Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Plasma fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetized plasma fusion reactor

InactiveUS20060198483A1Convenient introductionNuclear energy generationLow temperature fusion reactorLiquid mediumWavefront

A fusion reactor apparatus for initiating a fusion reaction in a fusionable material is disclosed. The apparatus includes a vessel operable to contain a liquid medium and a vortex generator operable to generate a vortex in the liquid medium. The apparatus also includes a plasma generator operable to generate a magnetized plasma of the fusionable material and to introduce the magnetized plasma into the vortex and a pressure wave generator operably configured to cause a pressure wavefront in the liquid medium to envelope the magnetized plasma and to converge on the magnetized plasma to impart sufficient energy to the fusionable material to initiate fusion in the fusionable material.

Owner:GENERAL FUSION INC

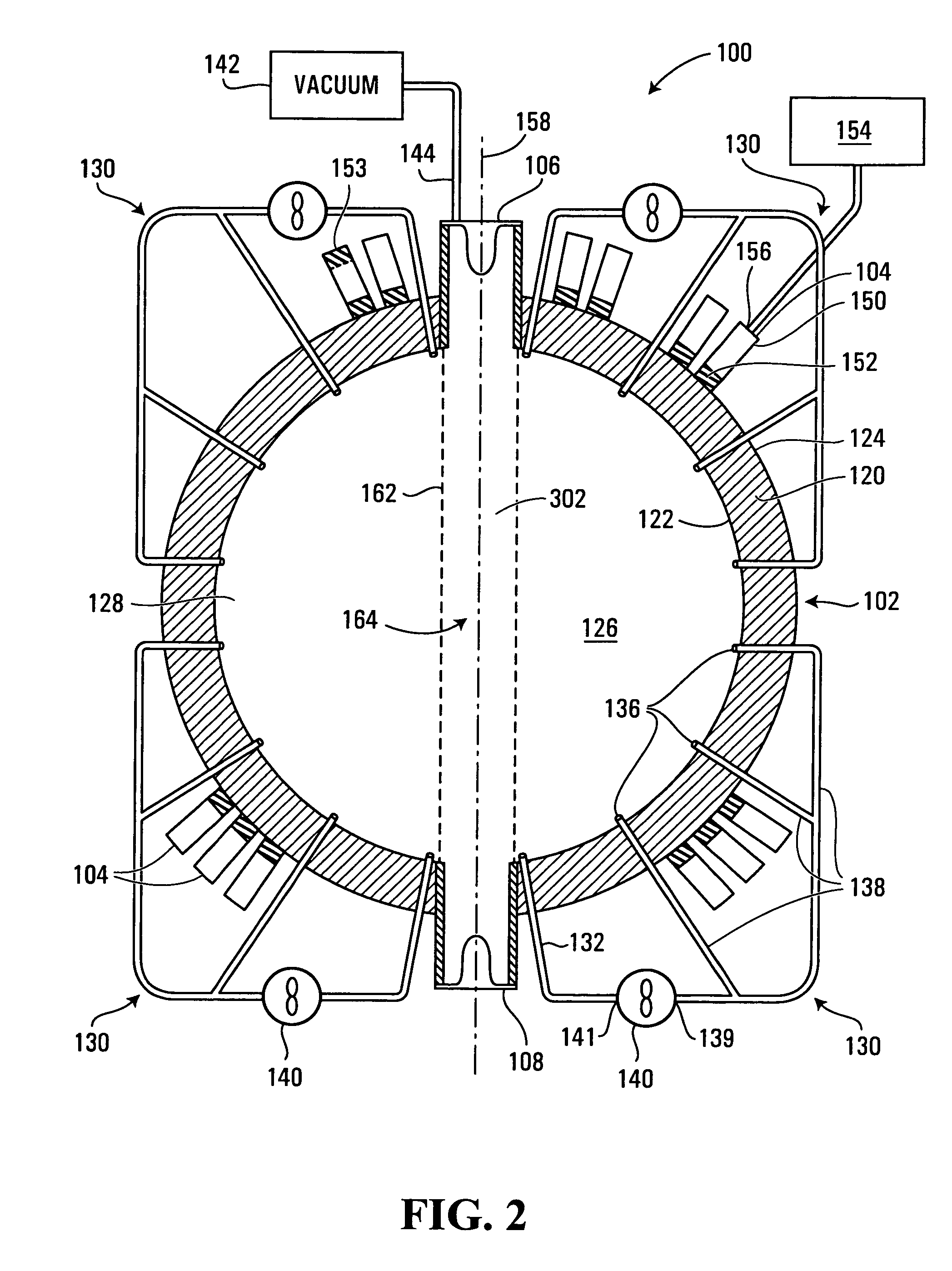

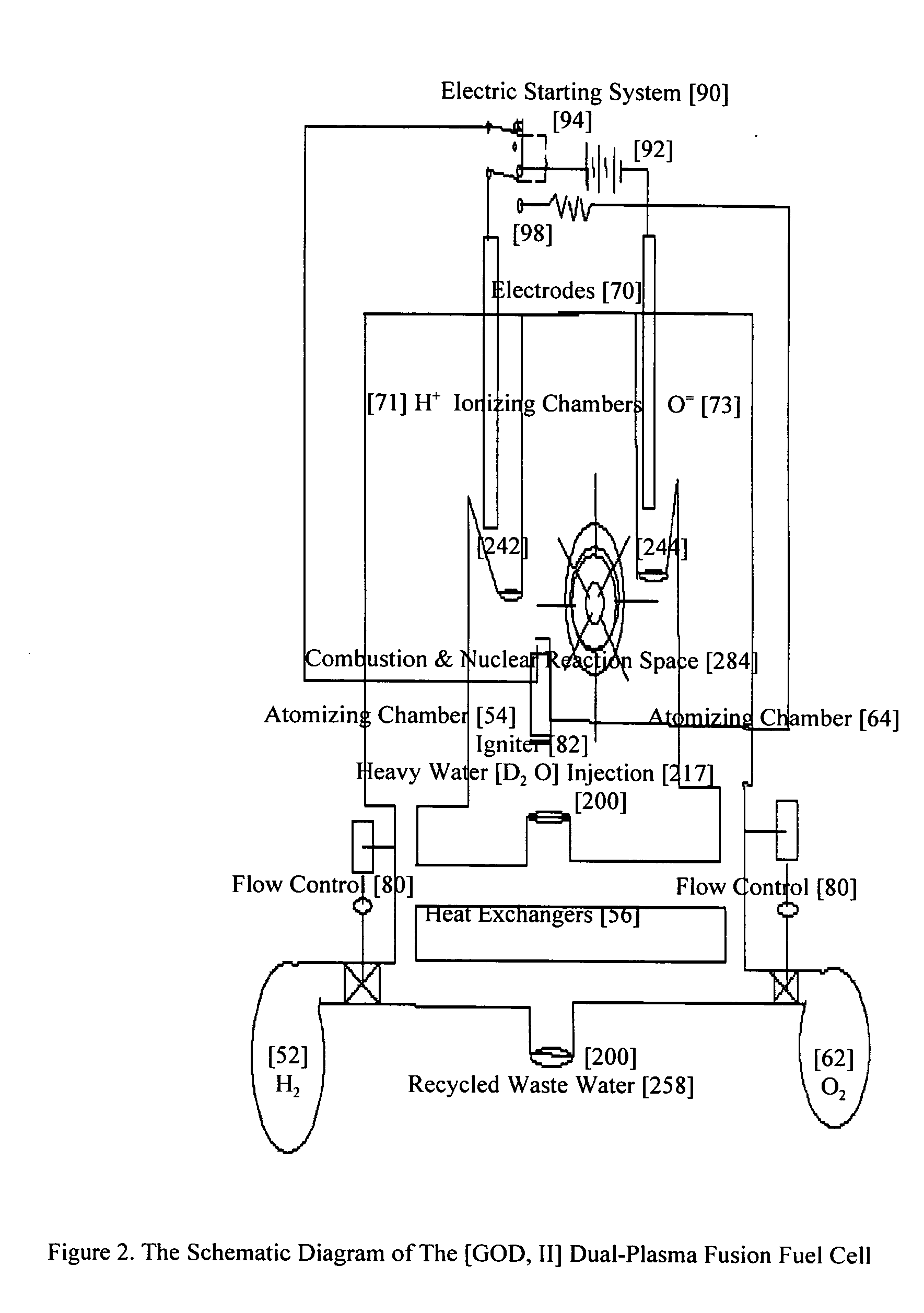

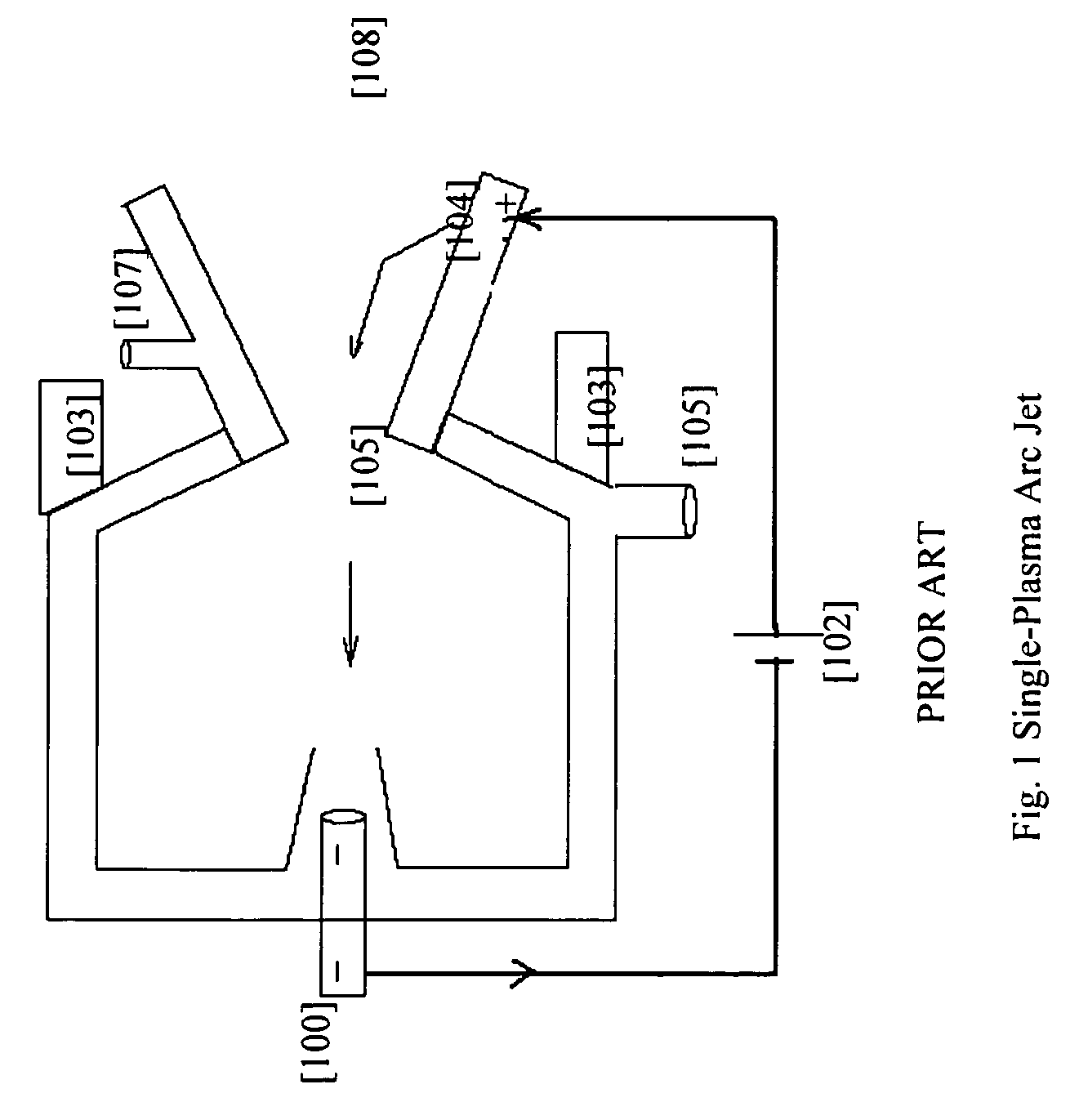

Dual-plasma fusion and fission fuel cells

InactiveUS20060045228A1More powerMore electricityNuclear energy generationMachines/enginesThermal energyElectric force

New [GOD, I], [GOD, II], & [GOD, III] dual-plasma fuel cells provide the electric start systems to start their warm-up processes, automatically. After their warm-up processes done and the operation temperatures reached, the dual-plasma fuel cells will run independently by continuously supplying fuels and moisture into the units. In dual-plasma nuclear [fusion and / or fission] fuel cells' configuration, electrical power will be generated from the nuclear-thermal-plasmas reaction by exothermal heating from combustion & nuclear reactions. With conducting high-electrons' current, the cable, loads, and electrodes are connected among one another between two plasmas' ionizing chambers for civil utility purposes. In the [GOD, II] dual-plasma fusion fuel cell, heavy water [D2O] injection into the atomizing chambers increases the plasmas heating and electrical conductivities. And the un-like charges of the heavy water's [D2O+], & [D2O−] react with plasmas' [2H+& O=] combustion heating which will induce the fusion reaction and release much more nuclear heating power for initiation of the next plasmas-generation cycle much easily. For the [GOD, III] dual-plasma fission fuel cell, fission fuels located in the combustion & nuclear reaction space through robotic movements provide additional nuclear-thermal energy that allows for initiation of the plasmas-generation process for the next cycle. For [GerTh. I] dual-plasma jet thruster, the dual plasmas are ejected to an opening end of a ‘C’ shaped magnet, and linear thrust is generated, according to the right-hand rule as in a jet thruster of propulsion for space traveling.

Owner:DAW SHIEN SCI RES & DEV

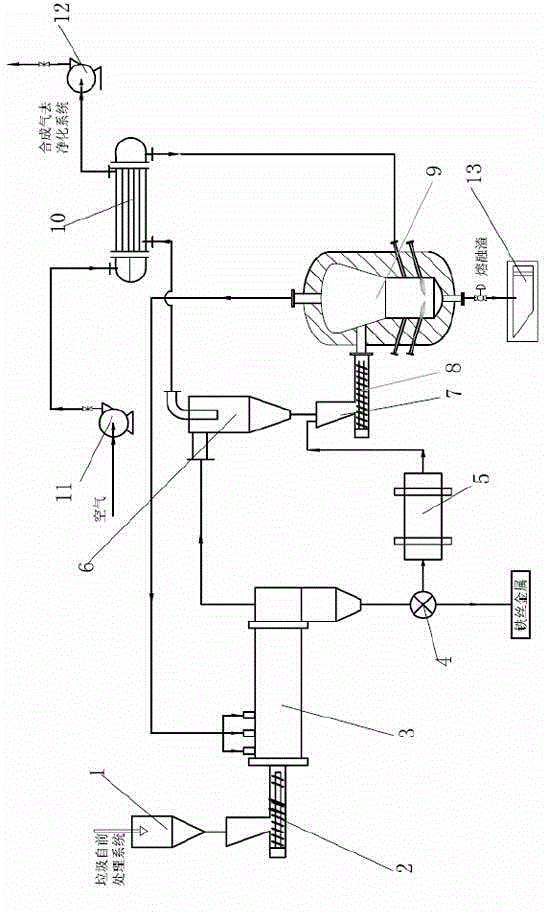

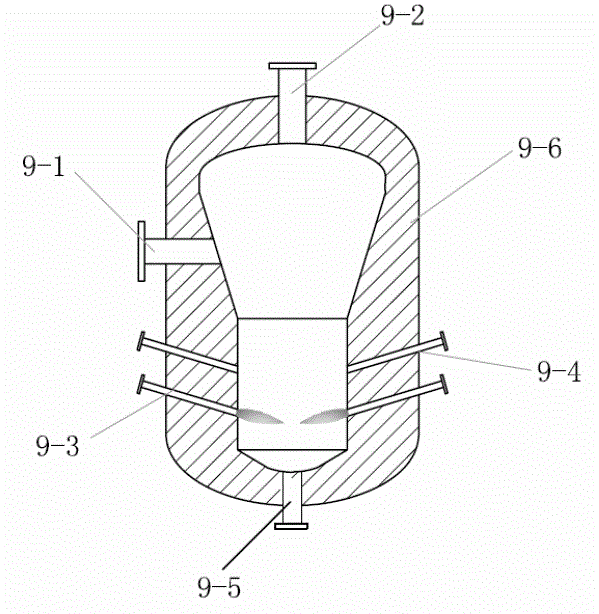

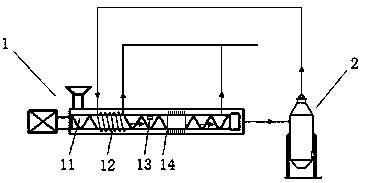

Household garbage classified gasification system with rotary kiln gasification and plasma fusion capability

ActiveCN104976622AReduce energy consumptionReduce processing costsIncinerator apparatusAir preheaterCyclone

