Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Increase the degree of lysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel function flame-proof fibre and preparation method thereof

InactiveCN1920128AReduce surface temperatureDifficult to form diffusionFlame-proof filament manufactureMelt spinning methodsFiberCellulose

The invention relates to a functional frame-proof fiber and relative preparation, wherein it is characterized in that: it also comprises nanometer additive powder with tourmaline and tourmaline; and its components comprises cellulose at 75-95%; said nanometer additive powder at 5-25%; and its preparation comprises: preparing the tourmaline and tourmaline into nanometer additive powder; mixing the powder with cellulose with different ratios, via static mixer; using fusion mixing method to prepare the spinning liquid. The inventive fiber has lower cost and controllable parameter.

Owner:太原伦嘉生物科技股份有限公司

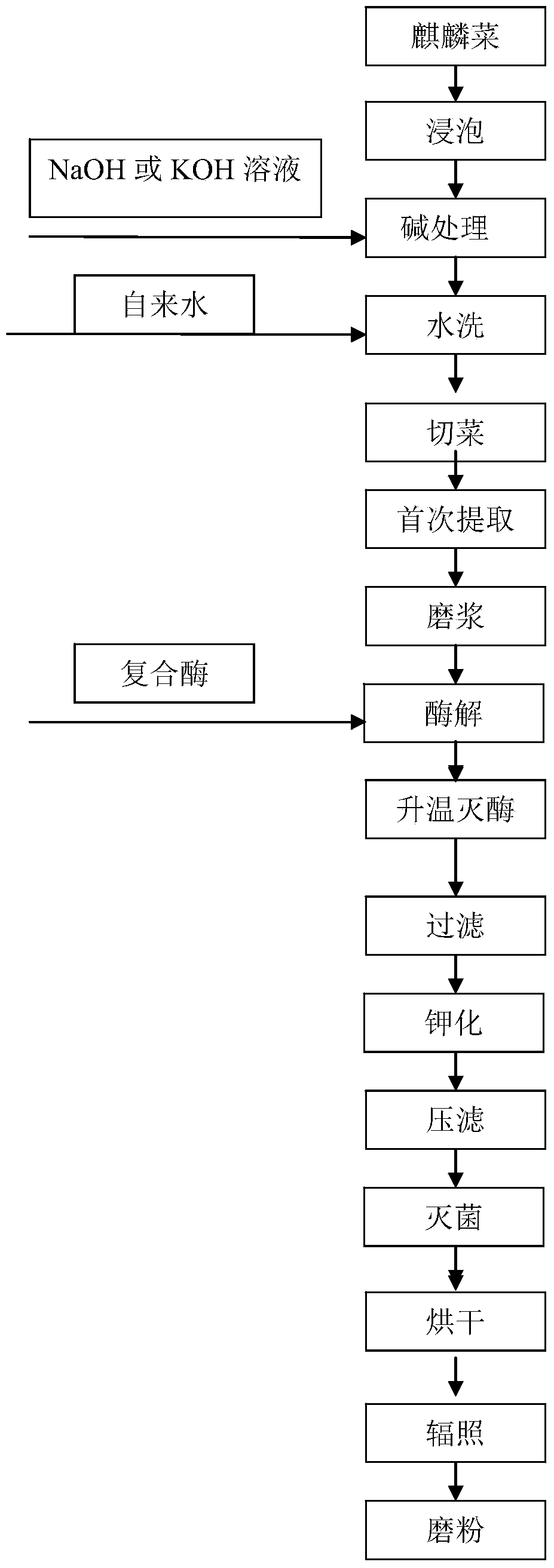

Preparation method of carrageenan oligosaccharides

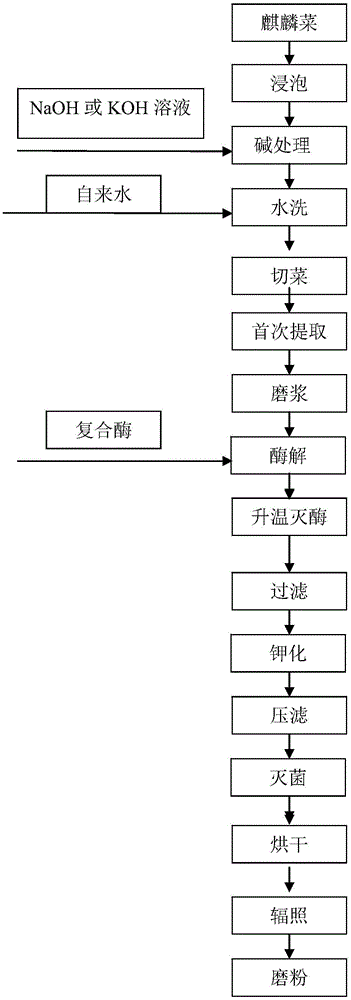

The invention relates to a preparation method of carrageenan oligosaccharides. The preparation method sequentially comprises a raw material pretreatment process step, an extraction process step, an enzymolysis process step, a potassium chloride dissolution process step, a potassic alteration and dehydration process step, a squeezing process step, a sterilization process step, a crushing process step and a material mixing and re-sterilization process step, wherein an irradiation and degradation process step is further contained between the crushing process step and the material mixing and re-sterilization process step, and the irradiation and degradation process step is as follows: a semi-finished product obtained in the crushing process step is simply bagged and packaged, and then irradiated by an electronic accelerator with 10MeV and beam power of 500-650kW for 10-20h. A complex enzyme adopted by the invention has stronger destructive power against cellulose and high degree of carrageenan cracking, and can reduce the using quantity of steam and chemical raw materials in the production process of products and realize energy conservation, consumption reduction and clean production under the situation of ensuring the yield of the products. According to the preparation method provided by the invention, the irradiation method is adopted for degrading large molecular carrageenan into small molecular carrageenan, the addition of any impurities or harmful substances is avoided, and the degradation is fast and pollution-free.

Owner:青岛聚大洋藻业集团有限公司

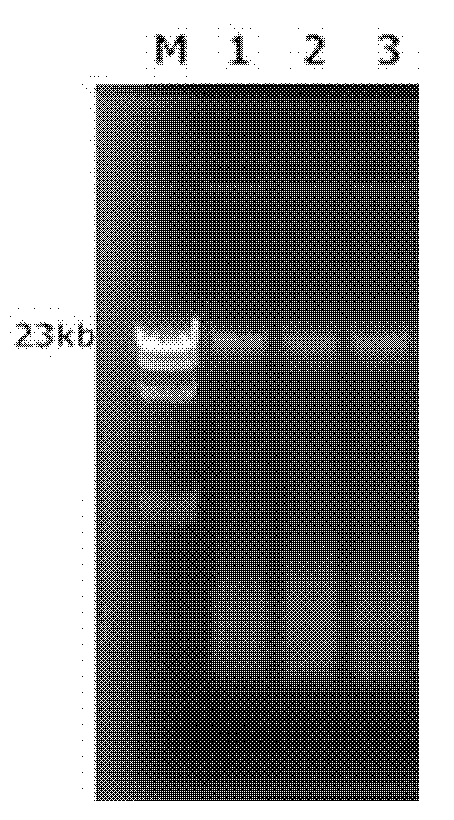

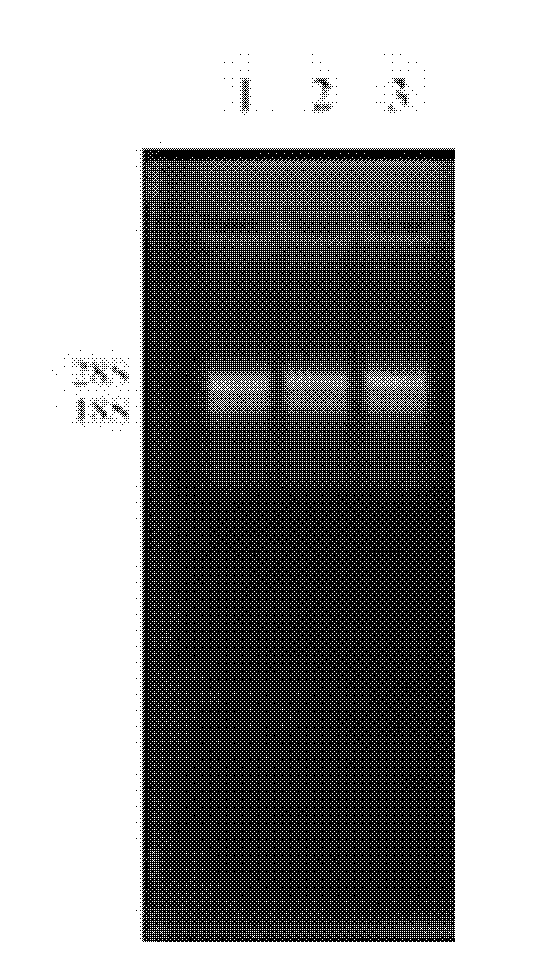

Method for simultaneously extracting total DNA and RNA from compost

InactiveCN101845436AIncrease the degree of lysisIncrease productionDNA preparationSodium acetateChloroform

The invention discloses a method for simultaneously extracting total DNA and RNA from compost, which comprises the following steps of: adding corrosion removal buffer solution into a compost sample, shaking and uniformly mixing the solution and the compost, standing the mixture, and centrifuging the suspension; repeating the operation till the centrifuged supernatant is clarified; grinding the sample after corrosion removal by using liquid nitrogen till the sample is powdery, then placing the powdery sample in cracking solution, shaking and uniformly mixing the sample and the solution, putting the mixture in an ice bath, and centrifuging the mixture; taking the cracked supernatant, adding sodium acetate and extraction buffer solution into the supernatant, and centrifuging the mixture after shaking; adding chloroform-isoamylol into the extracted upper aqueous phase, and centrifuging the mixture after shaking; adding isopropanol into the mixture to settle RNA, and washing, drying and dissolving the settled RNA to obtain purified RNA; and adding Tris alkali solution into the extracted organic phase, adding chloroform-isoamylol into the centrifuged upper aqueous phase, centrifuging the mixture, then adding sodium acetate and anhydrous ethanol into the mixture to settle DNA, and washing and dissolving the mixture to obtain purified DNA. The method has the advantages of large yield, good quality, low cost and the like.

Owner:HUNAN UNIV

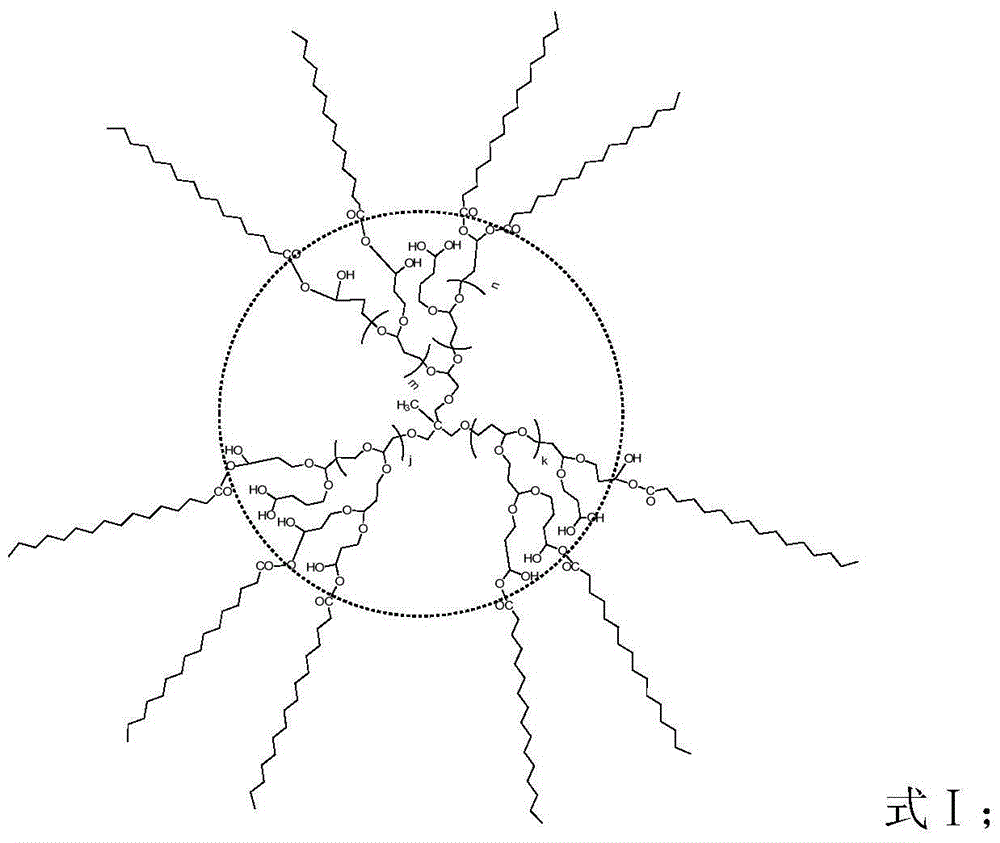

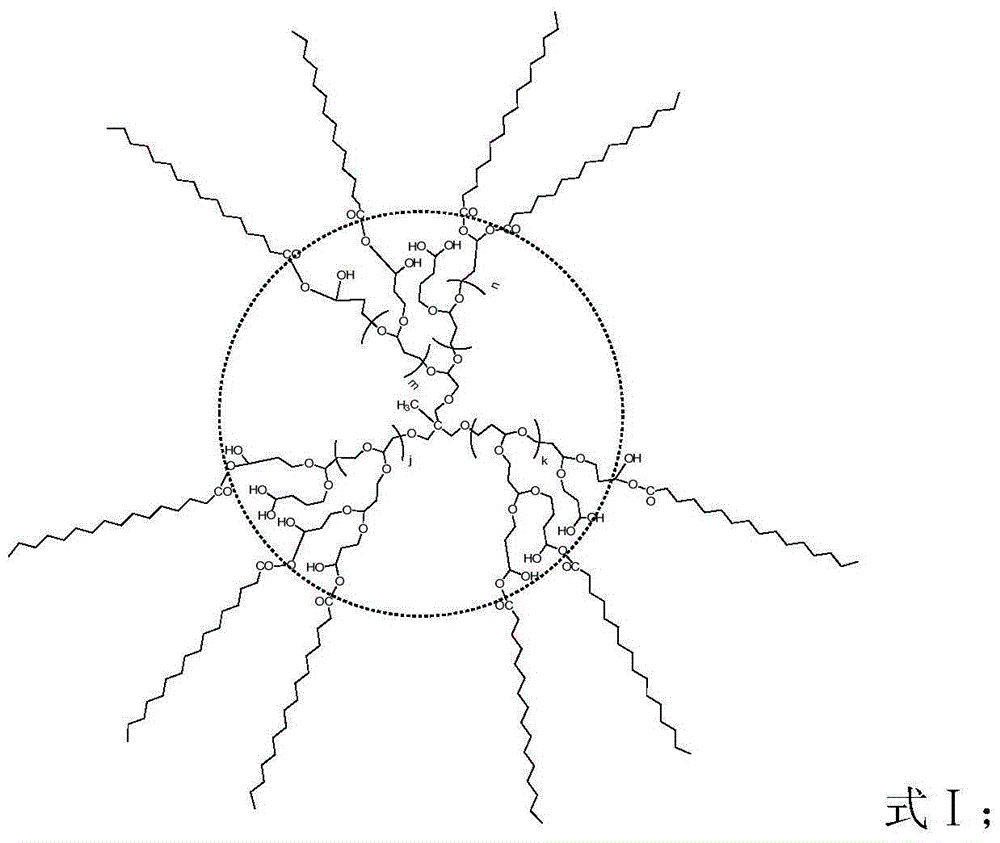

Hydrocarbon fuel composition with high heat sink

InactiveCN104059697AIncrease the degree of lysisImprove heat sinkLiquid carbonaceous fuelsHeat sinkHyperbranched polyglycerol

The invention discloses a hydrocarbon fuel composition with high heat sink. The hydrocarbon fuel is composed of the following raw materials in weight percentage: 100% of a hydrocarbon fuel and 0.01%-5% of HPG-C16. The invention discloses a novel hydrocarbon fuel composition, HPG-C16 (cetyl grafted hyperbranched polyglycerol) is used as an initiator to promote the cracking degree of hydrocarbon fuel, enhance heat sink of the hydrocarbon fuel, improve the heat absorption capacity of the hydrocarbon fuel, and proposes a novel development direction for the application of HPG-C16.

