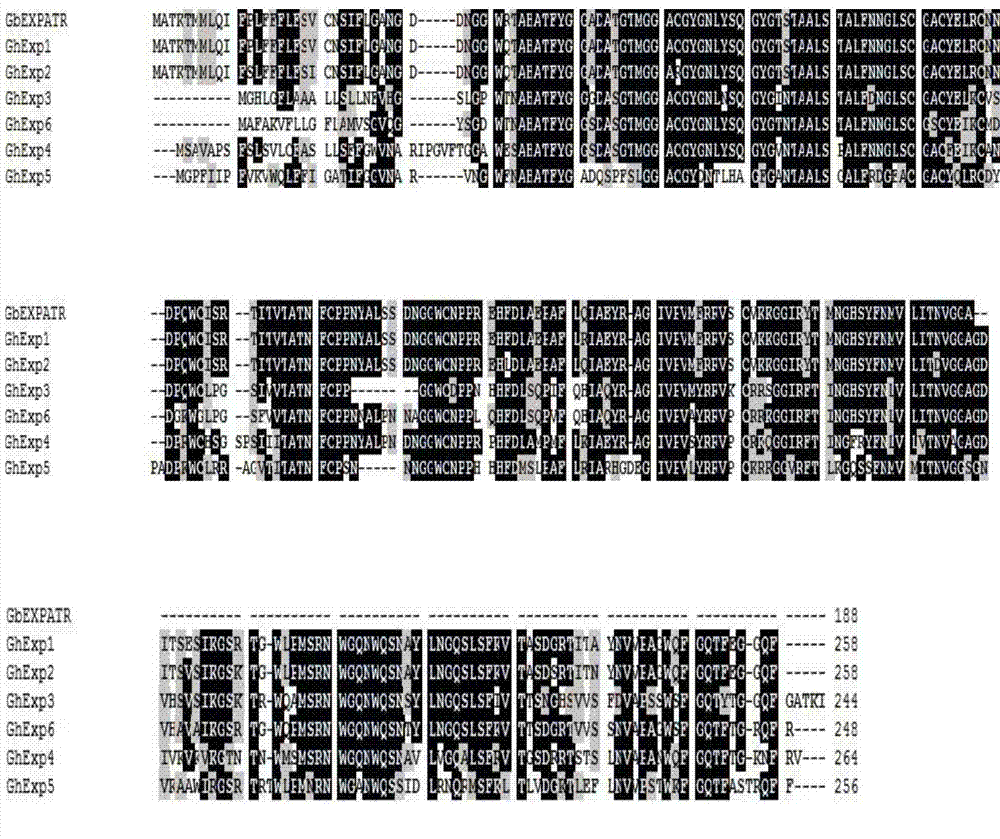

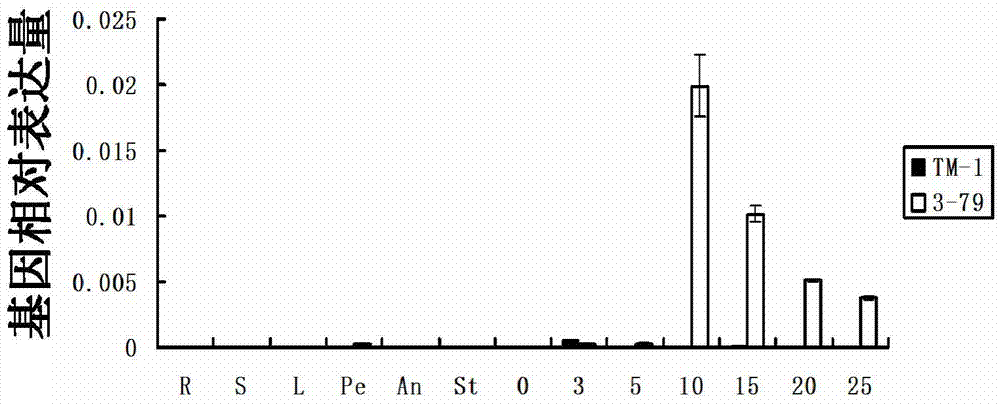

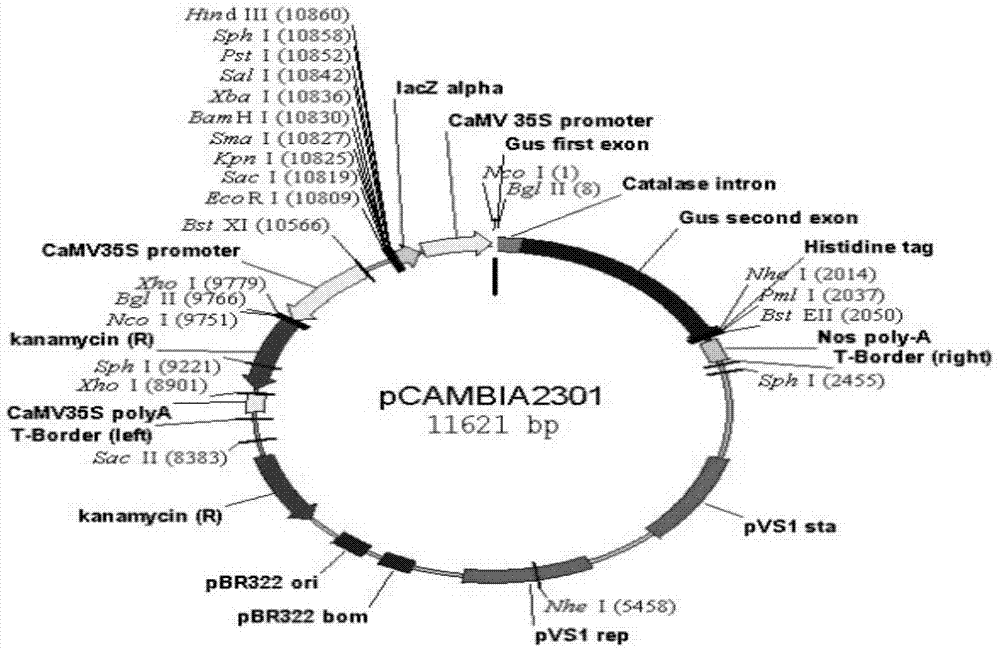

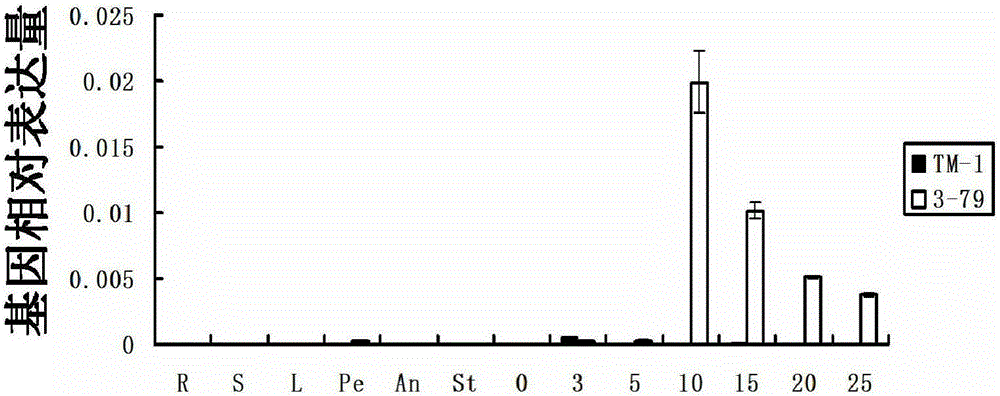

Two cotton fiber elongation stage preferential expression promoters and their application