The invention discloses a household garbage classified gasification system with rotary kiln gasification and plasma fusion capability. The household garbage classified gasification system comprises a rubbish feeder, a rotary kiln type pyrolysis vaporizer, a metal sorting machine, a crusher, a high-temperature cyclone separator, an ash hopper, an ash feeder, a plasma fusion furnace and an air preheater; household garbage is sequentially subjected to the pyrolysis gasification, metal sorting and crushing of the rotary kiln type pyrolysis vaporizer and the further gasification treatment of the plasma fusion furnace; the low-temperature rotary kiln vaporizer and the high-temperature plasma fusion furnace can be effectively combined, and the ash generated by pyrolysis and gasification of the rotary kiln vaporizer is fused by virtue of taking plasma torch as a high-quality heat source; the household garbage classified gasification system can effectively take the heat of synthesis gas and the gas fume generated by the fusion furnace as an outer heat source of the rotary kiln vaporizer so as to heat the air entering in the plasma fusion furnace, the comprehensive energy use efficiency is improved, and the secondary pollution problem of dioxin and heavy metal is avoided.

Owner:中国东方电气集团有限公司

Apparatus and method for disposing solid waste by using hot plasma

The invention discloses an apparatus and a method for disposing solid waste by using hot plasma, comprising a plasma fusion pyrolyzing furnace, a hot plasma generator, a working gas preparing and supplying apparatus, a feed apparatus, a slag emission and molten metal emission apparatus, a tail gas purification processing system and a corresponding measurement control system. By adopting the invention, hazardous and noxious organic components in various solid wastes can be eliminated thoroughly, resynthesis of the hazardous and noxious organic components can be avoided, and the wastes are converted into useful gases, stable, glass state slag without leaching toxicity and recyclable metal components substantially. In the disposing process, less smoke is generated; the purity of useful gases is high; the cost for cleaning the tail gas is lower; gas which is generated after purification processing of the tail gas can meet the emission requirements of air quality standard.

Owner:安徽中科华炬环保科技有限公司

System and method for treating hazardous wastes on the basis of plasma smelting furnace

InactiveCN104566396APrevent oxidationAvoid thermal conductivityEmission preventionIncinerator apparatusCombustion chamberPollution

The invention discloses a system for treating hazardous wastes on the basis of a plasma smelting furnace. The system comprises a pretreatment system, a pyrolysis fusion system and a smoke treatment system, wherein the pyrolysis fusion system comprises a plasma fusion furnace; the smoke treatment system successively comprises a secondary combustion chamber, a gravity settling chamber, a quench tower, an SCR (Selective Catalytic Reduction) system, a bag-type dust collector, an activated carbon adsorption tower, an alkali washing tower and a smoke discharging chimney. The system with the technical scheme is characterized in that a smoke tail gas stage treatment way is used for purifying smoke tail gas and realizing a purpose that stubborn hazardous wastes are thoroughly removed. When the system works, each equipment pipeline does not exchange air with outside, the smoke tail gas in equipment does not cause secondary pollution on external air, the smoke tail gas is treated according to stages and steps in smoke tail gas treatment, pollutants in the smoke tail gas are thoroughly treated, and secondary pollution on the environment due to the stubborn hazardous wastes and the smoke tail gas is avoided.