Owner:ZHEJIANG UNIV

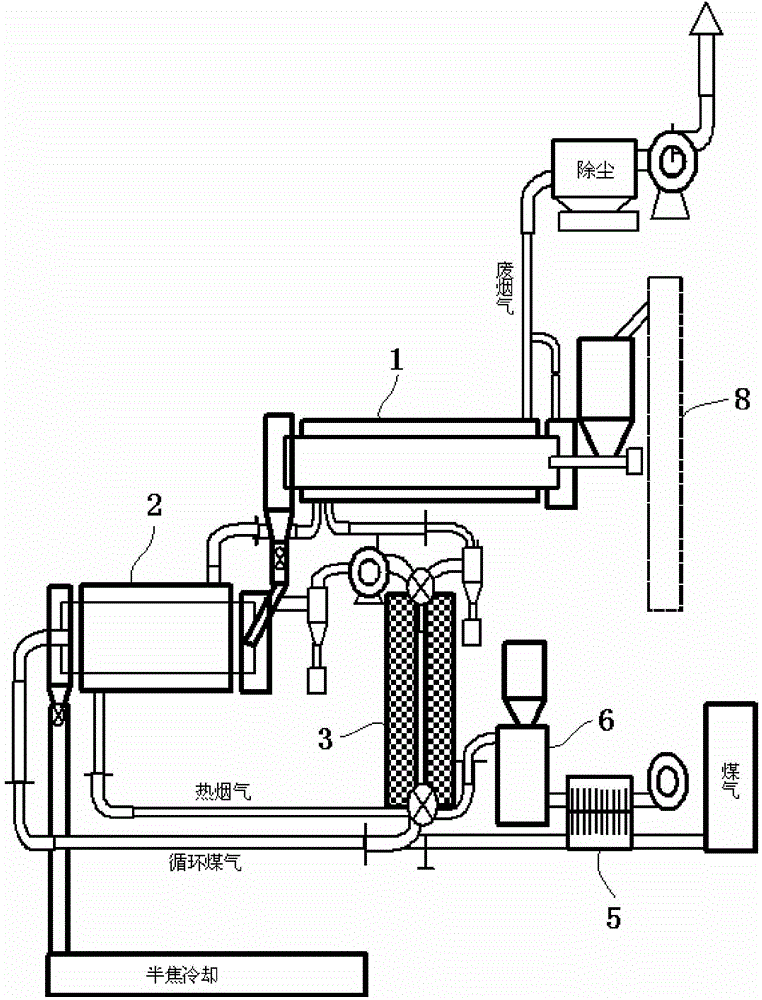

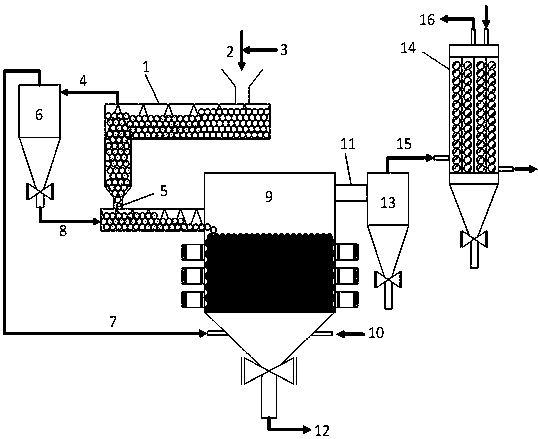

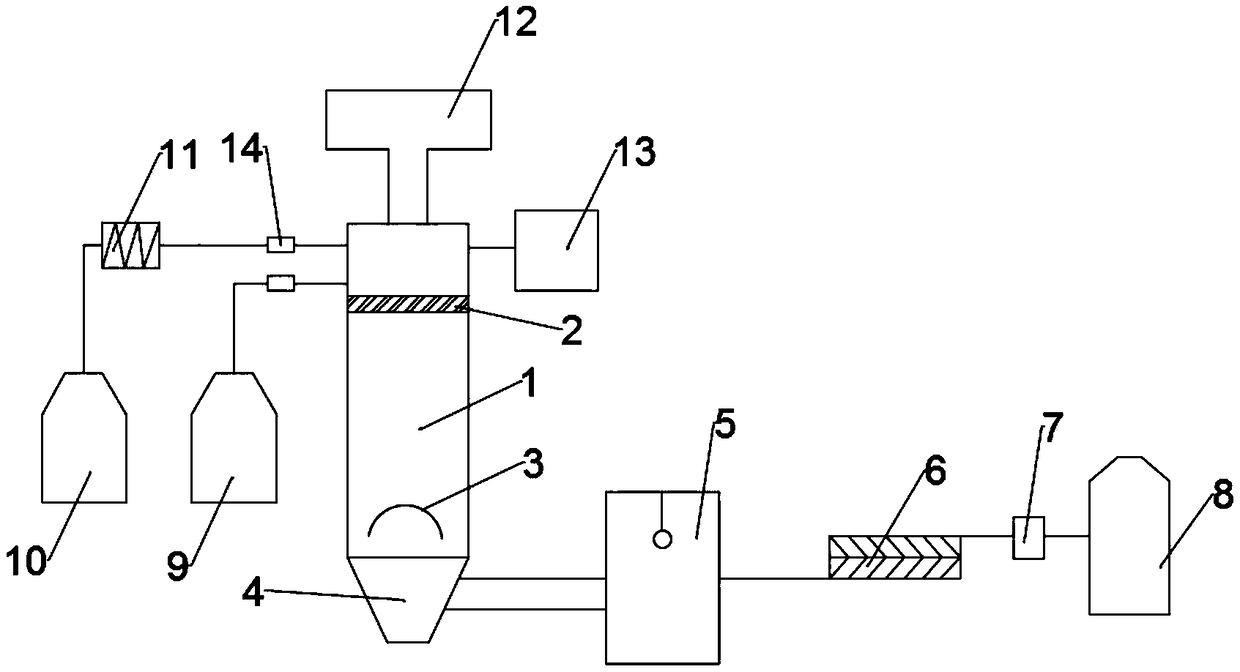

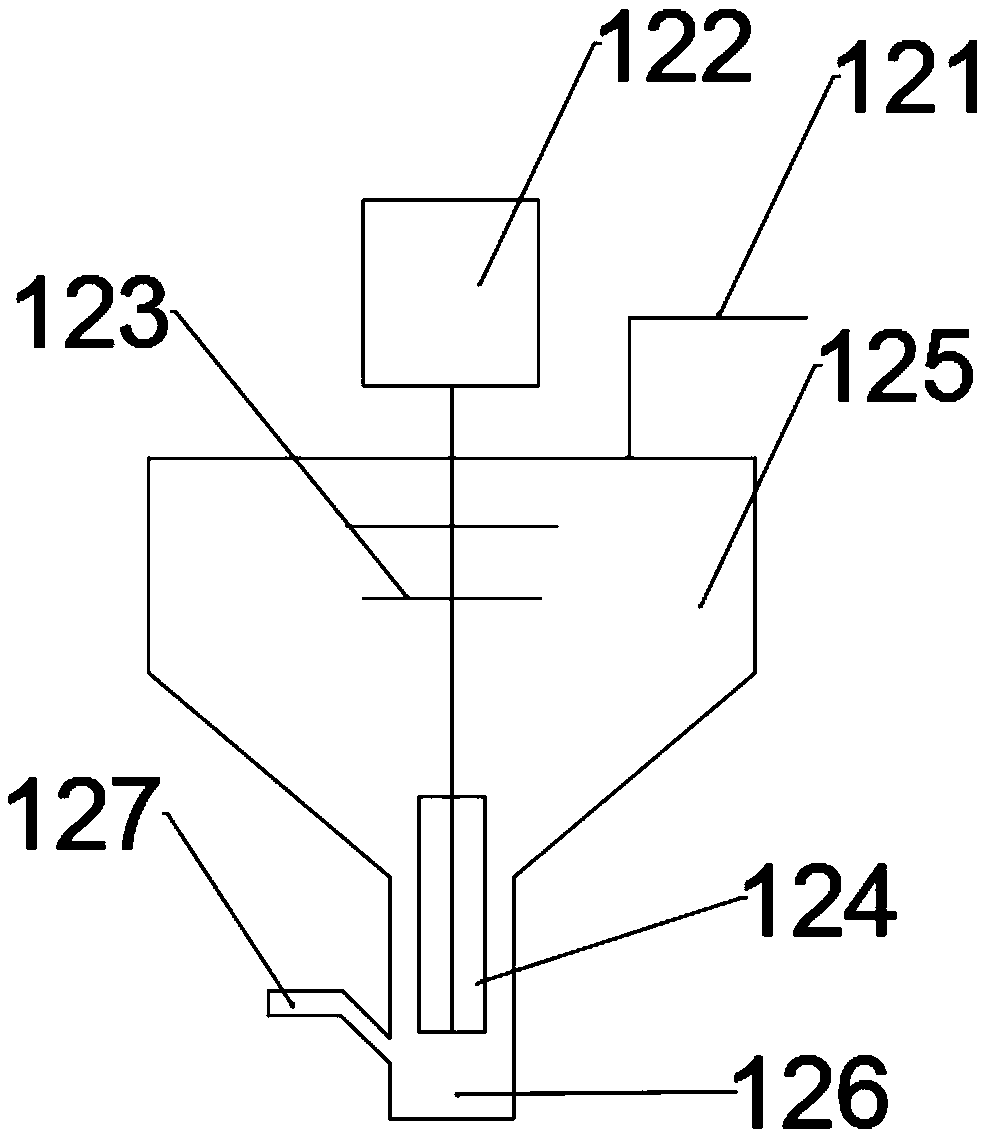

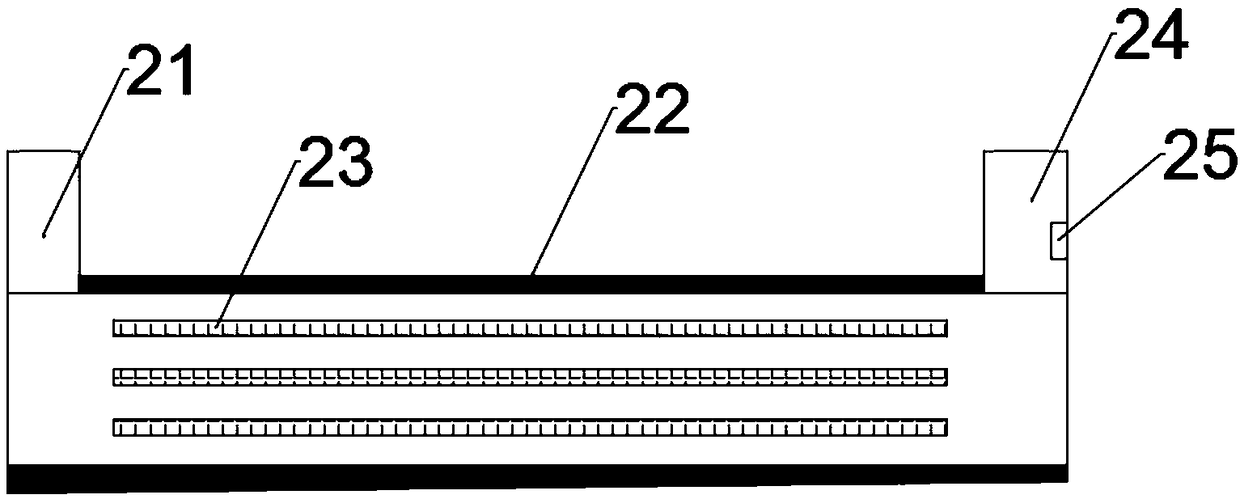

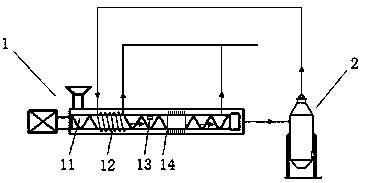

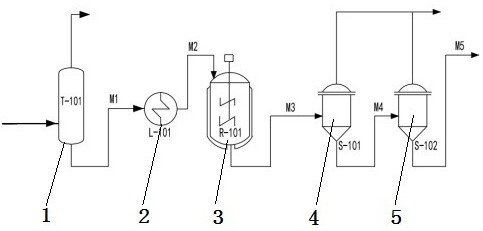

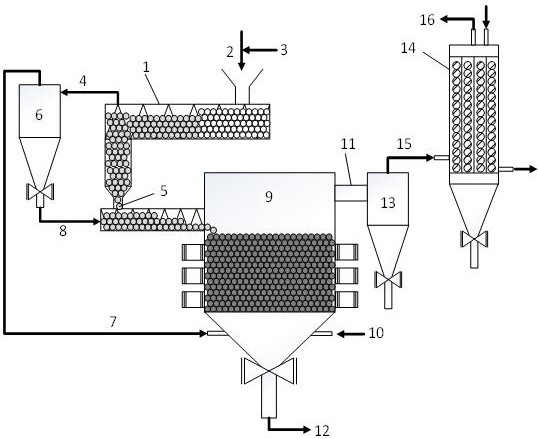

Method and device for producing coal gas by pulverized coal pyrolysis

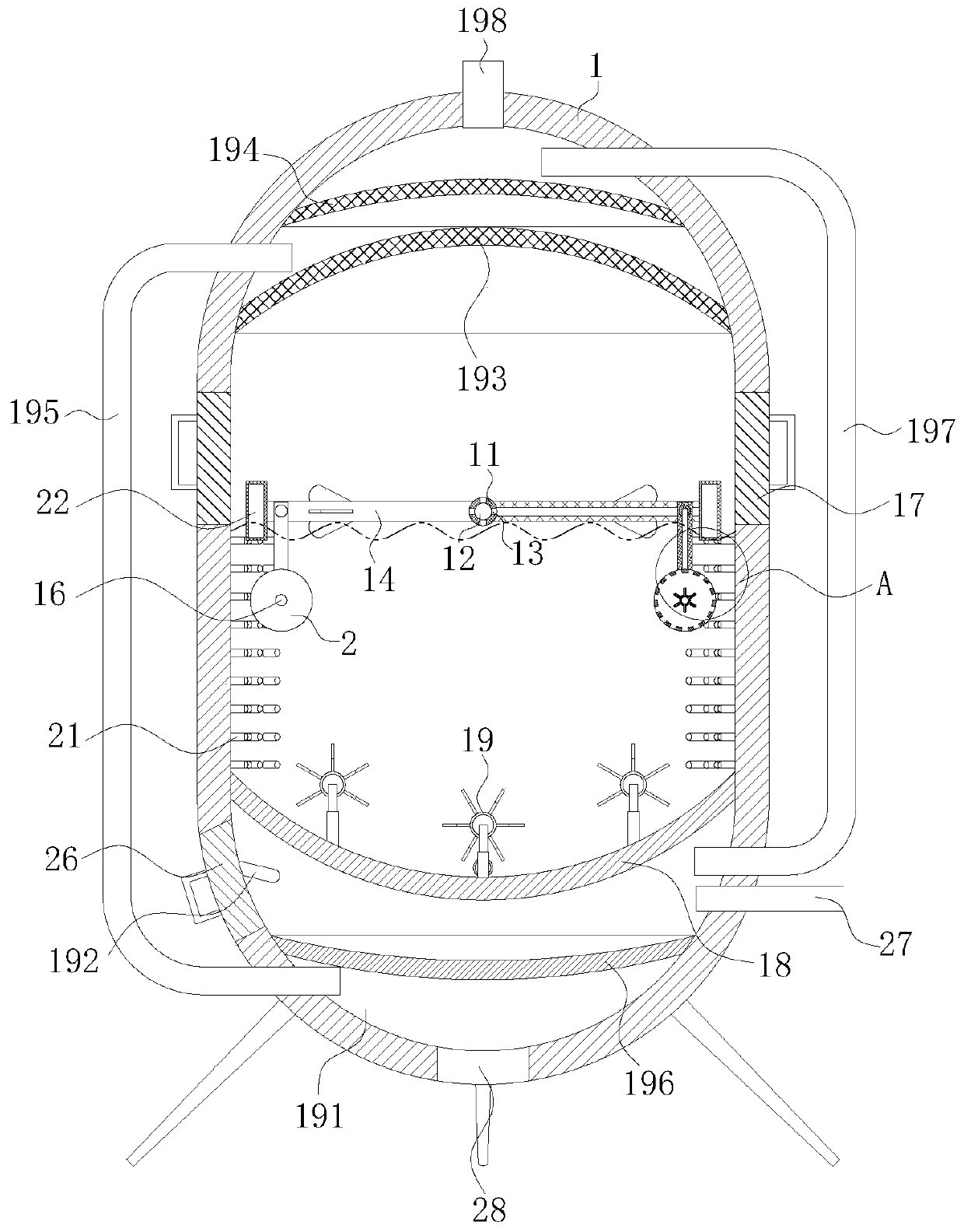

InactiveCN103980951APlay a filtering roleEasy to transportIndirect and direct heating destructive distillationGas purification by catalytic conversionWater vaporProcess engineering

The invention relates to a method and device for producing a coal gas by pulverized coal pyrolysis. The coal gas production method disclosed by the invention comprises the following step: with an unpurified raw gas which is obtained from raw coal by dry distillation pyrolysis as a raw material, producing the high-quality coal gas inside a regenerative chamber in a pyrolysis manner. The device disclosed by the invention comprises a raw coal drying oven, a dry distillation furnace, a regenerative chamber for pyrolyzing the raw gas, and a hot blast heater for supplying heat. The raw gas is pyrolyzed to produce the coal gas, water vapor in the raw gas reacts with coke powder to produce a water gas, and meanwhile tar is cracked into the coal gas, so as to serve multiple purposes. The method and device disclosed by the invention have the advantages of low energy consumption, low investment, high calorific value of the gas, low semicoke ash and low coal quality transformation cost.

Owner:CHANGAN UNIV

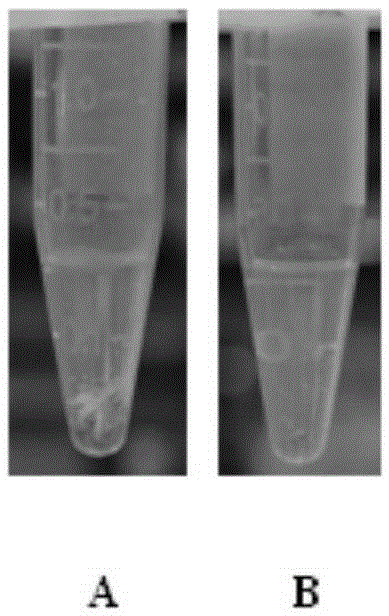

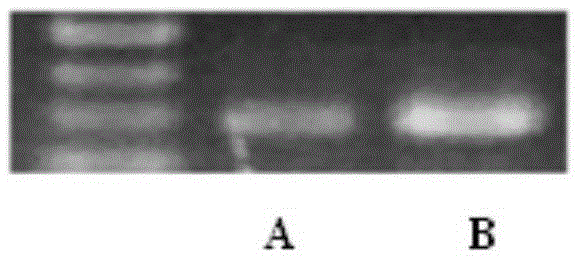

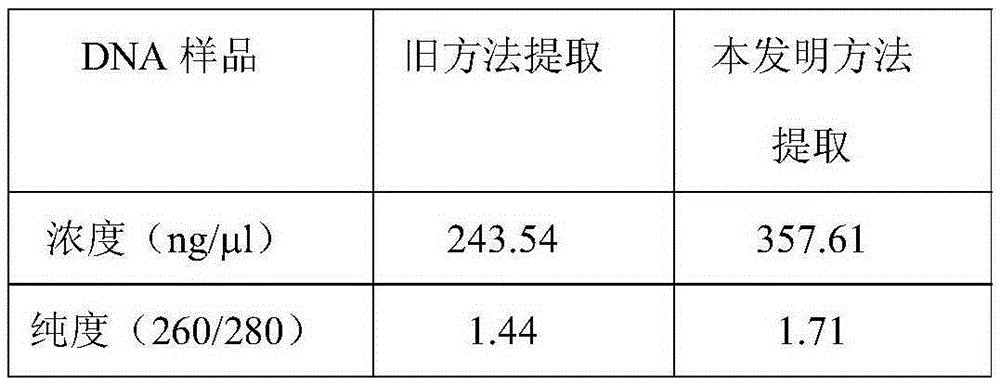

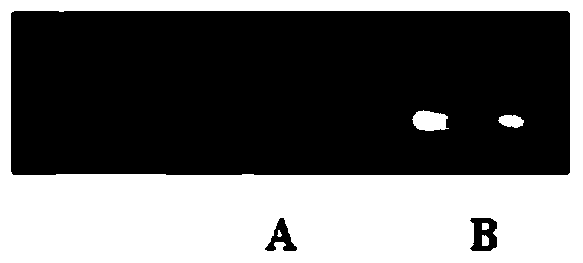

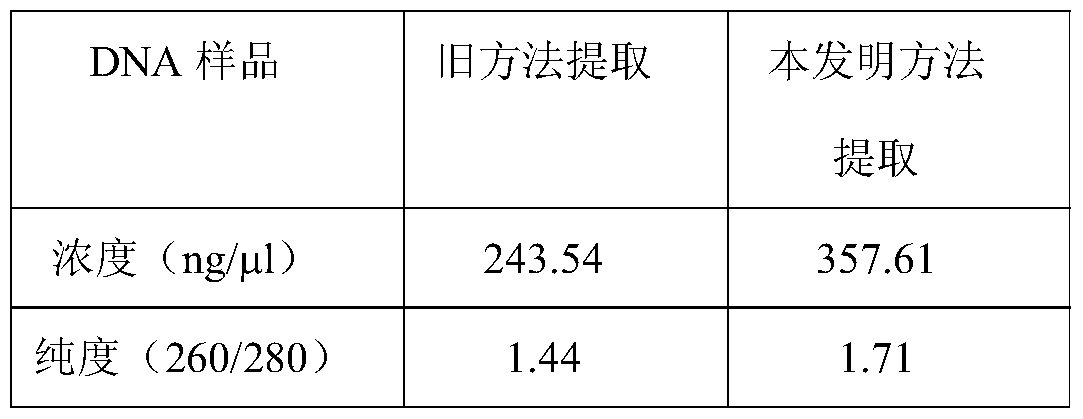

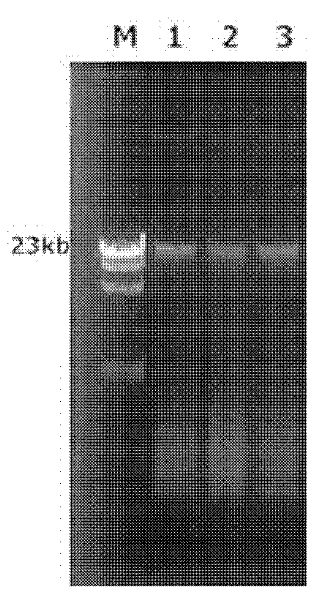

Lysis solution and method for extracting ancient biological bone DNA

ActiveCN105420229AImprove scalabilityIncrease the degree of lysisDNA preparationProtein solutionLysis

The invention discloses a lysis solution and method for extracting ancient biological bone DNA. The lysis solution is prepared from 10 mM of Tris-HCl with pH of 8.5, 10-15 mM of EDTA, 1.0-1.5 wt% of SDS, 150 mM of NaCl and 0.3-0.5 mg / ml of protease K. By means of improving the components of the SDS, the EDTA and the protease K respectively, the lysis degree of the lysis solution on bone tissue can be obviously improved. Meanwhile, when the lysis solution is used, by means of protein solution removing, DNA wash liquid treatment and a DNA centrifugal column method, impurity composition in DNA samples can be obviously reduced, the improvement of PCR amplification effect is facilitated, and therefore high-purity ancient biological bone DNA can be obtained conveniently.

Owner:CENT SOUTH UNIV

Pyrolysis processing method for red mud

ActiveCN110695055AImprove primary heat evaporationIncrease the degree of lysisTransportation and packagingSolid waste disposalRed mudPre treatment

The invention discloses a pyrolysis processing method for red mud, and relates to the technical field of harmless treatment of solid waste. The method comprises the following steps of: adding red mudinto a fed material pretreatment device, dividing the red mud into two and more than two parts, independently inputting the red mud into two and more than two cylinders, heating the red mud to enablethe red mud to be evaporated and pyrolyzed while a screw propeller of the fed material pretreatment device conveys materials; outputting materials to a high-temperature plasma fusion device from the output of the fed material pretreatment device by the fed material pretreatment device; carrying out high-temperature plasma torch fusion on input materials by the high-temperature plasma fusion device; and conveying the input materials into glass body waste residues and synthesis gases containing CO2, CO and H2. The method has the advantage of high harmless treatment degree.