InactiveCN102485894AVector-based foreign material introductionDNA/RNA fragmentationFiberAgricultural science

The invention relates to the field of plant gene engineering. The invention discloses two cotton fiber elongation stage preferential expression promoters and their application. In the invention, the two cotton fiber elongation stage preferential expression promoters of an island cotton gene GbEXPA1 and an island cotton gene GbEXPATR are cloned and identified, wherein nucleotide sequences of the two cotton fiber elongation stage preferential expression promoters are respectively shown in a sequence table 1 and a sequence table 2. In cotton, the two cotton fiber elongation stage preferential expression promoters are fiber specific / preferential expression promoters. A plant expression vector obtained by fusion construction of DNA sequences of a GUS gene and the two cotton fiber elongation stage preferential expression promoters of PGbEXPA1 and PGbEXPATR is transformed into cotton through an agrobacterium tumefaciens-mediated genetic transformation method and the transgenic cotton is subjected to dyeing identification. A result of the dyeing identification shows that the GUS gene is preferentially expressed in cotton fibers. Expression modes of the two cotton fiber elongation stage preferential expression promoters are almost same. Through a series of processes of fusion of cut promoter sequences and the GUS gene, a transgenic cotton verification result shows that a sequence of -461bp to -1bp is a core sequence of the promoter of PGbEXPA1. The invention also discloses a recombinant expression vector containing the promoter of PGbEXPA1. The recombinant expression vector can be utilized for cultivation of a transgenic plant, wherein the island cotton gene GbEXPA1 is specifically expressed in a root of the transgenic plant.

Owner:HUAZHONG AGRI UNIV

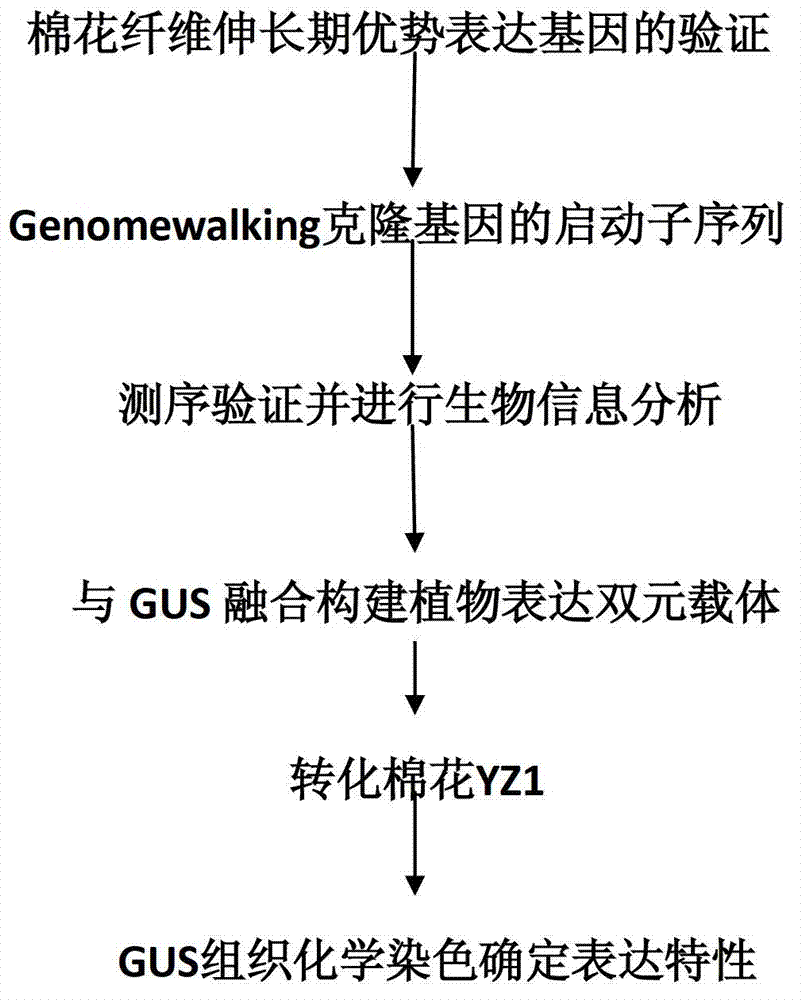

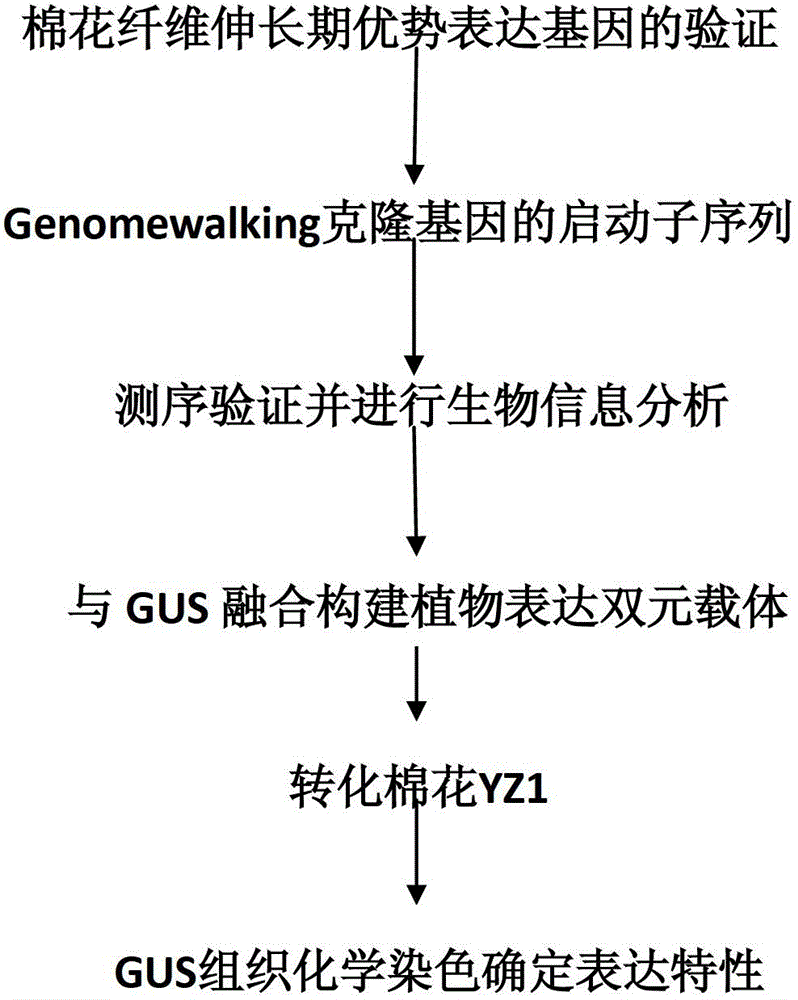

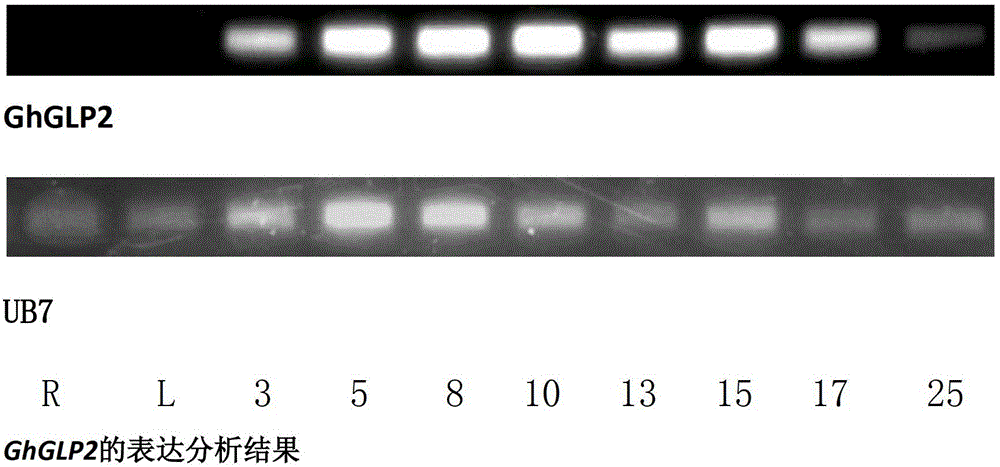

Fiber elongation-stage predominant-expression promoter, and preparation method and application thereof