Owner:安徽中科华炬环保科技有限公司

Advanced fusion-fission subcritical energy reactor core

ActiveCN103578579AProliferation effect is goodMeet core energy amplificationFuel elementsNuclear energy generationRadiation resistantNuclear power

The invention belongs to a nuclear power design technique, and particularly relates to a loading scheme of an advanced fusion-fission subcritical energy reactor core. The reactor core structure comprises a plurality of fuel assembly modules which are arranged in a hoop along an annular plasma fusion area, wherein each fuel assembly module comprises a plurality of fuel assemblies arranged in a polar direction of the plasma fusion area; a first heat-resistant and radiation-resistant wall is arranged at one side of each fuel assembly towards the plasma fusion area; a tritium-producing coating is arranged at the other side of each fuel assembly opposite to each first wall; an outer shielding layer is arranged outside each tritium-producing coating. By adopting the advanced fusion-fission subcritical energy reactor core, the design requirements of the energy magnification factor and the tritium breeding ratio can be simultaneously met; the continuous growth of the magnification factor and the tritium breeding ratio can be maintained within a long period of time; the breeding performance of the reactor core is good.

Owner:CHINA NUCLEAR POWER ENG CO LTD

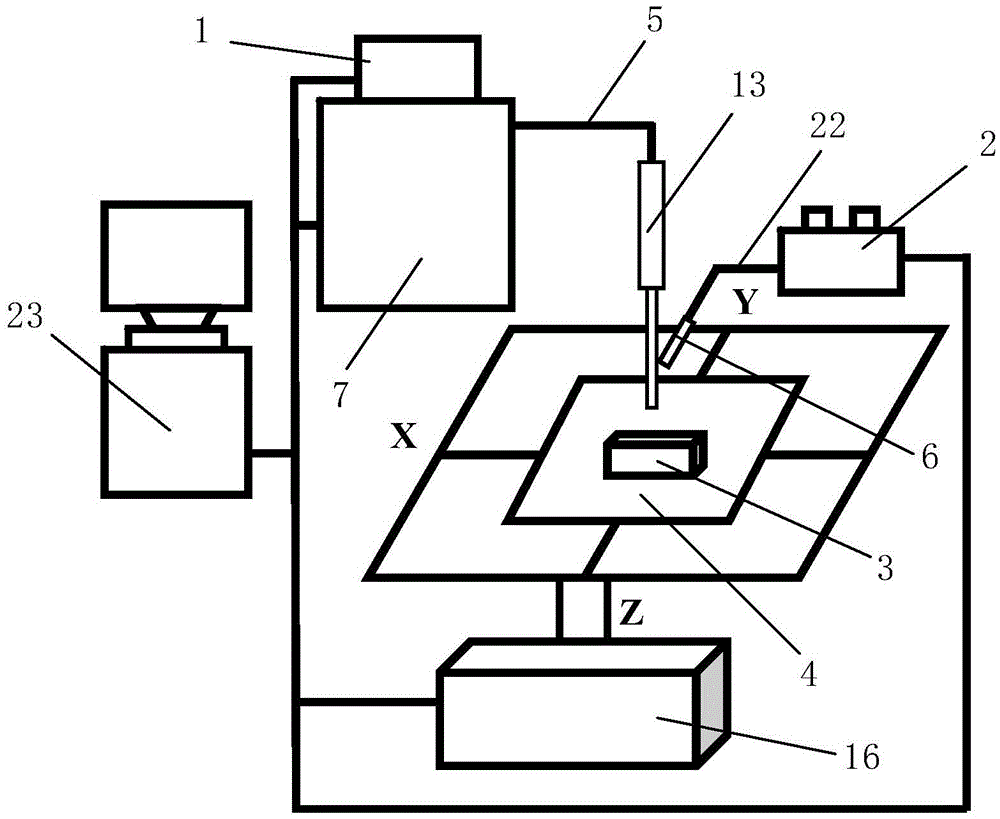

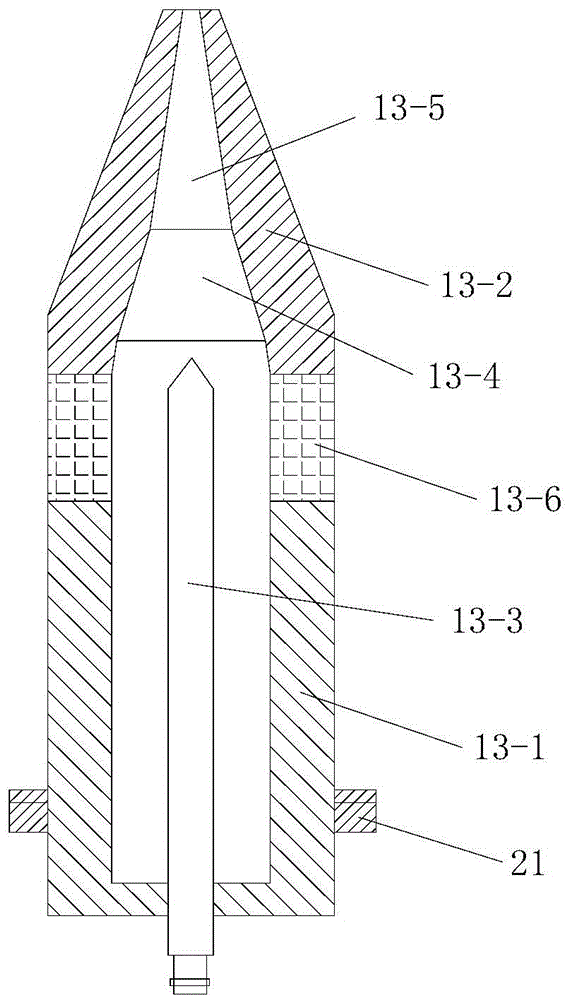

Plasma fusion covering direct manufacture 3D printing equipment and method

ActiveCN105922566ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusTemperature controlDistance detection

The invention discloses plasma fusion covering direct manufacture 3D printing equipment and a method. The equipment comprises a monitoring system, a plasma beam processing system, and a horizontal printing table. The plasma beam processing system includes a plurality of plasma beam processing devices; each plasma beam processing device comprises a plasma generator, a printing position adjustment controller, a gas supply device and a powder sending device. The monitoring system includes a plurality of beam processing supervising devices; each beam processing supervising device comprises a temperature detection unit, a horizontal movement controller, a distance detection unit and a printing distance adjustment controller. The temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be printed, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, and no need of enclosed moulding chamber, protection atmosphere, or vacuum environment.

Owner:中研碧诚(北京)科技有限公司

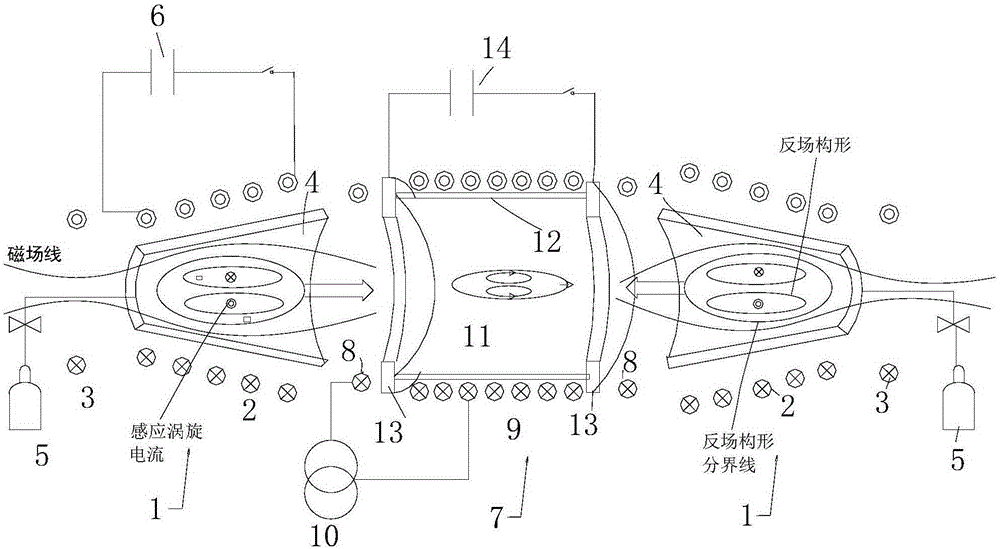

Magnetized plasma fusion ignition device and inertial magnetic confinement fusion method

InactiveCN105185417AStable lifeFulfil requirementsNuclear energy generationThermonuclear fusion reactorHead to headFusion ignition

The invention discloses a magnetized plasma fusion ignition device and an inertial magnetic confinement fusion method. The method comprises a field-reversed configuration (FRC) forming and accelerated transmission system, a merging collision system, and an implosion and compression system. The forming and accelerated transmission system is distributed on two sides symmetrically. The merging collision system is in the middle and comprises a metal sleeve, a coil sleeving the outer side of the metal sleeve, and magnetic mirror coils on two ends. The implosion and compression system comprises the metal sleeve and electrodes, and the electrodes are connected with a pulse driving power source capacitor set. The method comprises the following steps: by means of FRTP technology, initial FRC plasmas are formed and head-to-head collision is induced; in the space, the plasmas are merged into high-temperature high-density magnetized plasma targets with higher density and temperature than a single FRC plasma before collision; and the external pulse driving power source discharges to drive implosion in a solid sleeve to conduct quasi-adiabatic compression of the high-temperature high-density magnetized plasma targets, so that the temperature and density of the plasma targets rise to meet fusion ignition conditions.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS

