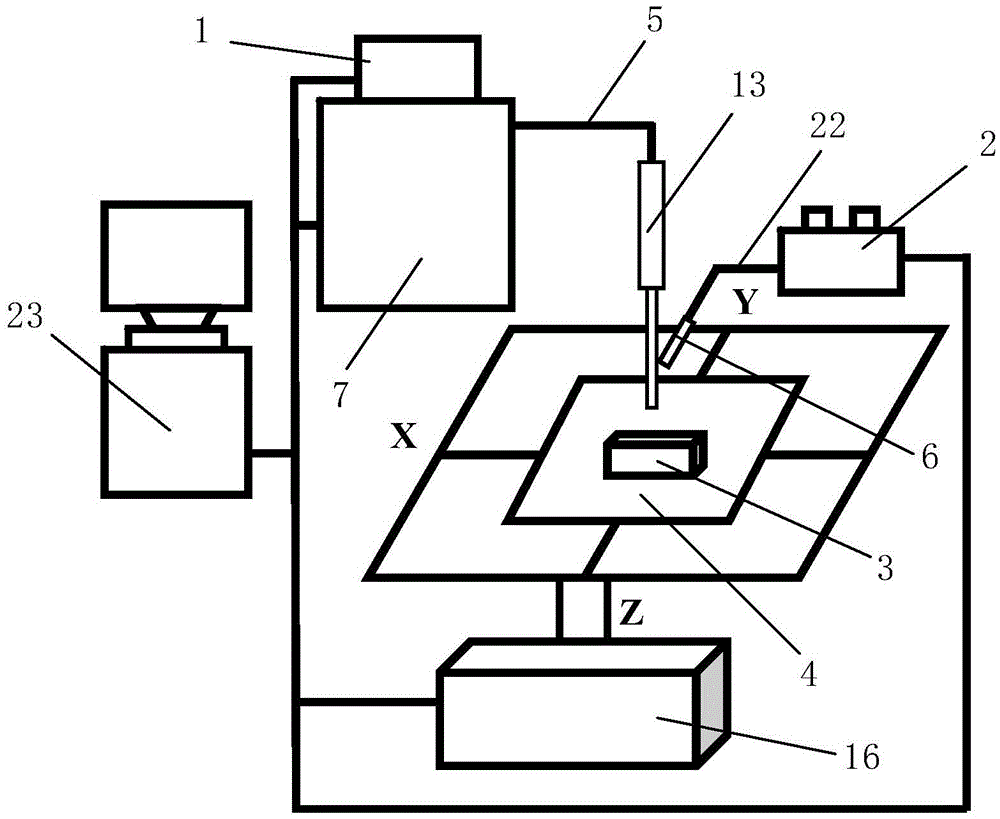

Plasma fusion covering manufacture rapid molding equipment and molding method

A technology of plasma cladding and forming equipment, applied in manufacturing tools, ceramic forming machines, additive processing, etc., can solve the problem of high maintenance cost, low mechanical properties of three-dimensional metal parts, difficult to achieve rapid prototyping of ceramic and composite parts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

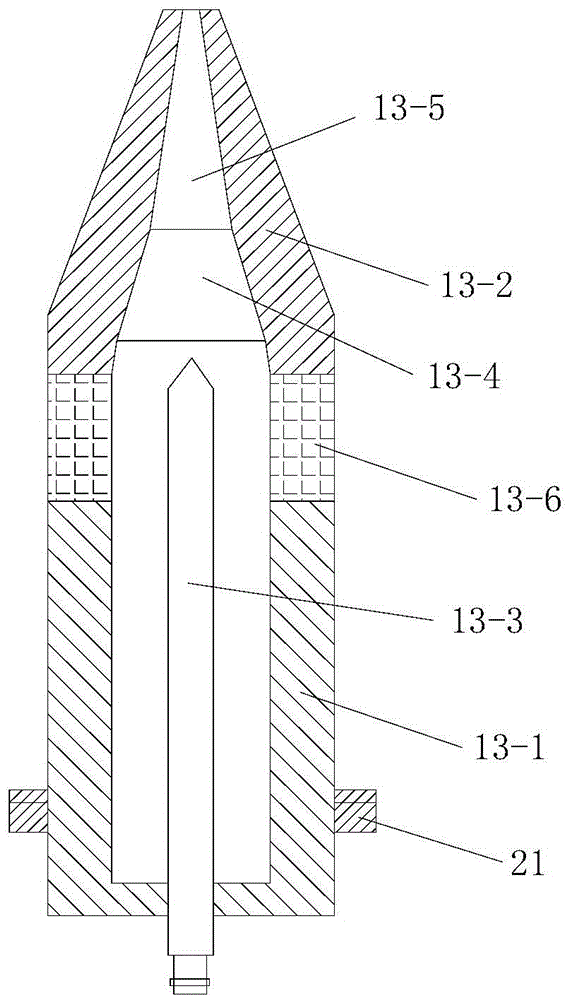

[0135] In this example, if Figure 7 As shown, the difference between the plasma cladding manufacturing rapid prototyping equipment used and the embodiment 1 is that the angle between the nozzle 13-5 and the central axis of the gun body 13-1 is 30°-45°.

[0136] In this way, after changing the direction of the plasma beam through the nozzle 13-5, the thermal load impact of the plasma jet on the anode nozzle 13-2 can be effectively reduced, and the anode ablation condition is improved.

[0137] In this embodiment, the structure, connection relationship and working principle of the remaining parts of the rapid prototyping equipment manufactured by plasma cladding are the same as those in Embodiment 1.

[0138] In this embodiment, the plasma cladding manufacturing rapid prototyping method adopted is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com