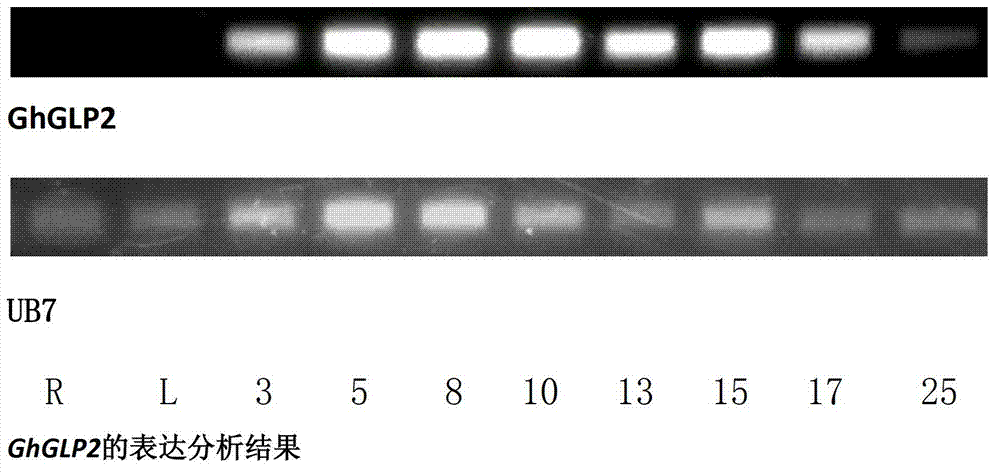

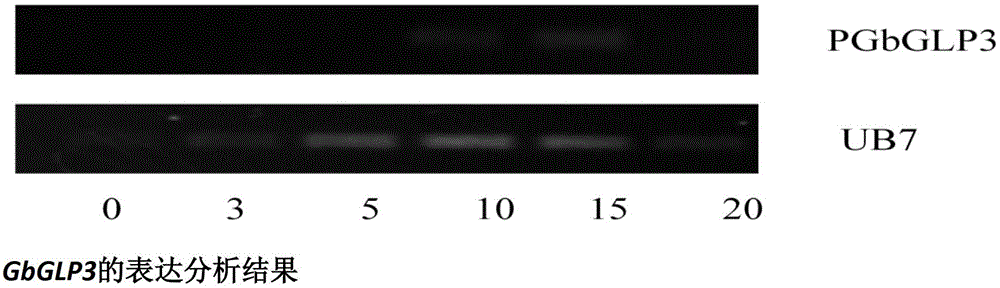

The invention discloses a fiber elongation-stage predominant-expression promoter, and a preparation method and an application thereof. The promoter mainly predominantly expresses in an elongation stage, two promoters comprising PGhGLP2 and PGbGLP3 and GUS are fused, and the obtained fusion converts cotton, chemical dyeing of fibers shows that the two promoters comprising PGhGLP2 and PGbGLP3 do not express in ovules in the bloom day, the expression of the GUS can be detected in fibers from 1DPA, and the expression of the GUS cannot be detected in the ovules. The expression peaks of the two promoters are in the cotton fiber elongation stage. The elongation stage is a very key stage for the cotton fibers, and the utilization of the specific expression of some genes important to the formation of high-quality fibers by the promoter in the heredity improvement will increase the cotton output without influencing the growth of other tissues and organs.