Capacity reduction treatment system and method for medium-low radioactive solid waste

PendingCN110176322AReduce disposal storage spaceReduce disposal costsRadioactive decontaminationReduction treatmentAir filter

The invention discloses a capacity reduction treatment system and method for medium-low radioactive solid waste. The system comprises a crusher, a sorting box, a plasma gasifier, a plasma fusion furnace, a burning chamber, a quench tower, a ceramic filter, an activated carbon adsorption tower, a deacidification washing tower, an efficient air filter, a chimney, a fused vitreous body receiver and aconveyor. Firstly, the medium-low radioactive solid waste is crushed by using a crushing device and then conveyed to the sorting device for sorting, the combustible waste is conveyed into the gasifier, organic components are subjected to a gasification reaction, and generated ash and noncombustible waste are collected and conveyed into the fusion furnace for vitreous fusion treatment, so that radioactive nuclide is fixed into the fused vitreous body; the vitreous body is cooled, barreled and stored by an automatic receiving system, and generated smoke is purified and then reaches the comprehensive emission standard of atmospheric pollutants, so that up-to-standard emission is achieved. The capacity reduction treatment system has a good capacity reduction effect and is high in safety reliability and nuclide stability.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Plasma fusion covering manufacture 3D printing equipment and method

ActiveCN105922574ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusTemperature controlMonitoring system

The invention discloses plasma fusion covering manufacture 3D printing equipment and a method. The equipment comprises a monitoring system, a plasma beam processing system, and a horizontal printing table for placing a workpiece to be printed. The plasma beam processing system includes a plasma generator, a gas supply device and a powder sending device for sending powder into plasma beam, and a printing position adjustment controller. The monitoring system includes a position adjustment controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller. The temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be printed, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber, protection atmosphere or vacuum environment, and direct molding of workpiece in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

Plasma fusion covering manufacture rapid molding equipment and molding method

ActiveCN105922569ASimple structureReasonable designAdditive manufacturing apparatusCeramic shaping apparatusDistance detectionPlasma generator

The invention discloses plasma fusion covering manufacture rapid molding equipment and a molding method. The equipment comprises a monitoring system, a plasma beam processing system, and a printing table. The plasma beam processing system includes a plasma generator, a printing position adjustment controller, a gas supply device and a powder sending device for sending powder into the plasma beam. The monitoring system includes a position adjustment controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller. The temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be molded, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, no need of enclosed moulding chamber, protection atmosphere or vacuum environment, and direct molding of workpiece in atmosphere environment.

