Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Controllable molding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma 3D printing remanufacturing equipment and method for train wheel

InactiveCN105710371ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyDistance detectionPlasma beam

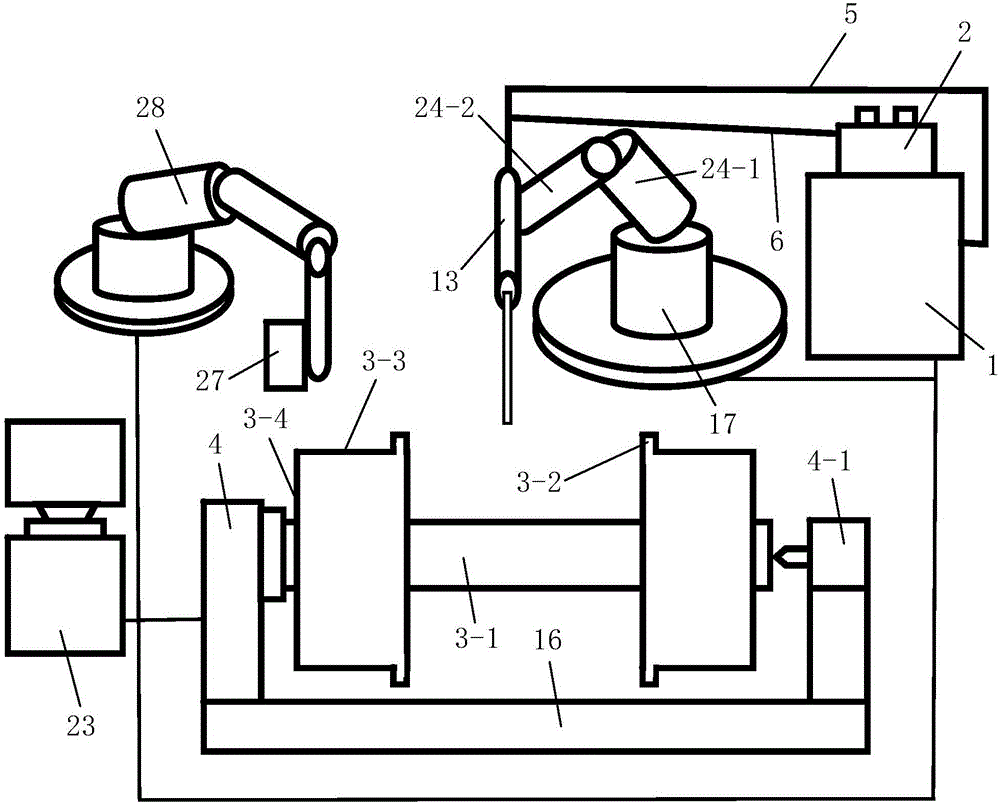

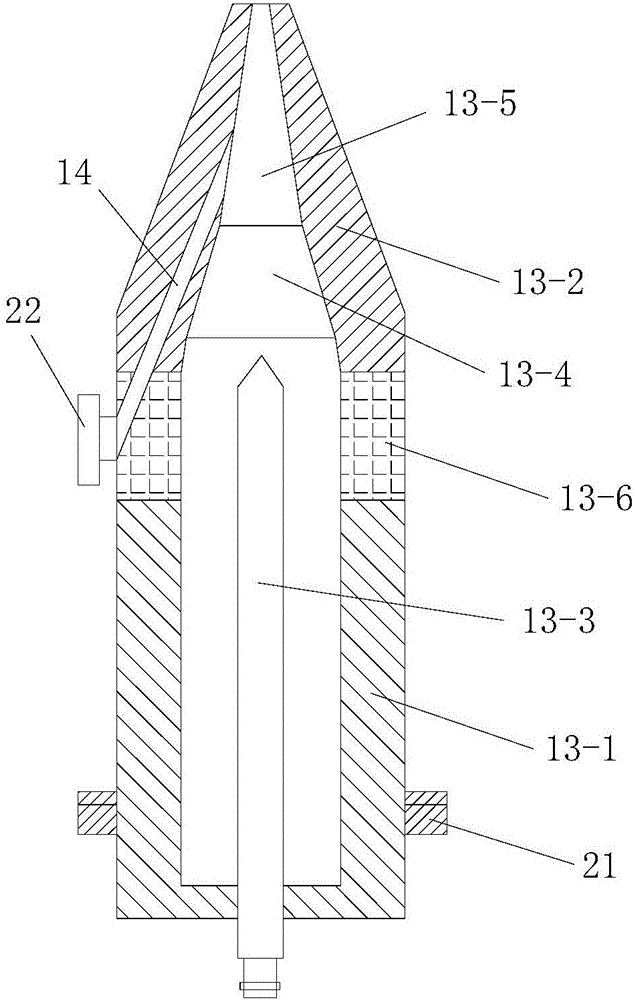

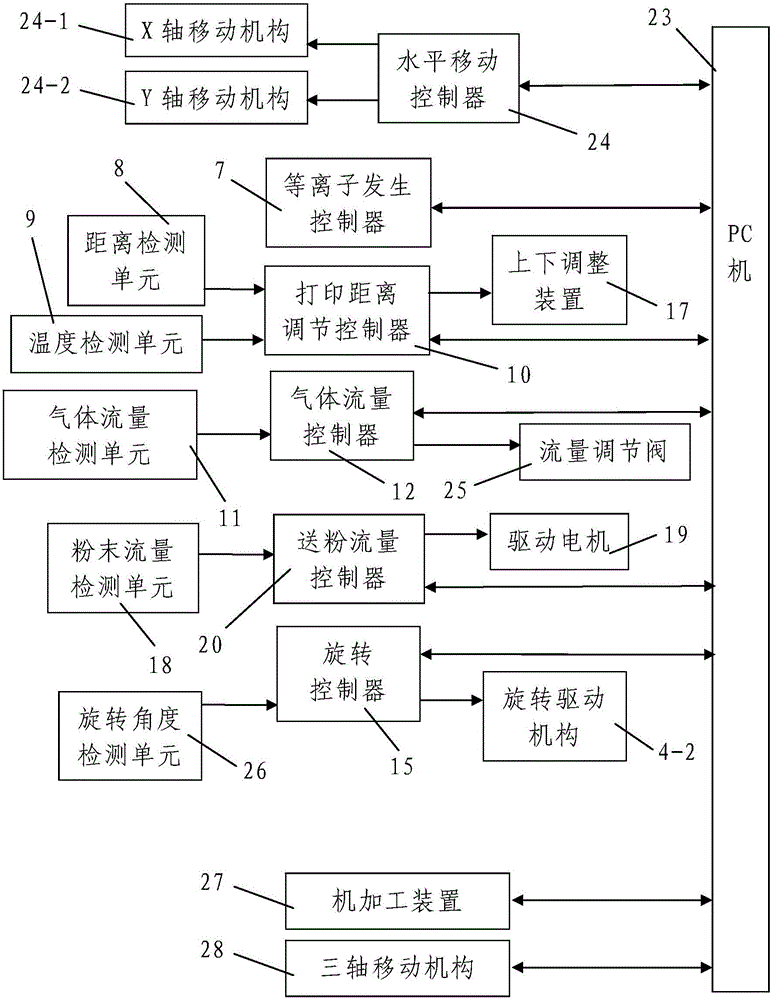

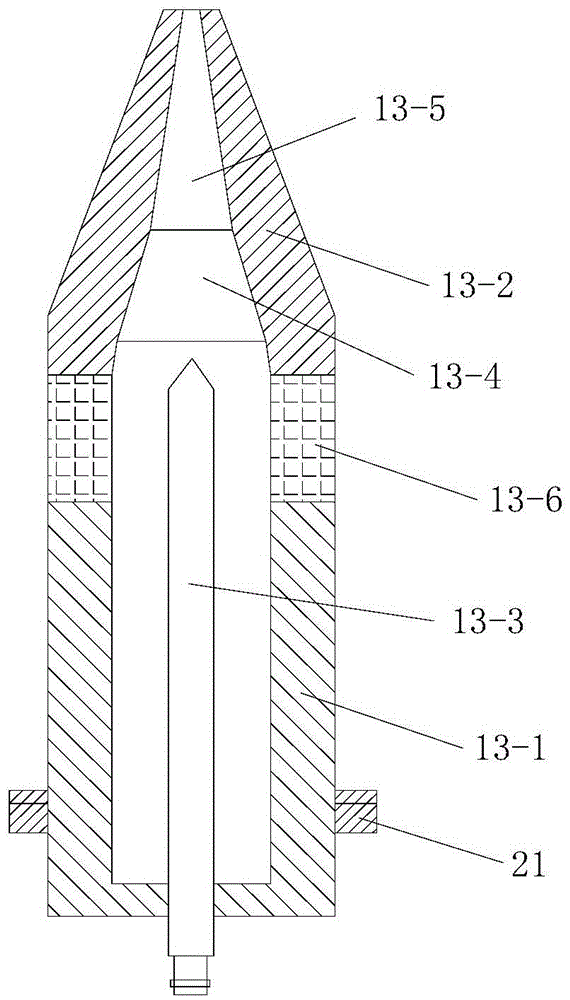

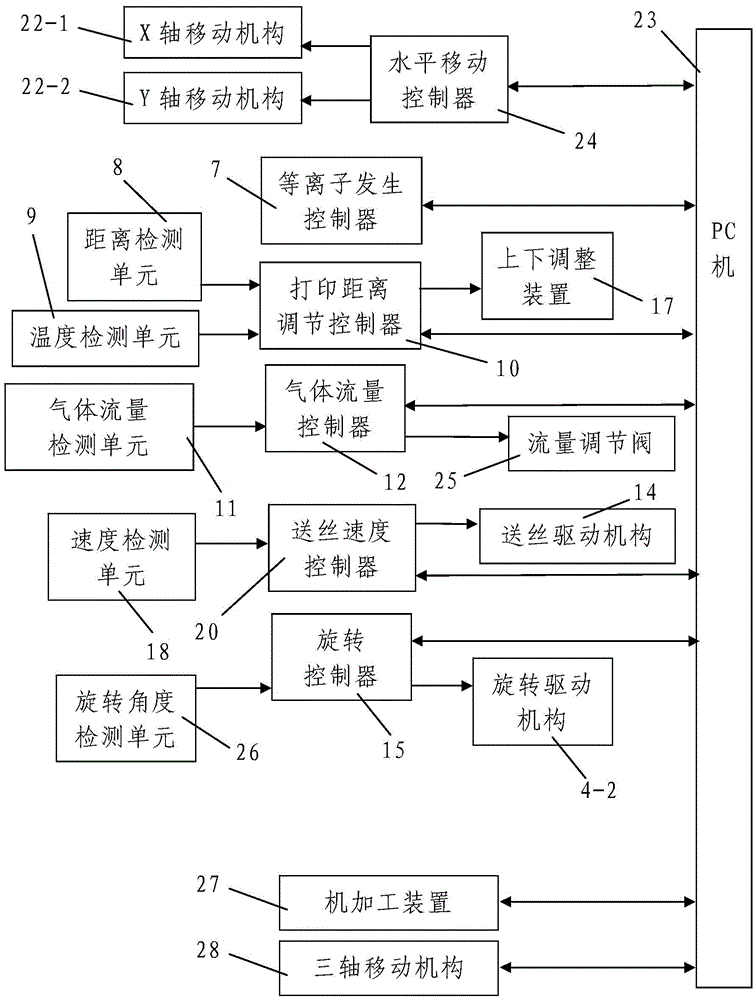

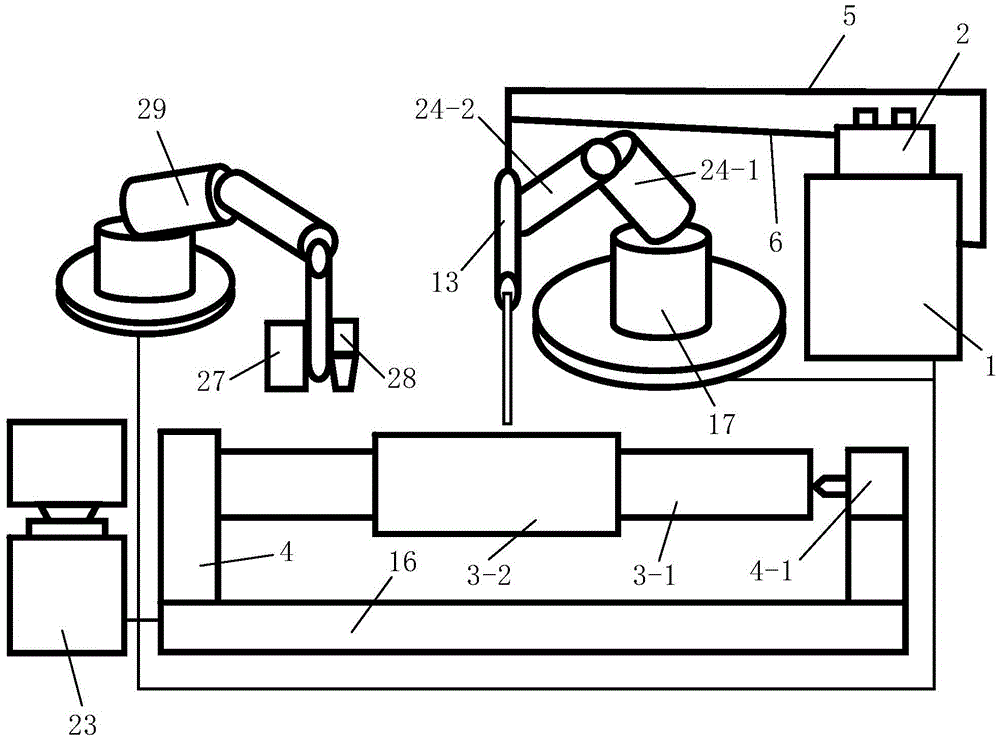

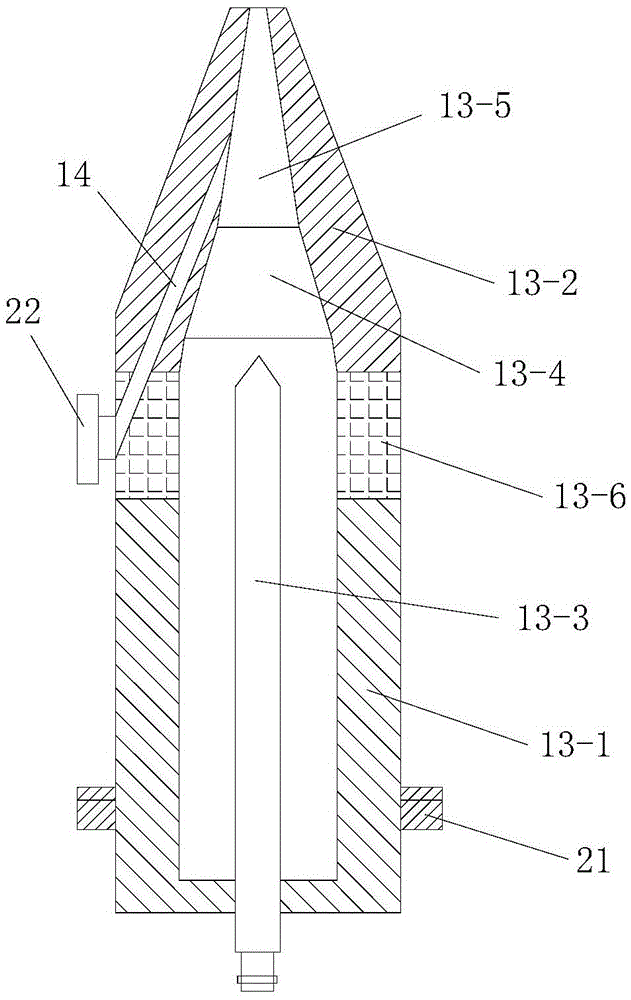

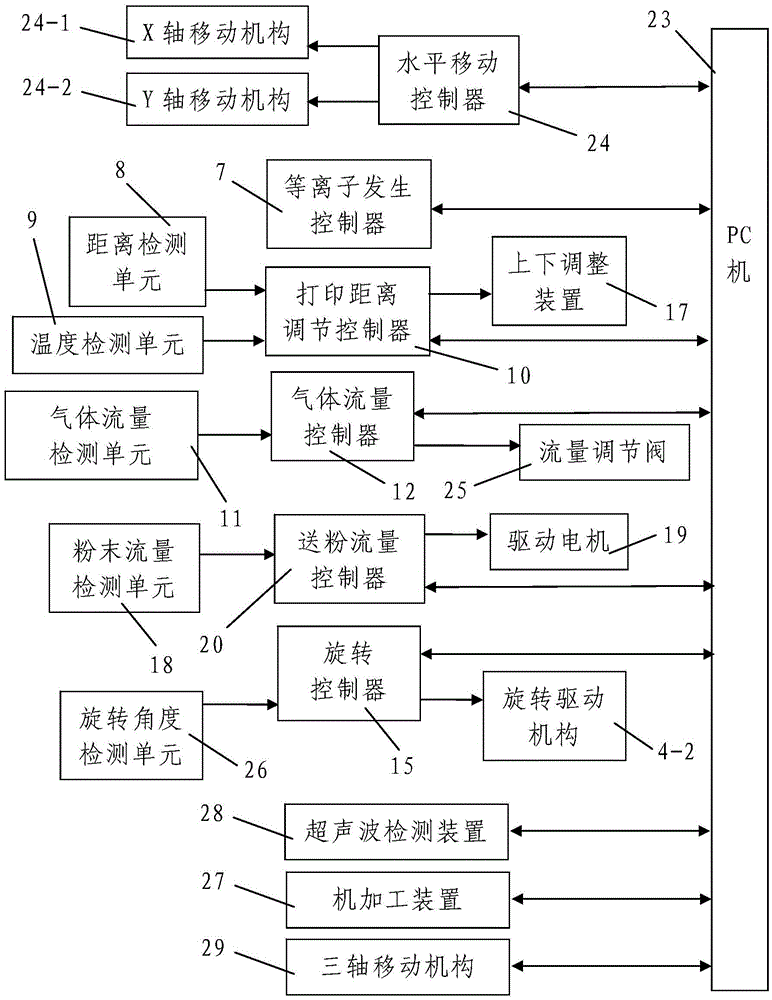

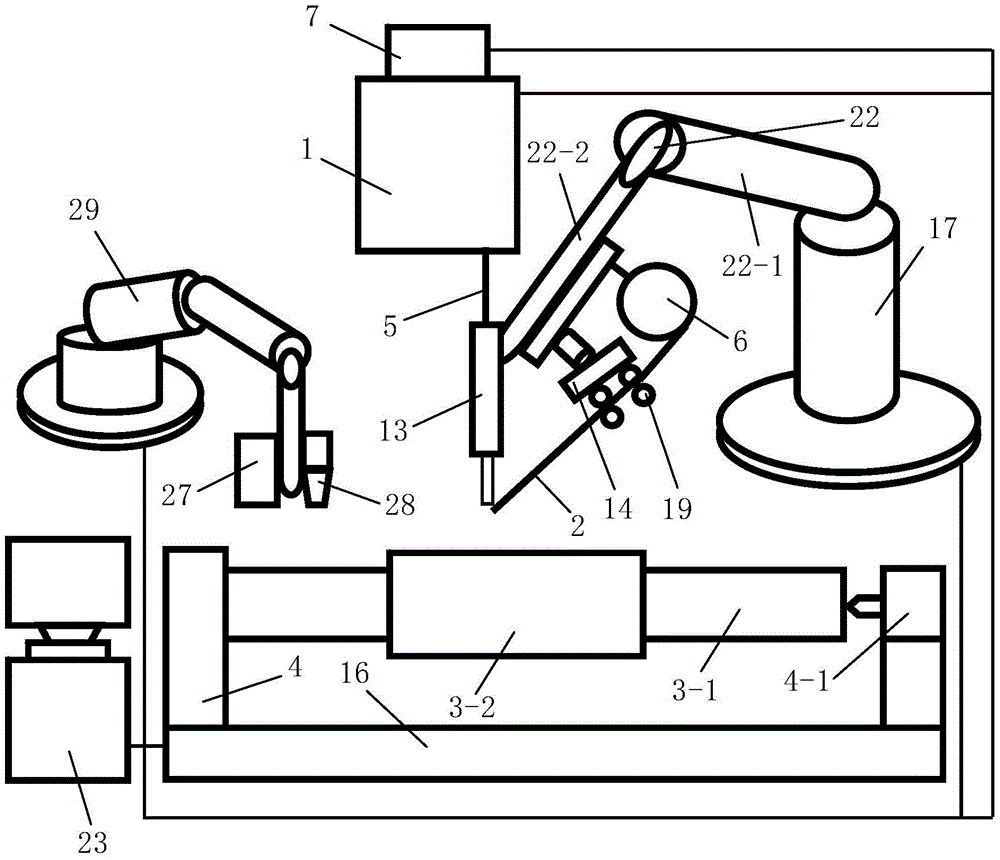

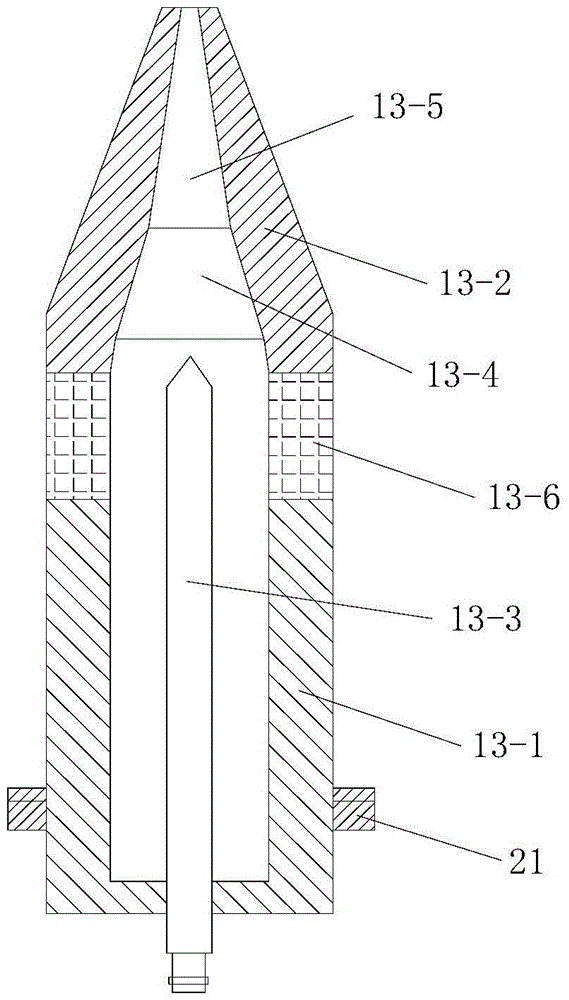

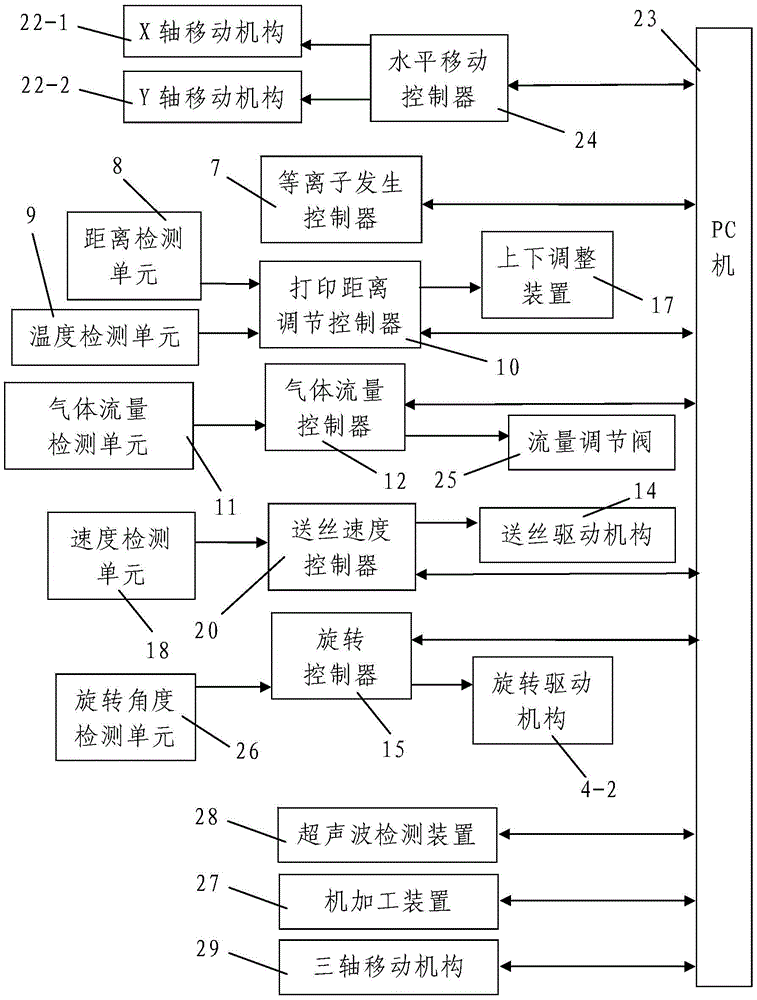