Owner:HUAZHONG AGRI UNIV

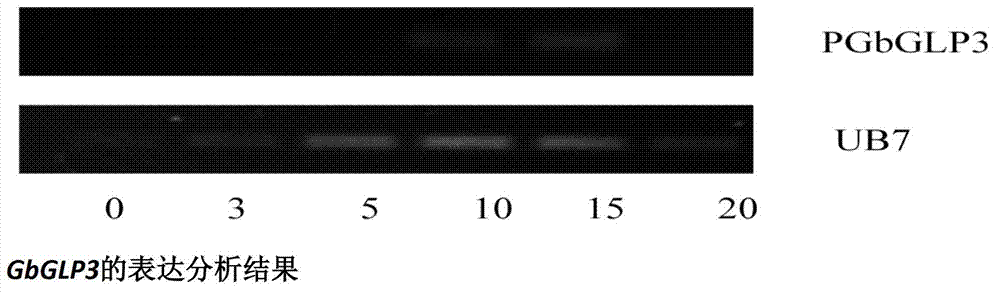

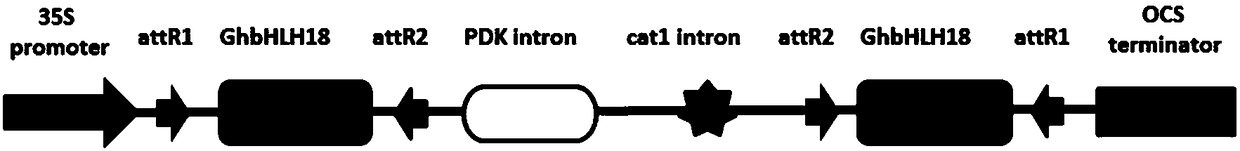

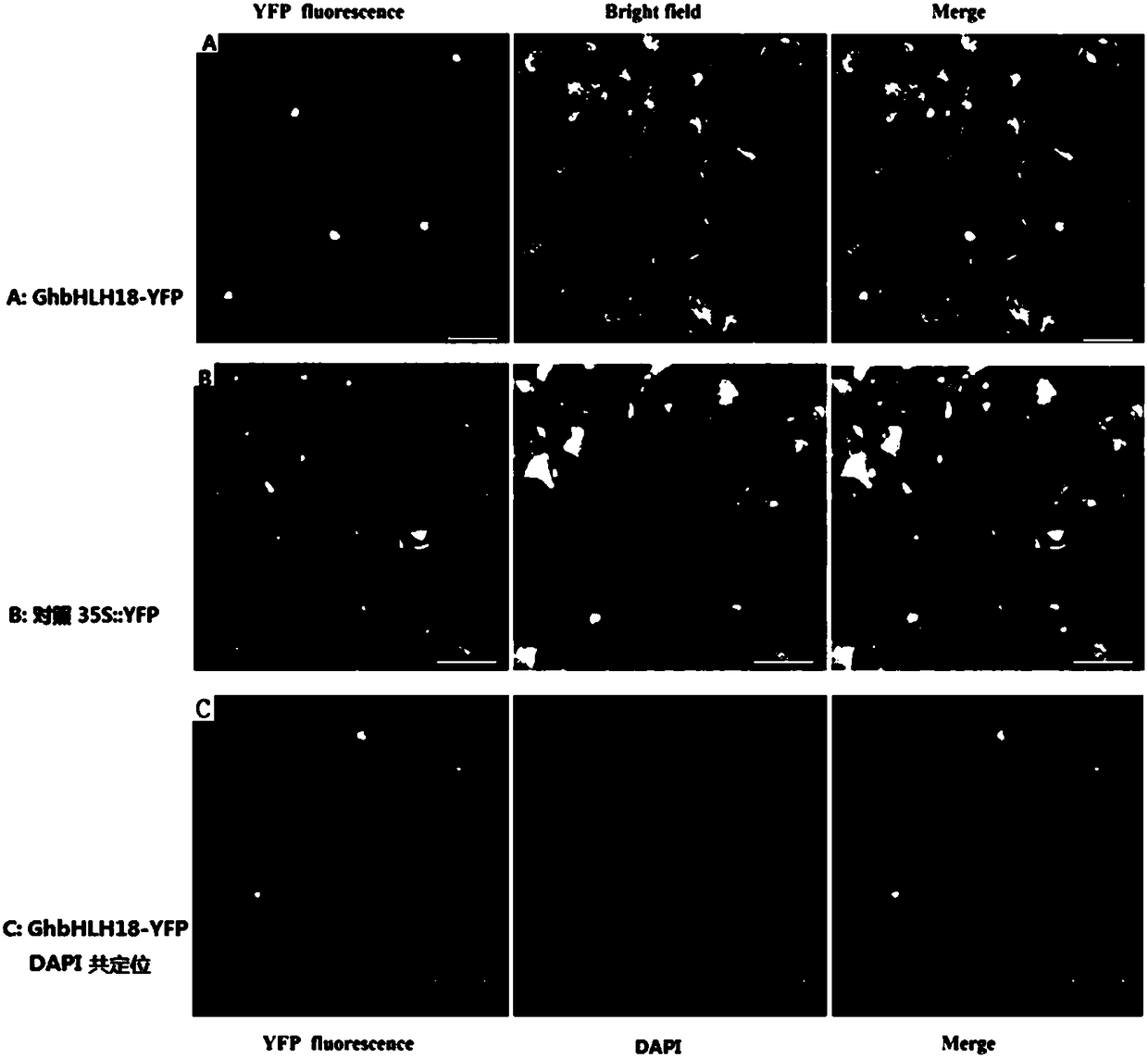

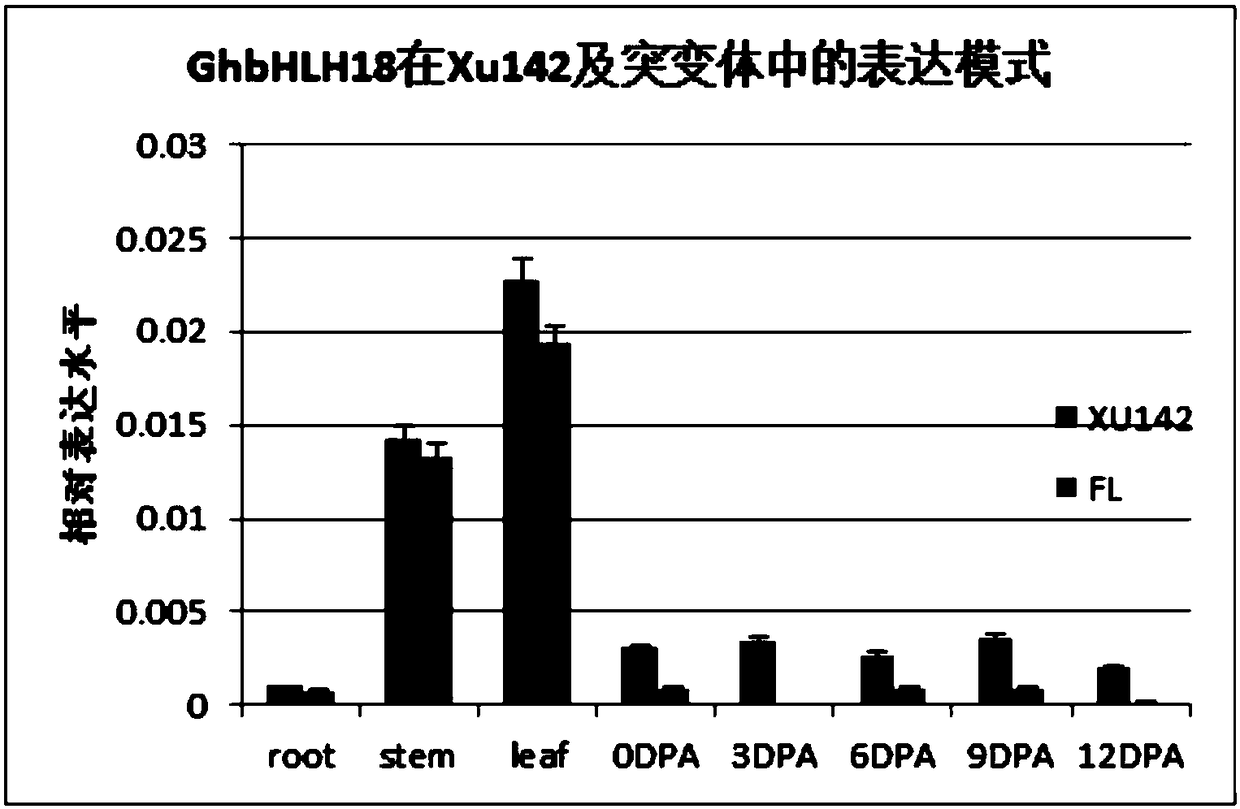

Transcription factor GhbHLH18 for expression of elongation period of cotton fibers and application thereof

The invention provides a transcription factor GhbHLH18 for expression of the elongation period of cotton fibers and application thereof, belongs to the field of plant molecular biology and gene engineering and discloses a transcription factor GhbHLH18 related to the development of the cotton fibers and playing an important role in the fiber-elongation process and application thereof. The nucleotide sequence of the transcription factor GhbHLH18 is shown in SEQ ID NO.1. The transcription factor GhbHLH18 has the following characteristics that (A) the expression condition in cotton tissues and fibrocytes in the fiber-elongation process is very clear, and the transcription factor is not reported on plants such as cotton; (B) the transcription factor provided by the invention plays an importantrole in adjustment in the cotton fibers-elongation process and has an influence on the quality of the cotton fibers.

Owner:SHANGHAI JIAO TONG UNIV

Skin core composite fiber, manufacturing method thereof and fabric

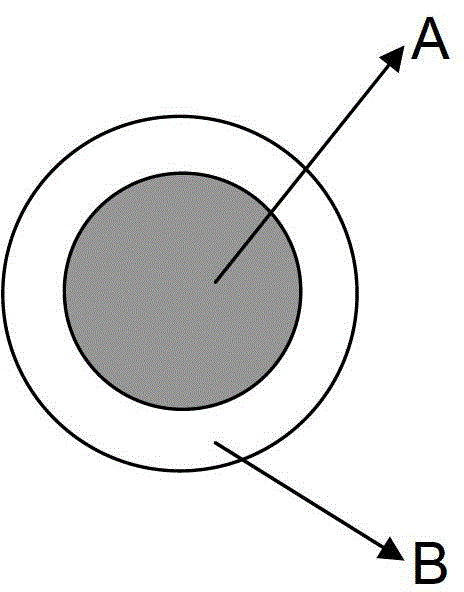

ActiveCN103014911BImprove spinnabilityReduce intensityFilament/thread formingWoven fabricsPolyesterPolyamide

This invention is a manufacturing method of a leather type composite fiber. The composite fiber comprises of a skin layer which is formed by polyamide and a core layer which is formed by polyester. The composite fiber satisfies the following characteristics: (1) 0.6g / d < fiber breakage strength < 2.5g / d; (2) 15% < fiber elongation < 50%; (3) 6g / d < fiber modulus 0 to 5% (Mod0 to 5%) < 40g / d; where Mod0 to 5%=(fiber strength at 5% elongation) / (0.05).