Owner:中研碧诚(北京)科技有限公司

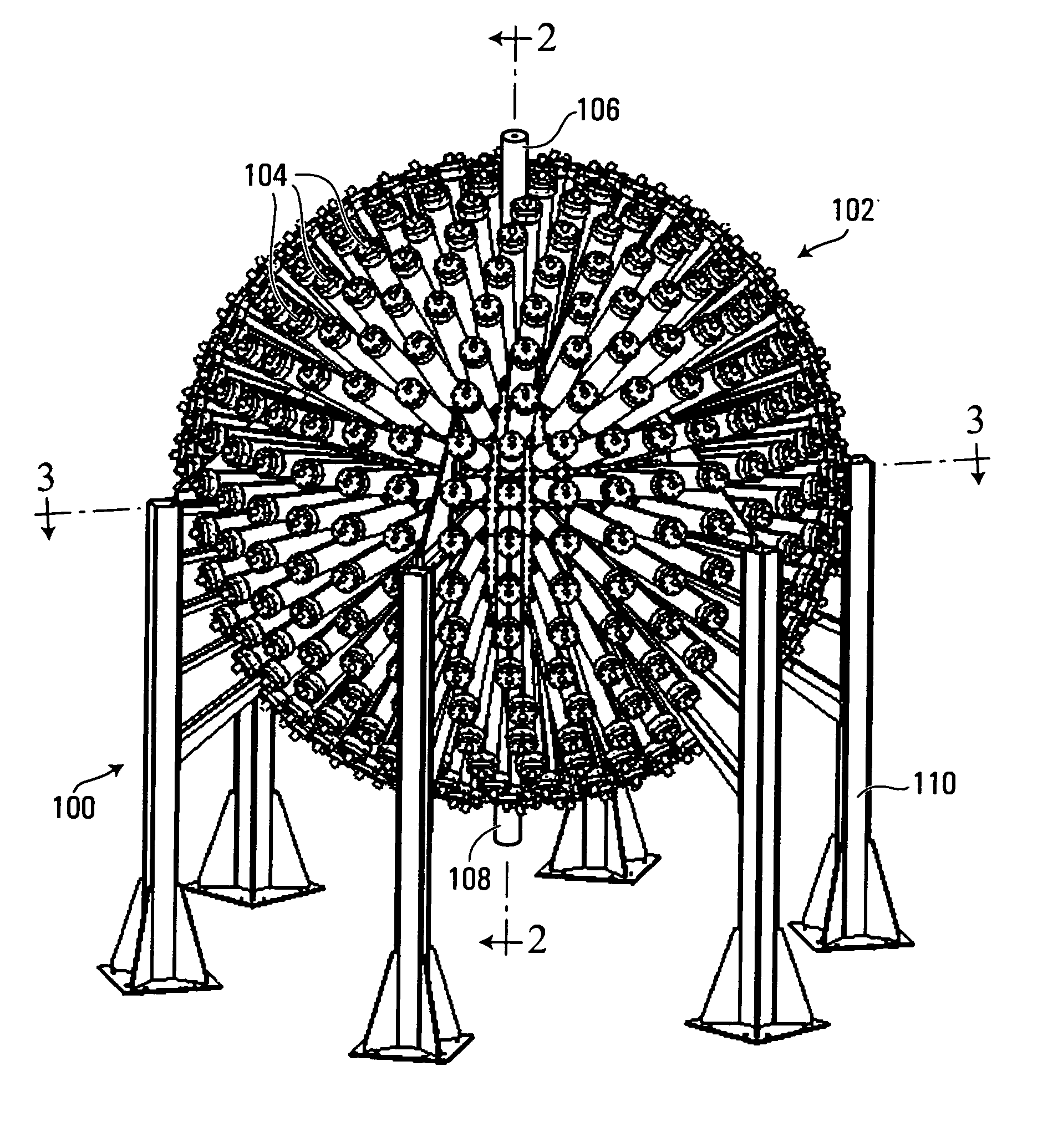

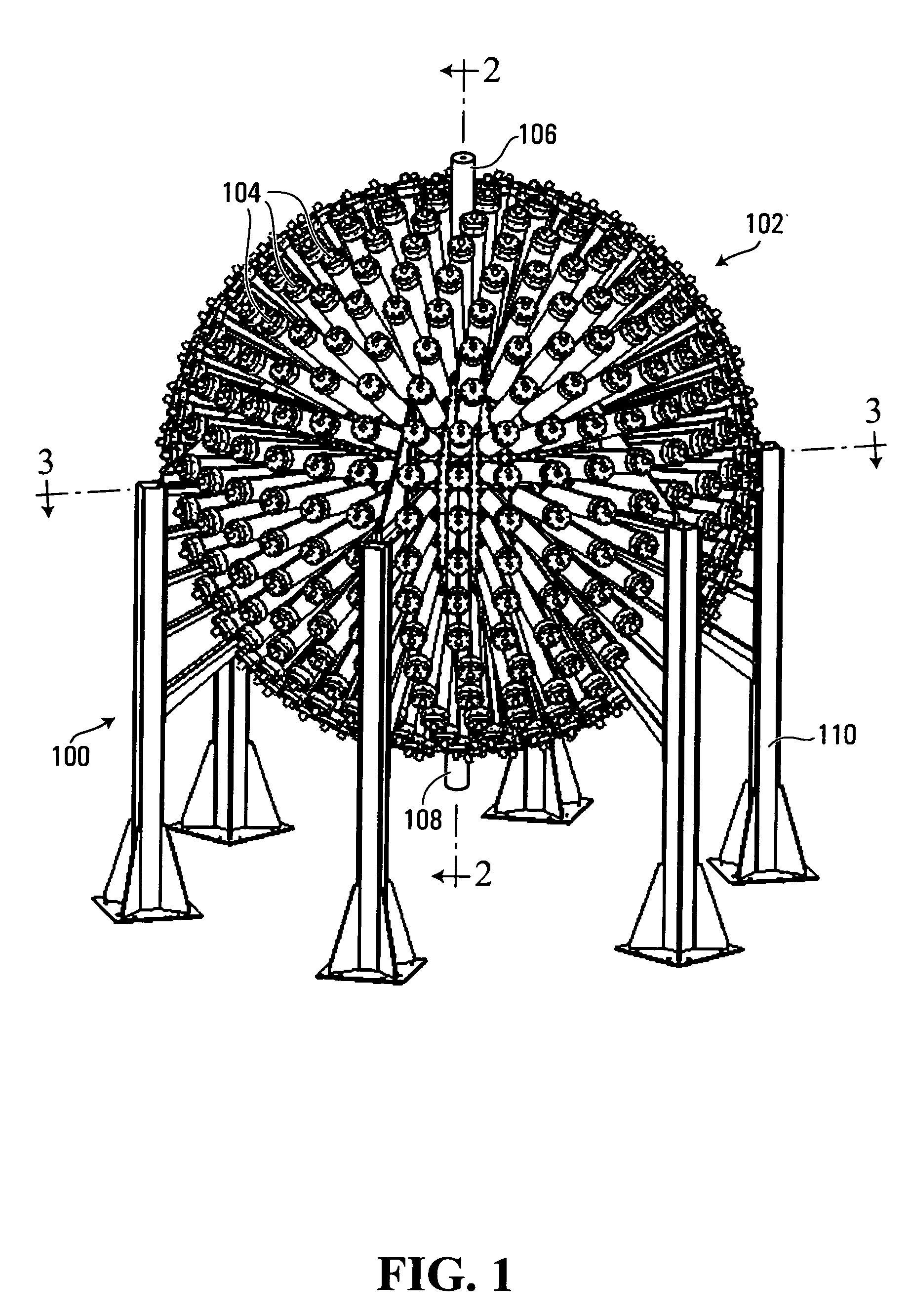

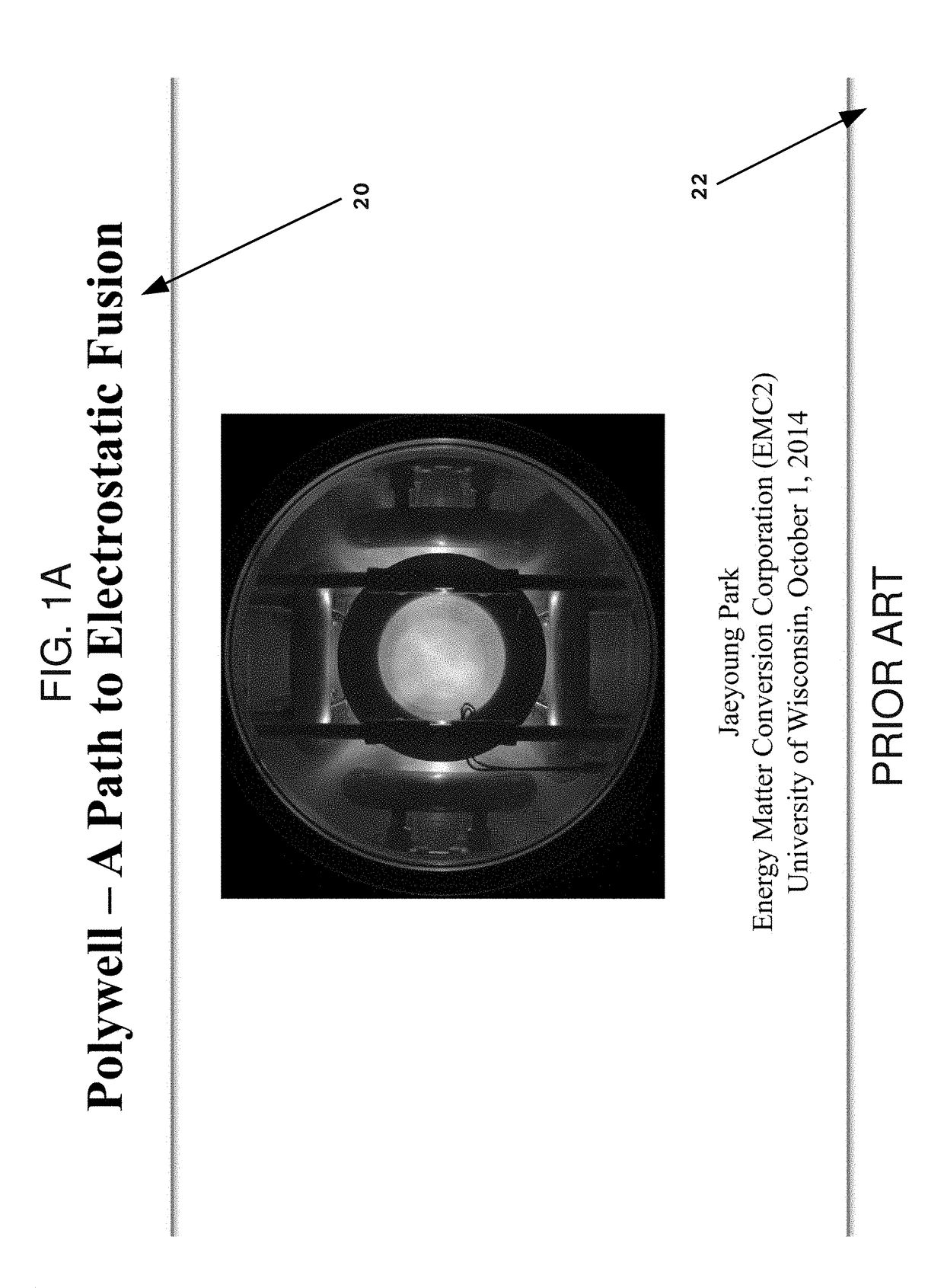

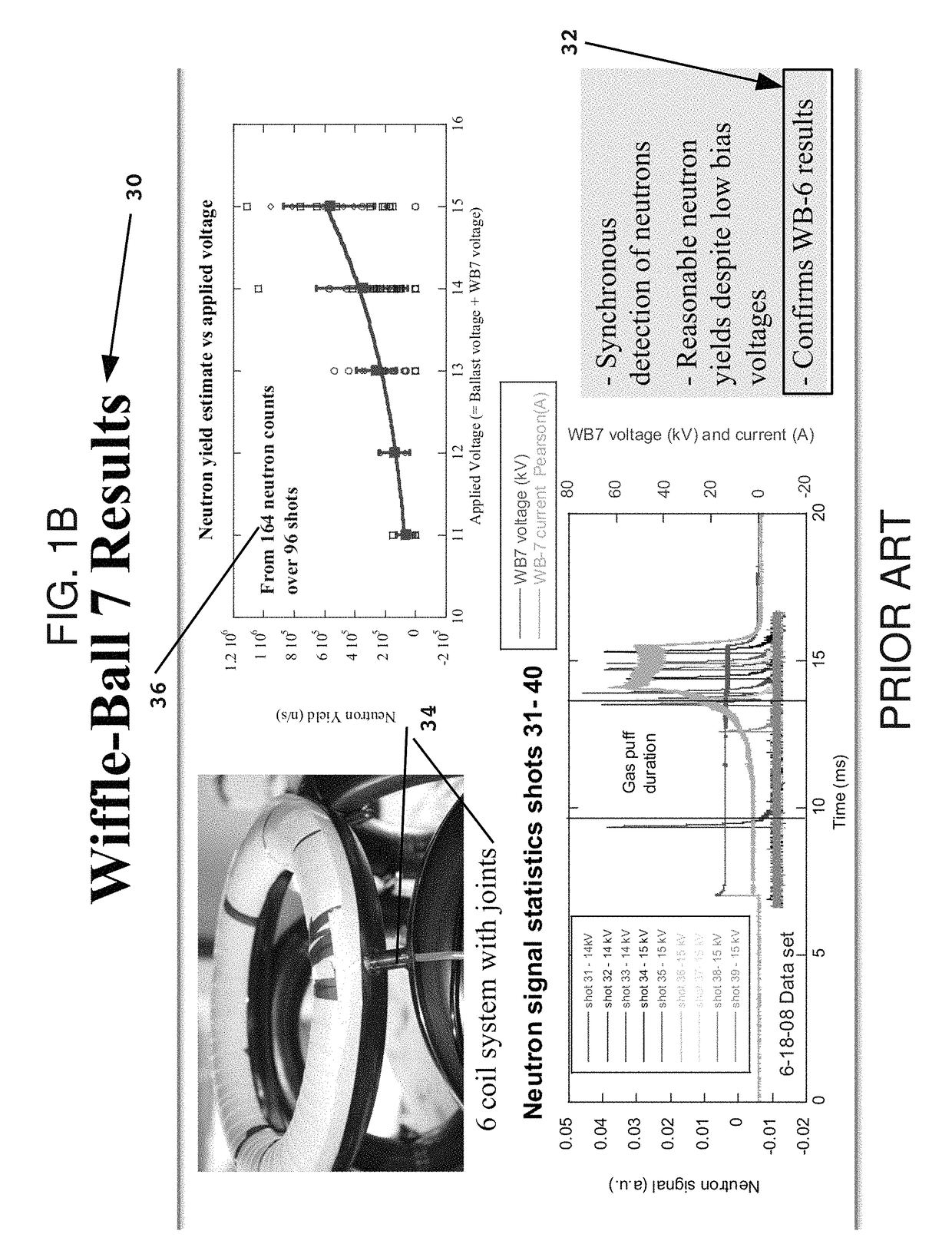

Apparatus and Method for Controlling a Plasma Fusion Reactor

InactiveUS20180114603A1Nuclear energy generationNuclear engineering problemsReactor designFull scale

Embodiments of a plasma fusion energy reactor based on Bussard's Polywell concept. The apparatus of the embodiments include interior, electron-extraction electrodes to remove cold, trapped electrons and replace them with hot electrons. Hot electrons efficiently confine a dense, hot plasma fuel. The method of the embodiments discloses a procedure for controlling the reactor during its start-up phase of operation. During start-up the reactor is changed from being in a cold, empty state to being in a stable steady-state of energy production. Reliable computer simulation predicts that in steady-state the disclosed apparatus and method will produce usable net-power continuously and for an indefinite period of operation. The full-scale reactor design is suitable for replacing most of the world's existing coal-fired power production with a clean, safe energy production alternative.