Owner:航天环保(北京)有限公司

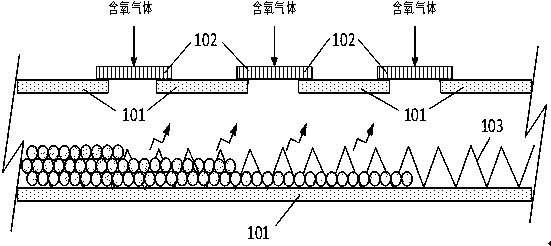

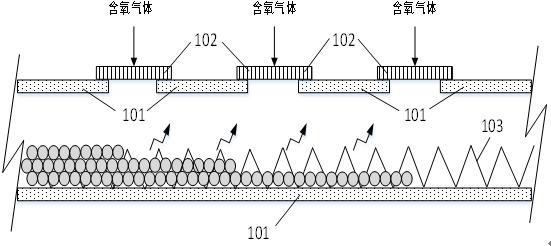

Oxygen-rich lost foam bubble garage kit

InactiveCN107175313AMake up for endothermic coolingIncrease the degree of lysisFoundry moulding apparatusOxygen enrichmentPyrolysis

The invention discloses an oxygen-enriched lost foam foam white mold, which belongs to the technical field of lost foam casting. In the foam structure of the foam white mold, the foam cavity gas is oxygen-enriched air or pure oxygen with an oxygen volume content of not less than 21%. Oxygen, the foam structure material includes EPS beads, EPMMA beads, STMMA beads and other commonly used expandable resin beads. The preparation method includes at least one of the oxygen-enriching method in the pre-foaming stage, the oxygen-enriching method in the drying and aging stage, and the oxygen-enriching method in the molding and foaming stage. On the one hand, the oxygen-enriched gas in the cavity can promote the combustion and gasification of carbon atoms in the white mold, and reduce the residual solid products produced by foam pyrolysis; The endothermic cooling of the white mold pyrolysis process; and more active oxygen atoms can promote the cracking degree and cracking speed of the white mold.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Auxiliary agent for biomass treatment and biomass gasification treatment method

ActiveCN111378513AReduce the degree of fractureInhibition formationGasification catalystsGasification processes detailsMANGANESE ACETATEManganese sulphate

The invention discloses an auxiliary agent for biomass treatment and a biomass gasification treatment method. The auxiliary agent comprises a component A, a component B and a component C, wherein thecomponent A comprises Lewis acid and one or more of optional organic acid and protonic acid, the component B is a salt of group IA, IIA and IIIA metals and ammonium, and the component C is one or moreof manganese acetate, manganese sulfate and manganese nitrate. The gasification treatment method comprises the following steps: mixing a biomass raw material and an auxiliary agent, and carrying outa reaction to obtain a volatile component and biological semicoke; performing a reaction on the solid-phase materials obtained after gas-solid separation of volatile components and the biological semicoke respectively in a biological coke microwave gasification reactor to obtain crude synthesis gas and activated carbon; and feeding the synthesis gas obtained after gas-solid separation of the crudesynthesis gas into a purification reactor to be treated, thus preparing purified synthesis gas. According to the biomass gasification treatment method and system, the yield of the synthesis gas can be increased, and the tar content in the obtained synthesis gas product is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