Owner:SHINKONG SYNTHETIC FIBERS

Method for preparing phenolic modified melamine fibers by one-step method

InactiveCN110846737AGood fiber mechanical propertiesImprove flame retardant safety performanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for preparing phenolic modified melamine fibers by a one-step method. The method comprises the steps of dissolving a water-soluble polymer in water, adding melamine, an aldehyde compound and a phenolic compound, and reacting under the action of an alkaline catalyst to obtain a resin solution of melamine modified by the phenolic compound; and performing wet spinningand heat curing to obtain the finished phenolic modified melamine fibers. The melamine fibers prepared through modification have the advantages of high nitrogen content, zero halogen, good flame retardance, high fiber elongation and the like, and have a good application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

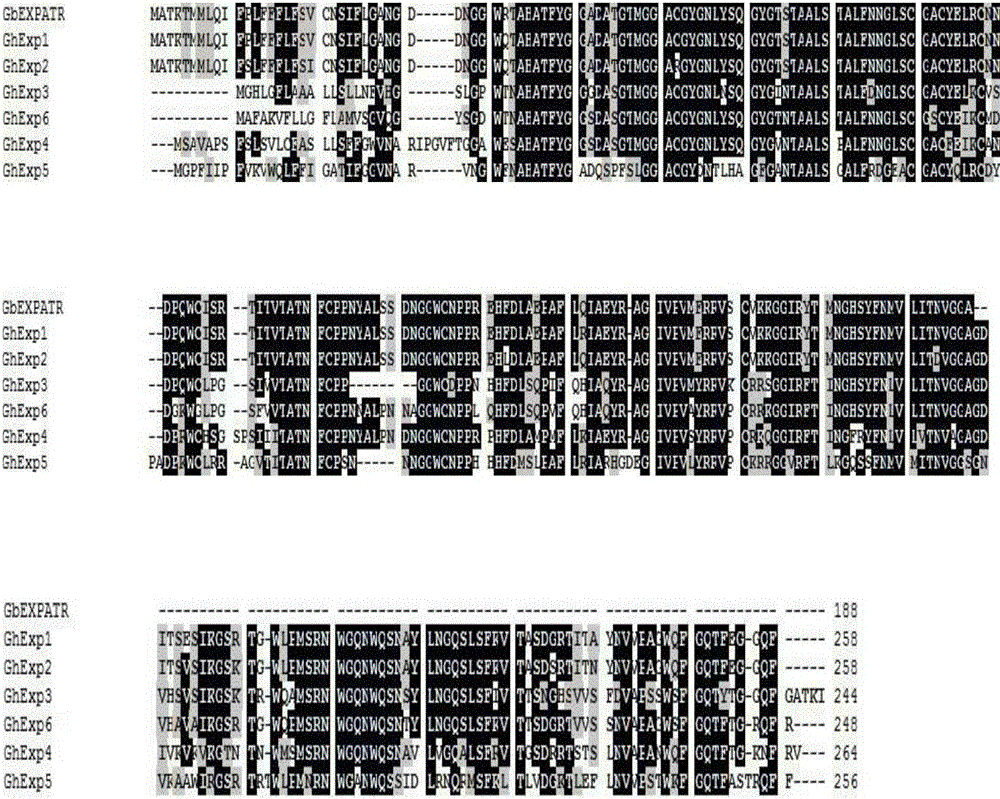

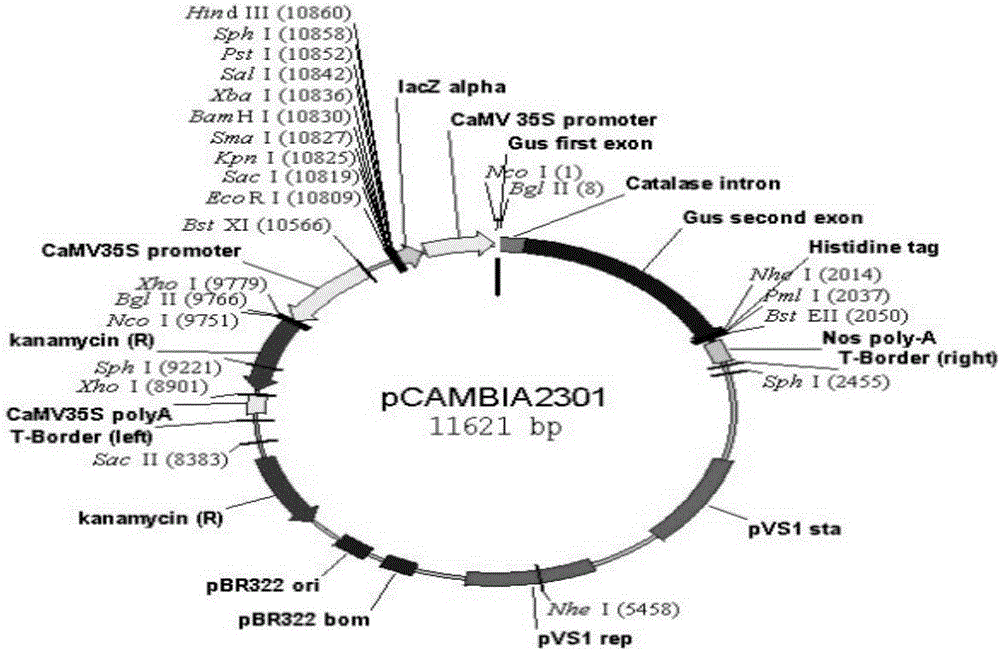

Cotton cell wall extensin gene GbEXPATR and application

The invention belongs to the technical field of plant genetic engineering and particularly relates to cell wall extensin gene GbEXPATR separated and cloned from cotton and application. The cell wall extensin gene GbEXPATR which is obtained through sea island cotton fiber specific expression in a cDNA library at different sea island cotton fiber development stages and lack of a second structural domain, and a nucleotide sequence is represented by SEQ ID NO:1, wherein 52-306 represents a basic group region which is a coding region and exceptionally and efficiently expressed in a sea island cotton fiber elongation period, a conversion period and a secondary wall synthesis initial stage. An obtained overall-length ORF is established on a plant excessive expression vector Pcambia2301M, sea island cotton is converted into upland cotton by using an agrobacterium-mediated transformation genetic transformation method, the quality of transgenic offspring fiber is analyzed, and the cell wall extensin gene GbEXPATR can effectively promote fiber elongation is proved. A Micron-aire reduced. The fiber quality is improved from the grade C2 to the grade B2. The breakage ratio and the strength are improved. The cotton fiber quality can be effectively improved by utilizing the cell wall extensin gene GbEXPATR.