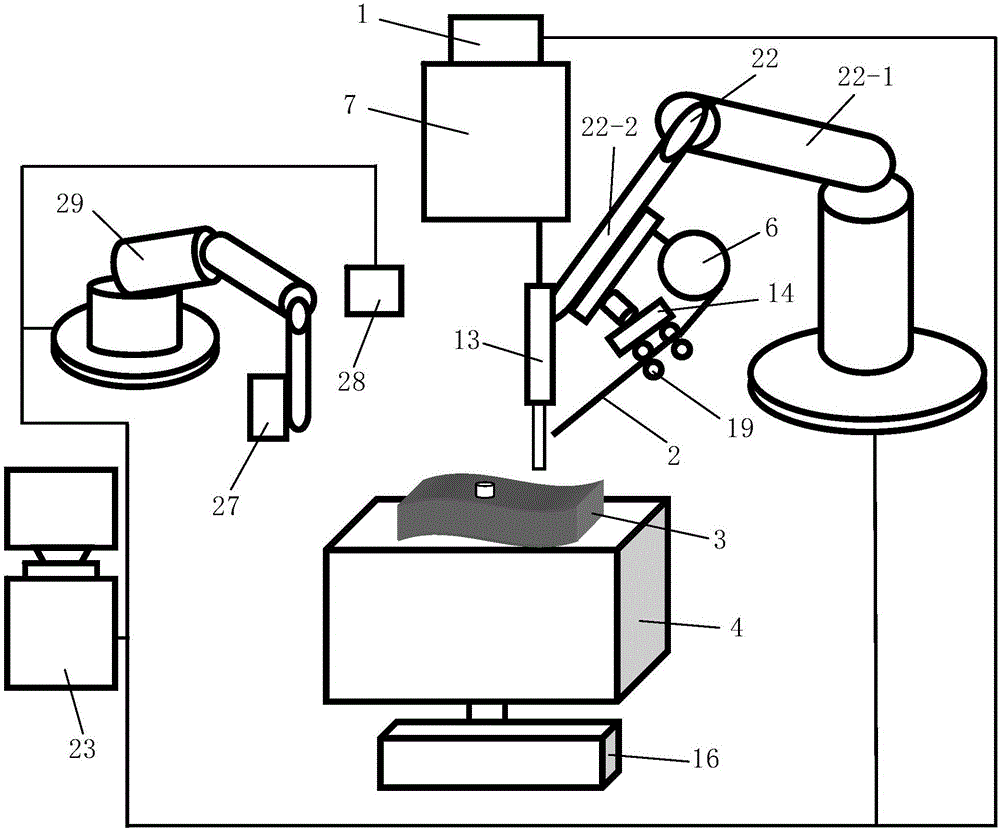

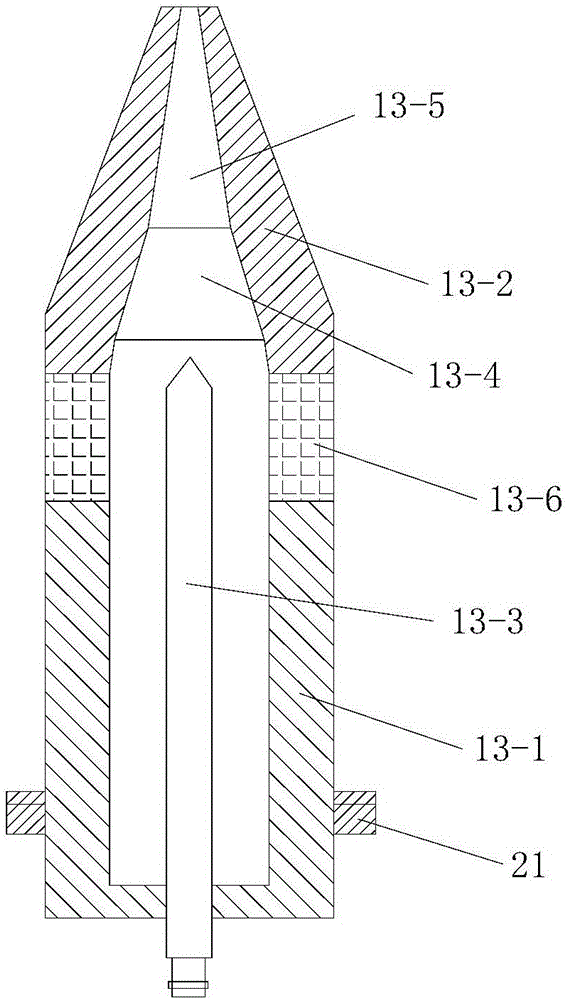

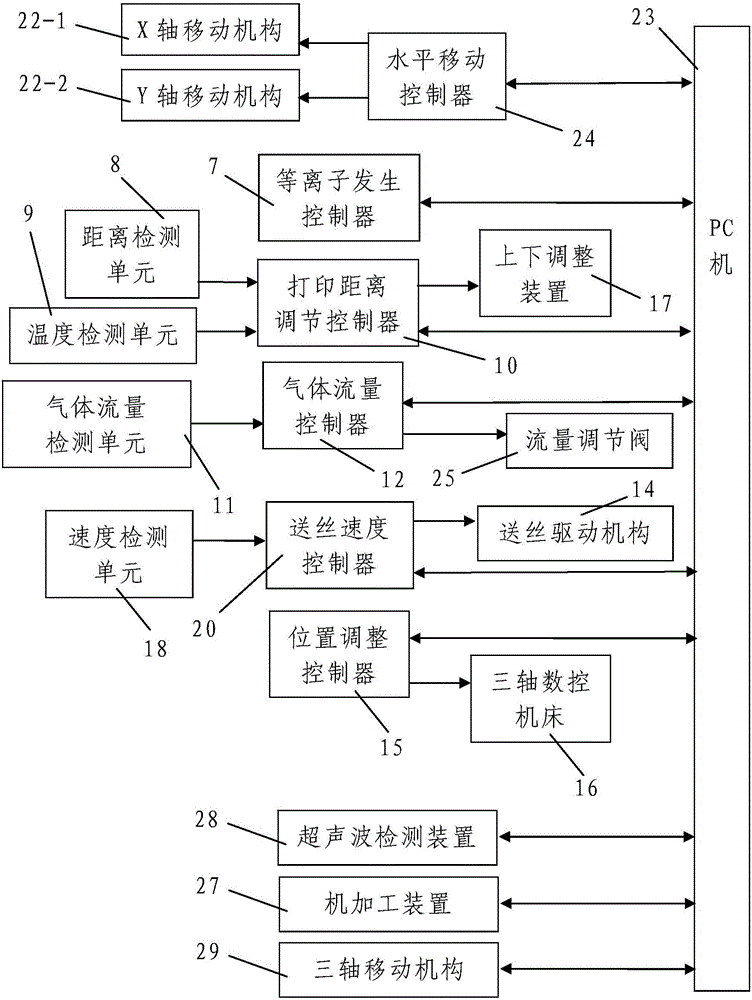

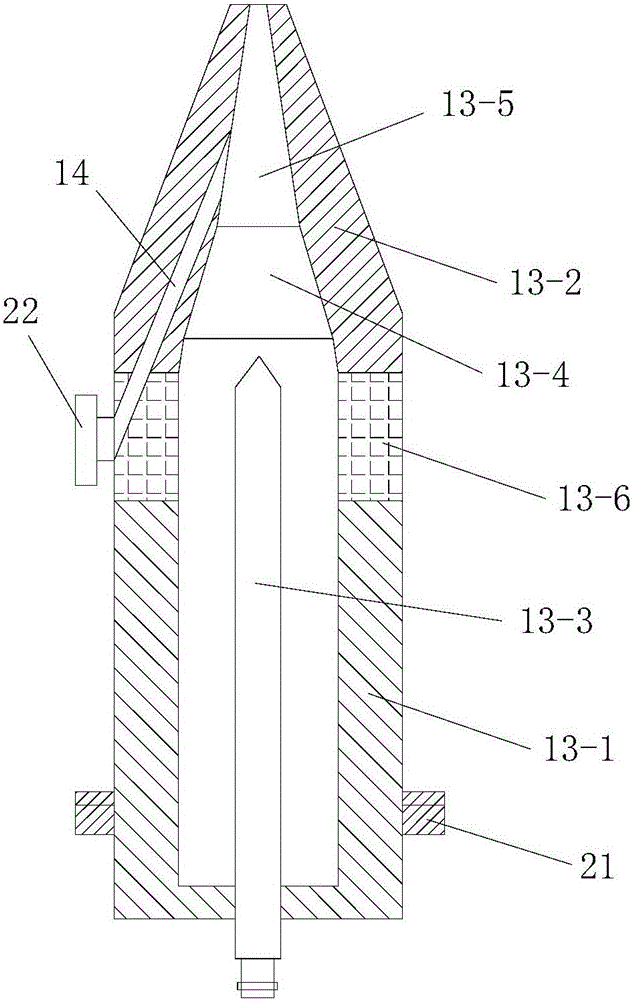

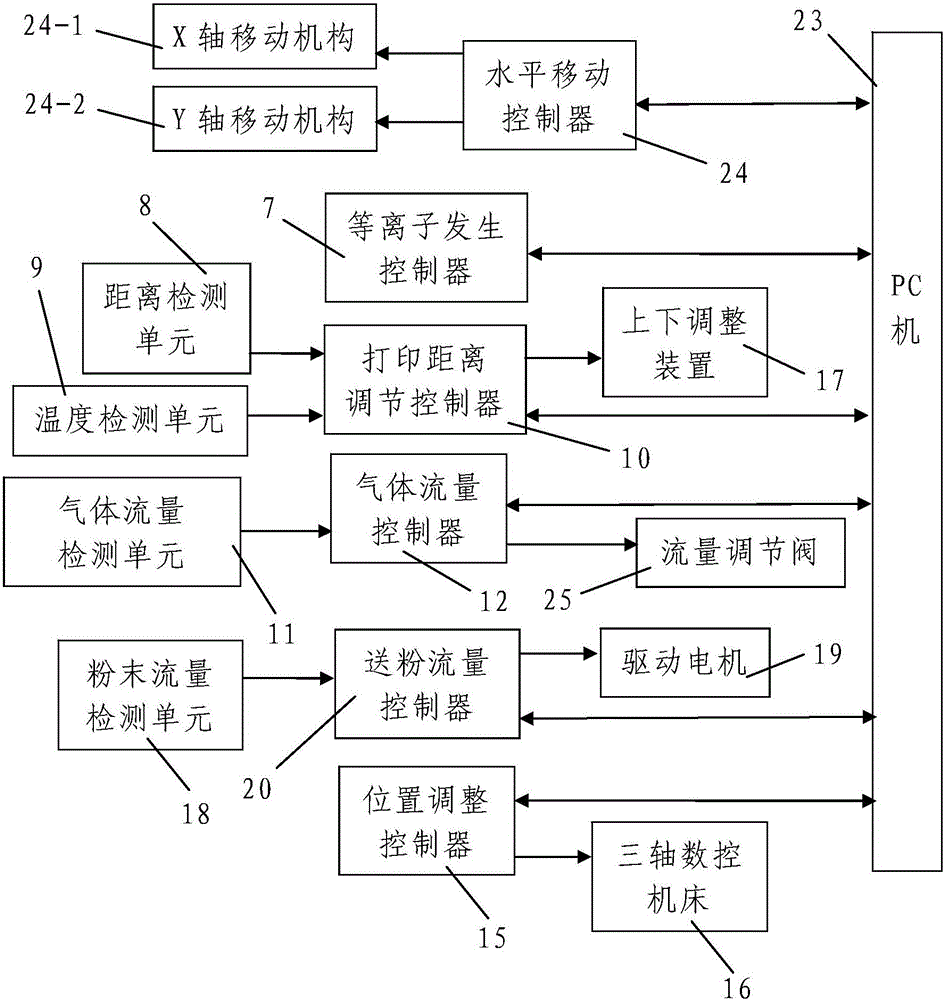

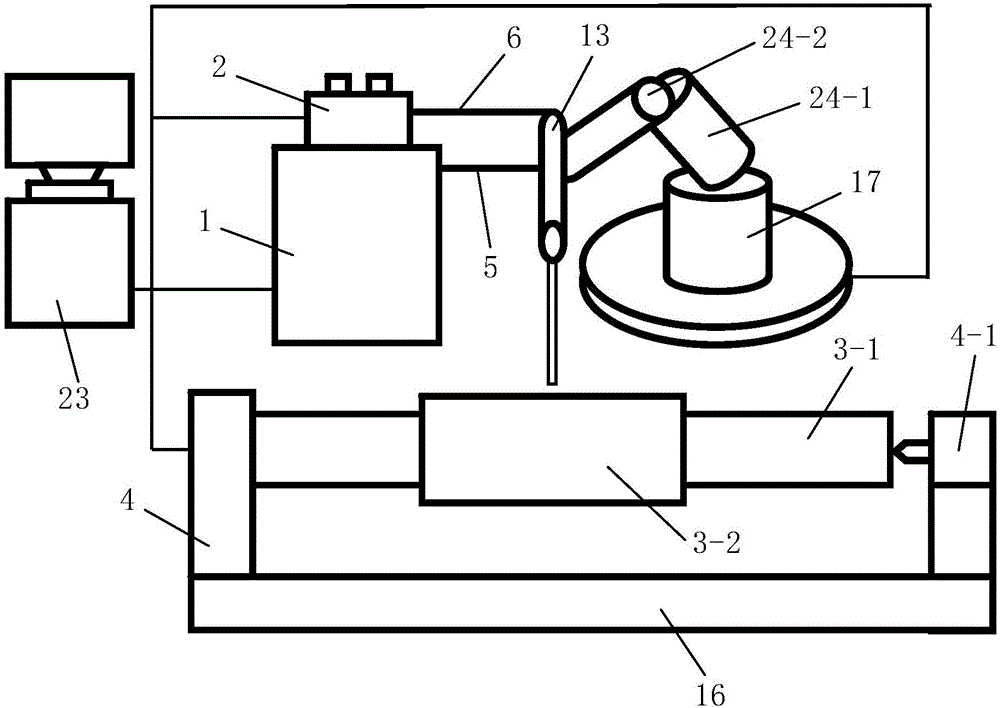

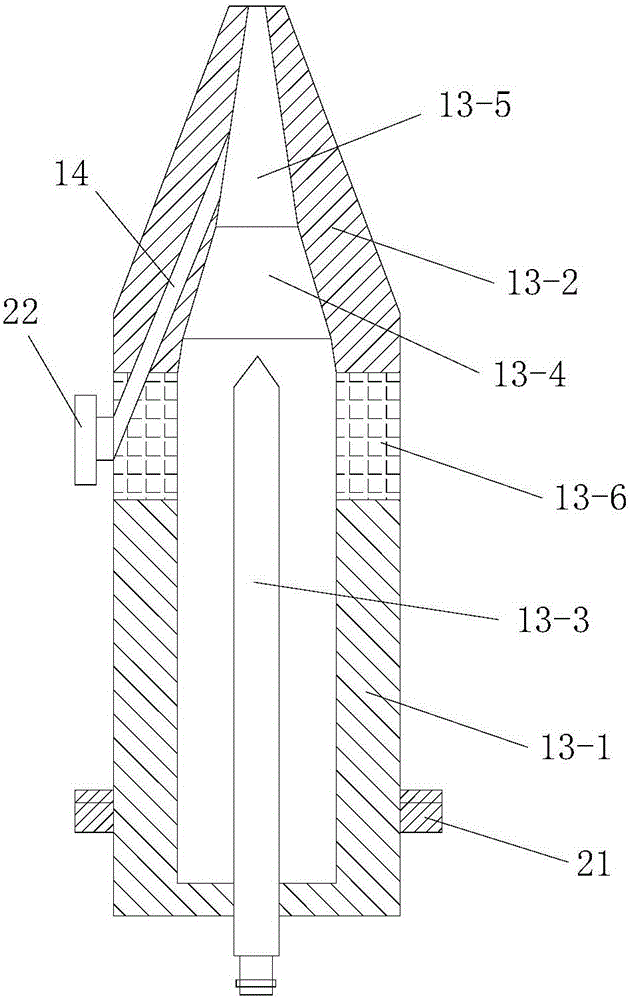

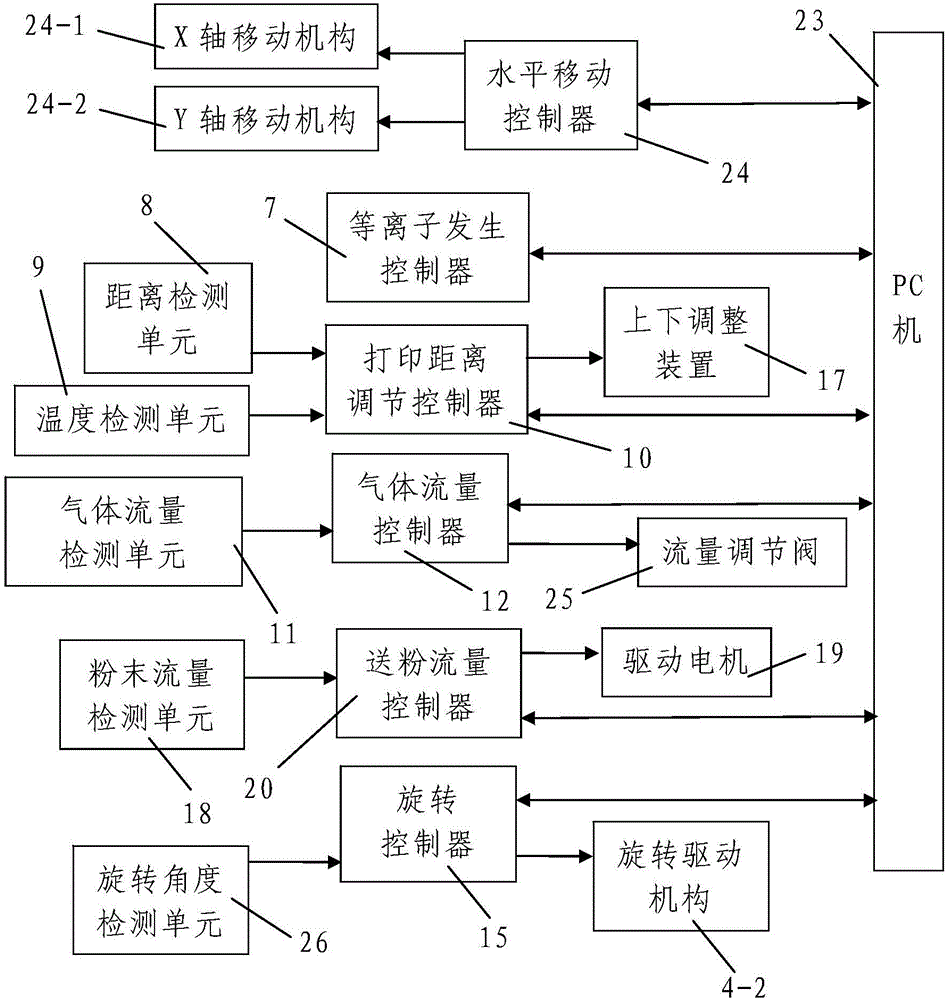

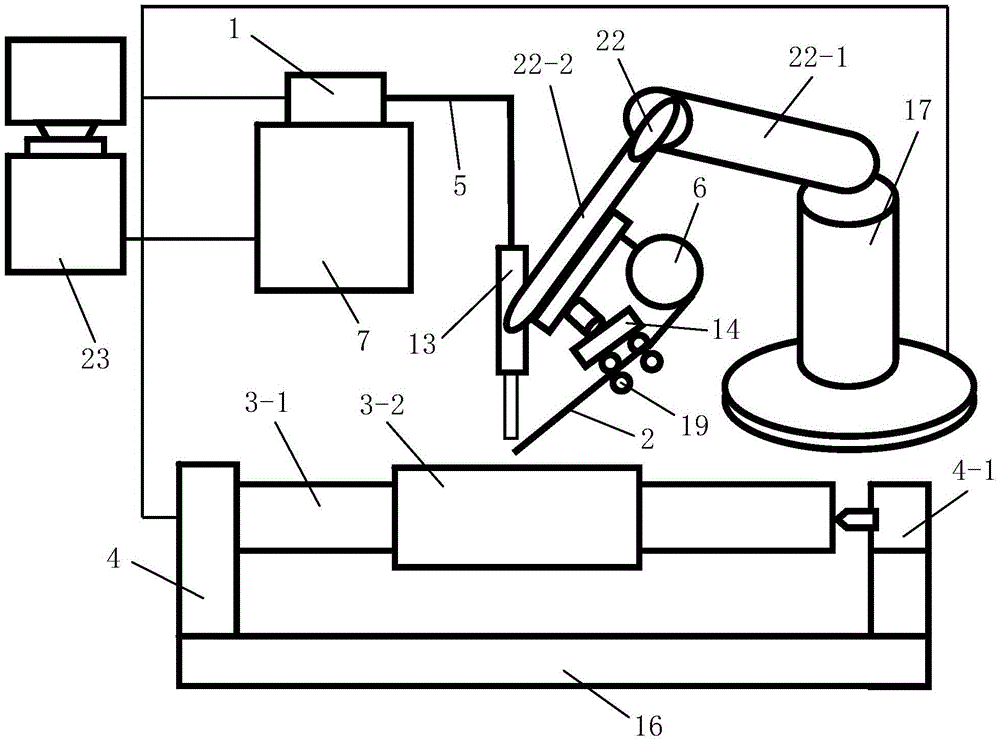

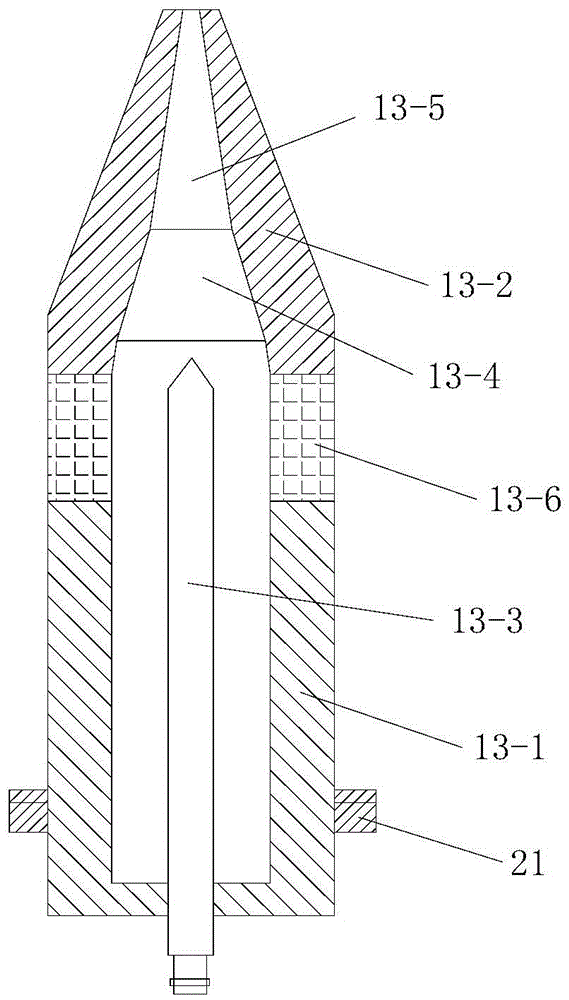

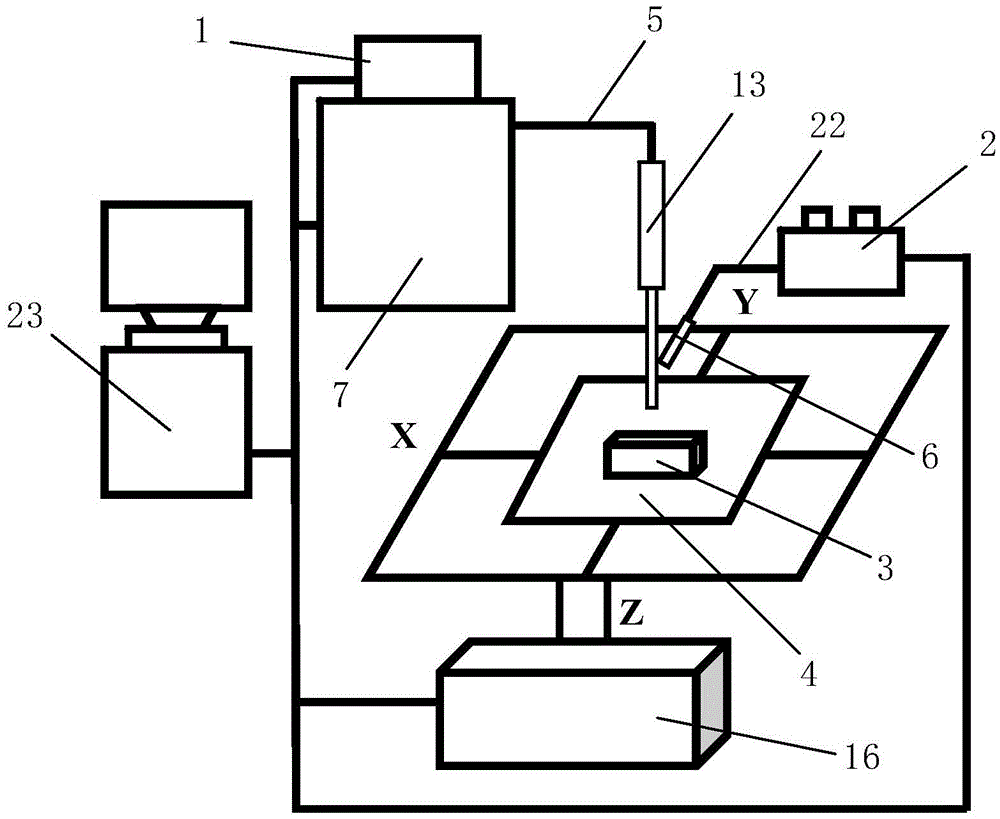

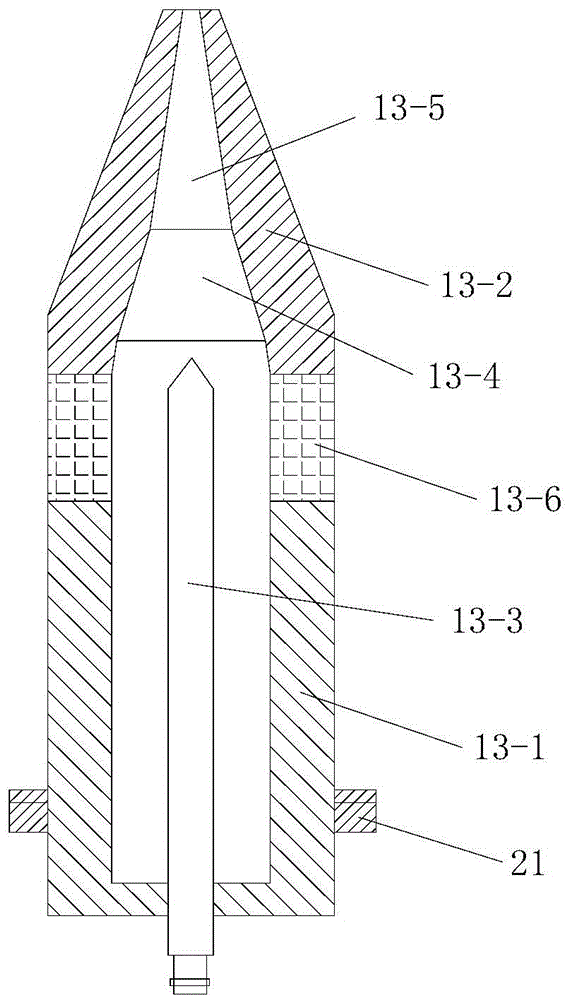

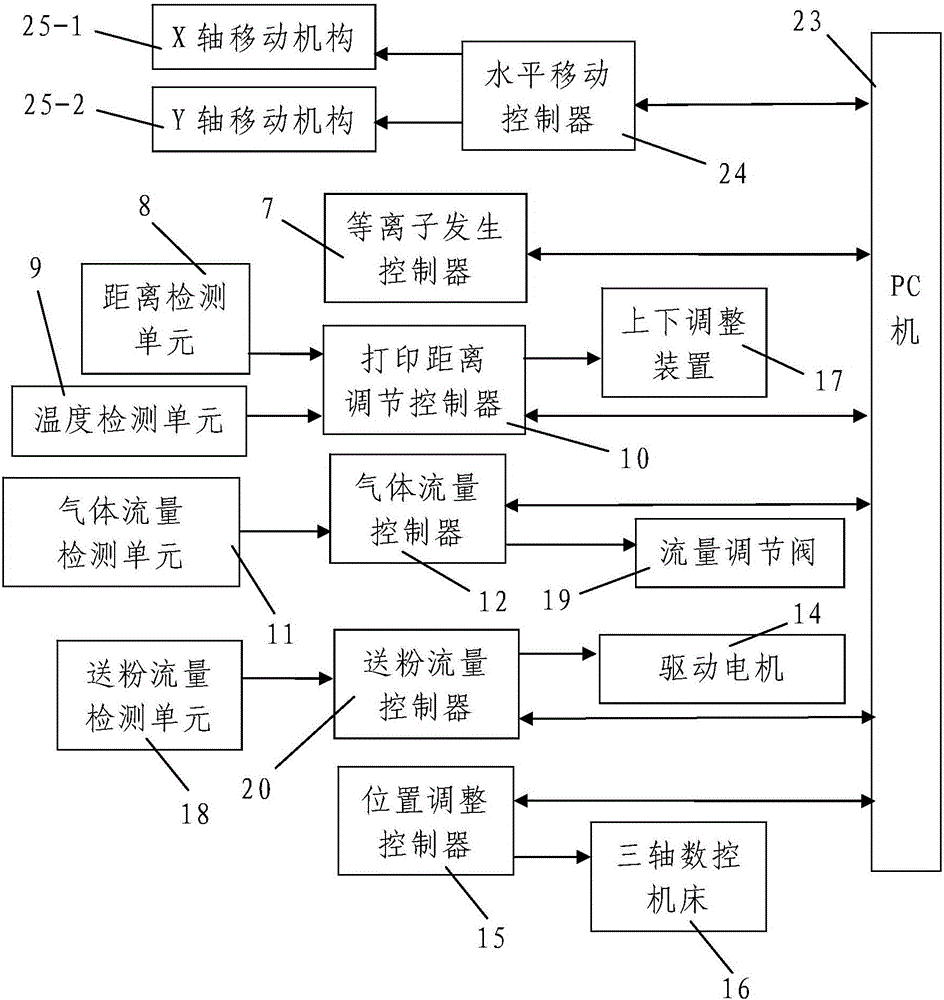

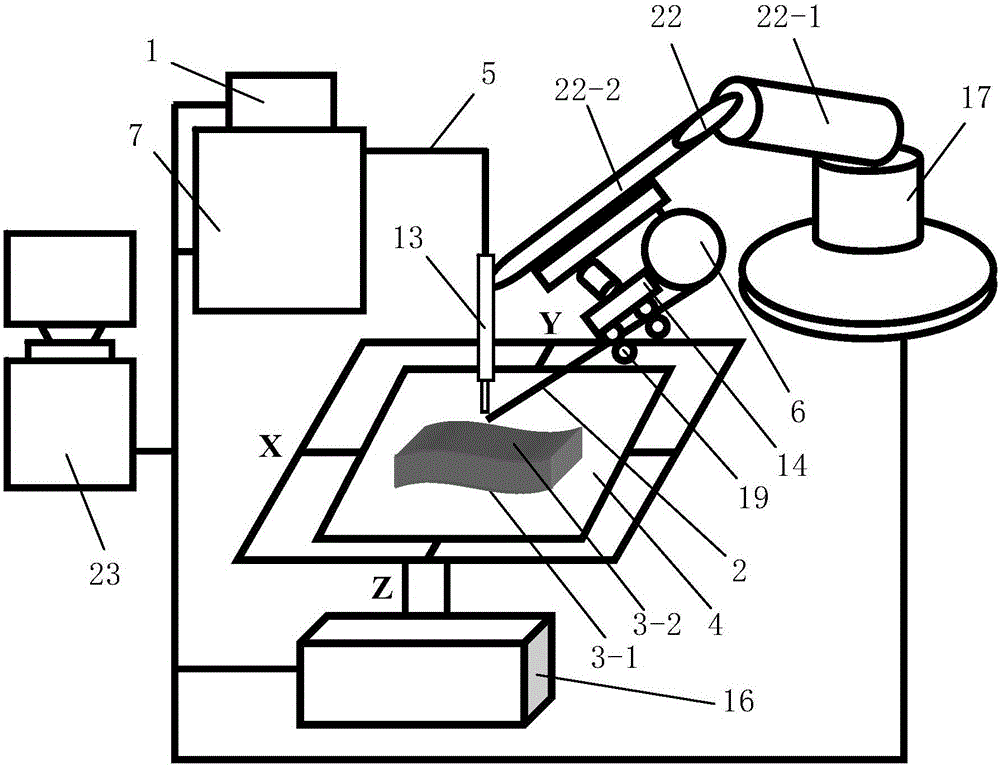

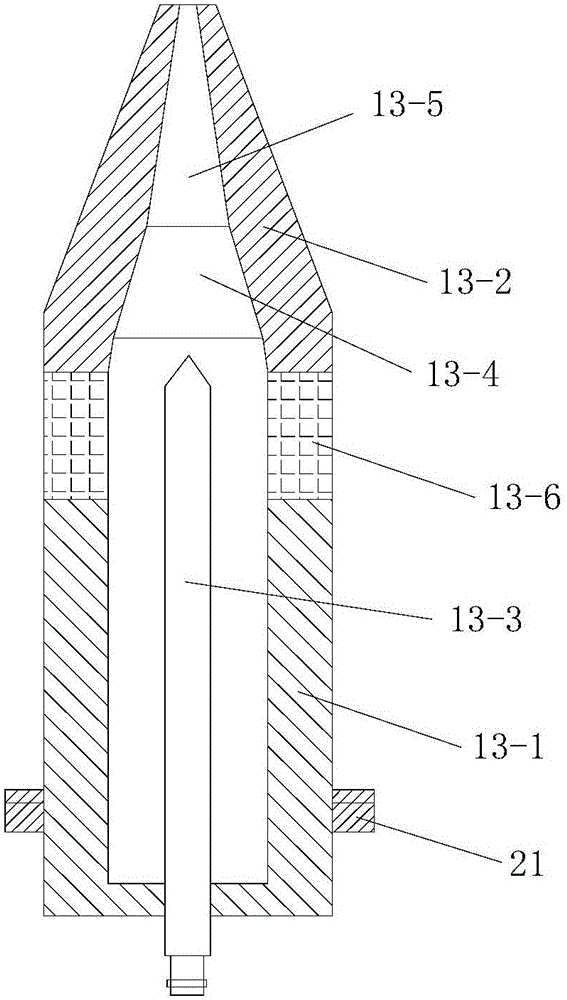

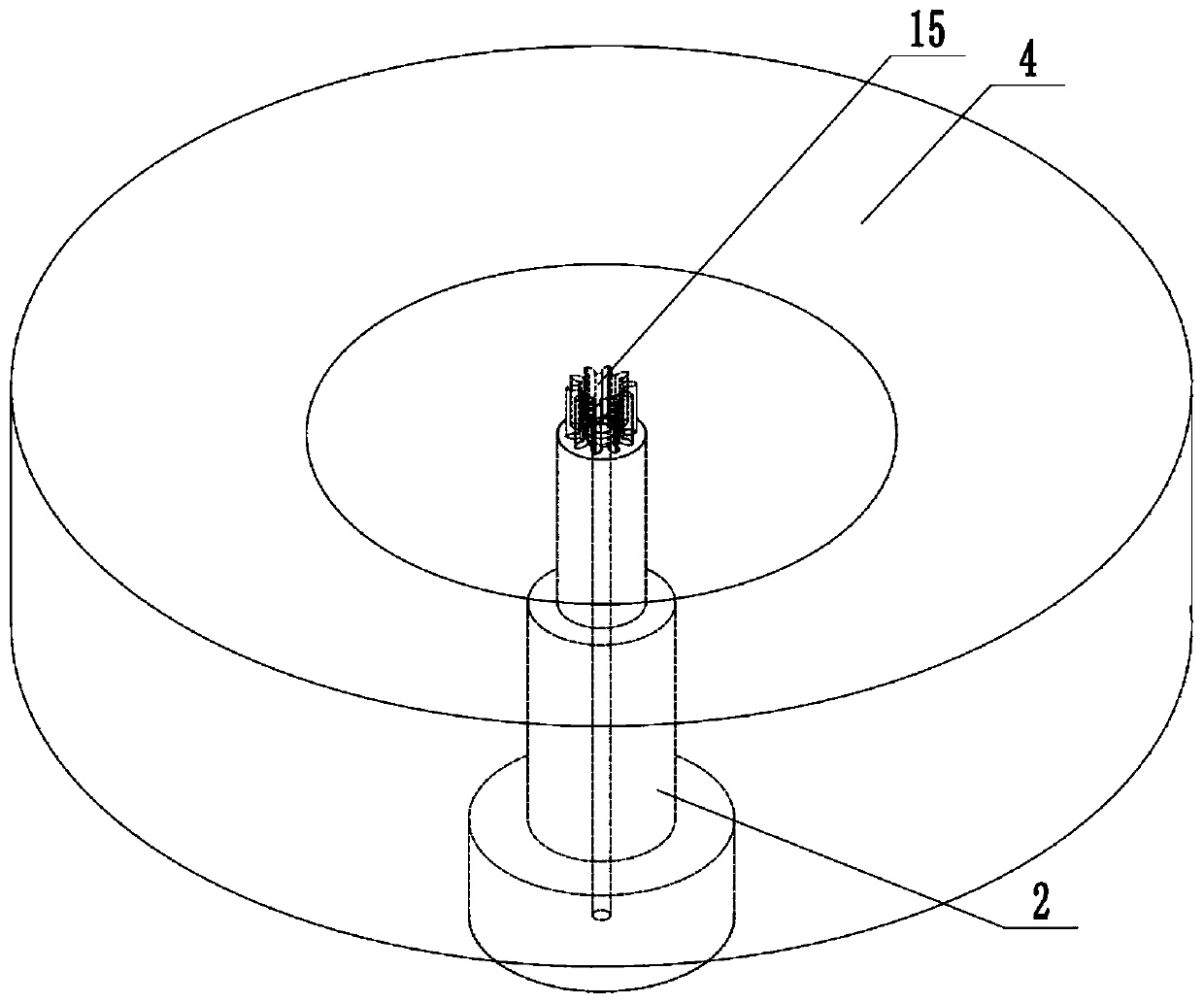

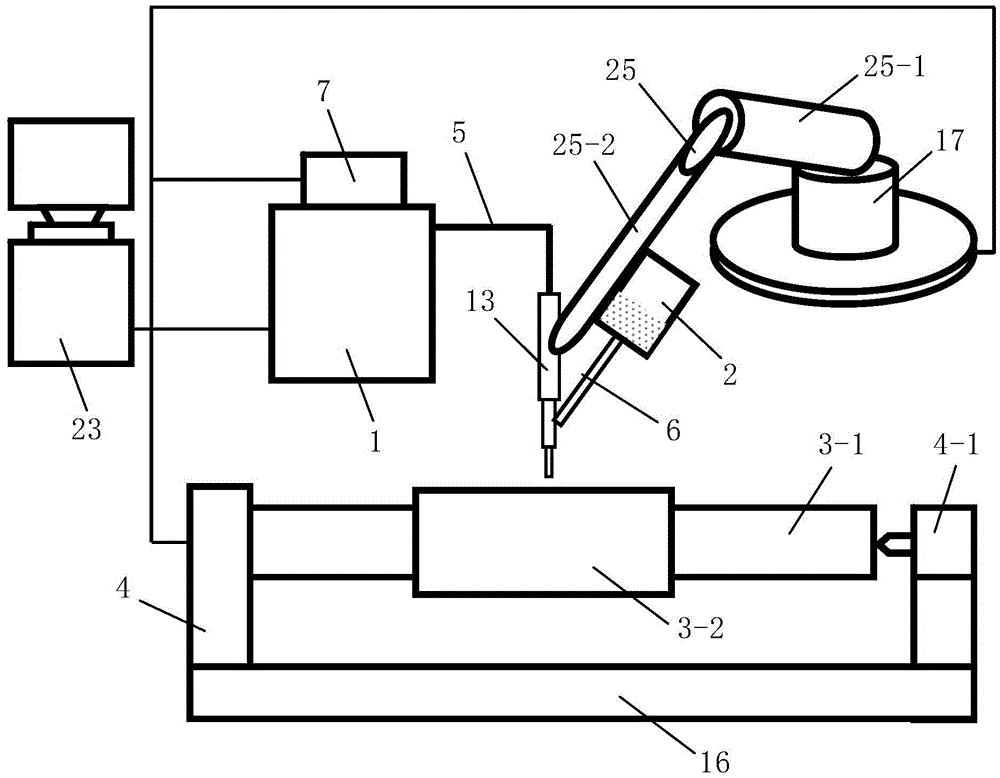

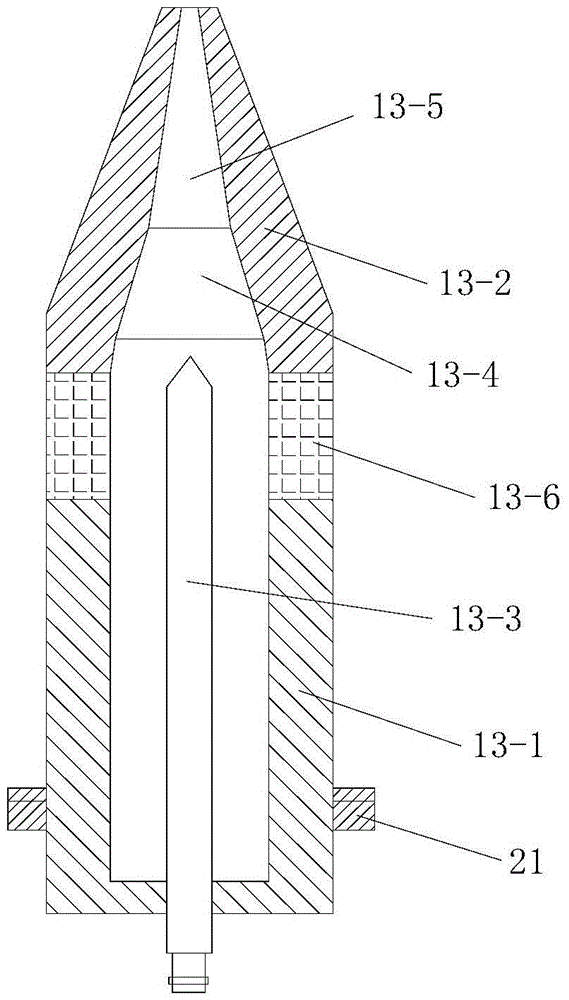

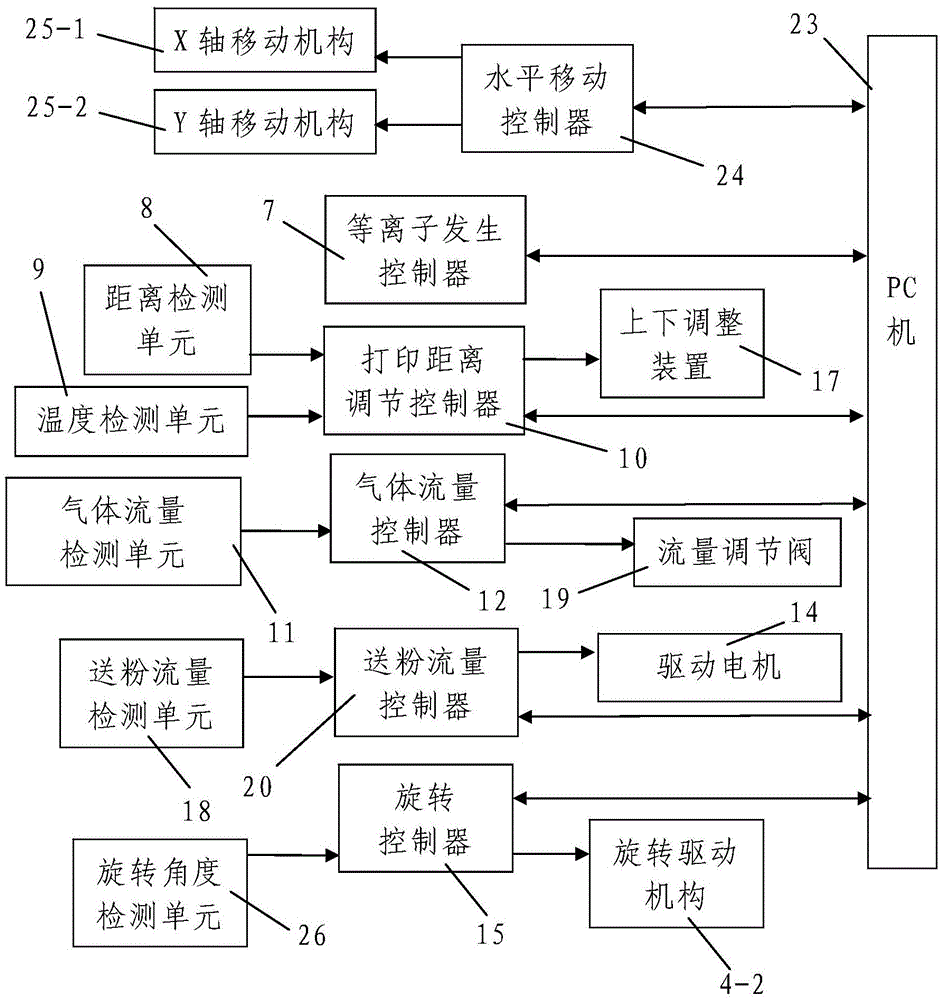