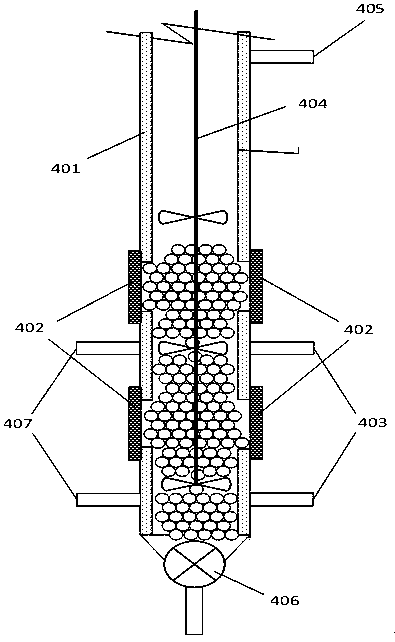

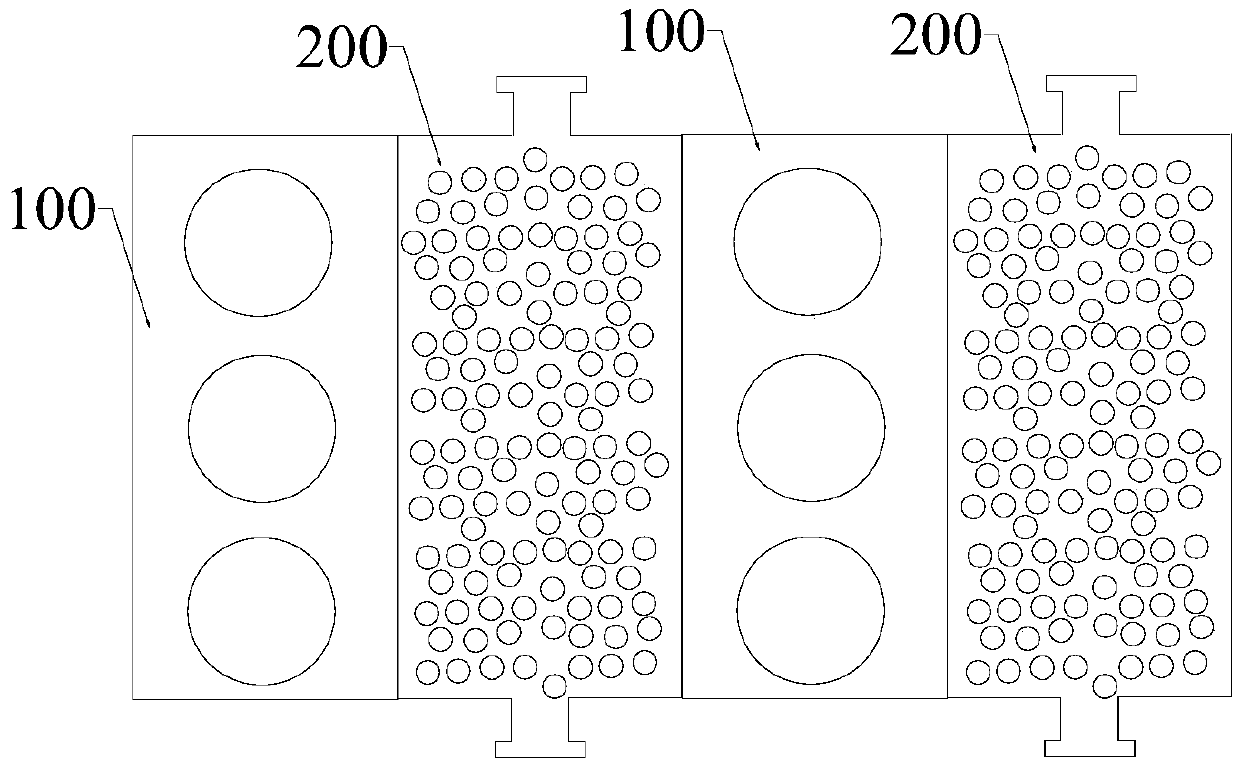

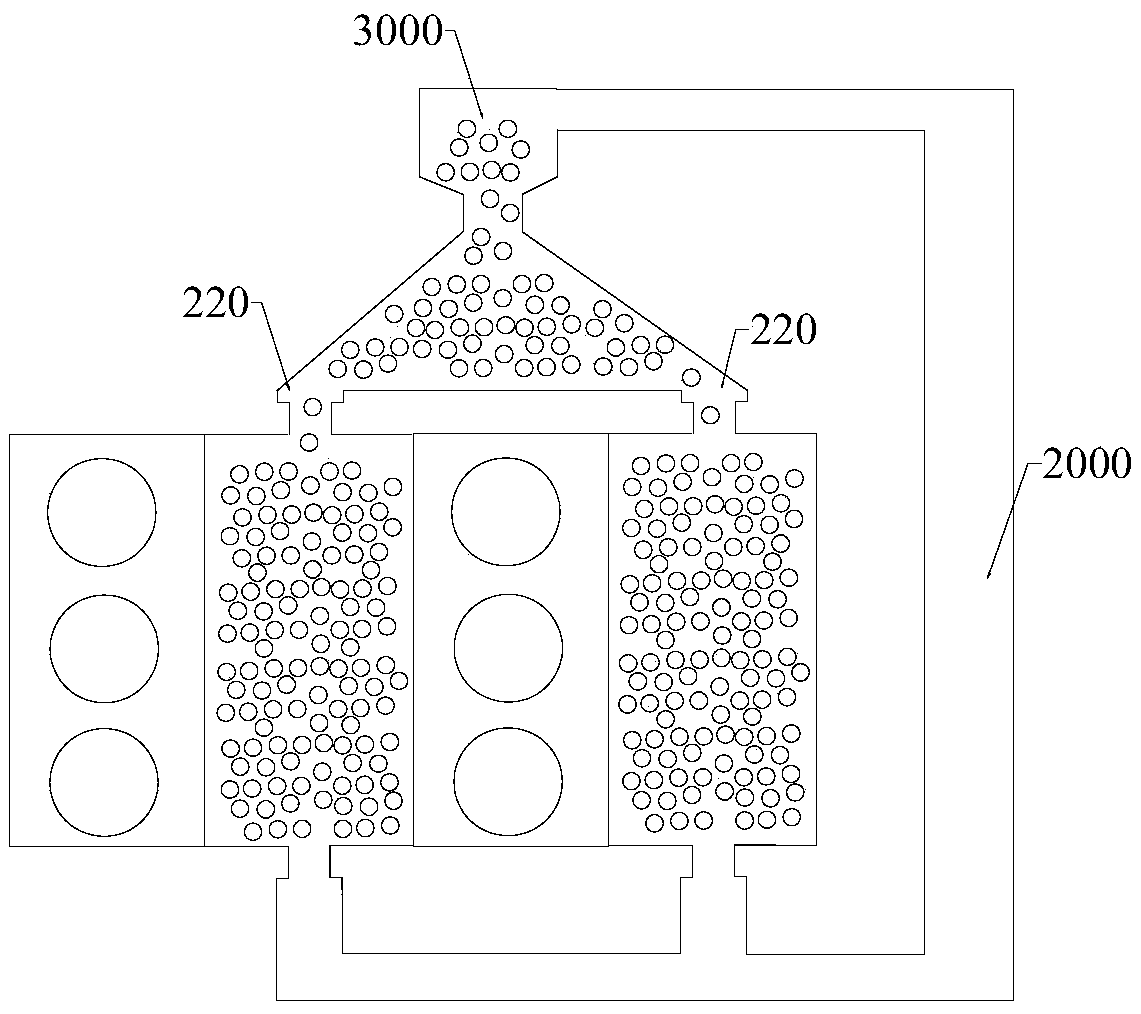

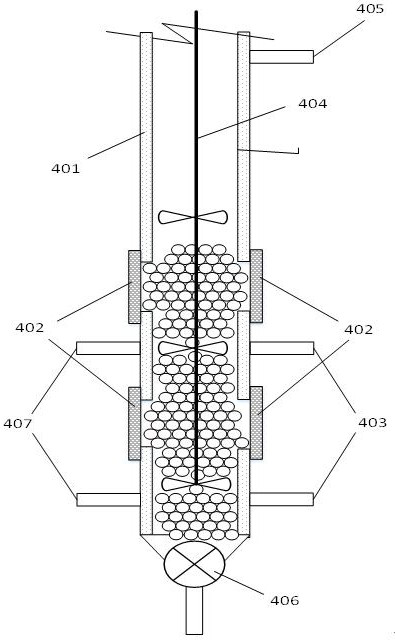

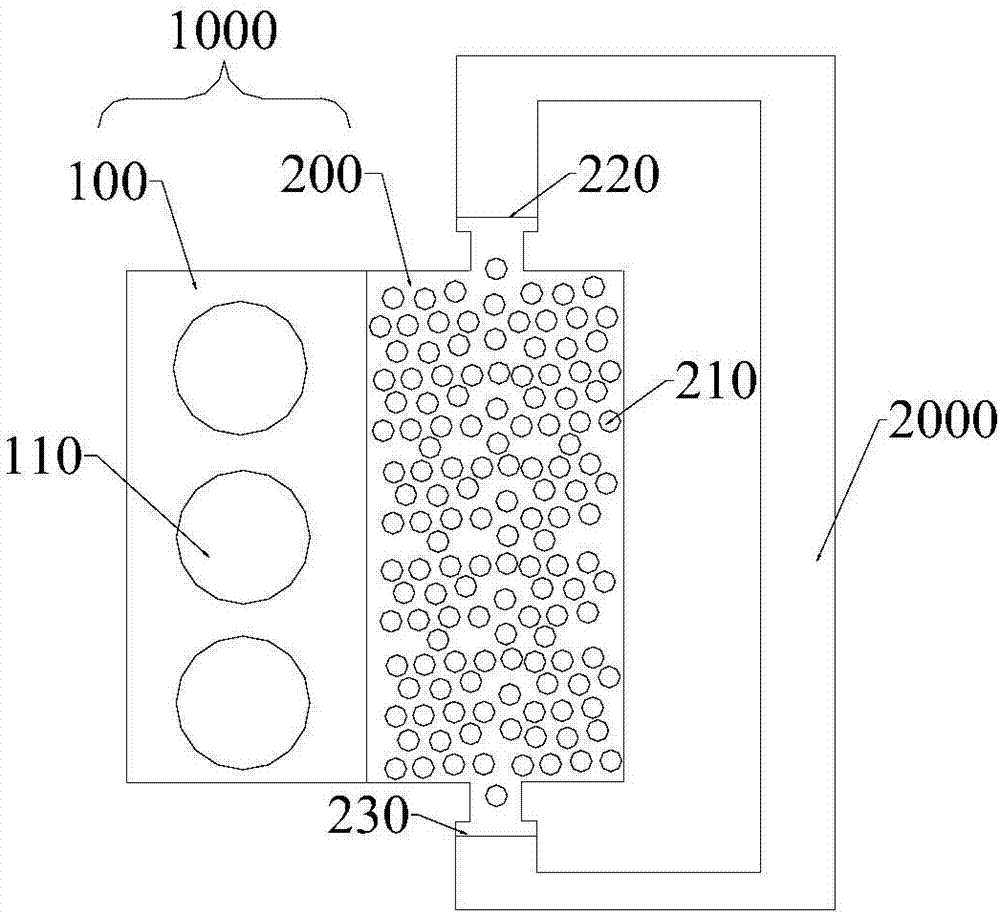

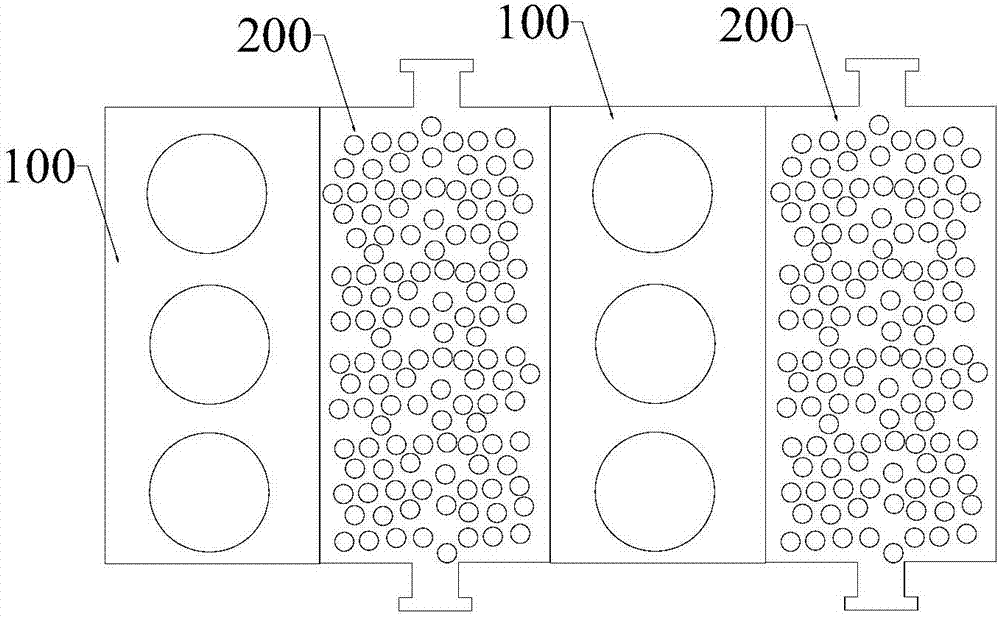

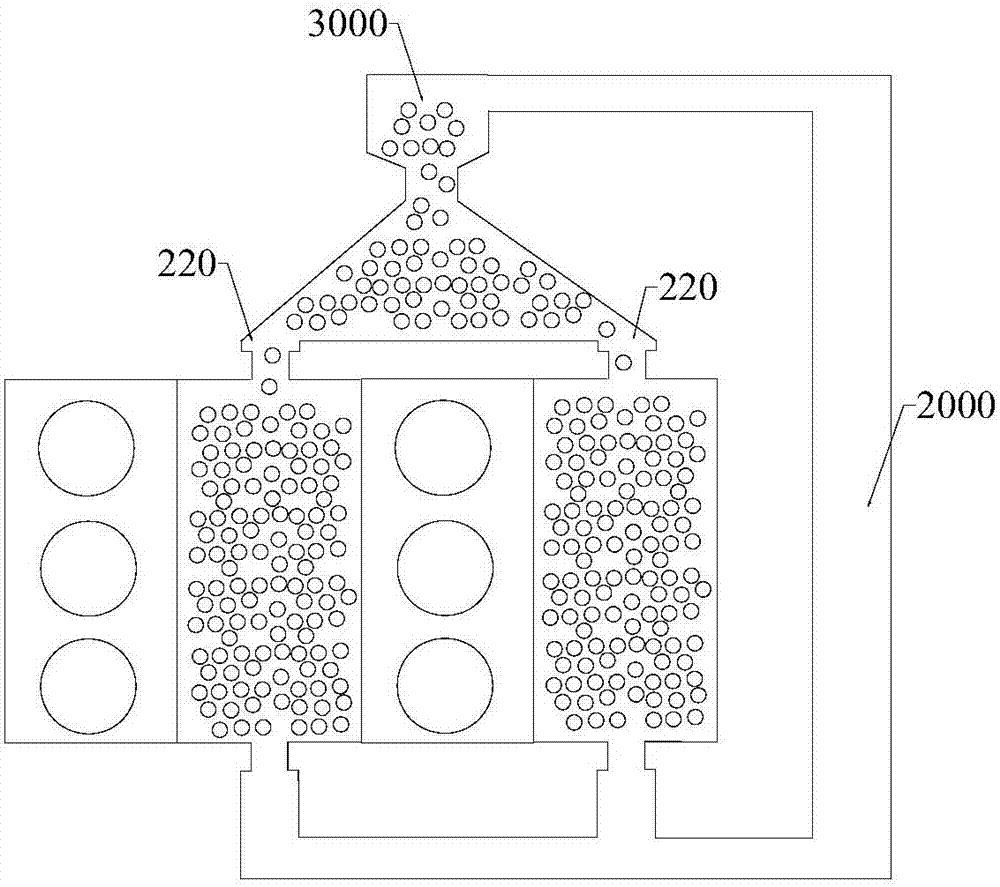

Tar cracking device and method

ActiveCN105505451AStable temperatureImprove cracking efficiencyTreatment with plural serial cracking stages onlyTarBiological activation

The invention provides a tar cracking device and method. The device comprises a cracker, radiant tubes, catalysts, catalyst feeding openings, catalyst discharging openings and catalyst activation pipelines, wherein the cracker is partitioned into thermal cracking chambers and catalytic cracking chambers by partition plates, and the partition plates are provided with through holes; the radiant tubes are arranged in the thermal cracking chambers; the catalysts are arranged in the catalytic cracking chambers; the catalyst feeding openings are formed in the tops of the catalytic cracking chambers; the catalyst discharging openings are formed in the bottoms of the catalytic cracking chambers; the catalyst activated pipelines are connected with the catalyst feeding openings and the catalyst discharging openings respectively. By means of the tar cracking device and method, tar cracking efficiency of the device is improved.

Owner:SHENWU TECH GRP CO LTD

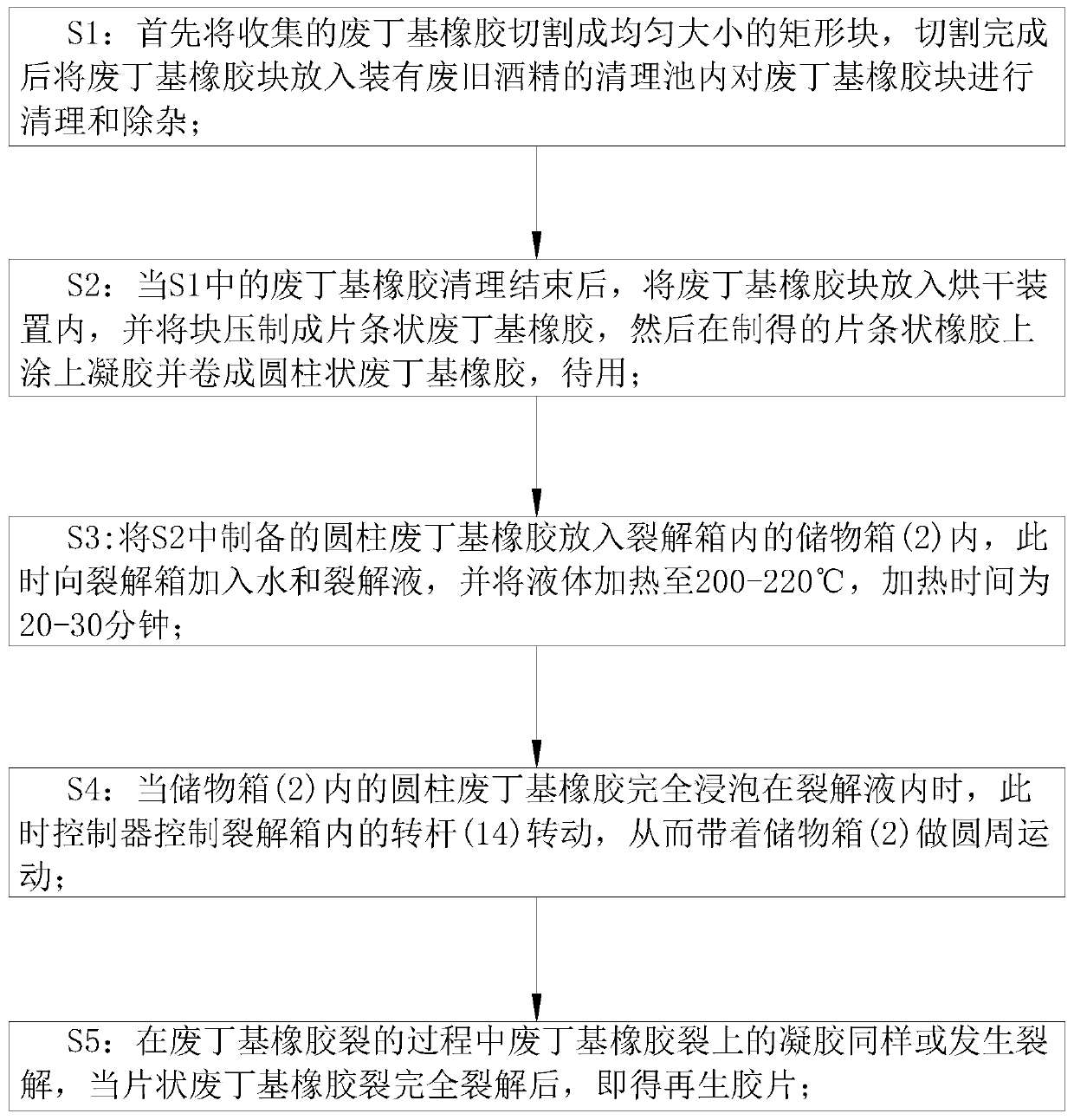

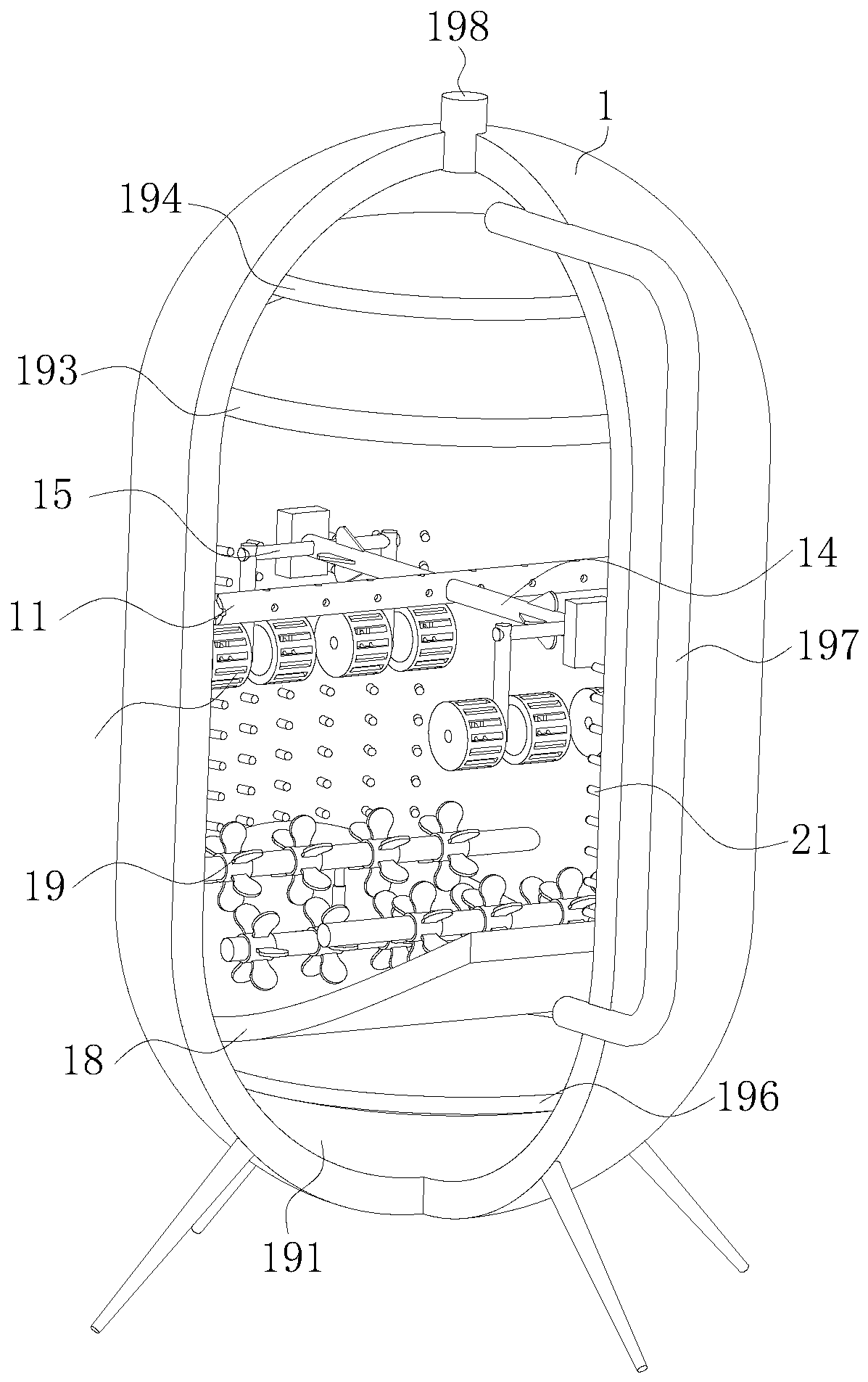

Cracking process of waste butyl rubber

InactiveCN111548530AAvoid accumulationDoesn't over crack the problemPlastic recyclingButyl rubberChemistry

The invention belongs to the technical field of cracking of waste butyl rubber, and particularly relates to a cracking process of waste butyl rubber. The cracking box comprises a box body; wherein a driving rod is rotationally connected into the inner wall of the box body through a motor; a circular groove is formed in the inner wall of the driving rod, and first through holes are uniformly formedin the inner wall of the circular groove; the outer surface of the driving rod is fixedly connected with rotating rods which are uniformly arranged, and the two rotating rods correspond to each other; the outer surface of each rotating rod is fixedly connected with a dorsal fin. According to the invention, the method is mainly used for solving the problems that during the pyrolysis process of waste butyl rubber in the prior art, the waste butyl rubber is usually directly put into a lysis solution, which may cause accumulation of the waste butyl rubber in the lysis solution, the cracking liquid can also precipitate and accumulate, so that the problems of partial excessive cracking and partial incomplete cracking of the waste butyl rubber are caused, and meanwhile, excessive cracking of thewaste butyl rubber can generate a large amount of harmful gas, so that the atmosphere and a water source can be polluted are solved.