Owner:ROGERS JOEL GUILD

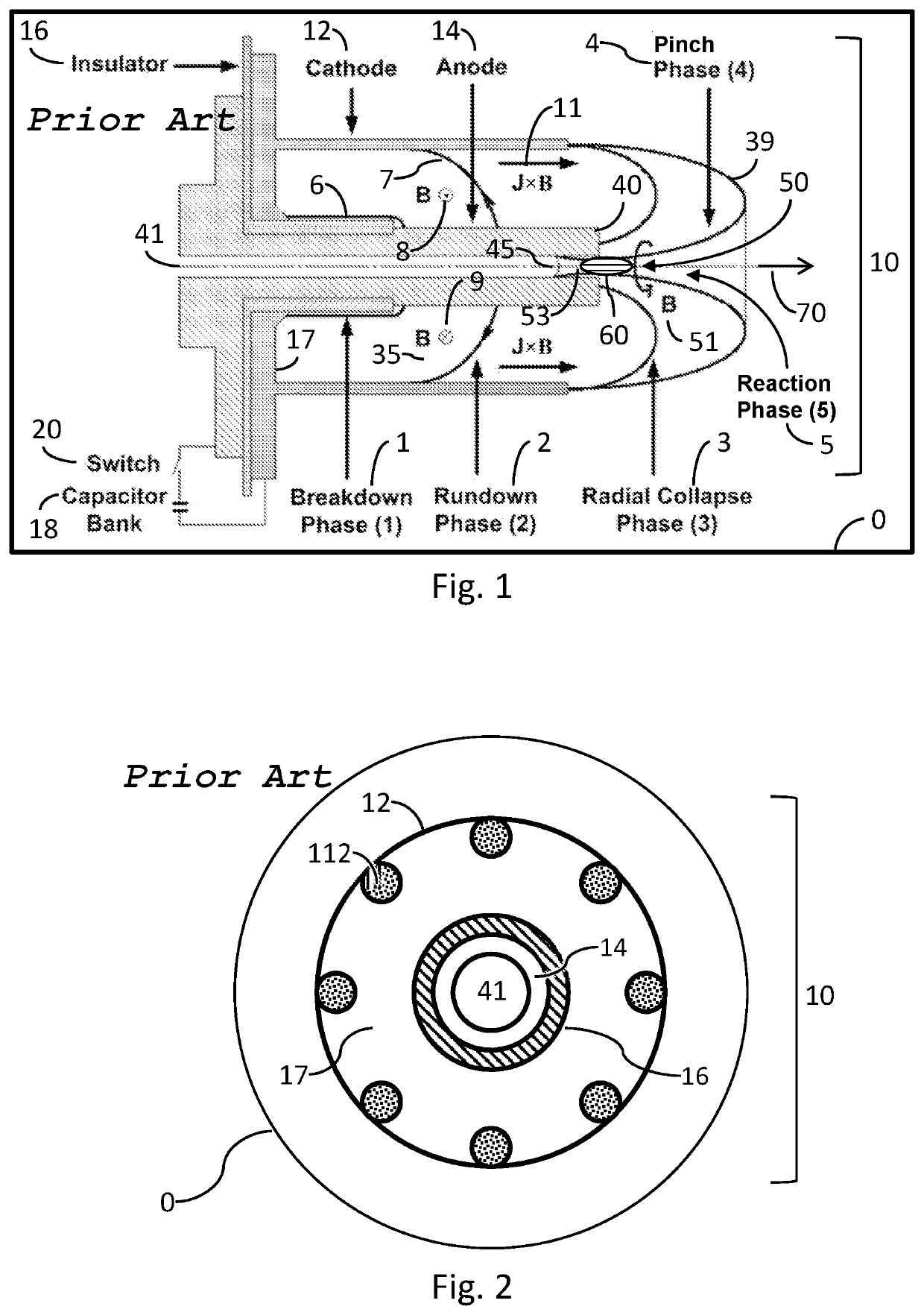

Improved dense plasma focus devices

ActiveUS20220124903A1Improve the axial symmetry of the plasma sheath or filamentsUniform plasmaNuclear energy generationPlasma techniquePlasma accelerationDense plasma focus

A system for performing enhanced dense plasma acceleration includes two dense plasma fusion accelerators, each having two electrodes. One of the electrodes is positioned within a volume of the other. A conductive ring couples electrodes of the two plasma fusion accelerators. A plasma sheath from one accelerator and a plasma sheath from the other accelerator interact to form a portion of a cusp pinch. The plasma sheaths form portions of the cusp pinch via apertures of electrodes.

Owner:FREENT TECH INC

Pyrolysis processing method for red mud

ActiveCN110695055AImprove primary heat evaporationIncrease the degree of lysisTransportation and packagingSolid waste disposalRed mudPre treatment

The invention discloses a pyrolysis processing method for red mud, and relates to the technical field of harmless treatment of solid waste. The method comprises the following steps of: adding red mudinto a fed material pretreatment device, dividing the red mud into two and more than two parts, independently inputting the red mud into two and more than two cylinders, heating the red mud to enablethe red mud to be evaporated and pyrolyzed while a screw propeller of the fed material pretreatment device conveys materials; outputting materials to a high-temperature plasma fusion device from the output of the fed material pretreatment device by the fed material pretreatment device; carrying out high-temperature plasma torch fusion on input materials by the high-temperature plasma fusion device; and conveying the input materials into glass body waste residues and synthesis gases containing CO2, CO and H2. The method has the advantage of high harmless treatment degree.

Owner:航天环保(北京)有限公司

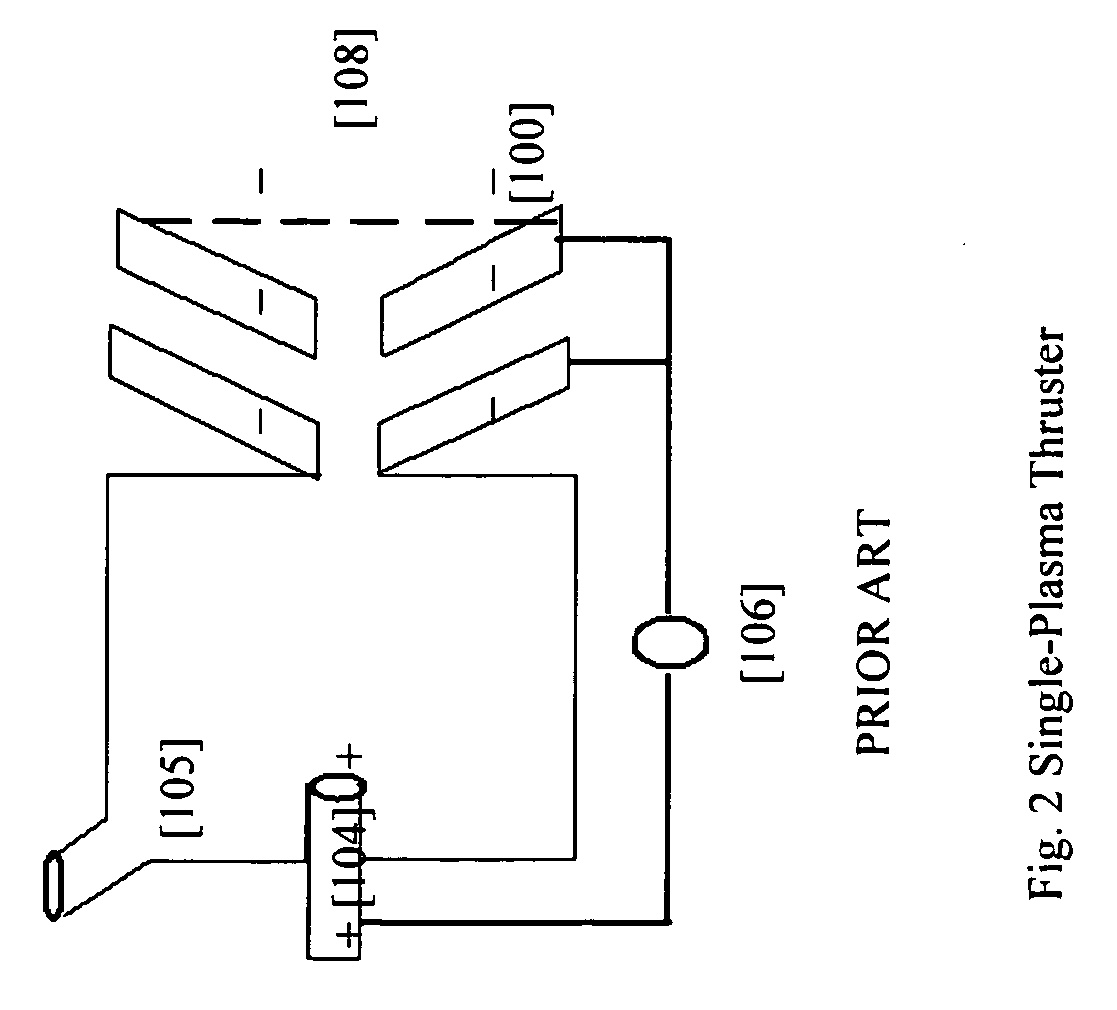

Dual-plasma-fusion jet thrusters using DC turbo-contacting generator as its electrical power source

InactiveUS20070113535A1Increase thrustImprove power densityCosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringOxygen

New [GerTh-DawShien. V] dual-plasma flying object and [GerTh-DawShien. VI] dual-plasma-fusion flying object provide the electric start system to start their warm-up process to their steady-states, automatically. After their warm-up processes done and the operation conditions reached, the [Thruster V]& [Thruster VI] will run themselves, independently by continuously supplying fuel, oxygen, and moisture into the units. Their electrical power will be generated from the [ShihHwa. V] DC turbo-contacting generator by different material-made surfaces and rollers contacting reaction and then, its electricity supplies transform gases from their molecular forms into ionized forms by electrifying reaction. When dual plasmas are fast ejected from nozzles into the ‘C’ shaped magnet's opening, their current will be increasing and plasmas will be bent downward, according to the right hand rule. The linear upward reaction thrust is generated. Thereafter, the plasmas combustion, neutralization, and fusion reactions are conducted also to the action direction and their reaction force for propelling the flying object in the opposite linear guided motion, upward and forward.