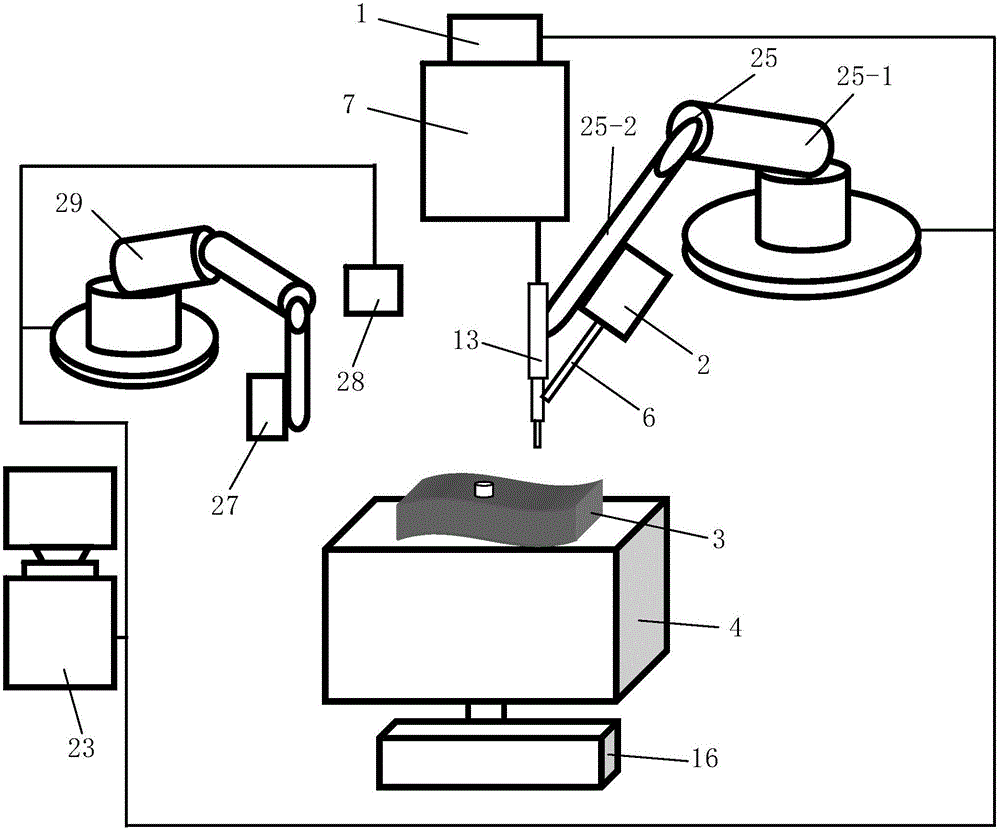

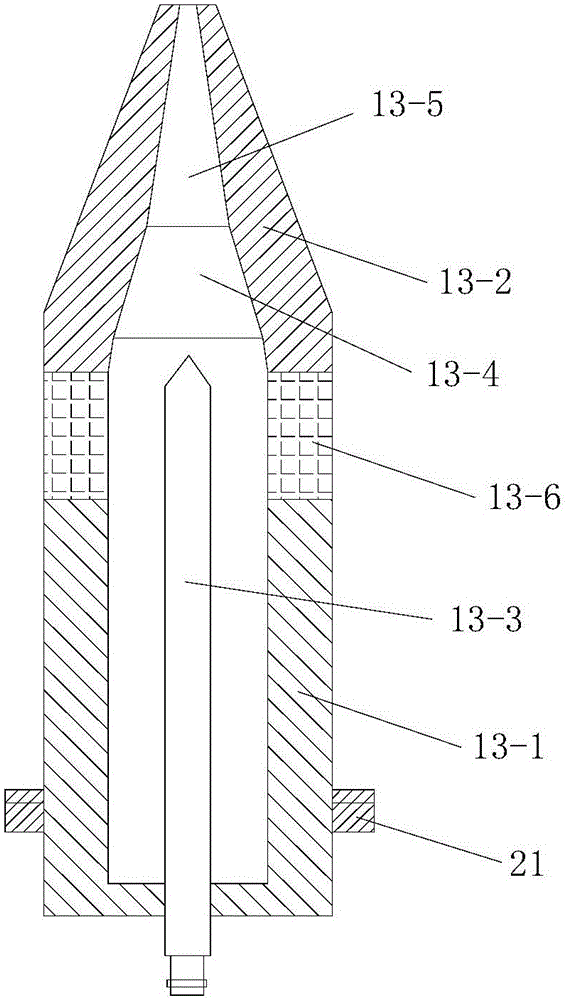

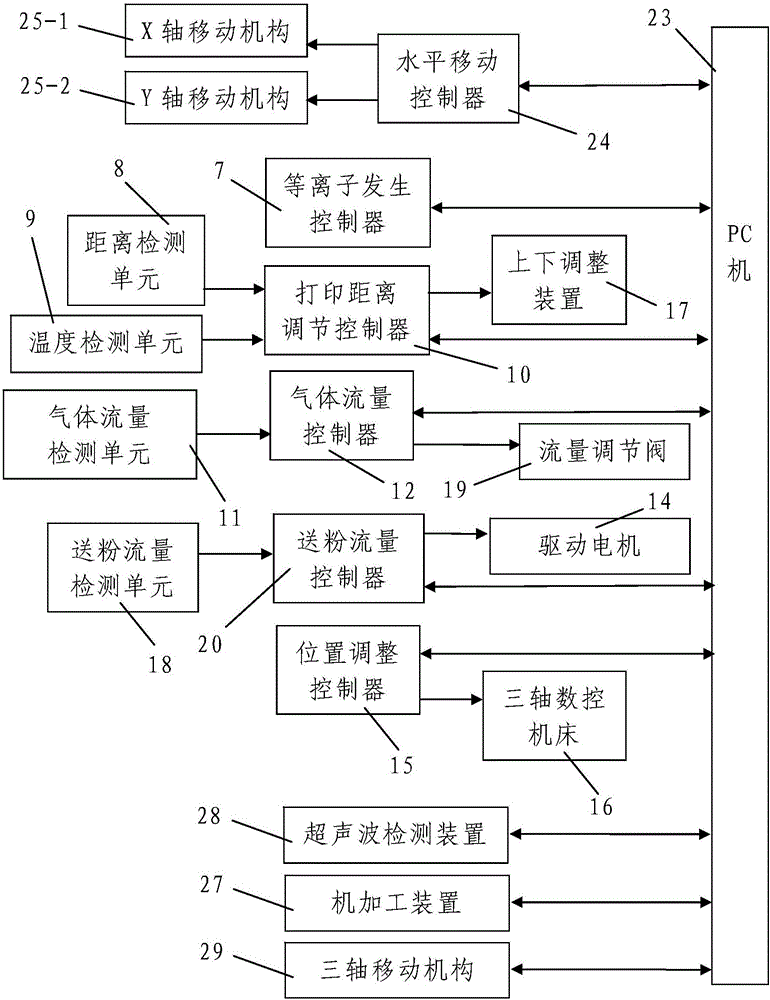

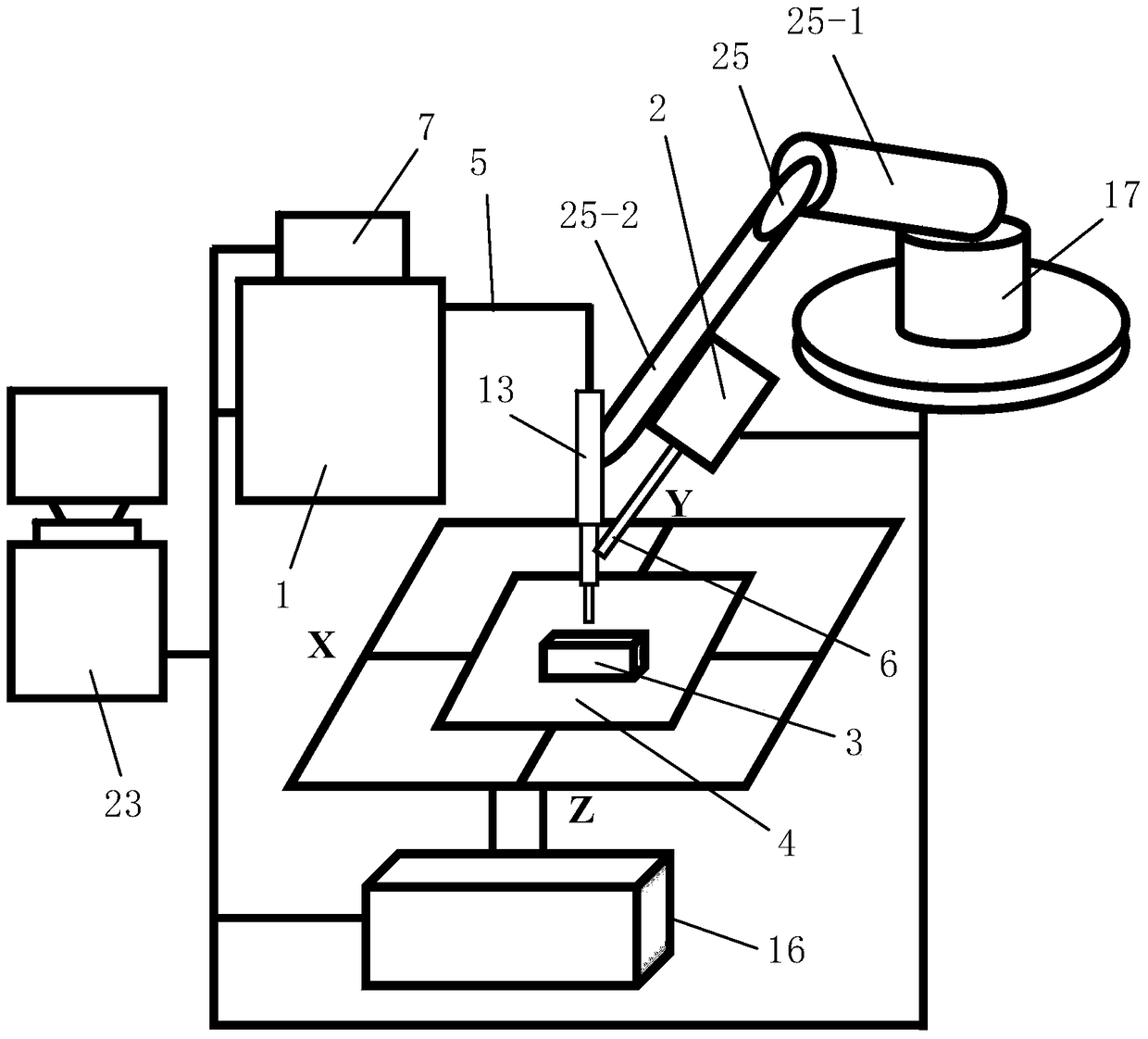

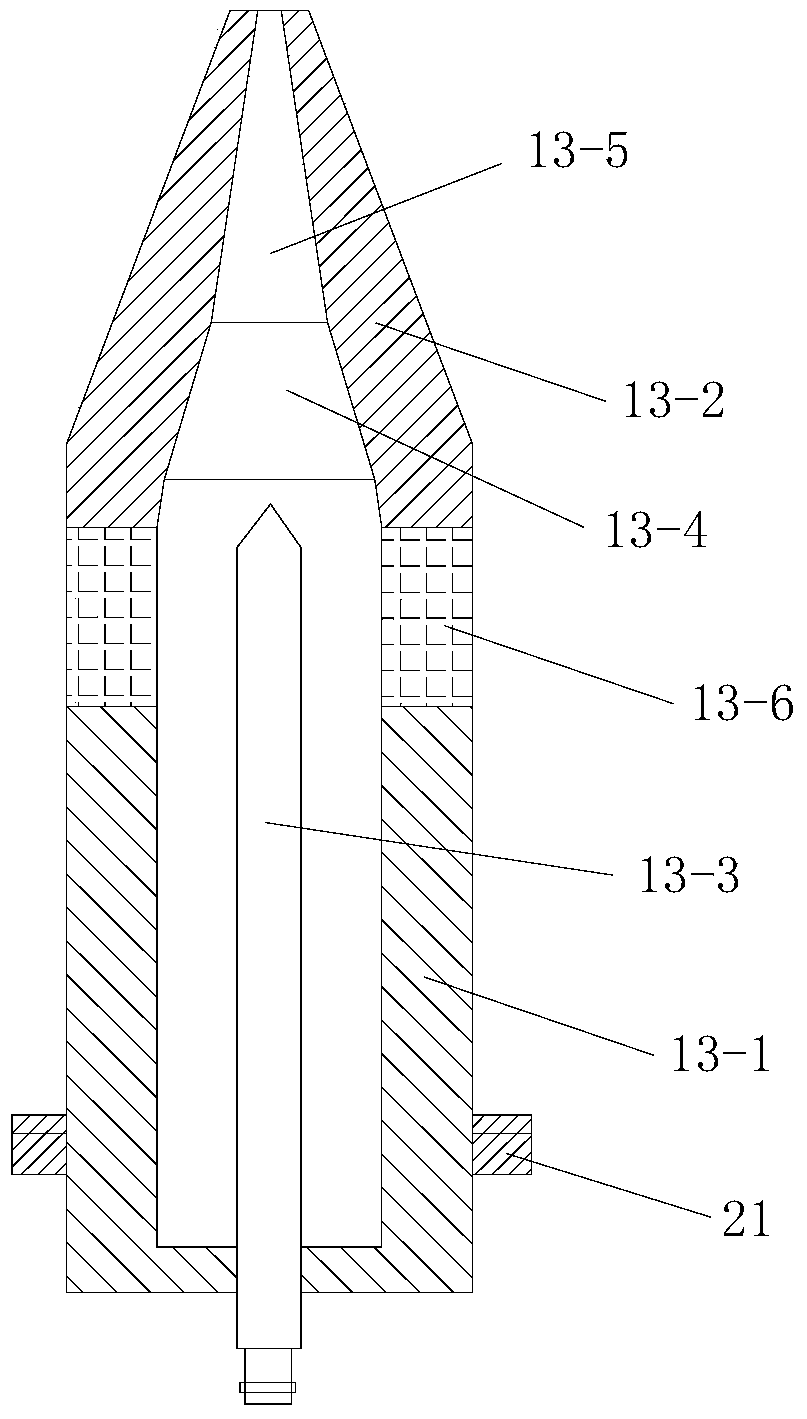

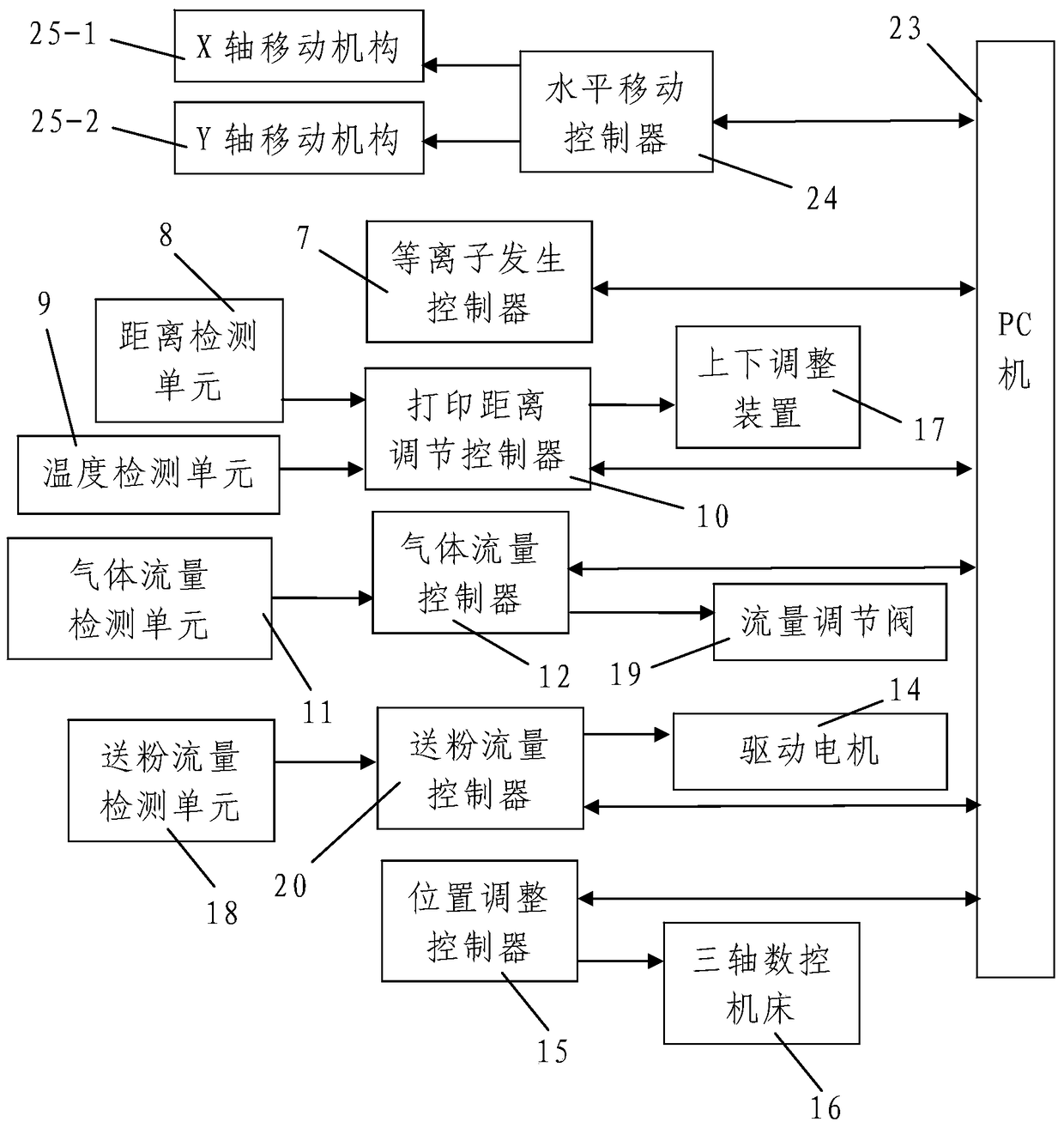

The invention discloses plasma 3D printing remanufacturing equipment and method for a train wheel. The plasma 3D printing remanufacturing equipment consists of a monitoring system, a plasma beam processing system, a machining device for machining a train wheel to be repaired, a triaxial moving mechanism used for driving the machining device to move and a horizontal printing platform used for placing the train wheel to be repaired, wherein the plasma beam processing system consists of a plasma generator, a printing position adjusting device, an air supply device and a powder feeder; and the monitoring system comprises a horizontal movement controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller constitute a temperature adjustment and control device. The plasma 3D printing remanufacturing method comprises the following steps: firstly, detecting defects of the train wheel; and secondly, repairing the train wheel. The plasma 3D printing remanufacturing equipment is reasonable in design, simple and convenient to operate, high in efficiency and good in using effect, the repair process is directly carried out in the atmospheric environment without a closed molding room, the repaired train wheel is good in quality, and the repair efficiency is high.