Owner:陈一帆

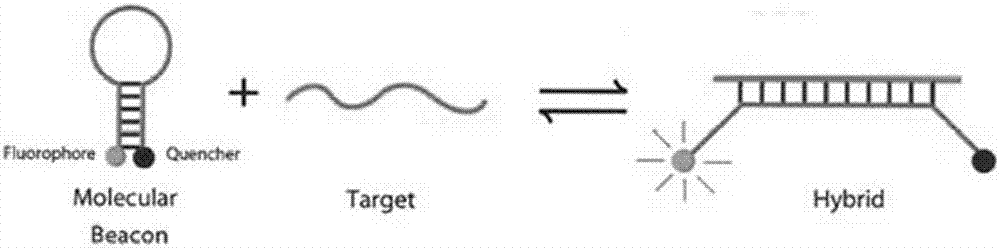

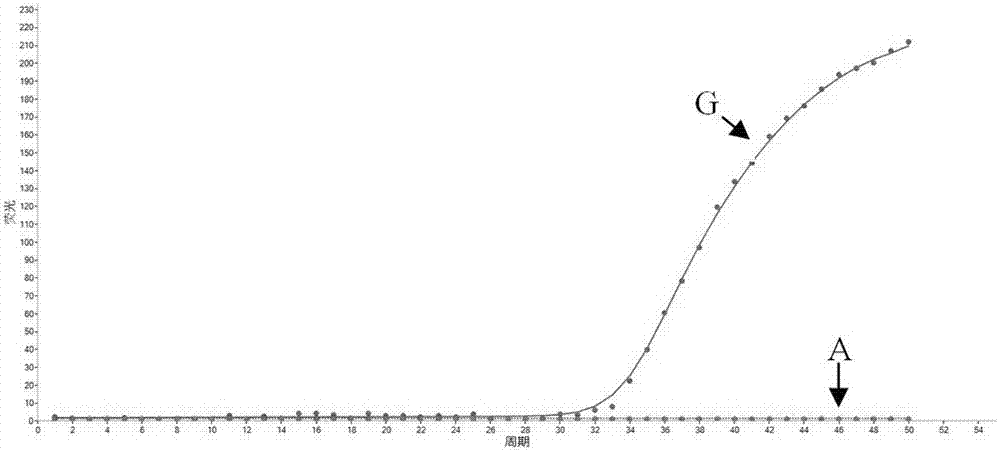

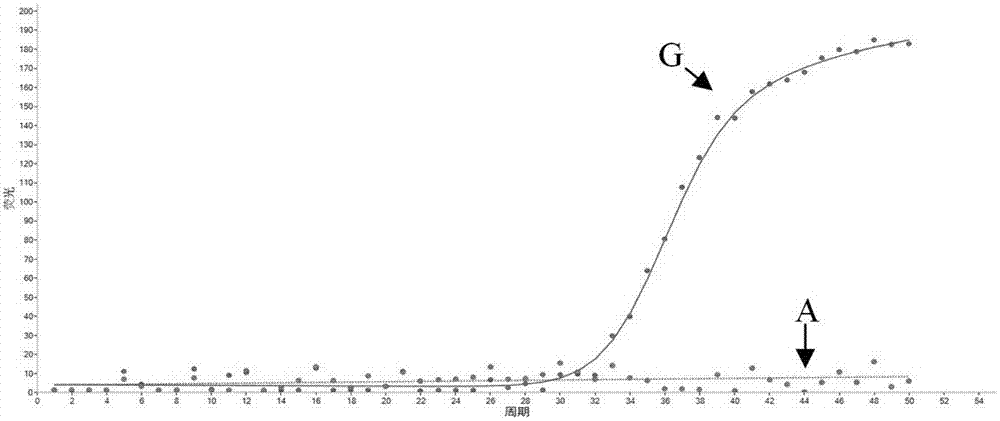

Primer, molecular beacon, kit and detection method for CYP2C19*3 gene polymorphism rapid detection

InactiveCN107312842AIncrease the degree of lysisReduce inhibitionMicrobiological testing/measurementDNA/RNA fragmentationPolyethylene glycolWild type

The invention discloses a kit for CYP2C19*3 gene polymorphism rapid detection. The kit is characterized by comprising a PCR reaction liquid, a specificity primer and a molecular beacon; the PCR reaction liquid comprises the following raw materials and concentrations: DNA polymerase 0.05 to 0.12 U / [mu]L; dNTPs 0.2 mM; 5X reaction buffer 1X; MgCl2 1.5 to 3.5 mM; lauryl sodium sulfate 0.0005 to 0.015 %(w / v); polyethylene glycol octylphenol ether 0.001 to 0.03 %(w / v); the specificity primer comprises a positive primer and a negative primer, and the final concentration of the positive primer and the final concentration of the negative primer are 0.2 to 0.5 [mu]M respectively; the molecular beacon comprises a mutant type probe and a wild type probe, and the final concentration of the mutant type probe and the final concentration of the wild type probe are 0.4 to 0.6 [mu]M; and the kit is used for detecting cell samples. The technical problem to be solved by the invention is to provide a primer, a molecular beacon, the kit and a detection method for CYP2C19*3 gene polymorphism rapid detection, which are simple in operation and rapid in detection and avoid pollution.

Owner:重庆京因生物科技有限责任公司

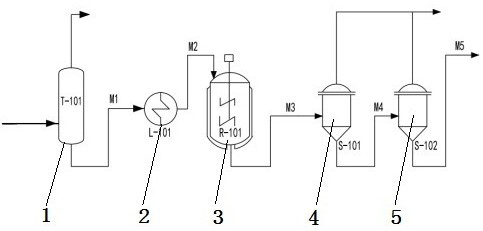

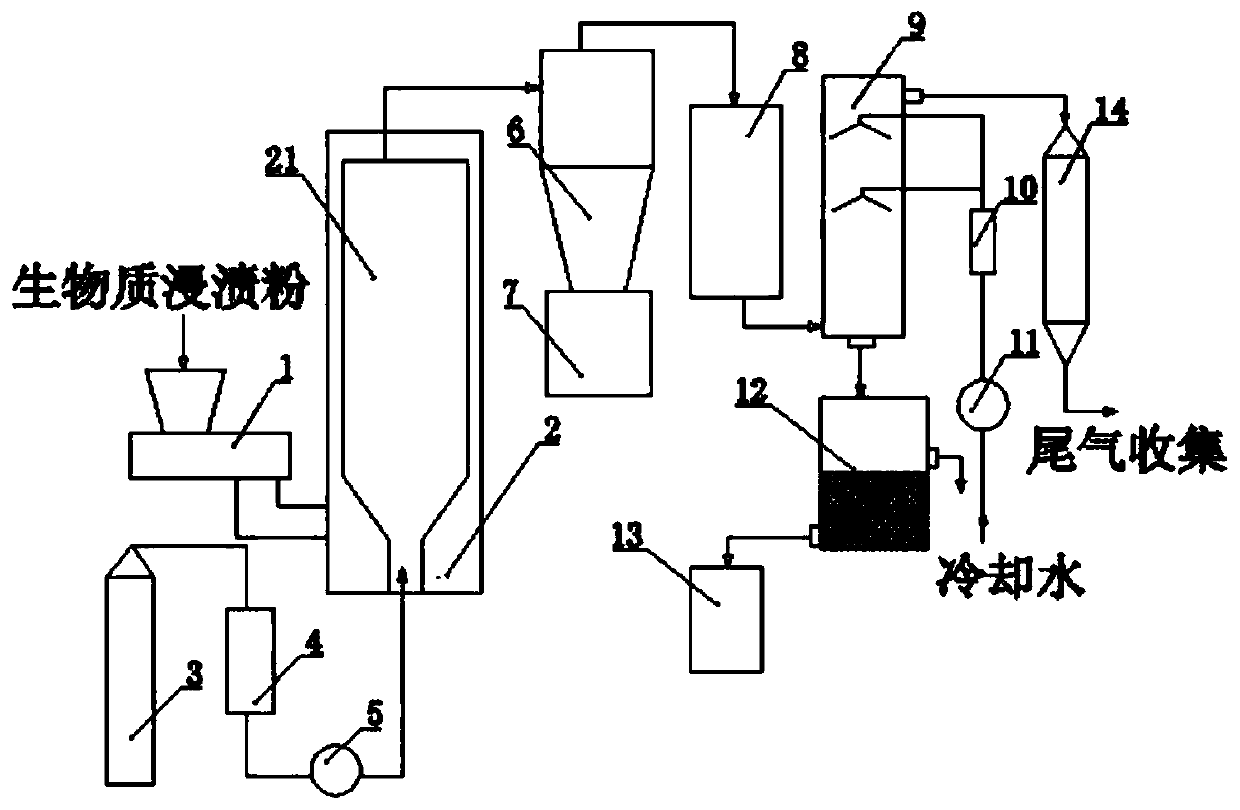

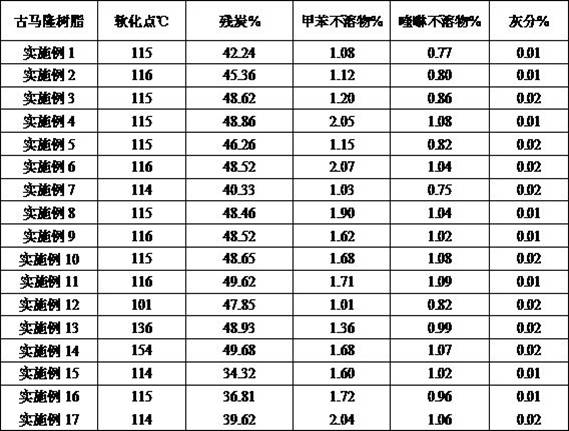

Preparation method of coumarone resin for high-carbon-residue carbon fibers

ActiveCN111909316AIncrease carbon residueHigh recombinant composition utilizationFibre chemical featuresFiberCarbon fibers

The invention relates to a preparation method of coumarone resin for high-carbon-residue carbon fibers, which comprises the following steps: removing light components from ethylene tar to obtain heavytar; carrying out high-temperature cracking on the heavy tar in a cracking furnace; polymerizing the heavy oil in a polymerization kettle at the temperature of 280-300 DEG C for 4-7 hours; and carrying out falling film flash evaporation on a product obtained by polymerization, and concentrating and granulating the product to obtain the coumarone resin. The coumarone resin produced in the invention has the advantages of high recombinant utilization rate, high carbon residue in the resin, basically unchanged toluene and quinoline insoluble content and small ash content, and is suitable for being used as a raw material for processing carbon fibers.

Owner:FUSHUN QILONG CHEM

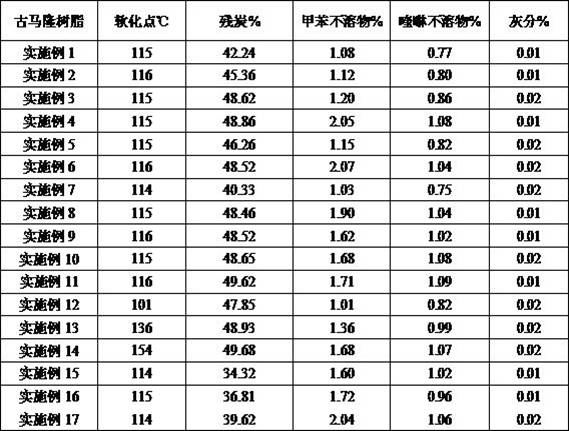

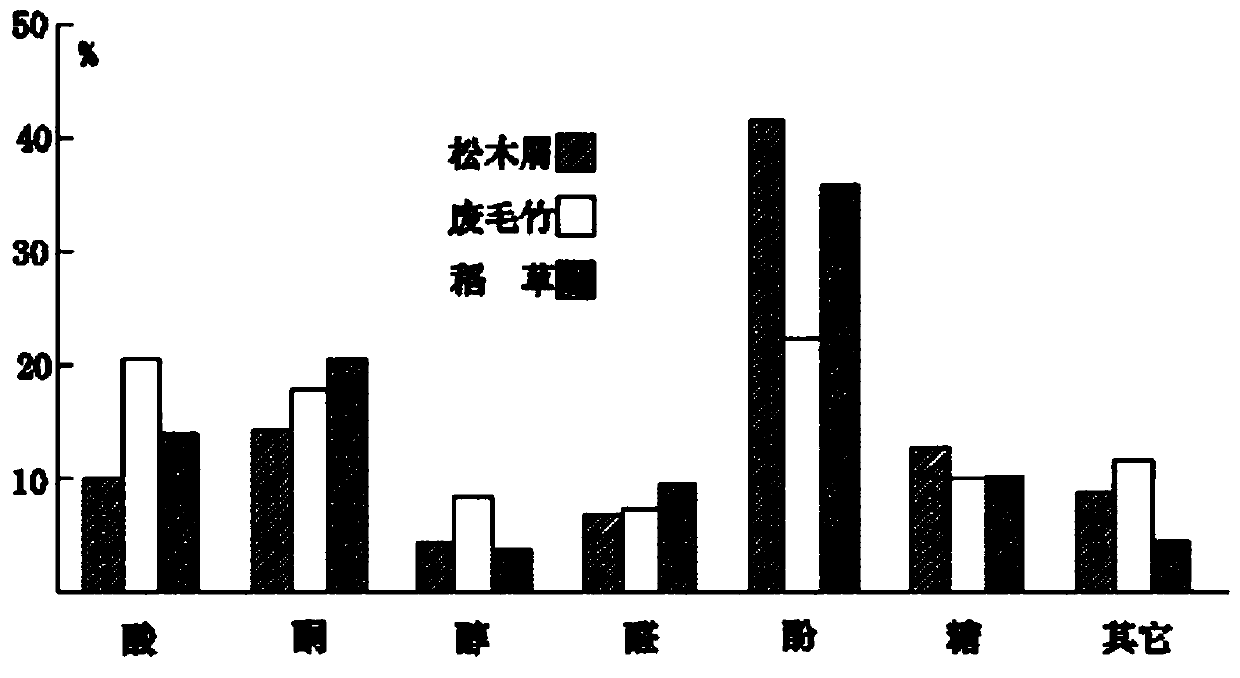

Method for preparation of bio-oil by microwave thermal cracking of biomass

InactiveCN110330995ARealize resource utilizationIncrease the degree of lysisLiquid hydrocarbon mixture productionHydrocarbon oils treatmentResource utilizationIonic liquid

The invention discloses a method for preparation of bio-oil by microwave thermal cracking of biomass. Specifically, biomass powder subjected to miniaturization pretreatment and moisture removal pretreatment is impregnated, ionic liquid is evenly attached to the surface of the biomass powder, heat energy can quickly be transferred to the wrapped biomass powder, so that the temperature inside the biomass powder can rise quickly, cracking reaction is carried out under the action of a catalyst, a spray tower cools a filtered volatile rapidly to prevent secondary cracking of the volatile, thus increasing the production of bio-oil. The method can realize the resource utilization of biomass and reduce pollutant discharge, and has the advantages of simple, safe and economical process operation.