Owner:DAW SHIEN SCI RES & DEV

Surfacing equipment method of high Al-Ti type high-temperature nickel base alloy

InactiveCN102218618AAchieve recyclabilityNo damage surfacingWelding apparatusWelding power supplyAlloy

The invention discloses surfacing equipment and method. The surfacing equipment comprises a protective gas hood, a welding gun and a fusion welding power supply, wherein the circumferential periphery of the protective gas hood is provided with a sensing coil so as to heat a workpiece in the protective gas hood by virtue of sensing; the welding gun is connected with the fusion welding power supply so as to carry out plasma fusion welding surfacing on the workpiece; and the lower end of the protective gas hood is connected with gas hood protective gas, so that the protective gas flows from bottom to top in the protective gas hood, and inert atmosphere protection is provided for the workpiece. According to the technical scheme disclosed by the invention, the whole welding line zone has no fissure, and the surface no-damage welding of high Al-Ti type high-temperature nickel base alloy (the sum of Al and Ti contents is more than 6%) can be effectively realized.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

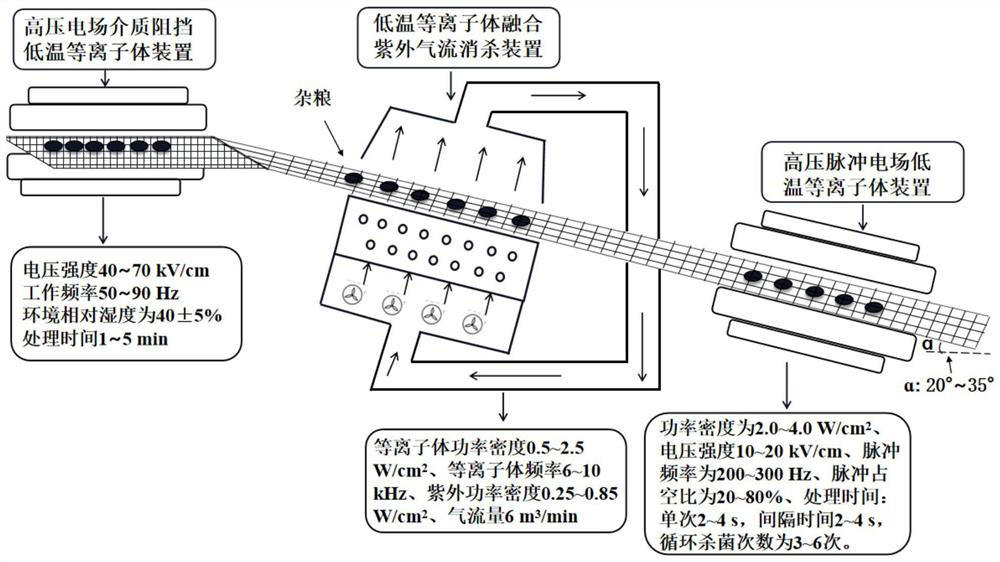

Low-temperature plasma cold sterilization and mycin degradation method for aspergillus flavus in coarse cereals

PendingCN114747619AEfficient degradationEfficient killingFood freezingSeed preservation by irradiation/electric treatmentDielectricPlasma generator

According to the low-temperature plasma cold sterilization and mycin degradation method for the aspergillus flavus in the coarse cereals, different low-temperature plasma treatment combination modes are adopted for cold sterilization of the aspergillus flavus in the coarse cereals, and meanwhile the toxin degradation effect is achieved. The specific mode is that high-voltage electric field dielectric barrier low-temperature plasma, low-temperature plasma fusion ultraviolet airflow sterilization and high-voltage pulse electric field low-temperature plasma cold sterilization are combined to sterilize coarse cereals. Wherein the excitation conditions of the high-voltage electric field dielectric barrier low-temperature plasma are as follows: the voltage intensity is 40-70kV / cm, the frequency is 50-90Hz, and the treatment conditions of the low-temperature plasma and ultraviolet airflow combined sterilization device are as follows: the power density of the low-temperature plasma is 0.5-2.5 W / cm < 2 >, the frequency of the low-temperature plasma is 6-10kHz, the ultraviolet power density is 0.25-0.85 W / cm < 2 >, and the airflow is 6m < 3 > / min; the voltage intensity of the high-voltage pulsed electric field low-temperature plasma generator is 10-20 kV / cm, the pulse frequency is 200-300 Hz, and the power density is 2.0-4.0 W / cm < 2 >. According to the method, the treatment time is 2.5 + / -0.5 min, the killing rate of aspergillus flavus in the corn reaches 99.70 + / -0.05%, and meanwhile, the degradation rate of aflatoxin reaches 72.98 + / -0.11%.

Owner:SUZHOU YIRUN FOOD TECH CO LTD +1

Systems and methods for plasma containment

InactiveCN1973338AConvenience constraintsConstrained byNuclear energy generationDirect voltage acceleratorsCompact dimensionEnergy variation

An apparatus (12) and method for plasma containment is disclosed. A stable equilibrium of a plasma (100) is determined by varying the system energy subject to Maxwell's equations, momentum moment equations, and adiabatic equations of state, without imposing a quasi-neutrality condition. In one embodiment, electrons are confined by magnetic forces and ions by internal, electrostatic forces that arise due to charge separation of the two fluids. In one embodiment, input parameters for the energy variation process are selected so as to satisfy a plasma beta parameter condition, thereby reducing the number of control variables by one. The radial scale length for cylindrically symmetric plasmas in one-dimensional equilibrium is characterized by the electron skin depth. Such plasmas can be confined as a high aspect ratio toroid having compact dimensions. Applications of the compact plasma fusion devices include neutron generation, x-ray generation, and power generation.

Owner:UTAH STATE UNIVERSITY

A rotary kiln gasification and plasma melting domestic waste graded gasification system

ActiveCN104976622BReduce energy consumptionReduce processing costsIncinerator apparatusAir preheaterCyclone

The invention discloses a household garbage classified gasification system with rotary kiln gasification and plasma fusion capability. The household garbage classified gasification system comprises a rubbish feeder, a rotary kiln type pyrolysis vaporizer, a metal sorting machine, a crusher, a high-temperature cyclone separator, an ash hopper, an ash feeder, a plasma fusion furnace and an air preheater; household garbage is sequentially subjected to the pyrolysis gasification, metal sorting and crushing of the rotary kiln type pyrolysis vaporizer and the further gasification treatment of the plasma fusion furnace; the low-temperature rotary kiln vaporizer and the high-temperature plasma fusion furnace can be effectively combined, and the ash generated by pyrolysis and gasification of the rotary kiln vaporizer is fused by virtue of taking plasma torch as a high-quality heat source; the household garbage classified gasification system can effectively take the heat of synthesis gas and the gas fume generated by the fusion furnace as an outer heat source of the rotary kiln vaporizer so as to heat the air entering in the plasma fusion furnace, the comprehensive energy use efficiency is improved, and the secondary pollution problem of dioxin and heavy metal is avoided.

Owner:中国东方电气集团有限公司

System and method for disposing garbage through cold plasma fusion technology

InactiveCN107377585AThe total amount of solutions is smallSolve problems where practical applications are limitedWaste processingCarbon compoundsTemperature controlSewage

The invention discloses a system for disposing garbage through the cold plasma fusion technology. The system comprises a cold plasma fusion device, a garbage disposal reaction chamber, an air cooling heat exchange system, an antiparticle reactor, a drier, a gas turbine generator and a temperature control type cold plasma resolver. The invention further discloses a method for disposing the garbage through the cold plasma fusion technology. According to the system for disposing the garbage through the cold plasma fusion technology, combination and spatial three-dimensional configuration are achieved; the defects, such as compost, incineration and landfill, of traditional garbage disposal modes are overcome, and the problems that at present, the total amount of garbage disposed through electric arcs is small, and practical application is limited are solved. Compared with other modes, the daily disposal capacity of the urban and rural garbage and waste water is greatly increased.

Owner:广州仁廙环保技术有限公司

Apparatus and method for controlling a plasma fusion reactor

Embodiments of a plasma fusion energy reactor based on Bussard's Polywell concept. The apparatus of the embodiments include interior, electron-extraction electrodes to remove cold, trapped electrons and replace them with hot electrons. Hot electrons efficiently confine a dense, hot plasma fuel. The method of the embodiments discloses a procedure for controlling the reactor during its start-up phase of operation. During start-up the reactor is changed from being in a cold, empty state to being in a stable steady-state of energy production. Reliable computer simulation predicts that in steady-state the disclosed apparatus and method will produce usable net-power continuously and for an indefinite period of operation. The full-scale reactor design is suitable for replacing most of the world's existing coal-fired power production with a clean, safe energy production alternative.