Owner:HUAZHONG AGRI UNIV

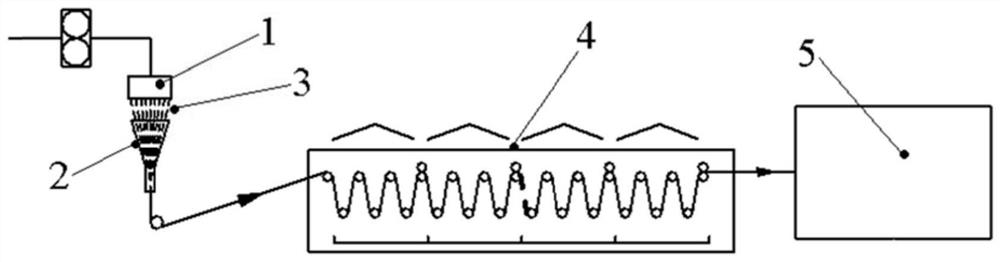

A kind of continuous preparation method of cellulose fiber

ActiveCN111155183BControllable molding processOptimal Control StructureSpinnerette packsArtificial thread manufacturing machinesPolymer scienceCellulose fiber

The invention discloses a continuous preparation method of cellulose fibers. The preparation method applies a forming tension of 0.1 to 1.9 cN / dtex to a thin stream of raw liquid obtained by extrusion through a spinneret and cooling through an air gap, and then the feeding speed is 80 ~1000m / min coagulation bath, and continue to apply a pulling tension of 0.075~1.5cN / dtex to the washed fibers in the washing system after the coagulation bath, and finally send it to the post-processing system to achieve continuous high efficiency at a speed of 80~1000m / min Fibres for textile products. The preparation method provided by the invention can significantly adjust the problems of obvious fibrillation, low fiber elongation, and poor fiber uniformity of cellulose fibers under high-speed traction, realize high-speed and high-quality preparation of cellulose fibers, and further greatly improve production efficiency. The production cost is reduced, and an efficient and continuous method for preparing cellulose fibers that is more suitable for industrialization is formed.

Owner:CHINESE TEXTILE ACAD

Viscose filament yarn semi-continuous spinning machine and spinning process thereof

ActiveCN101824663BAvoid damageLow elongationNew-spun product collectionArtificial thread manufacturing machinesViscoseEngineering

The invention relates to a viscose filament yarn semi-continuous spinning machine and a spinning process thereof. The viscose filament yarn semi-continuous spinning machine comprises a frame. A glue spray device, a lower solidifying roller and an upper solidifying roller are arranged on the frame. An upper drafting disc is coaxially arranged at the end part of the upper solidifying roller and a lower drafting disc is coaxially arranged on the lower solidifying roller. Since the upper drafting disc and the lower drafting disc are arranged for drafting nascent filaments to break down a large draft multiple into a plurality of small draft multiples for times of drafting, the invention has the advantages that the one-step large-multiple drafting is avoided, the situation that the fiber elongation is reduced because the filaments are damaged is avoided, viscose filament yarns with high strength and elongation which satisfies process requirements can be spun, the strength of the viscose filament yarns can reach above 2.5CN / dtex and the viscose filament yarns can be used as both the warps and the wefts of fabrics.

Owner:潍坊欣龙生物材料有限公司

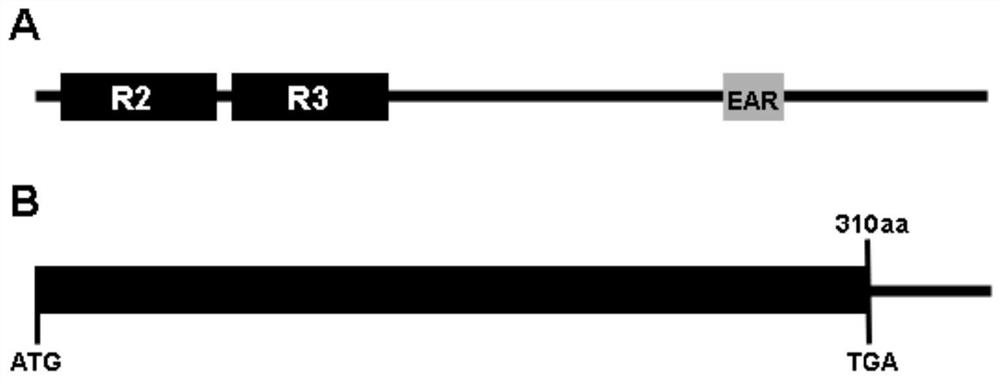

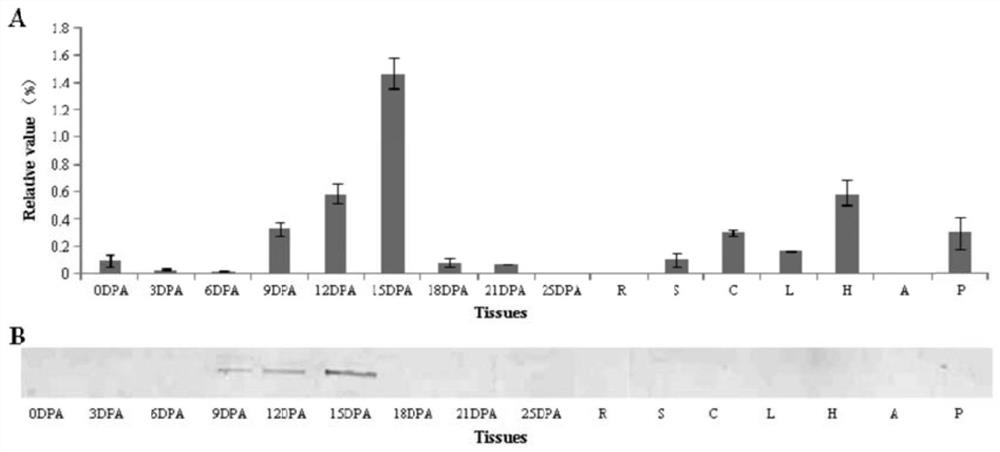

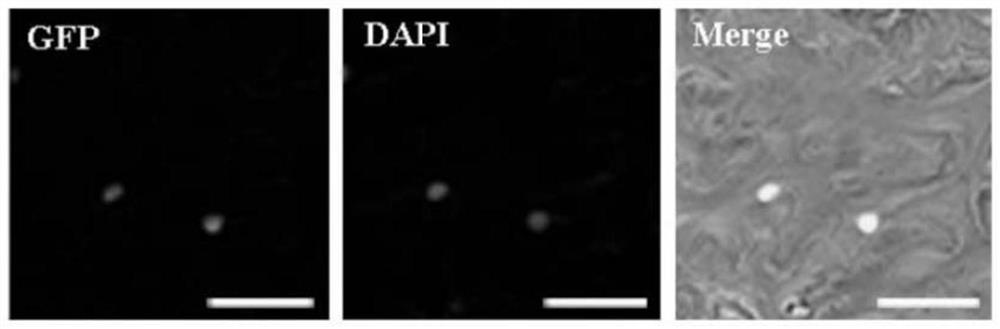

A myb gene regulating cotton fiber elongation and its application

ActiveCN112111500BConfirmed regulationLocation verificationPlant peptidesFermentationOpen reading frameNucleotide

The invention relates to a MYB gene for regulating the elongation and growth of cotton fibers and its application. The gene is derived from Gossypium hirsutum, and its full-length nucleotide sequence is 1149 bp, without introns, and its open reading frame is 933 bp, encoding a protein with 310 amino acids. This transcription factor has a typical MYB domain and a transcriptional repressor-binding domain (EAR-domain). The present invention verifies the function of the gene in regulating the elongation and development of cotton fibers through genetic transformation. Using RNAi technology to reduce the expression of the gene in cotton fibers can significantly reduce the length of cotton fibers, indicating that the gene is a positive regulator of cotton fiber elongation. The long-developed genes are of great value in the improvement of cotton fiber quality, and can be used for molecular breeding research on cotton fiber quality improvement through hybridization, transgenic and other methods.