Owner:SINOADDITIVE MFG EQUIP CO LTD

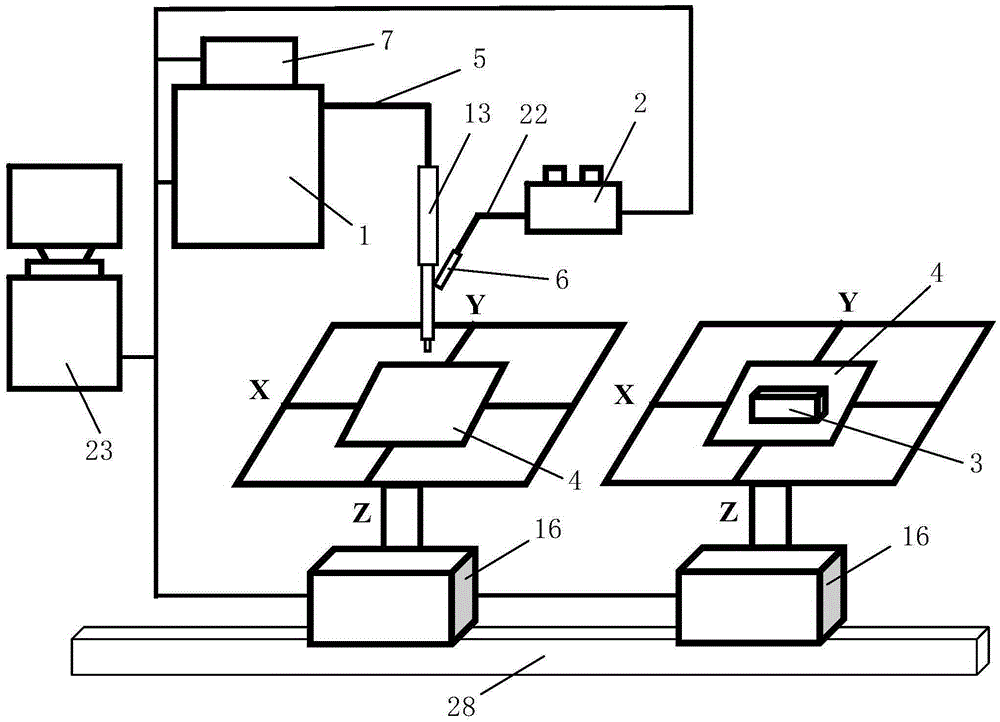

Plasma 3D fast forming and remanufacturing method and equipment of train wheels

InactiveCN105522155ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyMonitoring systemPlasma generator

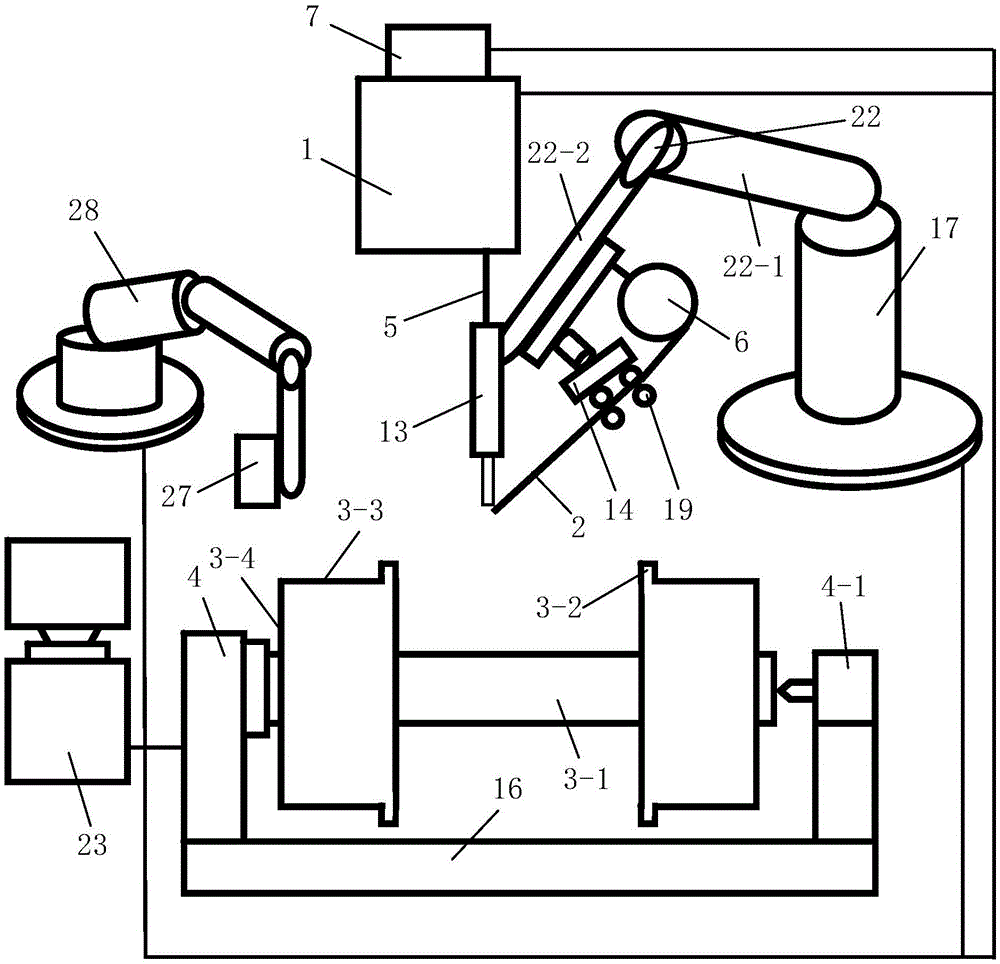

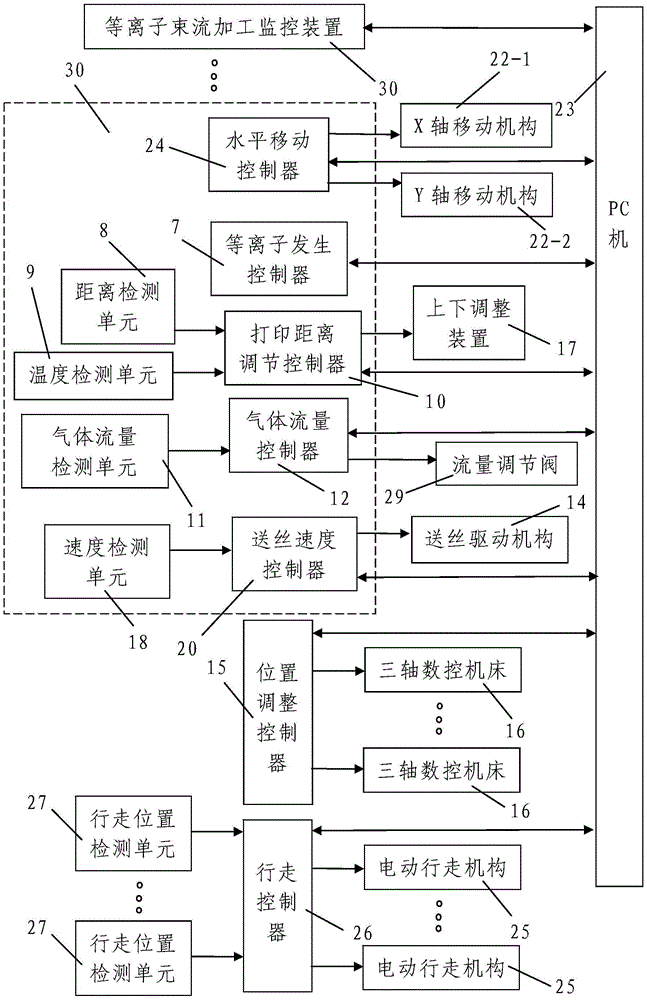

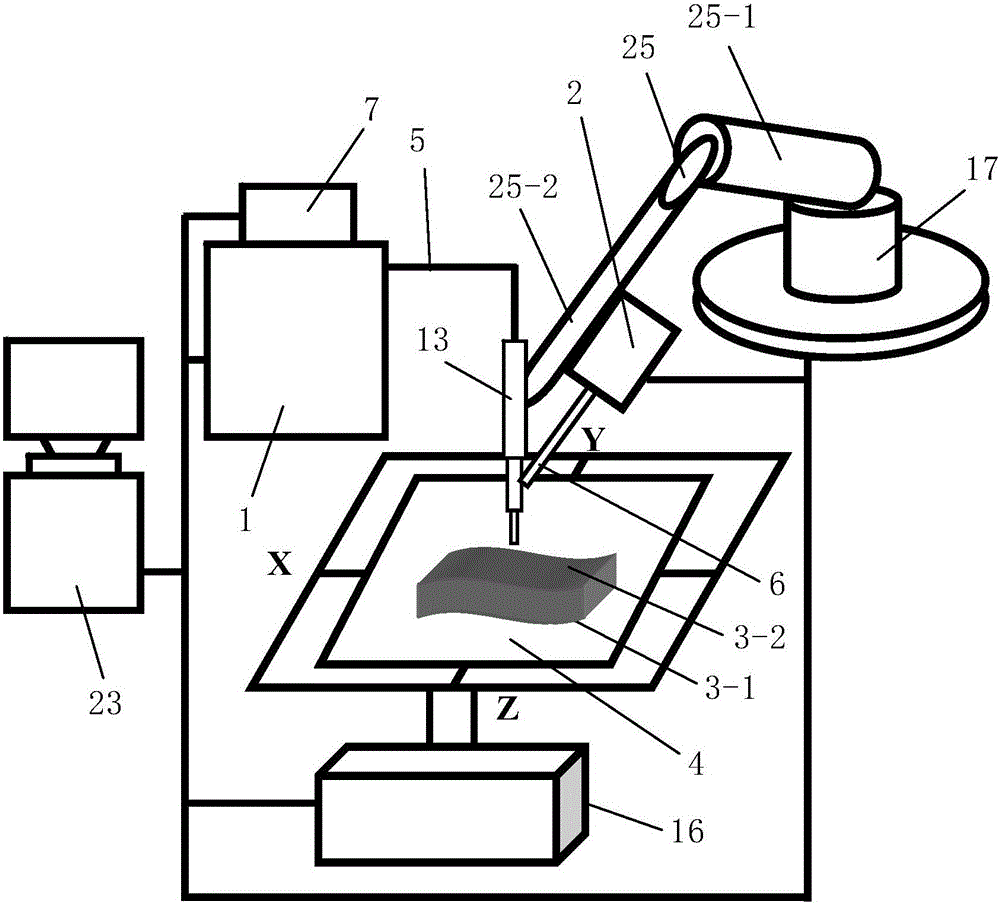

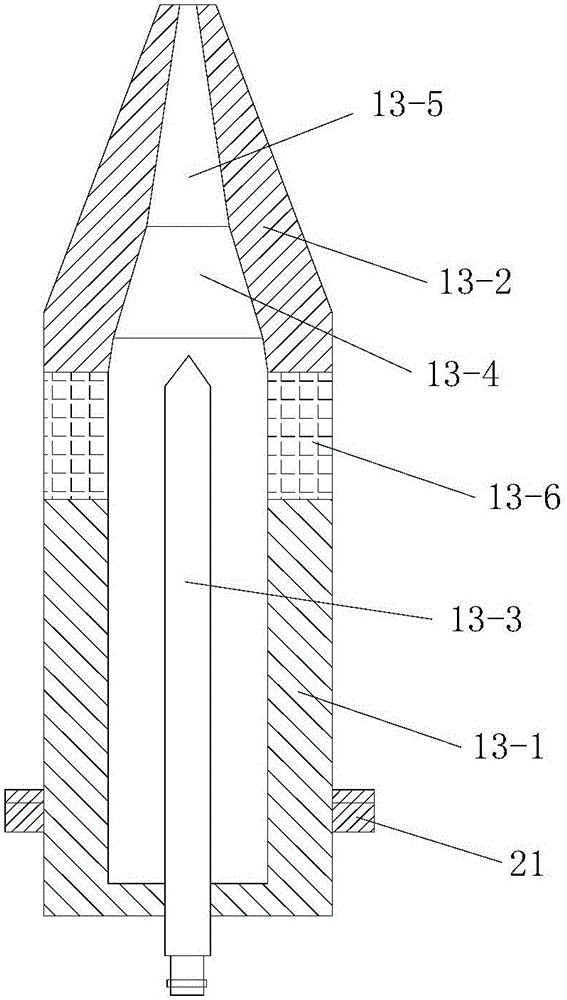

The invention discloses a plasma 3D fast forming and remanufacturing method and equipment of train wheels. The equipment comprises a monitoring system, a plasma beam machining system, a machining device for machining to-be-repaired train wheels, a three-axis moving mechanism for driving the machining device to move and a horizontal printing platform for placing the to-be-repaired train wheels. The plasma beam machining system comprises a plasma generator, a gas supply device, a feeding device and a printing positioning adjusting device. The monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit, a printing distance adjusting controller and a rotation controller, wherein the temperature detecting unit and the printing distance adjusting controller form a temperature adjusting and control device. The method includes the steps of firstly, detecting train wheel defects; secondly, repairing the train wheels. The plasma 3D fast forming and remanufacturing method and equipment has the advantages that the equipment is reasonable in design, simple to operate, high in efficiency, good in use effect and high in repairing efficiency, a closed forming room is not needed, the repairing process is directly performed under an atmospheric environment, and the repaired train wheels are good in quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Plasma 3D printing remanufacturing equipment and method for mold

InactiveCN105642895ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorDistance detection

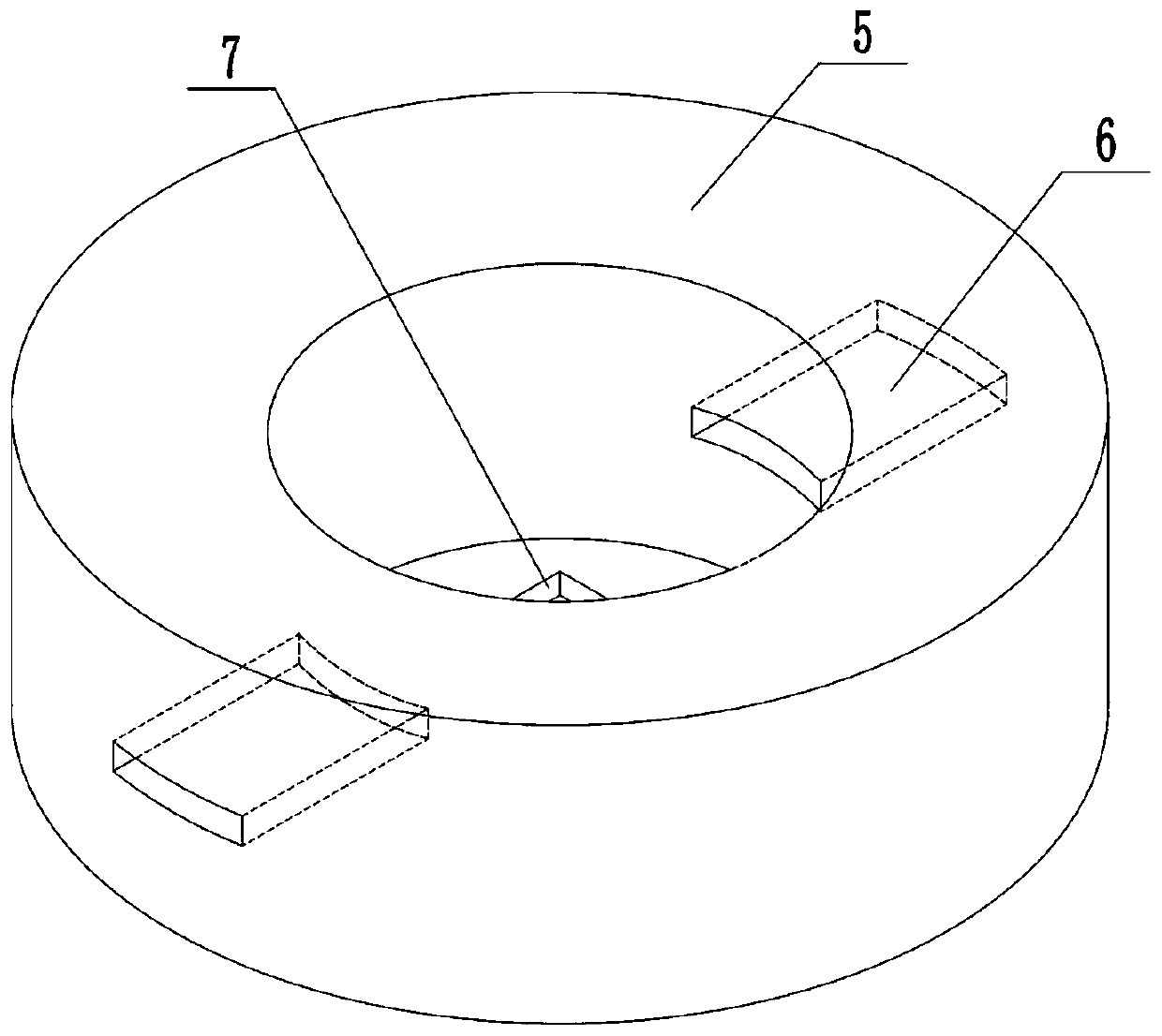

The invention discloses plasma 3D printing remanufacturing equipment and method for a mold. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired mold, a horizontal printing table for accommodating the to-be-repaired mold and a temporary fixing element for fixing the to-be-repaired mold temporarily, wherein the plasma beam processing system comprises a plasma generator, a printing position adjusting device, a gas supply device and a powder feeder; the monitoring system comprises a horizontal motion controller, a temperature detection unit, a distance detection unit, a printing distance adjusting controller and a rotation controller, and the temperature detection unit and the printing distance adjusting controller constitute a temperature regulation device. The remanufacturing method comprises steps of 1, mold defect detection and 2, mold repair. The plasma 3D printing remanufacturing equipment and method for the mold have the advantages that the design is reasonable, the operation is simple, convenient and high in efficiency, the use effect is good, a molding cavity is not needed to be closed, a repair process is performed directly in an atmospheric environment, and the quality of the repaired mold is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Plasma 3D printing remanufacturing equipment and method for roller

InactiveCN105543768ASimple structureReasonable designAdditive manufacturing apparatusMolten spray coatingTemperature controlDistance detection

The invention discloses plasma 3D printing remanufacturing equipment and method for a roller. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired roller and a horizontal printing table for holding the to-be-repaired roller, wherein the plasma beam processing system comprises a plasma generator, a printing position adjustment device, a gas supply device and a powder feeder, and the printing position adjustment device comprises a horizontal moving device and a printing distance adjustment device; the monitoring system comprises a horizontal moving controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller form a temperature control device. The remanufacturing method comprises steps as follows: 1, roller defect detection; 2, roller repair. The plasma 3D printing remanufacturing equipment is reasonable in design, simple and convenient to operate, high in efficiency and good in use effect, a forming chamber is not required to be closed, the roller is repaired directly in the atmospheric environment, and the quality of the repaired roller is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Plasma 3D quick-forming remanufacturing equipment and method for roller

InactiveCN105543769ASimple structureReasonable designAdditive manufacturing apparatusMolten spray coatingTemperature controlDistance detection

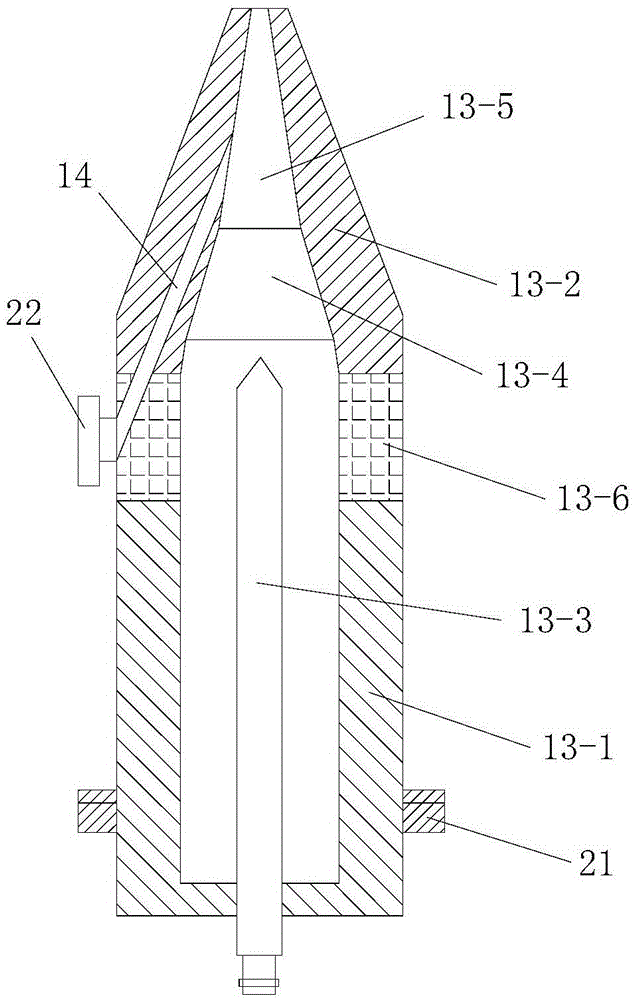

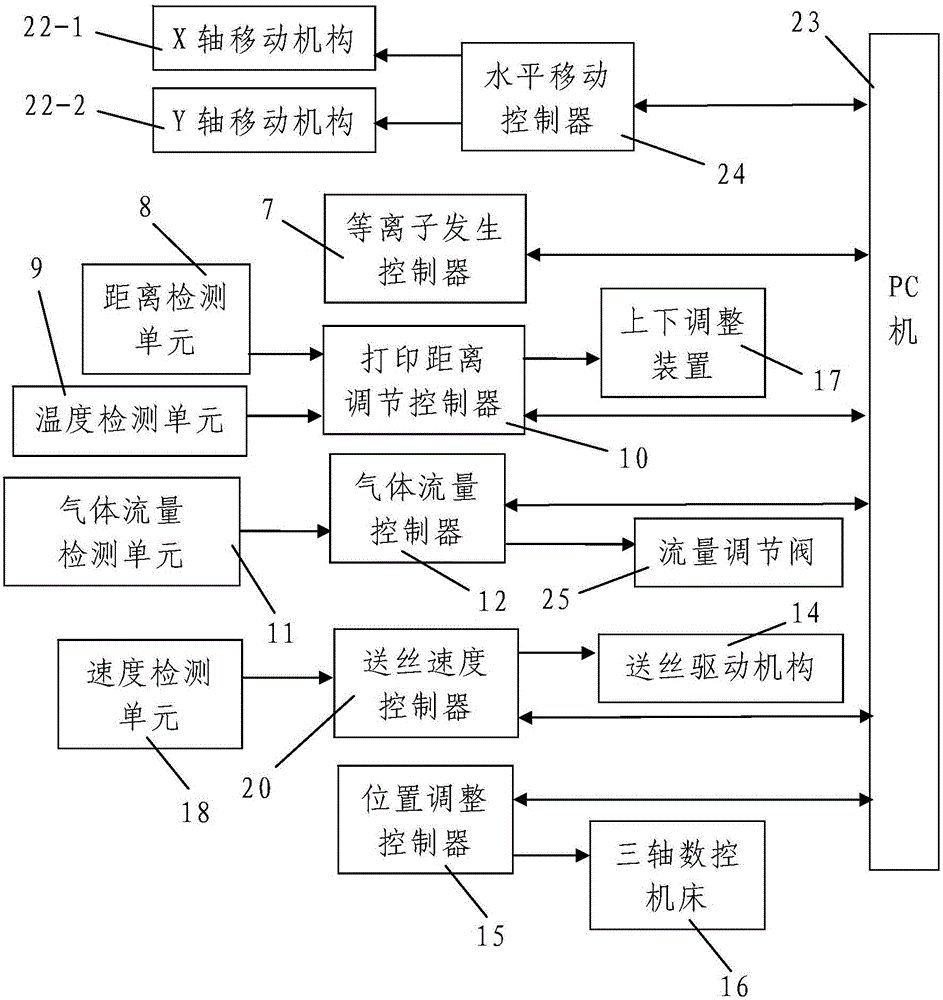

The invention discloses plasma 3D quick-forming remanufacturing equipment and method for a roller. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired roller and a horizontal printing table for holding the to-be-repaired roller, wherein the plasma beam processing system comprises a plasma generator, a gas supply device, a wire feeding device for machined wires and a printing position adjustment device, and the printing position adjustment device comprises a horizontal moving device and a printing distance adjustment device; the monitoring system comprises a horizontal moving controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises steps as follows: 1, roller defect detection; 2, roller repair. The plasma 3D quick-forming remanufacturing equipment is reasonable in design, simple and convenient to operate, high in efficiency and good in use effect, the roller is repaired directly in the atmospheric environment, and the quality of the repaired roller is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