Owner:CHAOHU UNIV

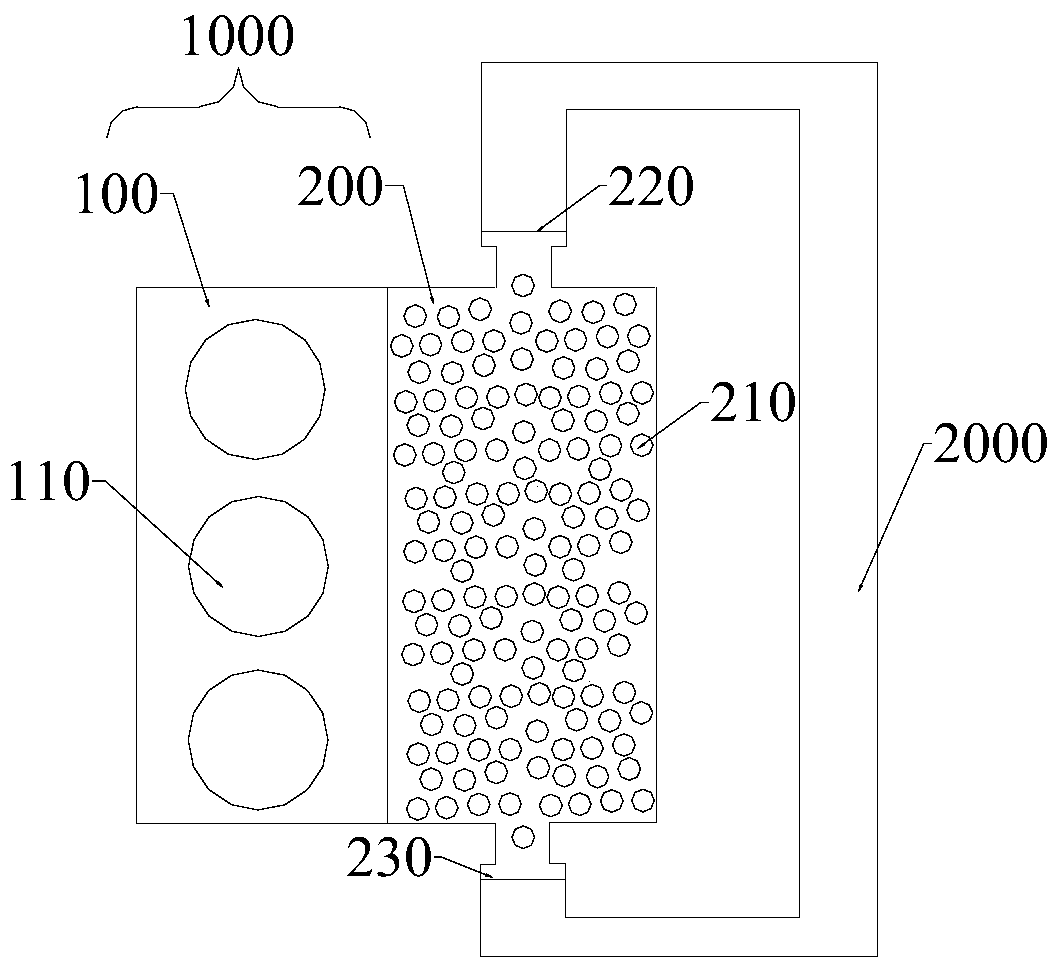

Method for preparing biomass gasified syngas and equipment thereof

InactiveCN109370653AImprove gasification efficiencyIncrease productionGranular/pulverulent flues gasificationSyngasHusk

The invention discloses a method for preparing biomass gasified syngas. The method comprises the following steps: (1) adding neodymium chloride and promethium chloride into water, uniformly mixing andstirring, and adding sodium erucate to prepare a gasifying additive; (2) drying corn straws, adding rice husks into the dried corn straws, uniformly mixing, and grinding to prepare a biomass raw material; (3) mixing the biomass raw material, the gasifying additive and potassium fluotitanate, and drying to prepare a gasifying raw material; (4) performing cracking treatment on the gasifying raw material; and (5) treating the cracked syngas by adopting a settling ash hopper, introducing into a spray chamber, spraying a spray liquid from the upper part of the spray chamber for cooling treatment,and treating the syngas through a demister and a dryer. The method for preparing biomass gasifying syngas is simple and stable in process and low in cost, and can be used for effectively improving thegasifying efficiency of raw materials; and the gas prepared by the method has relatively high calorific value.

Owner:董林妤

Novel function flame-proof fibre and preparation method thereof

InactiveCN100513654CReduce surface temperatureIncrease the degree of lysisFlame-proof filament manufactureMelt spinning methodsCelluloseFiber

The present invention relates to a functional flame-retardant fiber and a production method thereof. The main feature is that it also contains tourmaline and silicon dioxide nano-scale additive powder; its components are: cellulose: 75% to 95%; tourmaline and Nano-scale additive powder of silicon dioxide: 5% to 25%; the production process sequence includes the following steps: making tourmaline and silicon dioxide into nano-scale additive powder respectively; uniformly mixing nano-scale additive powder with cellulose Mixing, the nano-scale additive powder is 5% to 25% by weight; a static mixer is used to prepare a spinning solution by melting and blending; spinning to make a flame-retardant fiber. It has low cost, simple process, environmental protection and no pollution, can continuously emit far infrared rays and permanently release negative ions, and has a wide range of applications.

Owner:太原伦嘉生物科技股份有限公司

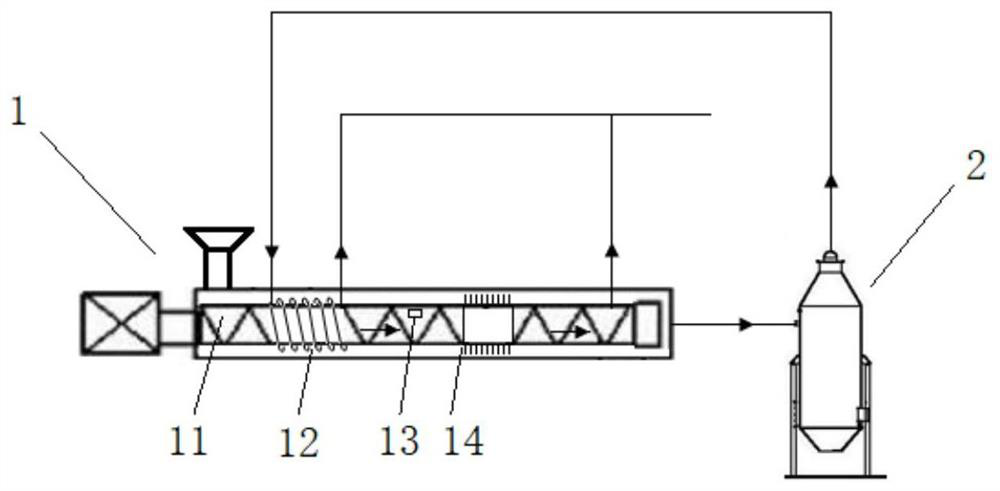

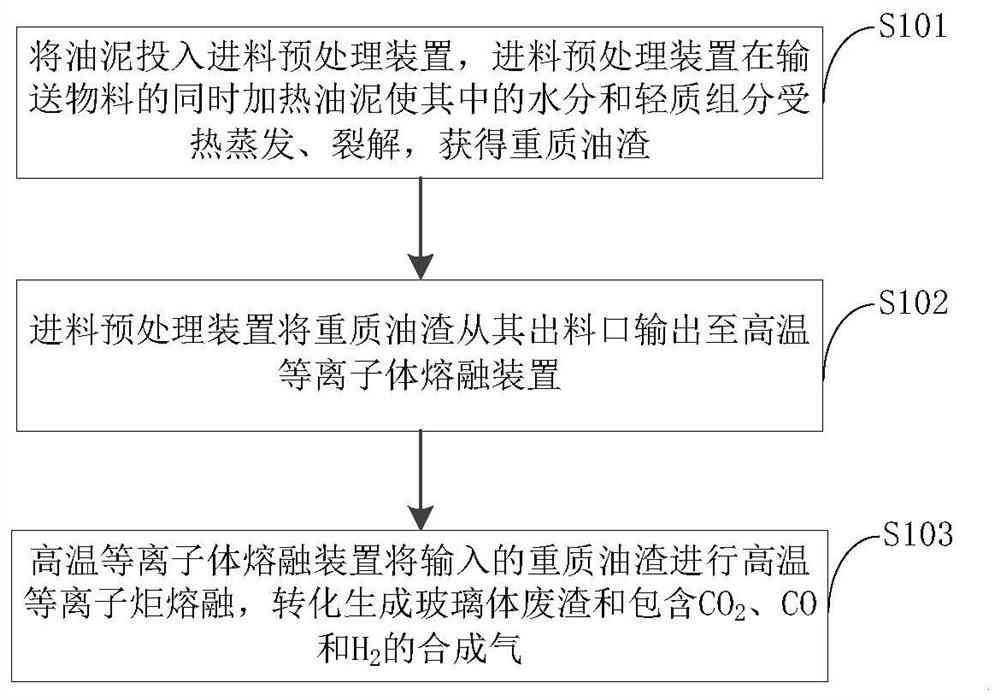

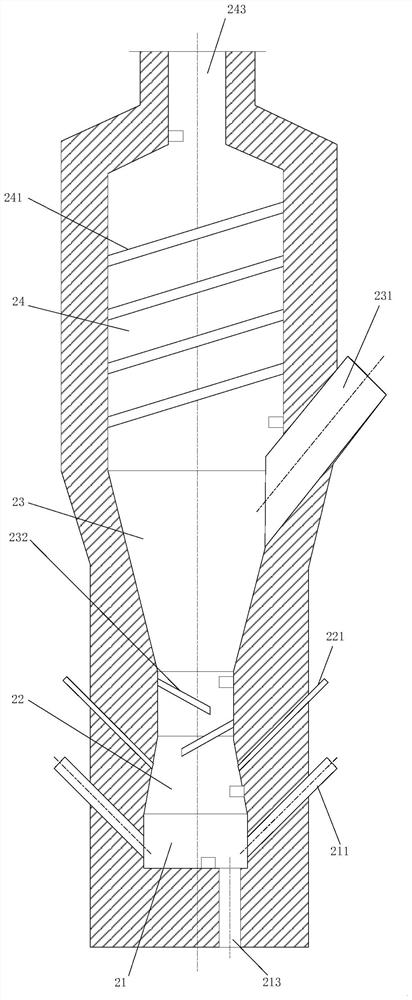

Sludge splitting decomposition treatment method

ActiveCN110695057AAccelerate heat evaporationIncrease the degree of lysisSolid waste disposalTransportation and packagingHeating oilSyngas

The invention discloses a sludge splitting decomposition treatment method, and relates to the technical field of solid waste harmful treatment. The sludge splitting decomposition treatment method comprises the steps that sludge is thrown into a feeding pretreatment device, when the feeding pretreatment device conveys materials, sludge is heated, water and light components in the sludge are heated,evaporated and subjected to splitting decomposition, and heavy oil residues are obtained; the feeding pretreatment device outputs the heavy oil residues to a high-temperature plasma fusion device from a discharging port of the feeding pretreatment device; and the high-temperature plasma fusion device conducts high-temperature plasma torch fusion on the input heavy oil residues, and glass body waste slag and synthesis gas containing CO2, CO and H2 are generated through conversion. The sludge splitting decomposition treatment method has the advantage that the harmless treatment degree is high.

Owner:航天环保(北京)有限公司

A kind of preparation method of coumarone resin for high carbon residue carbon fiber

ActiveCN111909316BIncrease carbon residueHigh recombinant composition utilizationFibre chemical featuresFiberPolymer science

The invention relates to a preparation method of coumarone resin for high-carbon-residue carbon fiber. The light components are removed from ethylene tar to obtain heavy tar; the heavy tar is subjected to high-temperature cracking in a cracking furnace; and the heavy oil is polymerized in a polymerization kettle , polymerized at 280‑300°C for 4 to 7 hours; the product obtained from the polymerization was subjected to falling film flash evaporation, concentrated and granulated to obtain coumarone resin. The coumarone resin produced by the invention has high utilization rate of recombinant composition, high carbon residue in the resin, basically unchanged content of toluene and quinoline insolubles, and small ash content, and is suitable as a raw material for processing carbon fibers.

Owner:FUSHUN QILONG CHEM

Hydrocarbon fuel composition with high heat sink

InactiveCN104059697BIncrease the degree of lysisImprove heat sinkLiquid carbonaceous fuelsHeat sinkHydrocarbon

The invention discloses a hydrocarbon fuel composition with high heat sink. The hydrocarbon fuel is composed of the following raw materials in weight percentage: 100% of a hydrocarbon fuel and 0.01%-5% of HPG-C16. The invention discloses a novel hydrocarbon fuel composition, HPG-C16 (cetyl grafted hyperbranched polyglycerol) is used as an initiator to promote the cracking degree of hydrocarbon fuel, enhance heat sink of the hydrocarbon fuel, improve the heat absorption capacity of the hydrocarbon fuel, and proposes a novel development direction for the application of HPG-C16.