Owner:HUAZHONG NORMAL UNIV

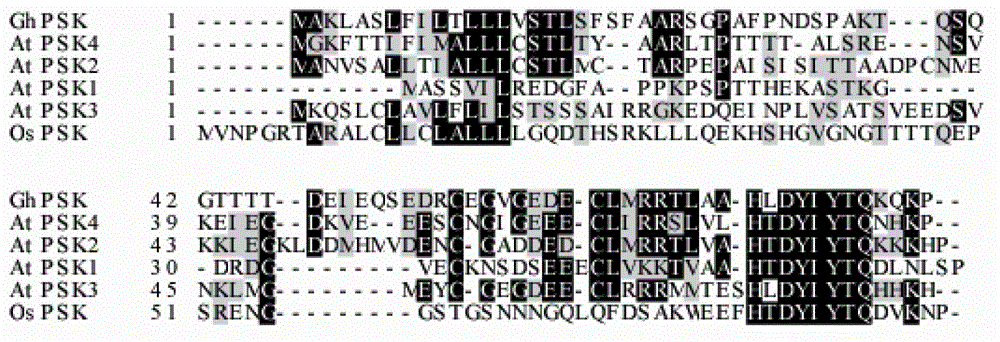

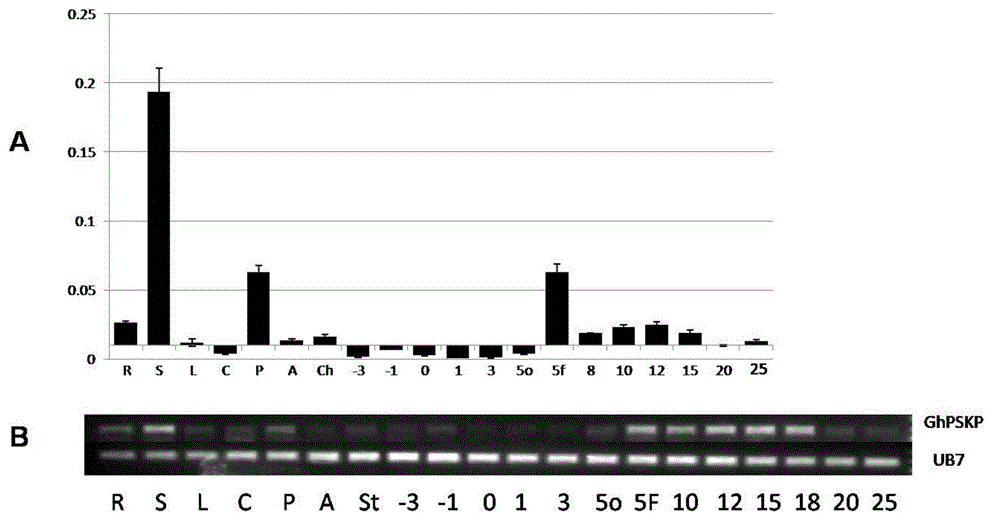

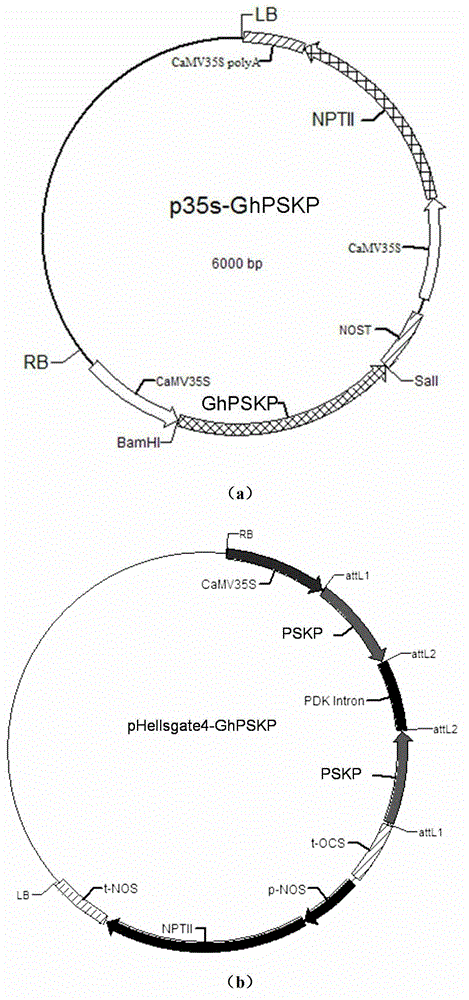

A kind of cotton phytosulfokine precursor gene ghpskp and its preparation method and application

InactiveCN103571850BImprove accuracyEfficient methodPlant peptidesFermentationFiberAgricultural science

The invention discloses a cotton phytosulfokine precursor (PSKP) gene GhPSKP and its preparation method and use. Through the preparation method, an EST which is highly homologous with a PSKP gene of other plants is separated from expression profiles of different cotton fiber growth periods, and bioinformatics analysis proves that the EST contains a complete ORF and is named as GhPSKP; the gene GhPSKP can be expressed highly in all fiber elongation periods, 10 DPA fiber total RNA is extracted from an upland cotton variety YZ1, the total RNA is reversely-transcribed by a reverse transcriptase Superscript III so that cDNA is obtained, and a full-length cDNA of the gene GhPSKP is obtained by amplification adopting primers of GhPSKPF and GhPSKPR; and the PCR product obtained by amplification is introduced into a pGEM-T carrier, positive clone is screened and is subjected to sequencing so that the full-length cDNA of the gene GhPSKP is obtained. An experiment proves that the gene GhPSKP can be preferentially expressed in the cotton fiber fast-elongation stage. Through excess expression of the gene GhPSKP based on a transgenosis method, fiber elongation is effectively promoted. The gene GhPSKP can effectively promote cotton fiber elongation and improve cotton fiber quality.