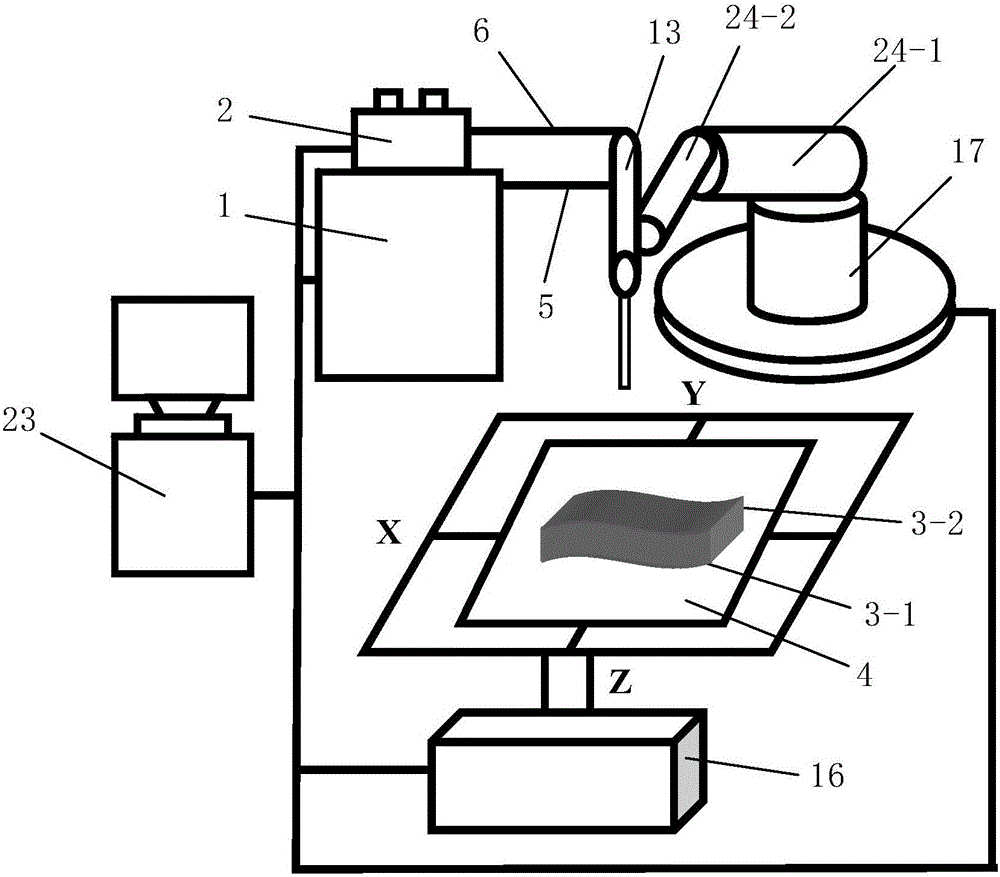

Selective plasma melting rapid prototyping equipment and method

ActiveCN105922567ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusPlasma generatorMonitoring system

The invention discloses selective plasma melting rapid prototyping equipment and method. The equipment comprises a monitoring system, a plasma beam processing system, and a level printing table a powder sending and spreading device. The plasma beam processing system includes a plurality of plasma beam processing devices; each plasma beam processing device is composed of a plasma generator, a printing position adjusting device, a gas supply device and a wire sending device; the monitoring system includes a plurality of plasma beam processing monitoring devices; each plasma beam processing monitoring device includes a temperature detection unit, a horizontal movement controller, a distance detecting unit and a printing distance adjusting controller. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be molded, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber or the vacuum environment, and no need of protection atmosphere or vacuum environment.

Owner:中研碧诚(北京)科技有限公司

Mold plasma 3D rapid prototyping remanufacturing device and method

InactiveCN105689715ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyDistance detectionMonitoring system

The invention discloses a mold plasma 3D rapid prototyping remanufacturing device and method. The device comprises a monitoring system, a plasma beam processing system, a machining device used for machining a to-be-repaired mold, a level printing table used for placing the to-be-repaired mold, and a temporary fixing part used for temporarily fixing the to-be-repaired mold, wherein the plasma beam processing system comprises a plasma generator, an air supply device, a wire feeding device and a printing position adjusting device; the monitoring system comprises a horizontal motion controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller; and the temperature detection unit and the printing distance adjustment controller form a temperature regulating device. The remanufacturing method comprises the steps of I, mold defect detection and II, mold repairing. According to the mold plasma 3D rapid prototyping remanufacturing device and the method, the design is reasonable, the operation is simple and convenient, the efficiency is high, the using effect is good, a sealed shaping room is not needed, the repairing process is directly carried out in the atmospheric environment, and the quality of the mold is good after repairing.

Owner:SINOADDITIVE MFG EQUIP CO LTD

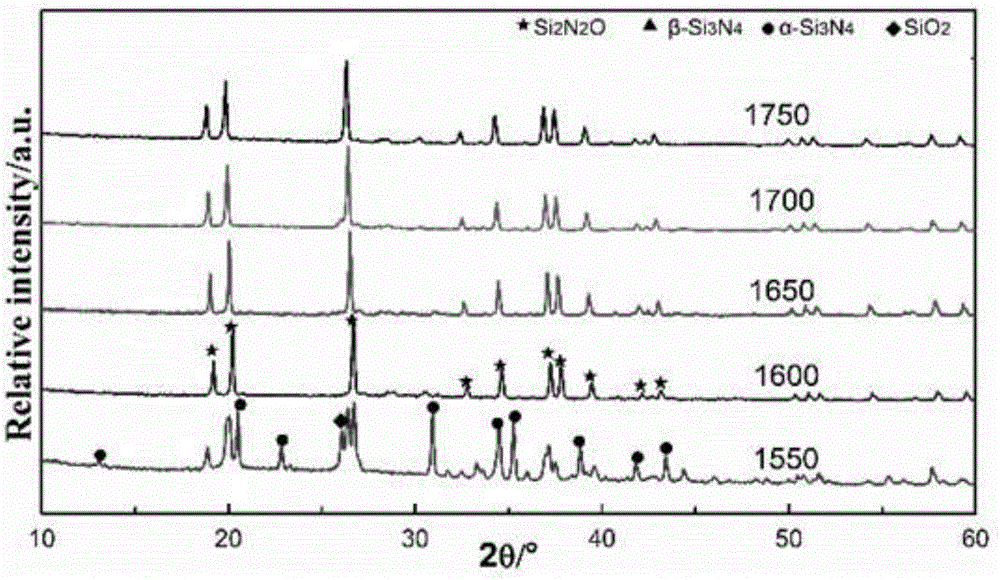

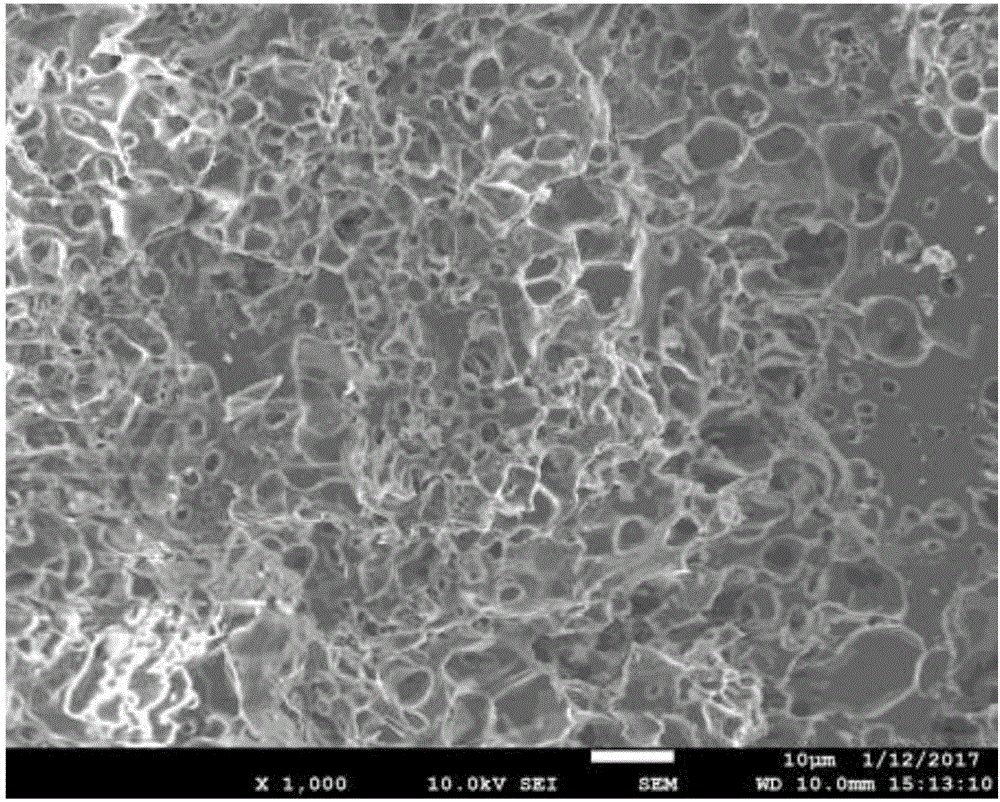

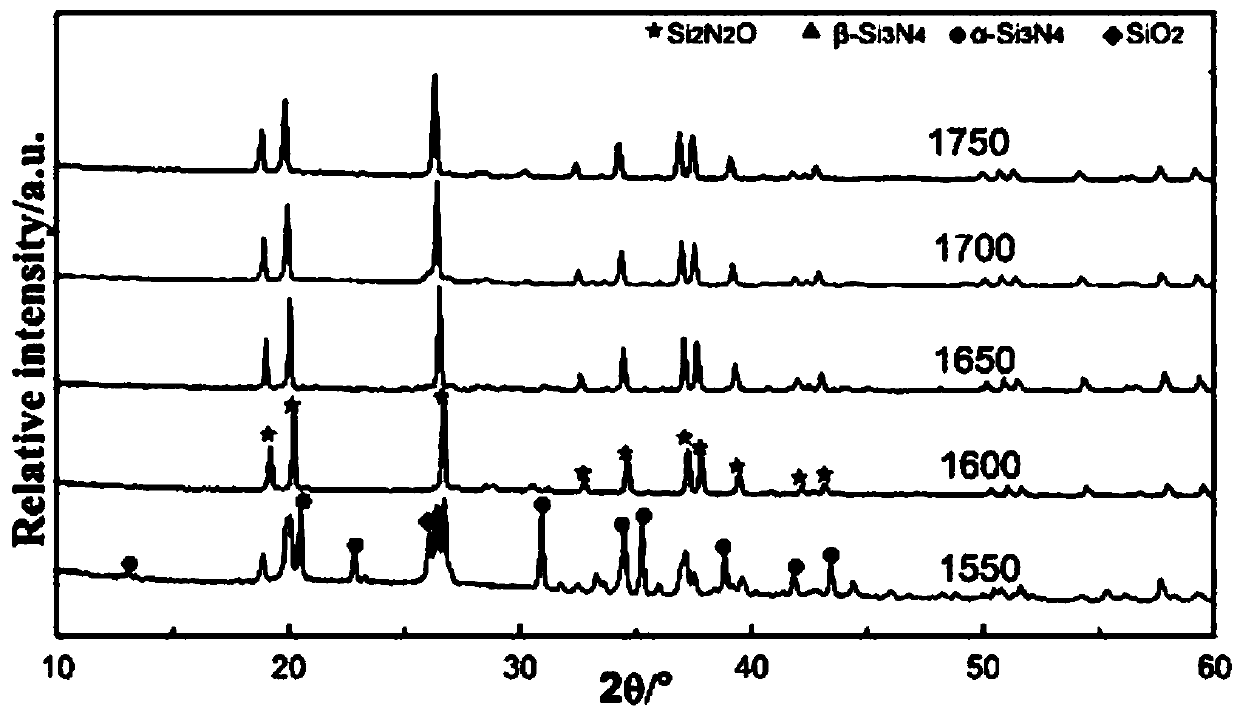

Si2N2O wave transmission-heat insulation integrated inner lining material for microwave kiln, and preparation method of material

ActiveCN106747574ASimple preparation processThe molding process is easy to controlCeramicwareTransmittanceSilicon nitride

The invention belongs to the field of refractory materials, and in particular relates to a Si2N2O wave transmission-heat insulation integrated inner lining material for a microwave kiln, and a preparation method of the material. The preparation method of the Si2N2O wave transmission-heat insulation integrated inner lining material for the microwave kiln comprises the following step: calcining silicon nitride gel, the surface of which is coated with SiO2, for 60-80min at the temperature of 1600-1750 DEG C under the protection of inert atmosphere so as to obtain the Si2N2O wave transmission-heat insulation integrated inner lining material. The Si2N2O wave transmission-heat insulation integrated inner lining material for the microwave kiln has the porosity of 60-70%, the dielectric constant of 3.4-5.3 and the dielectric loss tg delta of less than 2.5*10<-3>; the material is excellent in heat preventing and heat insulation performances, bearing performance, impact resistance, wave transmittance and the like under the harsh conditions of high temperature, high pressure, strong corrosion and the like, thus having better application prospect in the aspect of microwave high temperature sintering kilns.

Owner:ZHENGZHOU UNIV +1

Plasma cladding direct manufacturing rapid prototyping apparatus and method

InactiveCN105921745ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyMonitoring systemPlasma generator

The invention discloses a plasma cladding direct manufacturing rapid prototyping apparatus and method. The device consists of a monitoring system, a plasma beam machining system and multiple print platforms. Each print platform includes a horizontal print station, a print station position adjusting device and an electric walk mechanism. The plasma beam machining system consists of a plasma generator, a print distance adjusting device, a gas supply device and a powder feeder. The monitoring system includes a walk controller, a plurality of walk position detecting units, a temperature detecting unit, a distance detecting unit and a print distance adjusting controller. The method comprises the steps of first, acquisition of a three-dimensional model of a workpiece to be prototyped and layered slicing processing; second, scan path filling; third, print path acquisition; and fourth, printing layer by layer from the bottom to the top. The invention is reasonable in design, simple to operate, high in prototyping efficiency and good in using effect, and requires neither a closed prototyping room nor a protective atmosphere or vacuum environment, with the workpiece prototyping process performed directly under atmospheric conditions.

Owner:SINOADDITIVE MFG EQUIP CO LTD

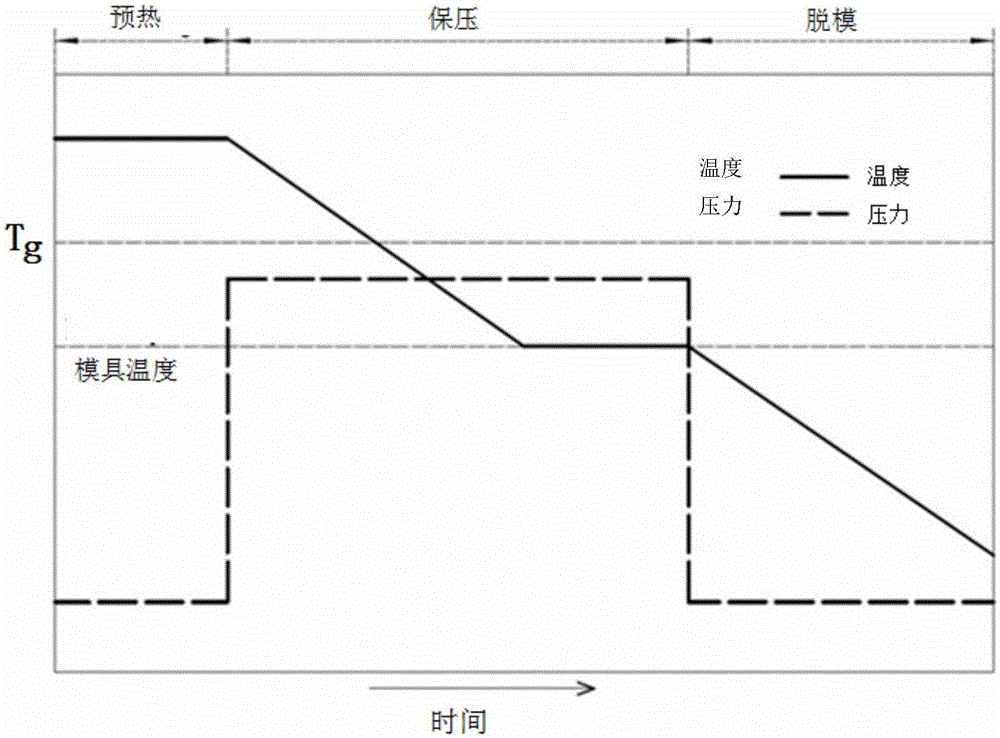

Process for quick hot stamping of polymer microstructure isothermal flat plate

ActiveCN105058770ASimplify the hot embossing processHot embossing fastDecorative surface effectsChemical vapor deposition coatingHot stampingPolymer science

The invention relates to a process for quick hot stamping of a polymer microstructure isothermal flat plate. On the conditions that the temperature is 5-20 DEG C below the glass transition temperature Tg of a hot stamping amorphous polymer or is 10-50 DEG C below the crystal melting point Tm of a hot stamping crystallization type polymer, hot stamping is performed on a polymer substrate through a microstructure die; after the hot stamping is ended, demolding is directly performed on the conditions of the die temperature is kept unchanged, and a polymer device with the surface provided with a microstructure is obtained. According to the process, the microstructure forming is performed by utilizing plastic deformation near the glass transition temperature (Tg) or below the crystal melting point (Tm) in a polymer solid state, the die temperature is kept constant in the hot stamping process, and the time consumption caused by repeated heating and cooling is avoided, so that the hot stamping of the microstructure flat plate is finished quickly. The plastic deformation of the microstructure flat plate is performed at a strain flowing stage through temperature control, the plastic deformation is prevented from entering a strain hardening stage, and it is guaranteed that a microstructure has high replication rate.

Owner:BEIJING UNIV OF CHEM TECH

Plasma fusion covering manufacture 3D printing equipment and method

ActiveCN105922574ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusTemperature controlMonitoring system

The invention discloses plasma fusion covering manufacture 3D printing equipment and a method. The equipment comprises a monitoring system, a plasma beam processing system, and a horizontal printing table for placing a workpiece to be printed. The plasma beam processing system includes a plasma generator, a gas supply device and a powder sending device for sending powder into plasma beam, and a printing position adjustment controller. The monitoring system includes a position adjustment controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller. The temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be printed, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber, protection atmosphere or vacuum environment, and direct molding of workpiece in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

Mould plasma 3D printing equipment and mould plasma 3D printing method

InactiveCN105750542ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlPlasma generator

The invention discloses a mould plasma 3D printing equipment and a mould plasma 3D printing equipment method. The equipment consists of a monitoring system, a plasma beam processing system, a horizontal printing table for placing a to-be-formed mould and a temporary fixing member, wherein the plasma beam processing system consists of a plasma generator, a printing position adjusting device, a gas supply device and a powder supplier; the printing position adjusting device comprises a horizontal moving device and a printing distance adjusting device; the monitoring system comprises a horizontal movement controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller; the temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: (I) obtaining three-dimensional stereo model and carrying out hierarchical slicing treatment; (II) scanning path filling; (III) printing path obtaining; and (IV) carrying out layer-by-layer printing from bottom to top. The equipment and the method disclosed by the invention have the advantages of reasonable design, simplicity and convenience in operation, high efficiency and good use effect; and moreover, the forming process is directly carried out in the atmospheric environment, and the formed mould has good quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

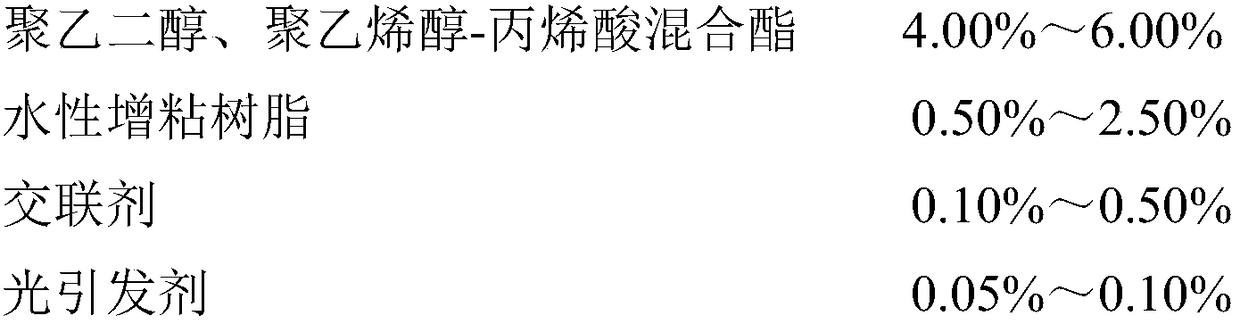

Preparation method and product of hydrogel plaster for cold compress

InactiveCN108159023ALow viscosityEasy to operateCosmetic preparationsSenses disorderWater basedCooling effect

The invention discloses a preparation method and a product of a hydrogel plaster for cold compress. The method comprises the following steps: (1) performing an esterifying reaction on polyethylene glycol, polyvinyl alcohol and acrylic acid in the presence of an esterification catalyst to obtain polyethylene glycol and polyvinyl alcohol mixed acrylate; (2) mixing the polyethylene glycol and polyvinyl alcohol mixed acrylate with water-based tackifying resin, a crosslinking agent, a photoinitiator, a humectant, a mildew inhibitor, a cooling agent and water to obtain a hydrogel plaster stock solution for cold compress; and (3) continuously coating a substrate with the hydrogel plaster stock solution for cold compress through a coater, performing ultraviolet illumination to cure the gel, and cutting and packaging the cured gel to obtain the hydrogel plaster product. The preparation method of the hydrogel plaster has the advantages of convenient sources of raw materials, simple production process, rapidness and completeness in gel curing, and suitableness for mass production, and the obtained product has the advantages of stability in storage, no bubbles, high transparency, obvious cooling effect, good applicability and good moisture retention property.