Owner:ROGERS JOEL GUILD

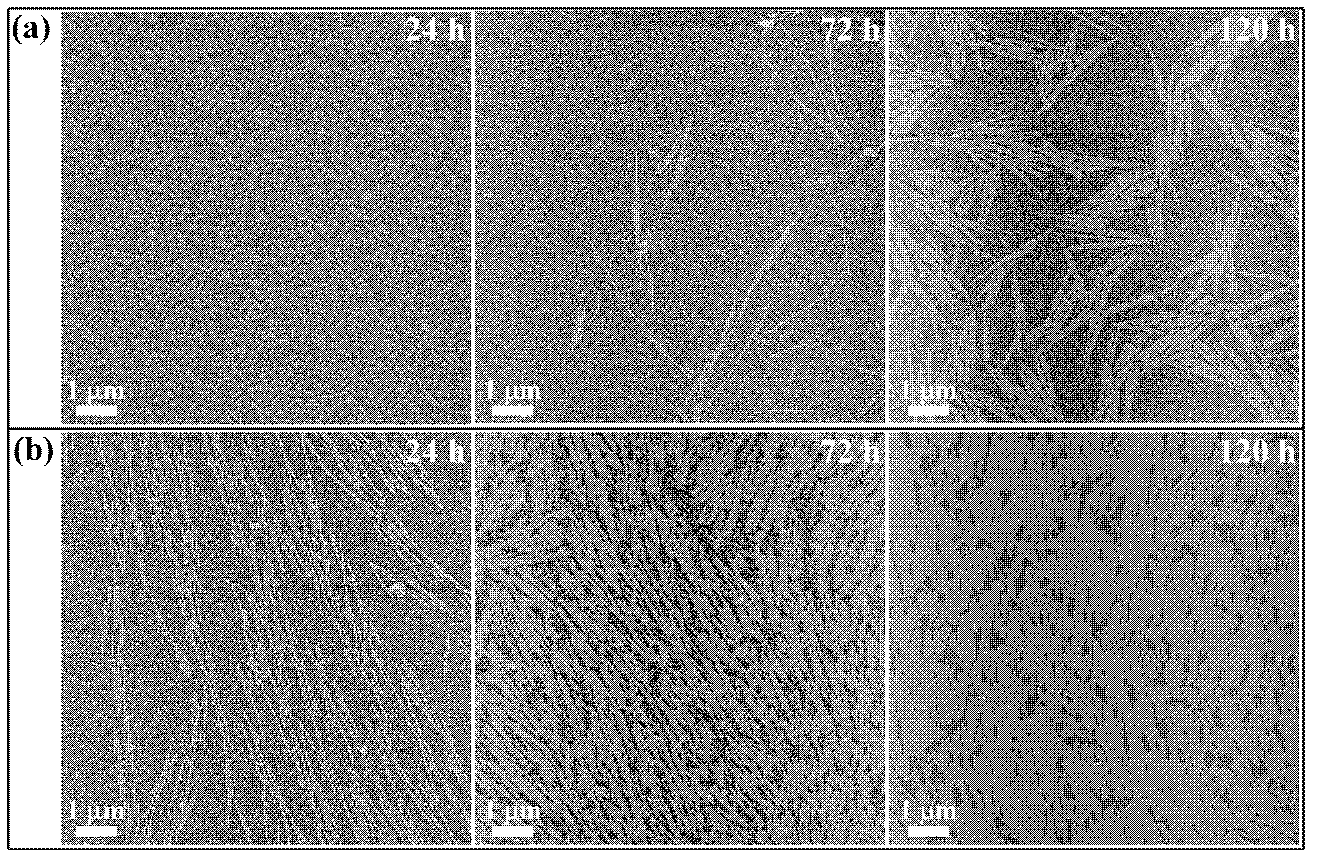

Method for preparing membrane materials through biomolecular self assembly under the condition of cold plasma

InactiveCN102671850AQuick assemblyEnhanced interactionLiquid surface applicatorsNanomedicineAlternating currentHigh pressure

The invention relates to a method for preparing membrane materials through biomolecular self assembly under the condition of cold plasma, which comprises the following steps of: dissolving biomolecules in triple distilled water to prepare a solution with the concentration of 20-200 mol / L; directly putting the biomolecular solution into a plasma discharger; vacuumizing the plasma discharger, and then leading plasma discharge gas with the pressure of 50-200 Pa; utilizing a high-voltage power supply to apply 100-3000 V direct current or alternating current to both ends of an electrode to make the discharge gas discharge and form plasma with the processing time of 1-15 minutes; and putting the solution into a shaking table at a constant temperature to be cultured for 5-240 hours after the plasma is processed. According to the method, cold plasma is integrated into the process of the biomolecular self assembly, and products of the biomolecular self assembly are changed from nanofibers, nanorods, nanotubes or nanoparticles into biological membranes. The method has the advantages of easiness and convenience for operation, less time consumption, high efficiency, low energy consumption and friendliness to environment.

Owner:TIANJIN UNIV

Formation of microstructured fiber preforms using porous glass deposition

InactiveCN102050569AAvoid breakingInhibit swellingGlass making apparatusGlass fibre productsMicrostructure fiberMaterials science

A method of making a microstructured optical fiber preform uses the plasma fusion of a powder layer deposited onto a substrate under conditions that prevent the deposited layer from completely densifying, thereby yielding the formation of bubbles within the layer. By systematic control of powder melt and delivery, while maintaining the process temperature below a temperature associated with densifying the deposited layer, the powder particles densify only partially on the substrate and create bubbles of a fairly narrow (and thus controllable) diameter range within a defined region of the preform. Upon drawing a fiber from the preform, the bubbles will extend into gas lines, forming a desired microstructure arrangement.

Owner:OFS FITEL LLC

Sludge splitting decomposition treatment method

ActiveCN110695057AAccelerate heat evaporationIncrease the degree of lysisSolid waste disposalTransportation and packagingHeating oilSyngas

The invention discloses a sludge splitting decomposition treatment method, and relates to the technical field of solid waste harmful treatment. The sludge splitting decomposition treatment method comprises the steps that sludge is thrown into a feeding pretreatment device, when the feeding pretreatment device conveys materials, sludge is heated, water and light components in the sludge are heated,evaporated and subjected to splitting decomposition, and heavy oil residues are obtained; the feeding pretreatment device outputs the heavy oil residues to a high-temperature plasma fusion device from a discharging port of the feeding pretreatment device; and the high-temperature plasma fusion device conducts high-temperature plasma torch fusion on the input heavy oil residues, and glass body waste slag and synthesis gas containing CO2, CO and H2 are generated through conversion. The sludge splitting decomposition treatment method has the advantage that the harmless treatment degree is high.

Owner:航天环保(北京)有限公司

Magnetized plasma fusion ignition device and its local rapid accelerated heating and ignition method

ActiveCN106981317BReach fusion ignition conditionsIncreased temperature densityNuclear energy generationThermonuclear fusion reactorMagnetizationParticle loss

The invention provides a magnetized plasma fusion ignition device and a local fast acceleration heating ignition method thereof. The magnetized plasma fusion ignition device comprises a formation system for generating reversed-field configuration plasma, a multistage acceleration system for accelerating the reversed-field configuration plasma, and a compression injection system for enabling the reversed-field configuration plasma to satisfy a local fusion ignition condition. The plasma generated according to the present invention has a strong magnetization characteristic, increases energy deposition, and reduces particle losses, and the special magnetic field structure of the plasma contributes to the restraint and stability of the plasma itself and satisfies the ignition requirement of the fusion plasma.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Cold plasma fusion technology waste treatment system and method

InactiveCN107377585BWon't happenEfficient recyclingWaste processingCarbon compoundsSewageWaste treatment

The invention discloses a garbage treatment system of cold plasma fusion technology, comprising: a cold plasma fusion device, a garbage treatment reaction chamber, an air-cooled heat exchange system, an antiparticle generator, a dryer, a gas turbine generator and a temperature-controlled Cold plasma decomposer. The invention also discloses a garbage treatment method using cold plasma fusion reactor technology. The invention provides the waste treatment system of the cold plasma fusion technology, which is a combined and three-dimensional configuration. In addition to solving the shortcomings of traditional waste treatment such as composting, incineration, and landfilling, it also solves the overall problem of the current arc gasification waste. The quantity is small and the practical application is limited. Compared with other methods, the daily treatment capacity of urban and rural garbage and sewage is greatly improved.

Owner:广州仁廙环保技术有限公司

An advanced fusion-fission subcritical energy reactor core

ActiveCN103578579BProliferation effect is goodImprove securityFuel elementsNuclear energy generationRadiation resistantNuclear power

The invention belongs to a nuclear power design technique, and particularly relates to a loading scheme of an advanced fusion-fission subcritical energy reactor core. The reactor core structure comprises a plurality of fuel assembly modules which are arranged in a hoop along an annular plasma fusion area, wherein each fuel assembly module comprises a plurality of fuel assemblies arranged in a polar direction of the plasma fusion area; a first heat-resistant and radiation-resistant wall is arranged at one side of each fuel assembly towards the plasma fusion area; a tritium-producing coating is arranged at the other side of each fuel assembly opposite to each first wall; an outer shielding layer is arranged outside each tritium-producing coating. By adopting the advanced fusion-fission subcritical energy reactor core, the design requirements of the energy magnification factor and the tritium breeding ratio can be simultaneously met; the continuous growth of the magnification factor and the tritium breeding ratio can be maintained within a long period of time; the breeding performance of the reactor core is good.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Preparation method of coating for repairing surface of diesel engine cylinder cover

InactiveCN108866540AImprove thermal fatigue resistanceTightly boundMetallic material coating processesPowder mixtureCerium

The invention provides a preparation method of a coating for repairing the surface of a diesel engine cylinder cover. The method comprises the step that the surface of a substrate is covered with a powder mixture through fusion, so that the nickel-based composite coating is obtained. The powder mixture comprises nickel-chromium-boron-silicon powder, molybdenum powder and cerium dioxide powder. Thenickel-based composite coating is excellent in thermal fatigue resistance and can be applied to preparation and repair of workpieces conveniently. Furthermore, compared with existing composite coatings, the coating is preferentially prepared through plasma fusion covering; the coating is generally applied to the gray pig iron gray pig iron; nickel-based alloy can be tightly bonded to the substrate, in addition, the void ratio is low, and bonding performance is extremely good; and grinding and polishing can be conducted easily to achieve the quite low surface roughness, and it is especially important that the thermal fatigue resistance is more excellent.

Owner:如皋市欧马机械制造有限公司

A kind of plasma cladding direct manufacturing 3D printing equipment and method

ActiveCN105922566BSimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlDistance detection

The invention discloses plasma fusion covering direct manufacture 3D printing equipment and a method. The equipment comprises a monitoring system, a plasma beam processing system, and a horizontal printing table. The plasma beam processing system includes a plurality of plasma beam processing devices; each plasma beam processing device comprises a plasma generator, a printing position adjustment controller, a gas supply device and a powder sending device. The monitoring system includes a plurality of beam processing supervising devices; each beam processing supervising device comprises a temperature detection unit, a horizontal movement controller, a distance detection unit and a printing distance adjustment controller. The temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: 1, acquisition of a 3D model of a workpiece to be printed, and hierarchical slicing processing; 2, scanning path filling; 3, printing path acquisition; and 4, printing layer by layer from top to bottom. The invention has the advantages of reasonable design, simple operation, high molding efficiency, good usage effect, and no need of enclosed moulding chamber, protection atmosphere, or vacuum environment.

Owner:中研碧诚(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com