Owner:HUAZHONG AGRI UNIV

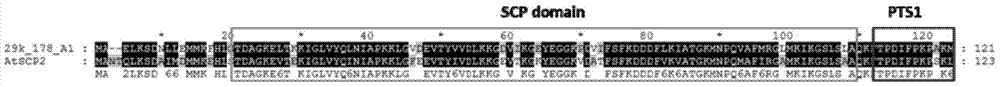

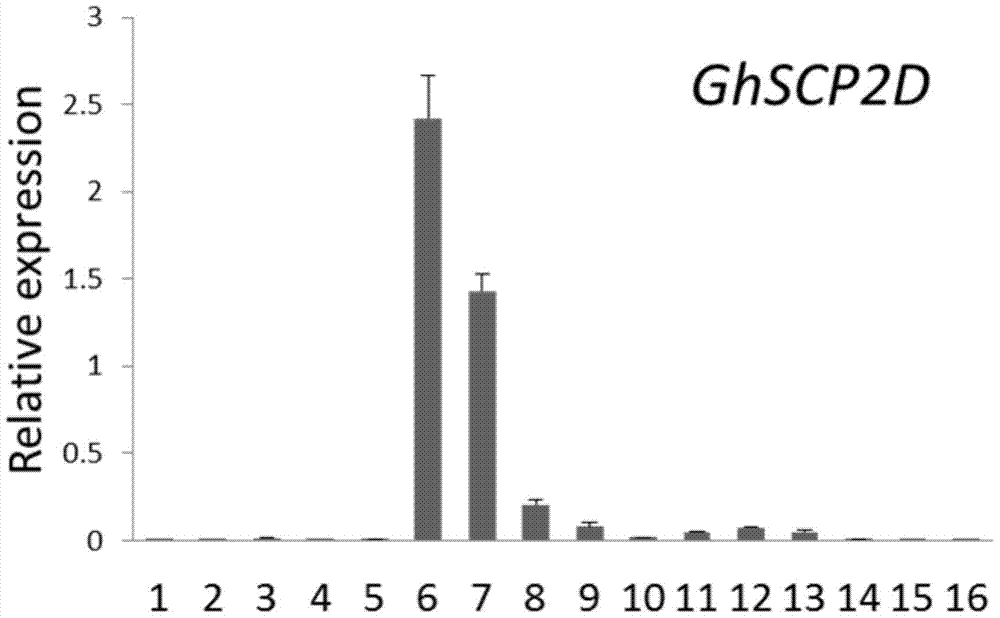

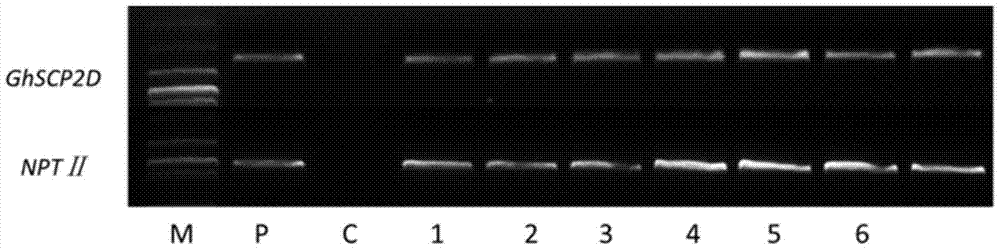

Cotton Sterol Carrier Protein Gene and Its Application

ActiveCN104894141BHigh elongationImprove qualityFermentationVector-based foreign material introductionFiberAgricultural science

A sterol carrier protein gene of cotton and applications thereof are disclosed. The sterol carrier protein gene is Gh SCP2D. The ORF sequence of the gene is shown as SEQ ID NO.1. The genomic sequence of the gene is shown as SEQ ID NO.2. Upland cotton is subjected to transgenic research by constructing a plant antisense expression vector, and expression analysis shows that expression of the gene is obviously inhibited, a phenotype of reduced velvet length is shown in transgenic plant, and the sucrose content is obviously reduced, so that the sterol carrier protein gene Gh SCP2D can be applied in sucrose transportation modification and cotton fiber elongation modification in cotton fiber development processes.

Owner:NANJING AGRICULTURAL UNIVERSITY

A promoter predominantly expressed during fiber elongation, its preparation method and application

The invention discloses a fiber elongation-stage predominant-expression promoter, and a preparation method and an application thereof. The promoter mainly predominantly expresses in an elongation stage, two promoters comprising PGhGLP2 and PGbGLP3 and GUS are fused, and the obtained fusion converts cotton, chemical dyeing of fibers shows that the two promoters comprising PGhGLP2 and PGbGLP3 do not express in ovules in the bloom day, the expression of the GUS can be detected in fibers from 1DPA, and the expression of the GUS cannot be detected in the ovules. The expression peaks of the two promoters are in the cotton fiber elongation stage. The elongation stage is a very key stage for the cotton fibers, and the utilization of the specific expression of some genes important to the formation of high-quality fibers by the promoter in the heredity improvement will increase the cotton output without influencing the growth of other tissues and organs.

Owner:HUAZHONG AGRI UNIV

Cotton cell wall extensin gene gbeexpatr and its application

Owner:HUAZHONG AGRI UNIV

Identification and application of a cotton bhlh transcription factor gene ghfp1 and its promoter

ActiveCN104711266BHigh specific expression activityHigh elongationMicrobiological testing/measurementPlant peptidesPromoter activityBHLH Proteins

The cotton GhFP1 gene is a member of the bHLH transcription factor gene family, and its cDNA is 1262bp in full length, encoding a bHLH protein containing 355 amino acids. GhFP1 was expressed in all tissues of cotton, and it was highly expressed in the pre-middle stage of fiber development. The GhFP1 promoter fragment with a length of 1061bp was isolated and cloned. The promoter activity was analyzed by GUS reporter gene, which showed that the promoter had high specific expression activity in cotton fiber. Experiments have shown that overexpression of GhFP1 in Arabidopsis leads to growth of leaf epidermis; overexpression of GhFP1 in cotton leads to up-regulation of brassinolide-related genes in cotton fiber cells and increased length of mature cotton fibers. The above results prove that GhFP1 protein plays a positive regulatory role in the process of cotton fiber elongation and promotes fiber cell elongation, which may have important application value for improving cotton fiber quality and increasing cotton yield.

Owner:HUAZHONG NORMAL UNIV

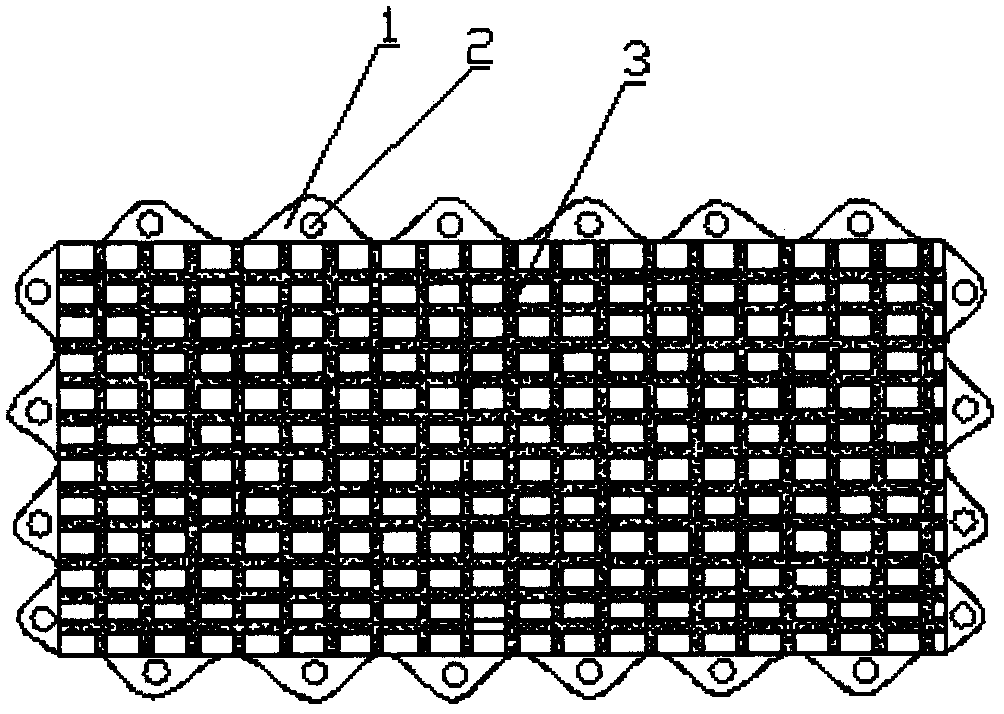

Person falling prevention flame retardant safety plain net structure and production technology

PendingCN109138472AImprove insulation performanceStrong heat resistanceBuilding material handlingGlass fiberEngineering

The invention discloses a person falling prevention flame retardant safety plain net production technology. The production technology comprises the following steps of step1, selecting a glass fiber filament, a chemical fiber elongation filament and a chemical fiber non-elongation filament as the raw materials of preparation; step2, weaving the glass fiber filament in the step1 into a net body through a rapier machine or a weaving loom; weaving the chemical fiber elongation filament and the chemical fiber non-elongation filament in the step1 into an external mesh through a net weaving machine;step3, adding an organic silicon coating, a polyethylene anticorrosive coating and a teflon coating in a number one dyeing cylinder, a number two dyeing cylinder and a number three dyeing cylinder, and uniformly stirring and mixing; and step4, putting the net body in the step 2 into the number one dyeing cylinder in the step3, and dipping for 2 to 4 minutes. When a human body falls on a safety plain net from a high place, under the effect of an external force, a glass fiber non-elongation filament is broken, and the glass fiber elongation filament is continuously under the stress till the filament is broken so that the effects of buffering and energy dissipation are achieved.

Owner:泰州市常沪线网有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com