Owner:杭州高斯博医疗用品有限公司

Roller plasma 3D printing equipment and method

InactiveCN105710367ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorMonitoring system

The invention discloses roller plasma 3D printing equipment and method. The equipment is composed of a monitoring system, a plasma beam machining system and a horizontal printing table; the plasma beam machining system is composed of a plasma generator, a printing position adjusting device, an air supply device and a powder feeder; the printing position adjusting device comprises a horizontal movement device and a printing distance adjusting device; and the monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit, a printing distance adjusting controller and a rotation controller, and a temperature adjusting and control device is composed of the temperature detecting unit and the printing distance adjusting controller. The method includes the steps that (1) a three-dimensional model is obtained, and hierarchy slicing treatment is carried out; (2) filling of a scanning path is carried out; (3) a printing path is obtained; and (4) layer-by-layer printing is carried out from inside to outside. The roller plasma 3D printing equipment is reasonable in design, easy and convenient to operate, high in molding efficiency and good in using effect; the molding process is directly carried out under the atmospheric environment; and molded rollers are good in quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Plasma 3D (three-dimensional) fast forming equipment and method for rollers

InactiveCN105522154ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorDistance detection

The invention discloses plasma 3D (three-dimensional) fast forming equipment and method for rollers. The equipment is composed of a monitoring system, a plasma beam machining system and a horizontal printing platform for holding to-be-formed rollers; the plasma beam machining system comprises a plasma generator, a gas supply device, a wire conveying device used for continuously conveying out machined wires and a printing position adjustment device; the monitoring system comprises a position adjustment controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller, form a temperature control device. The method includes the steps of 1, three dimensional model acquisition and hierarchical slicing, 2, scanning path filling, 3, printing path acquisition and 4, printing layer by layer from inside to outside. The equipment and method is reasonable in design, simple to operate, high in forming efficiency and good in using effect, and the formed rollers are high in quality as the forming process is conducted directly under the atmospheric environment.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Plasma fusion covering manufacture rapid molding equipment and molding method

ActiveCN105922569ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusDistance detectionPlasma generator

The invention discloses plasma fusion covering manufacture rapid molding equipment and a molding method. The equipment comprises a monitoring system, a plasma beam processing system, and a printing table. The plasma beam processing system includes a plasma generator, a printing position adjustment controller, a gas supply device and a powder sending device for sending powder into the plasma beam. The monitoring system includes a position adjustment controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller. The temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be molded, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber, protection atmosphere or vacuum environment, and direct molding of workpiece in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

Mold plasma 3D printing device and 3D printing method

InactiveCN105665702ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorDistance detection

The invention discloses a mold plasma 3D printing device and 3D printing method. The device is composed of a monitor system, a plasma beam machining system, a horizontal printing table for containing a mold to be formed and a temporary fixed piece. The plasma beam machining system is composed of a plasma generator, an air supply device, a powder feeding device and a printing position adjustment device. The printing position adjustment device comprises a horizontal movement device and a printing distance adjustment device. The monitor system comprises a horizontal movement controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller, and a temperature adjustment and control device is formed by the temperature detection unit and the printing distance adjustment controller. The method comprises the steps that firstly, a three-dimensional model is obtained, and layering slicing treatment is carried out; secondly, a scanning path is filled; thirdly, a printing path is obtained; and fourthly, printing is carried out layer by layer from bottom to top. The device is reasonable in design, easy and convenient to operate, high in efficiency and good in use effect, the forming process is directly carried out in the atmospheric environment, and a formed mold is good in quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Die plasma 3D rapid molding equipment and molding method

InactiveCN105689714ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorMonitoring system

The invention discloses die plasma 3D rapid molding equipment and molding method. The equipment is composed of a monitoring system, a plasma beam machining system, a horizontal printing table for containing a to-be-molded die and a temporary fixing piece; the plasma beam machining system is composed of a plasma generator, an air supply device, a wire feeding device and a printing position adjusting device; the printing position adjusting device comprises a horizontal movement device and a printing distance adjusting device; and the monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit and a printing distance adjusting controller, and a temperature regulation and control unit is composed of the temperature detecting unit and the printing distance adjusting controller. The molding method includes the steps of (1) three-dimensional model obtaining and layered slicing treatment; (2) scanning path filling; (3) scanning path obtaining; and (4) layer-by-layer printing from bottom to top. The die plasma 3D rapid molding equipment is reasonable in design, easy and convenient to operate, high in efficiency and good in using effect, the molding process is directly executed under the atmospheric environment, and the quality of the die is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

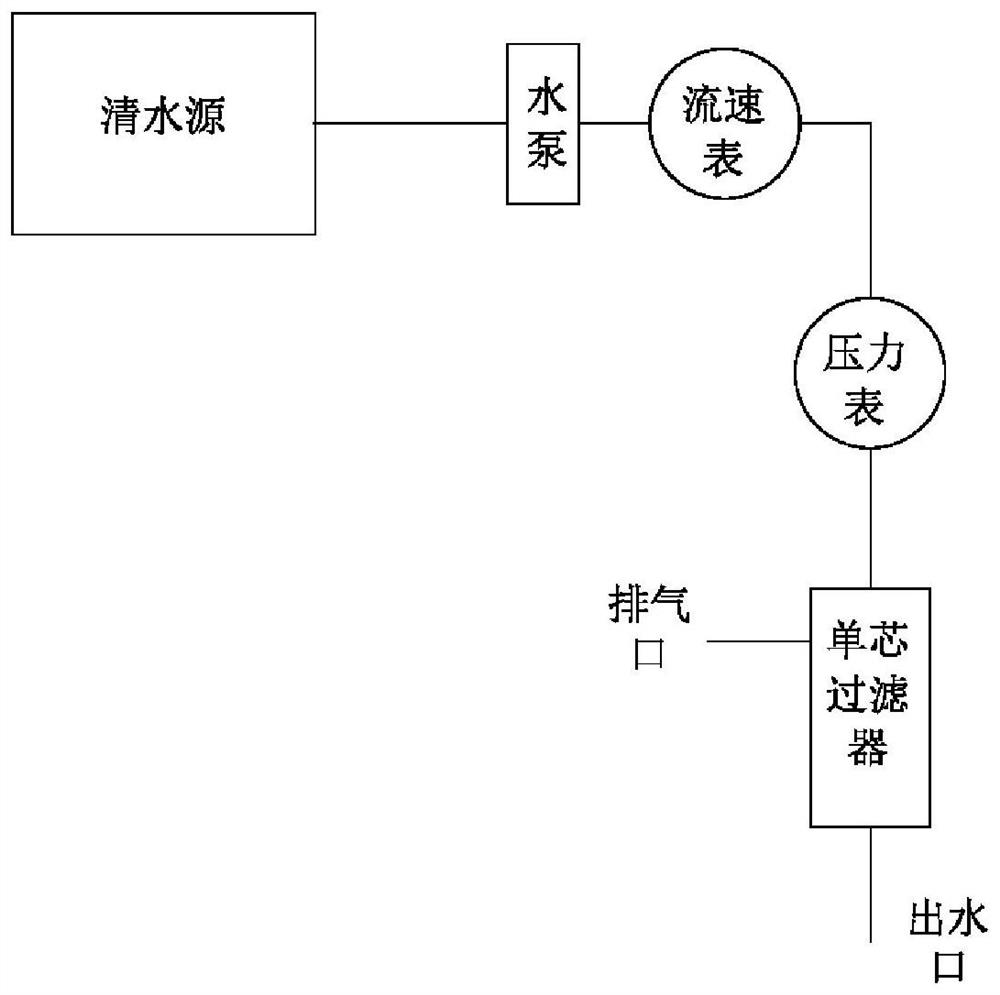

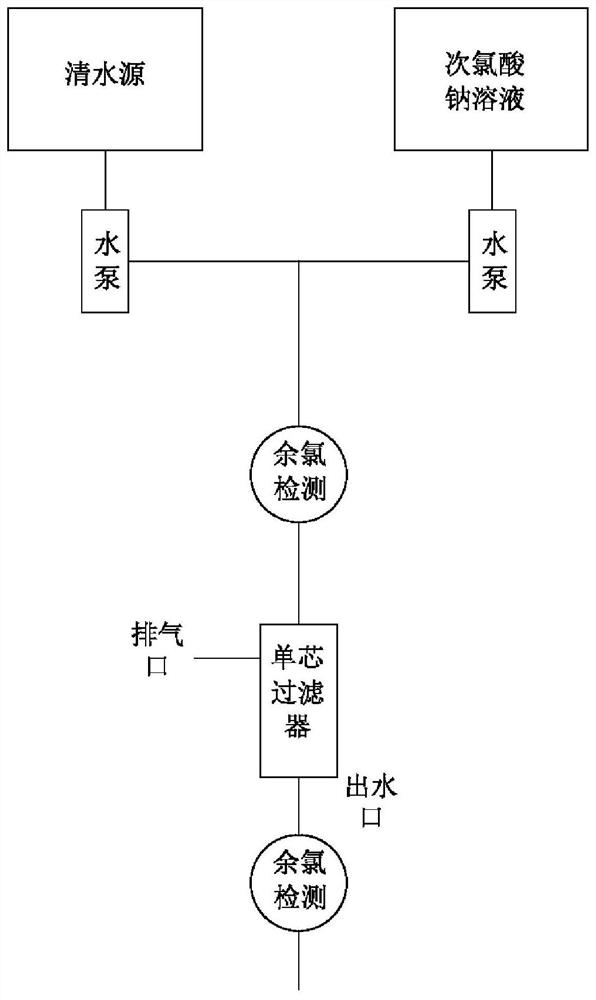

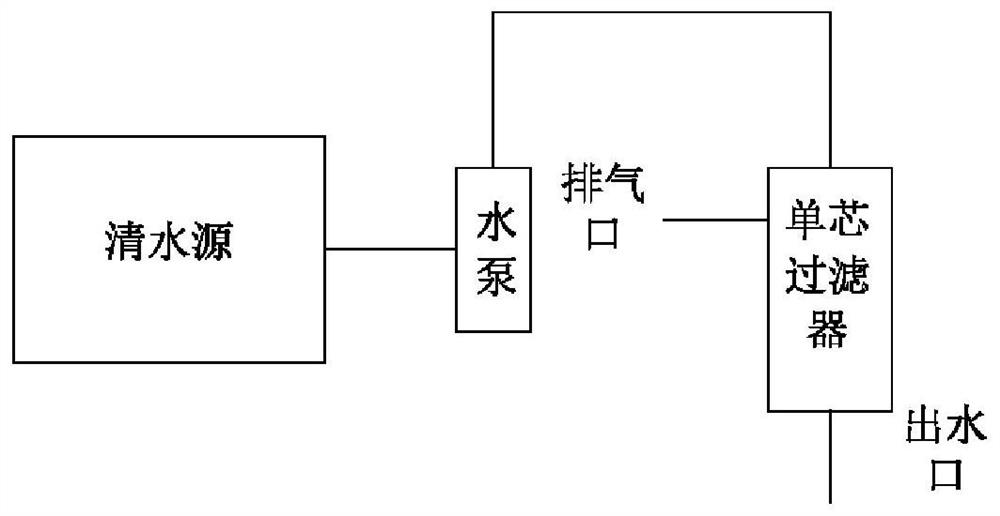

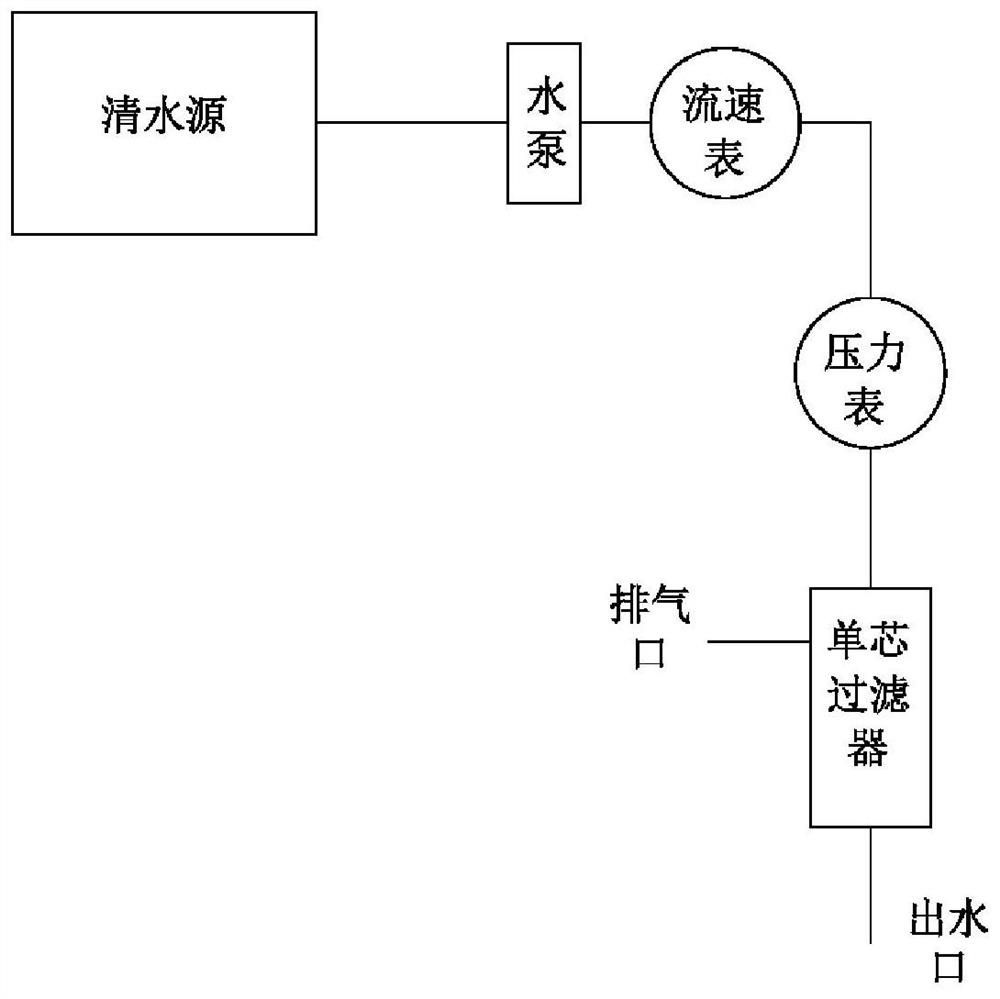

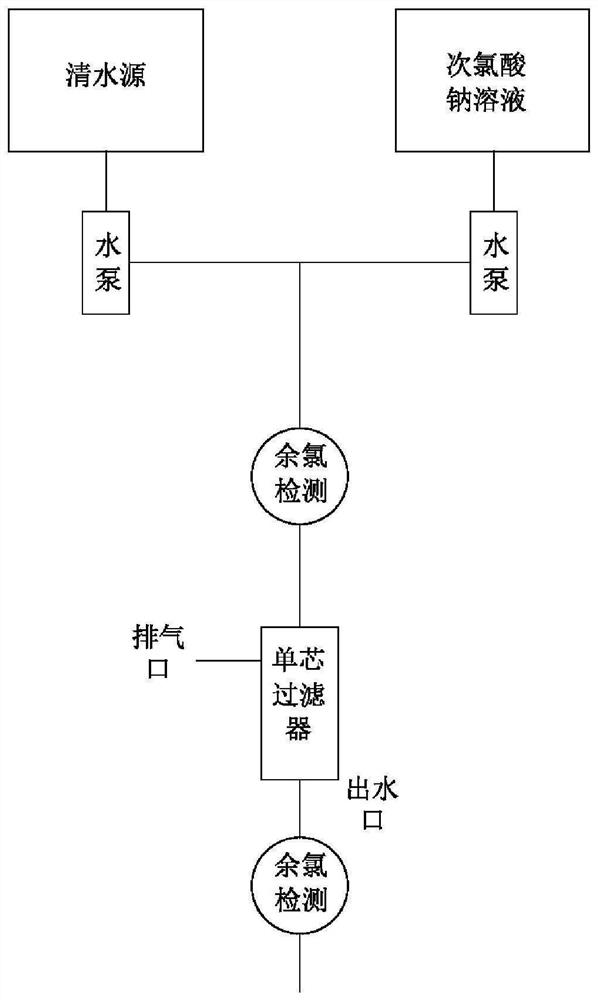

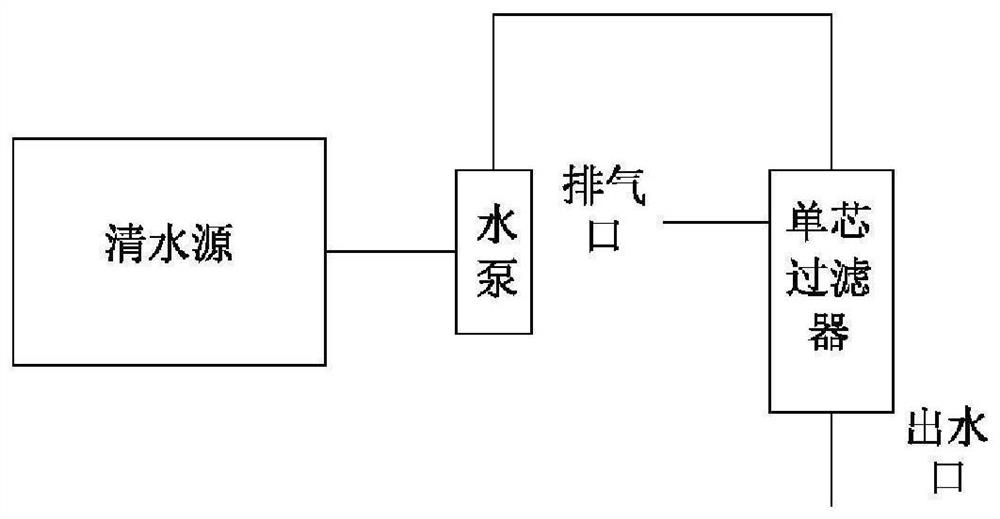

Activated carbon filter element and preparation method thereof

ActiveCN111744273AIncrease profitImprove structural strengthMembrane filtersFiltration separationActivated carbonFiber

The invention relates to an activated carbon filter element and a preparation method thereof. The activated carbon filter element comprises a cylindrical central rod and a filter layer arranged outside the central rod; the filtering layer comprises supporting fibers, bonding fibers and activated carbon particles, the supporting fibers cover the activated carbon particles to form a net-shaped structure, the bonding fibers are partially wound on the supporting fibers, partially wound on the activated carbon particles and partially simultaneously wound on the supporting fibers and the activated carbon particles, and the supporting fibers are subjected to fibrillation treatment. The invention aims at providing the activated carbon filter element which is higher in filtering flow rate and firmer in structure and the preparation method of the activated carbon filter element which is high in automation degree, free of pollution and capable of adjusting the size of the activated carbon filterelement at any time.

Owner:HANGZHOU COBETTER TECH CO LTD

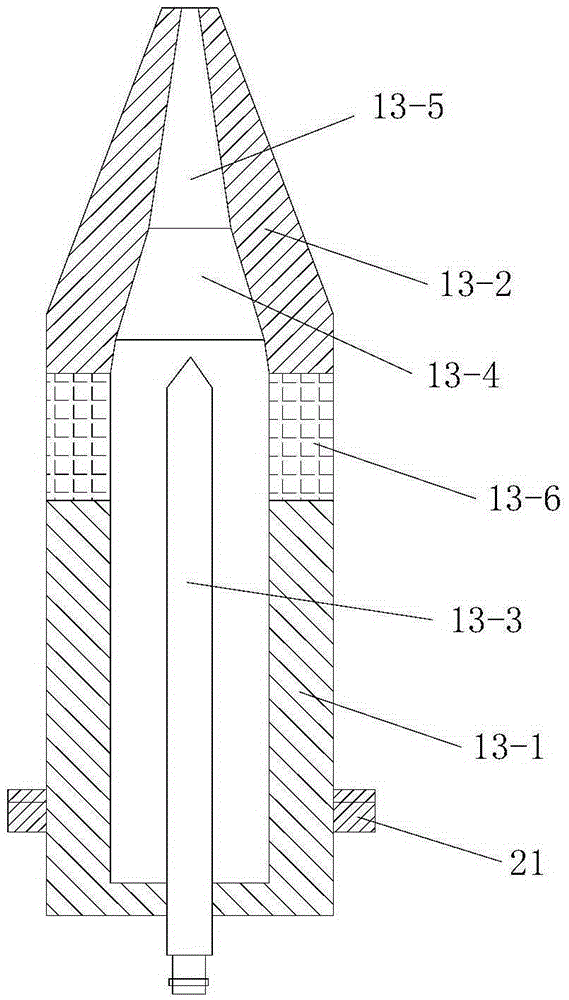

Mold and method for micro part machining

PendingCN111203479AReduce processing timeIncrease manufacturing costShaping toolsPerforating toolsEngineeringMachining

The invention discloses a mold and method for micro part machining. The die comprises an upper punch and a lower forming die which are oppositely arranged, a workpiece male die is arranged on the endface, facing the lower forming die, of the upper punch, a workpiece female die is arranged on the end face, facing the upper punch, of the lower forming die, and a flange lower die is arranged in thelower forming die in a sleeved mode; the top end face of the flange lower die abuts against the bottom end of the female die to jointly form a groove structure with an opening facing the male die, a matching hole is formed in the top of the supporting cover, the upper punch moves in the axial direction, penetrates through the matching hole and then is matched with the lower forming die to be usedfor enabling the male die and the female die to be matched to conduct punch forming on materials, punch forming is conducted through cooperation of plates of different thicknesses and a special punchdie, and the forming precision of micro parts is directly controlled by the precision of the die. Compared with traditional injection molding, powder forming and other modes, higher machining precision and machining efficiency can be provided, and therefore the existing precision requirement for micro parts is met.

Owner:SHANDONG UNIV +1

Plasma 3D printing equipment and method for roller

InactiveCN105642896ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyMonitoring systemDistance detection

The invention discloses a plasma 3D printing equipment and method for a roller. The equipment comprises a monitoring system, a plasma beam processing system and a horizontal printing table, wherein the plasma beam processing system comprises a plasma generator, a gas supply device, a powder feeder and a printing position adjusting device which comprises a horizontal moving device and a printing distance adjusting device; the monitoring system comprises a horizontal moving controller, a temperature detection unit, a distance detection unit, a printing distance adjusting controller and a rotation controller, and the temperature detection unit and the printing distance adjusting controller constitute a temperature regulation device. The method comprises steps of 1, obtaining of a 3D mold and layered slicing processing; 2, filling of a scanning path; 3, obtaining of a printing path; 4, layer-by-layer printing from inside to outside. The plasma 3D printing equipment and method for the roller have the advantages that the design is reasonable, the operation is simple, convenient and high in molding efficiency, the use effect is good, a molding process is performed directly in an atmospheric environment, and the quality of the molded roller is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

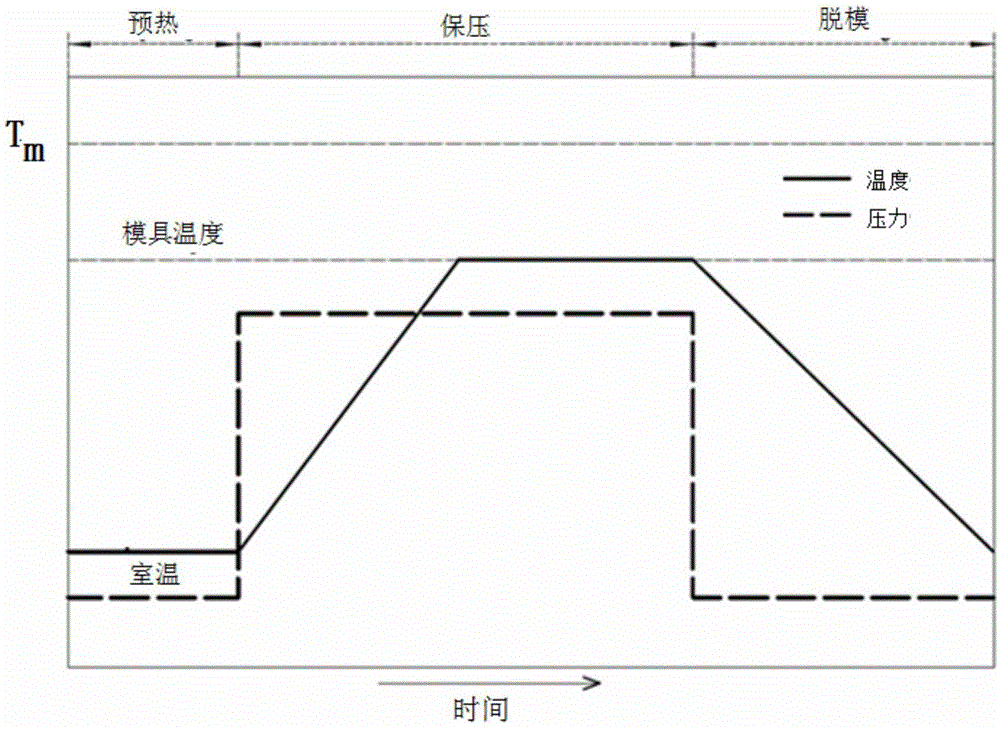

Rapid differential-temperature flat plate hot embossing process for polymer micro-nano structure

The invention discloses a rapid differential-temperature flat plate hot embossing process for a polymer micro-nano structure. The rapid differential-temperature flat plate hot embossing process is characterized in that temperature of a hot embossing mold is kept consistent in the whole embossing period, set temperatures of an upper half mold and a lower half mold are different, the aims of smooth mold filling and mold release of the micro-nano structure are achieved through the differential-temperature mode, and the rapid differential-temperature flat plate hot embossing process is particularly suitable for rapid hot embossing of a polymer product with the single-face micro-nano structure. The temperature of the side, provided with the micro-nano structure, of the mold is set as a higher value, and the side, not provided with the micro-nano structure, of the mold is set as a lower value. At the initial stage of hot embossing, the temperature of a polymer substrate making contact with the high-temperature half mold rapidly rises to a high temperature, and mold filing is completed; and at the pressure maintaining stage, the polymer substrate is cooled through the low-temperature half mold, the formed micro-nano structure is shaped, and demolding is facilitated. By means of the process, it is avoided that because the mold is repeatedly heated and cooled, energy is consumed, and meanwhile the forming period of hot embossing is remarkably shortened; controllability of the forming process is high, the forming precision is high, and the overall consistency is good; and the mold sticking phenomenon of the polymer product is obviously improved, and demolding defects are effectively avoided.

Owner:BEIJING UNIV OF CHEM TECH

Activated carbon filter element and preparation method thereof

ActiveCN111744272AImprove structural strengthReduce densityMembrane filtersFiltration separationActivated carbonFiber

The invention relates to an activated carbon filter element. The filter element comprises a cylindrical central rod and a filter layer arranged outside the central rod. The filter layer comprises activated carbon particles and fibers coating the activated carbon particles; the density of the innermost layer of the filtering layer is set to be 0.3 g / cm < 3 >-0.5 g / cm < 3 >, the density of the outermost layer of the filtering layer is set to be 0.2 g / cm < 3 >-0.4 g / cm < 3 >, and the density of the innermost layer of the filtering layer is larger than that of the outermost layer of the filteringlayer. The invention aims at providing an activated carbon filter element which has a gradient product structure and integrates a good filtering effect, a large flow rate and high strength. Meanwhile,the invention provides a preparation method of the filter element, which is relatively simple and low in pollution.

Owner:HANGZHOU COBETTER TECH CO LTD

Die plasma cladding direct remanufacturing equipment and remanufacturing method

InactiveCN105689713ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorMonitoring system

The invention discloses die plasma cladding direct remanufacturing equipment and a remanufacturing method. The equipment is composed of a monitoring system, a plasma beam machining system, a machining device for conducting machining on a to-be-repaired die, a horizontal printing table for containing the to-be-repaired die and a temporary fixing piece for conducting temporary fixing on the to-be-repaired die; the plasma beam machining system is composed of a plasma generator, an air supply device, a powder feeding device and a printing position adjusting device; and the monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit, a printing distance adjusting controller and a rotation controller, and a temperature regulation and control unit is composed of the temperature detecting unit and the printing distance adjusting controller. The remanufacturing method includes the steps of (1) die defect detection and (2) die repairing. The die plasma cladding direct remanufacturing equipment is reasonable in design, easy and convenient to operate, high in efficiency, good in using effect and free of sealing a molding chamber, the repairing process is directly executed under the atmospheric environment, and the quality of the repaired die is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

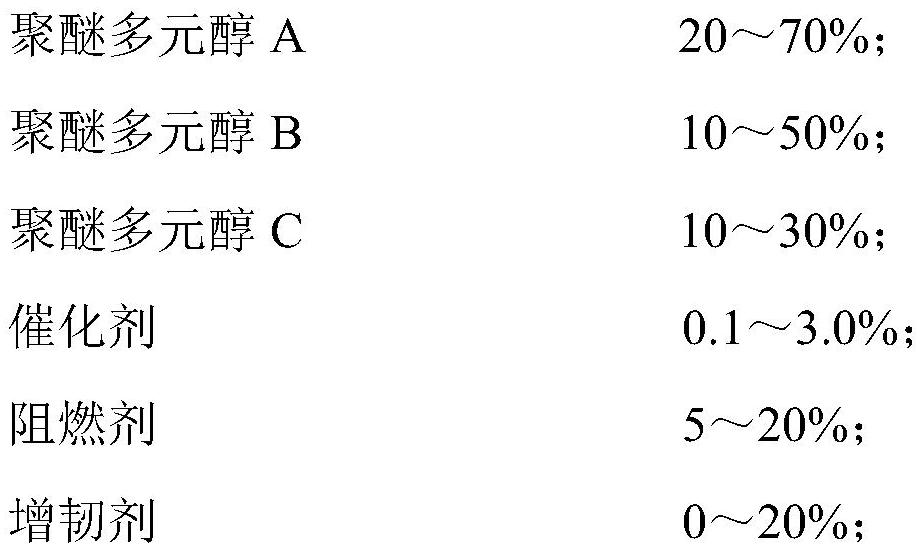

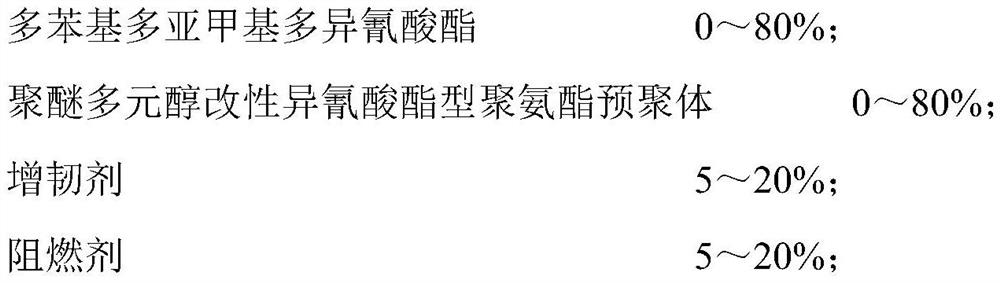

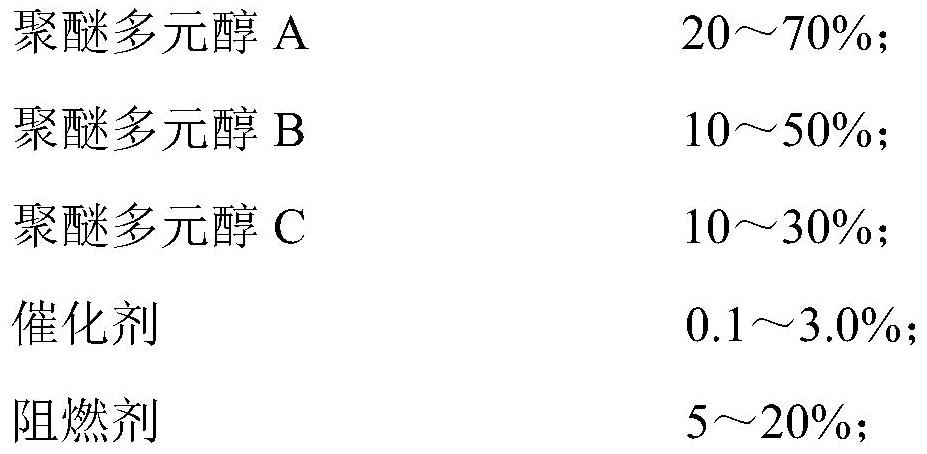

Low-temperature two-component polyurethane material used in field of coal and rock mass reinforcement and preparation method of low-temperature two-component polyurethane material

The invention belongs to the technical field of high polymer materials, and particularly relates to a low-temperature two-component polyurethane material used in the field of coal and rock mass reinforcement and a preparation method of the low-temperature two-component polyurethane material. The low-temperature two-component polyurethane material is prepared from a component A and a component B in a mass ratio of (1.0: 1)-(2.0: 1), wherein the component A is prepared from polyether polyol A, polyether polyol B, polyether polyol C, a catalyst, a flame retardant and a flexibilizer, and the component B is prepared from polyphenyl polymethylene polyisocyanate, an isocyanate type polyurethane prepolymer, a flexibilizer and a flame retardant. Through the structural design of the component A polyether polyol and the modification of the component B polyether polyol modified isocyanate type polyurethane prepolymer, the prepared polyurethane material has the advantages of low reaction temperature (the highest reaction temperature is less than 100 DEG C), high mechanical property (the compression strength is greater than 40MPa, and the performance requirements of the high polymer material for the coal mine to be implemented are met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Activated carbon filter element and preparation method thereof

ActiveCN111744271AImprove structural strengthEasy to washMembrane filtersFiltration separationActivated carbonMaterials science

The invention relates to an activated carbon filter element. The filter element comprises a cylindrical central rod and a filter layer arranged outside the central rod. The filter layer comprises activated carbon particles and fibers coating the activated carbon particles; the fiber content of the innermost layer of the filter layer is set between 30% and 70%, the fiber content of the outermost layer of the filter layer is set between 20% and 60%, and the fiber content of the innermost layer of the filter layer is higher than the fiber content of the outermost layer of the filter layer. The invention aims at providing an activated carbon filter element which has gradient change in product structure and has both good filtering effect, high flow velocity and high strength. Meanwhile, the invention provides a preparation method of the filter element, which is relatively simple and low in pollution.

Owner:HANGZHOU COBETTER TECH CO LTD

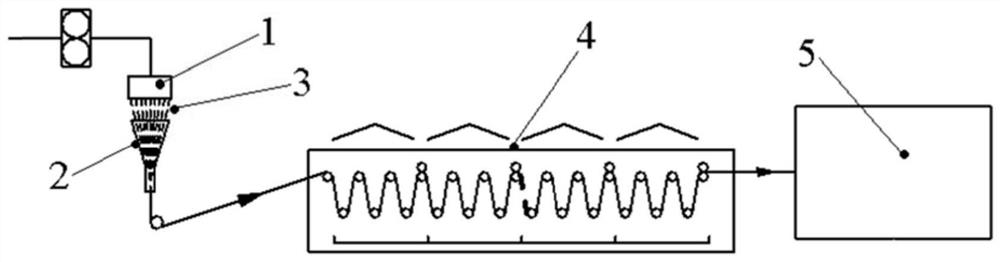

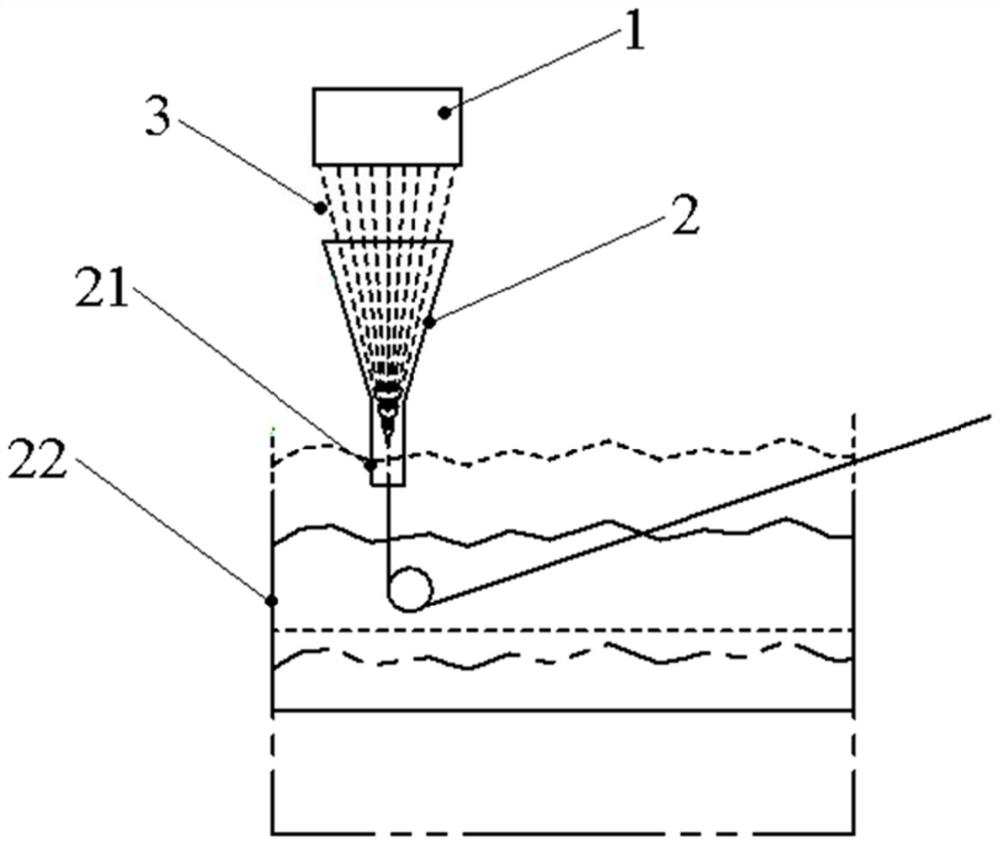

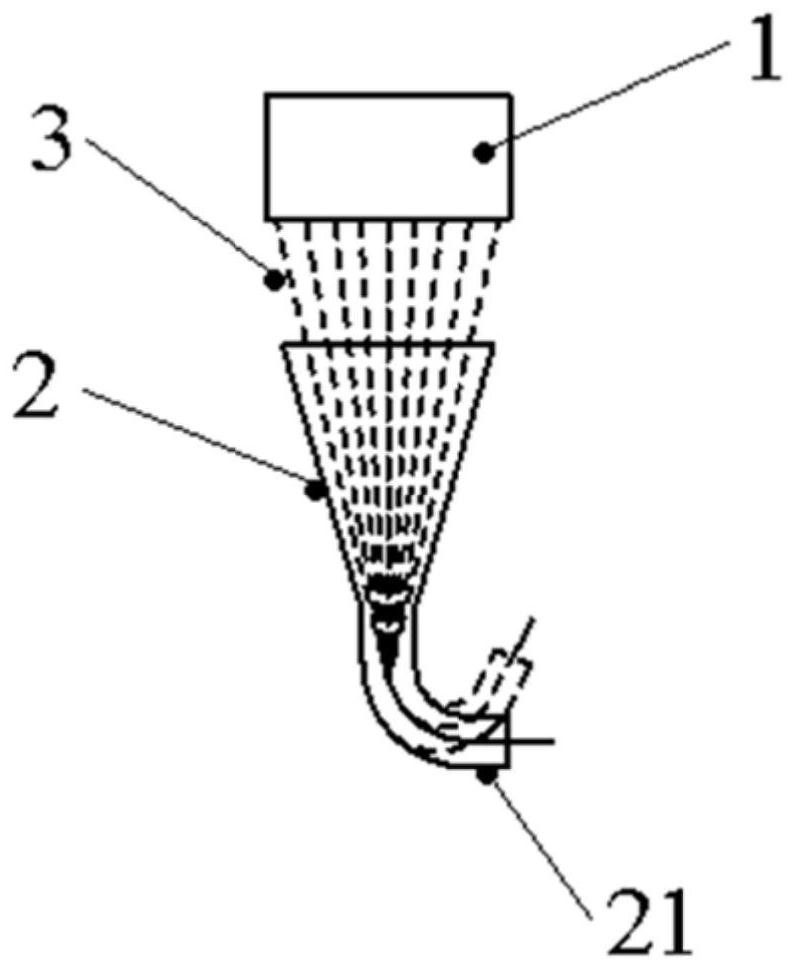

A kind of continuous preparation method of cellulose fiber

ActiveCN111155183BControllable molding processOptimal Control StructureSpinnerette packsArtificial thread manufacturing machinesPolymer scienceCellulose fiber

The invention discloses a continuous preparation method of cellulose fibers. The preparation method applies a forming tension of 0.1 to 1.9 cN / dtex to a thin stream of raw liquid obtained by extrusion through a spinneret and cooling through an air gap, and then the feeding speed is 80 ~1000m / min coagulation bath, and continue to apply a pulling tension of 0.075~1.5cN / dtex to the washed fibers in the washing system after the coagulation bath, and finally send it to the post-processing system to achieve continuous high efficiency at a speed of 80~1000m / min Fibres for textile products. The preparation method provided by the invention can significantly adjust the problems of obvious fibrillation, low fiber elongation, and poor fiber uniformity of cellulose fibers under high-speed traction, realize high-speed and high-quality preparation of cellulose fibers, and further greatly improve production efficiency. The production cost is reduced, and an efficient and continuous method for preparing cellulose fibers that is more suitable for industrialization is formed.

Owner:CHINESE TEXTILE ACAD

A kind of plasma cladding manufacturing 3D printing equipment and method

ActiveCN105922574BSimple structureReasonable design3D object support structuresAdditive manufacturing with solidsTemperature controlPlasma generator

The invention discloses a plasma cladding manufacturing 3D printing equipment and method. The equipment is composed of a monitoring system, a plasma beam processing system and a horizontal printing platform for placing workpieces to be printed; the plasma beam processing system consists of a plasma generator, It consists of a gas supply device, a powder feeding device that feeds powder into the plasma beam, and a printing position adjustment device; the monitoring system includes a position adjustment controller, a temperature detection unit, a distance detection unit, and a printing distance adjustment controller. The temperature detection unit and the printing distance The temperature control device is composed of an adjustment controller; the method includes steps: 1. acquisition of a three-dimensional model of the workpiece to be printed and layered slice processing; 2. filling of the scanning path; 3. acquisition of the printing path; 4. printing layer by layer from bottom to top. The invention is reasonable in design, easy to operate, high in molding efficiency and good in use effect, does not need a closed molding chamber, and does not need a protective atmosphere or a vacuum environment, and the workpiece molding process is directly carried out in an atmospheric environment.

Owner:中研碧诚(北京)科技有限公司

Si for a microwave kiln 2 no 2 o Wave-transmitting-heat-insulating integrated lining material and preparation method thereof

ActiveCN106747574BControl the stomata distributionSimple preparation processRadiating element housingsCeramicwarePorosityThermal insulation

The invention belongs to the field of refractory materials, and in particular relates to a Si2N2O wave transmission-heat insulation integrated inner lining material for a microwave kiln, and a preparation method of the material. The preparation method of the Si2N2O wave transmission-heat insulation integrated inner lining material for the microwave kiln comprises the following step: calcining silicon nitride gel, the surface of which is coated with SiO2, for 60-80min at the temperature of 1600-1750 DEG C under the protection of inert atmosphere so as to obtain the Si2N2O wave transmission-heat insulation integrated inner lining material. The Si2N2O wave transmission-heat insulation integrated inner lining material for the microwave kiln has the porosity of 60-70%, the dielectric constant of 3.4-5.3 and the dielectric loss tg delta of less than 2.5*10<-3>; the material is excellent in heat preventing and heat insulation performances, bearing performance, impact resistance, wave transmittance and the like under the harsh conditions of high temperature, high pressure, strong corrosion and the like, thus having better application prospect in the aspect of microwave high temperature sintering kilns.

Owner:ZHENGZHOU UNIV +1

Cast piece forming and solidifying method

The cast rod forming and hardening method is used in casting industry. The forming and hardening liquid is prepared with MgCl2 crystal, alum and other material, and the forming and hardening liquid may be further compounded into paste of 10-40 deg specific weight or added into material for casting. The said method has the advantages of simple molding, low cost, high product precision and roughness, no sand sticking, no scar, no limitation in product complication degree and weight, etc.

Owner:湖南黄金股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com