Owner:ZHEJIANG UNIV

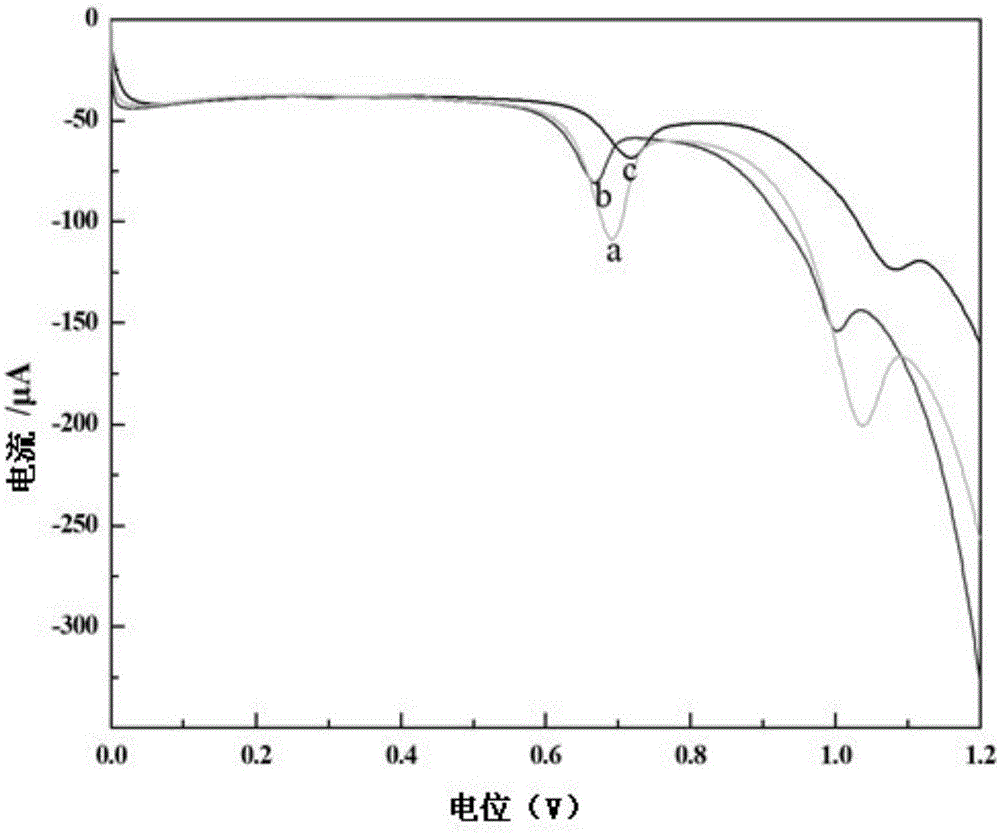

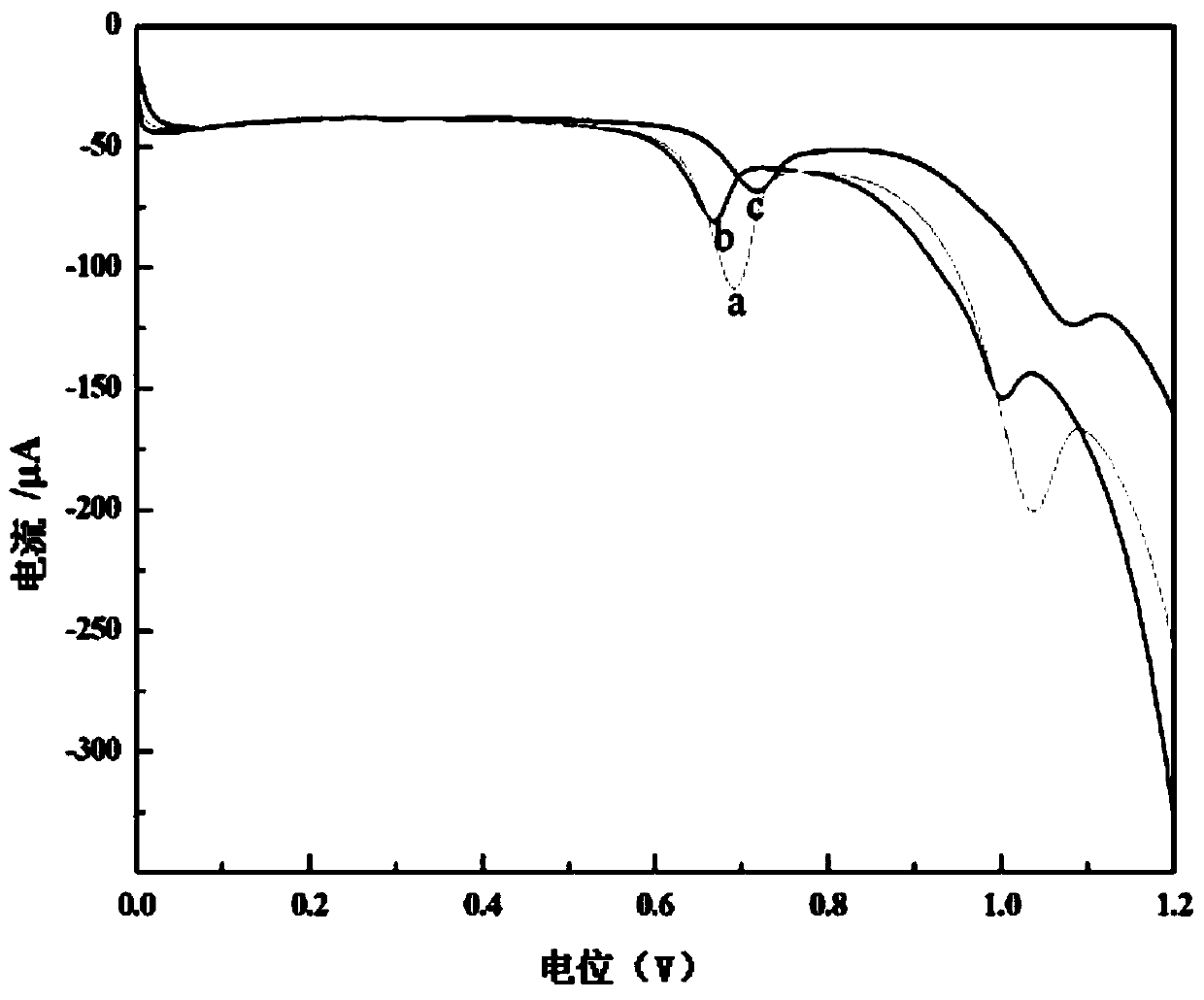

Cell pre-treatment method of electrochemical detection

ActiveCN105021671AIncrease the degree of lysisGood for activity detectionMaterial electrochemical variablesWater bathsCell membrane

The invention relates to a cell pre-treatment method of electrochemical detection. In the prior art, in the existing cell pre-treatment technology, electrically active substances can not be completely released, such that the cell activity change can not be truly reflected. A purpose of the present invention is to solve the problem in the prior art. The method comprises: inoculating cells to be detected into a culture dish, placing into an incubator with a temperature of 37 DEG C and a CO2 volume concentration of 5% to culture, removing the culture medium, adding a hypotonic lysis liquid, adjusting the cell concentration, and carrying out lysis under a water bath condition so as to complete the process. According to the cell in situ composite lysis of the present invention, the complete rupture of the cell membrane is achieved, the electrochemical signal is substantially enhanced, and the treatment is simplified, such that the electrochemical detection signal is strengthened, and the importantly the electrochemical detection results accurately reflect the real situation of the intracellular electrically active substance content; and the cell pre-treatment method is used in the biological analysis field.

Owner:JIAMUSI UNIVERSITY

A kind of preparation method of carrageenan oligosaccharide

The invention relates to a preparation method of carrageenan oligosaccharides. The preparation method sequentially comprises a raw material pretreatment process step, an extraction process step, an enzymolysis process step, a potassium chloride dissolution process step, a potassic alteration and dehydration process step, a squeezing process step, a sterilization process step, a crushing process step and a material mixing and re-sterilization process step, wherein an irradiation and degradation process step is further contained between the crushing process step and the material mixing and re-sterilization process step, and the irradiation and degradation process step is as follows: a semi-finished product obtained in the crushing process step is simply bagged and packaged, and then irradiated by an electronic accelerator with 10MeV and beam power of 500-650kW for 10-20h. A complex enzyme adopted by the invention has stronger destructive power against cellulose and high degree of carrageenan cracking, and can reduce the using quantity of steam and chemical raw materials in the production process of products and realize energy conservation, consumption reduction and clean production under the situation of ensuring the yield of the products. According to the preparation method provided by the invention, the irradiation method is adopted for degrading large molecular carrageenan into small molecular carrageenan, the addition of any impurities or harmful substances is avoided, and the degradation is fast and pollution-free.

Owner:青岛聚大洋藻业集团有限公司

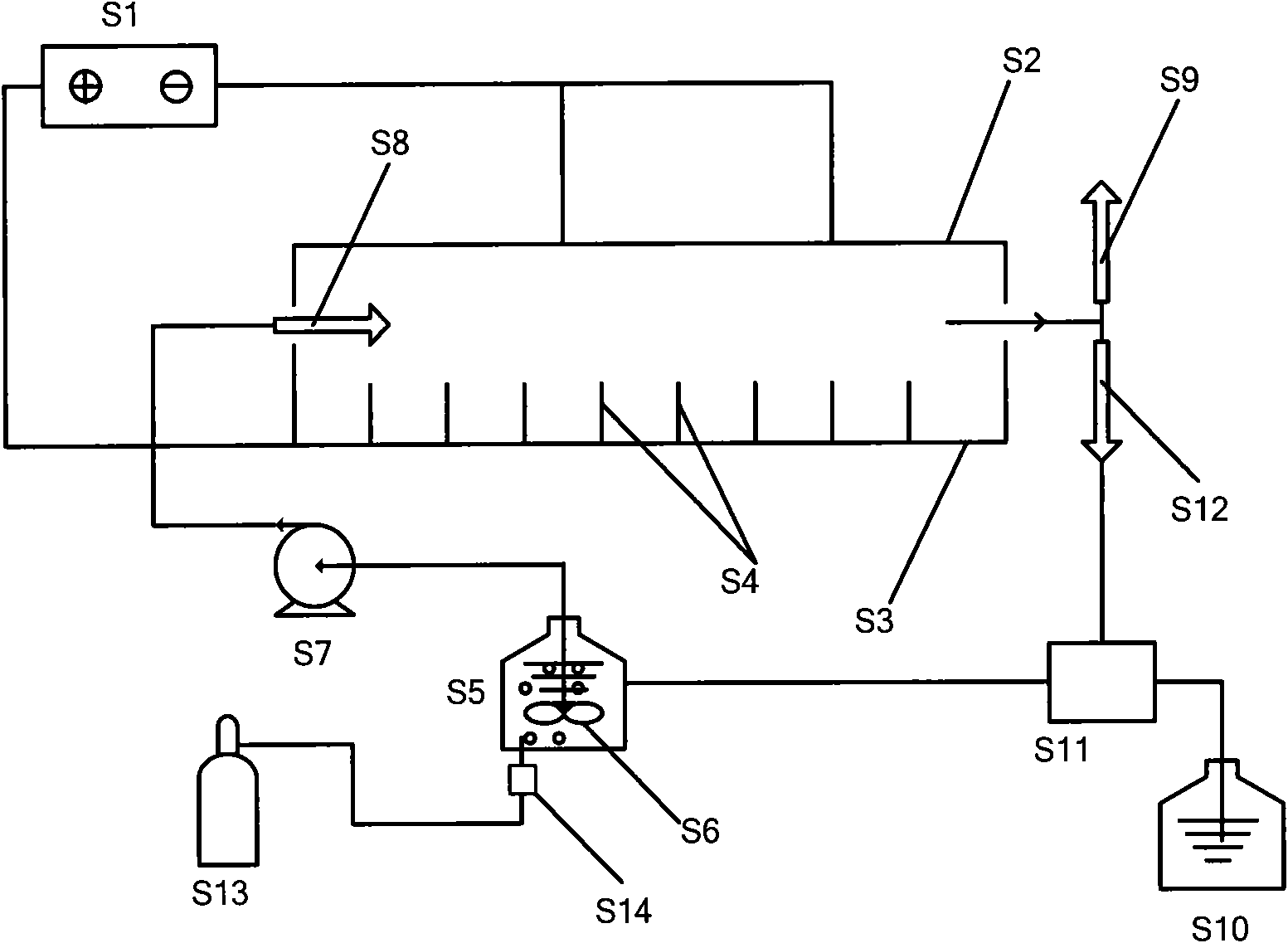

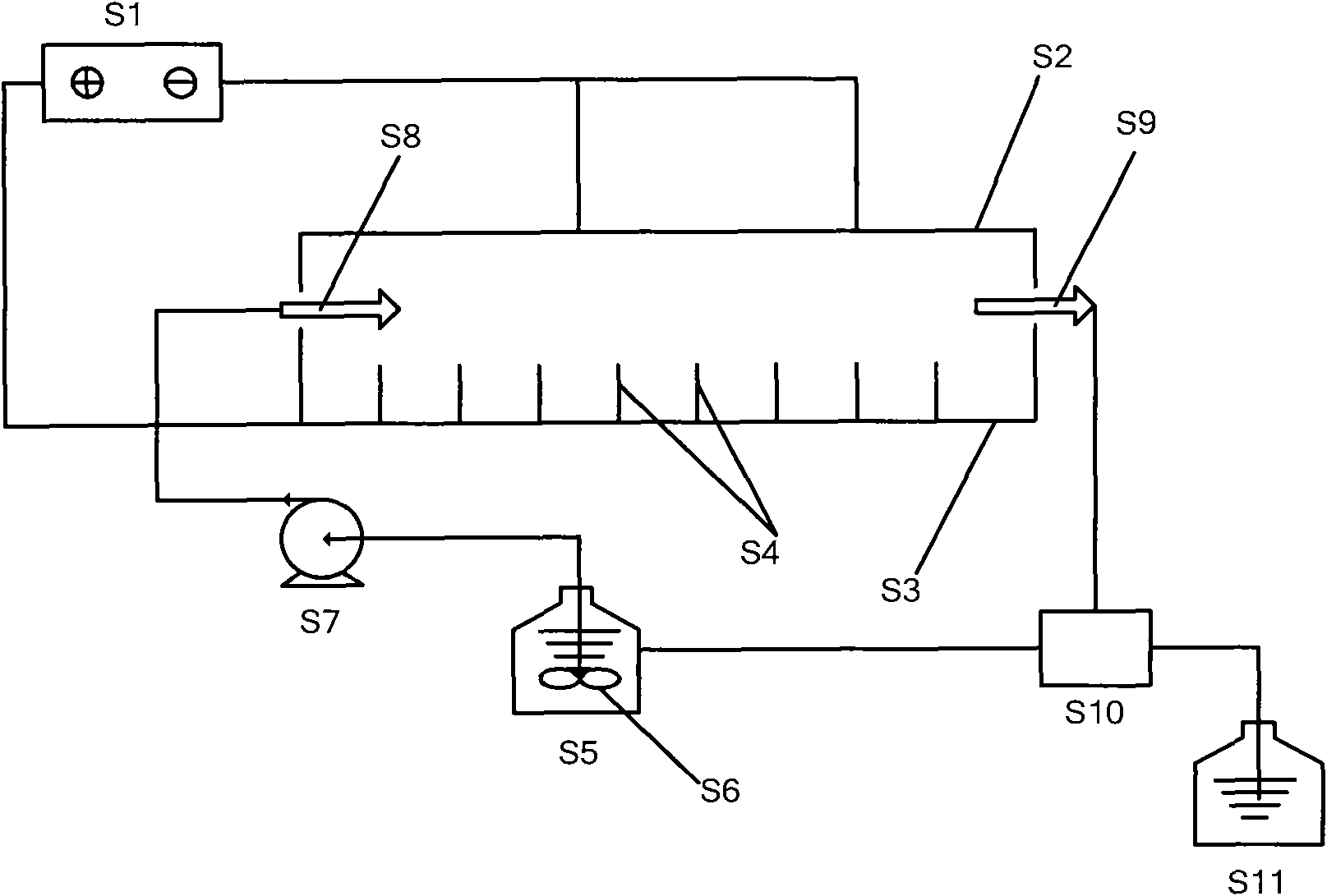

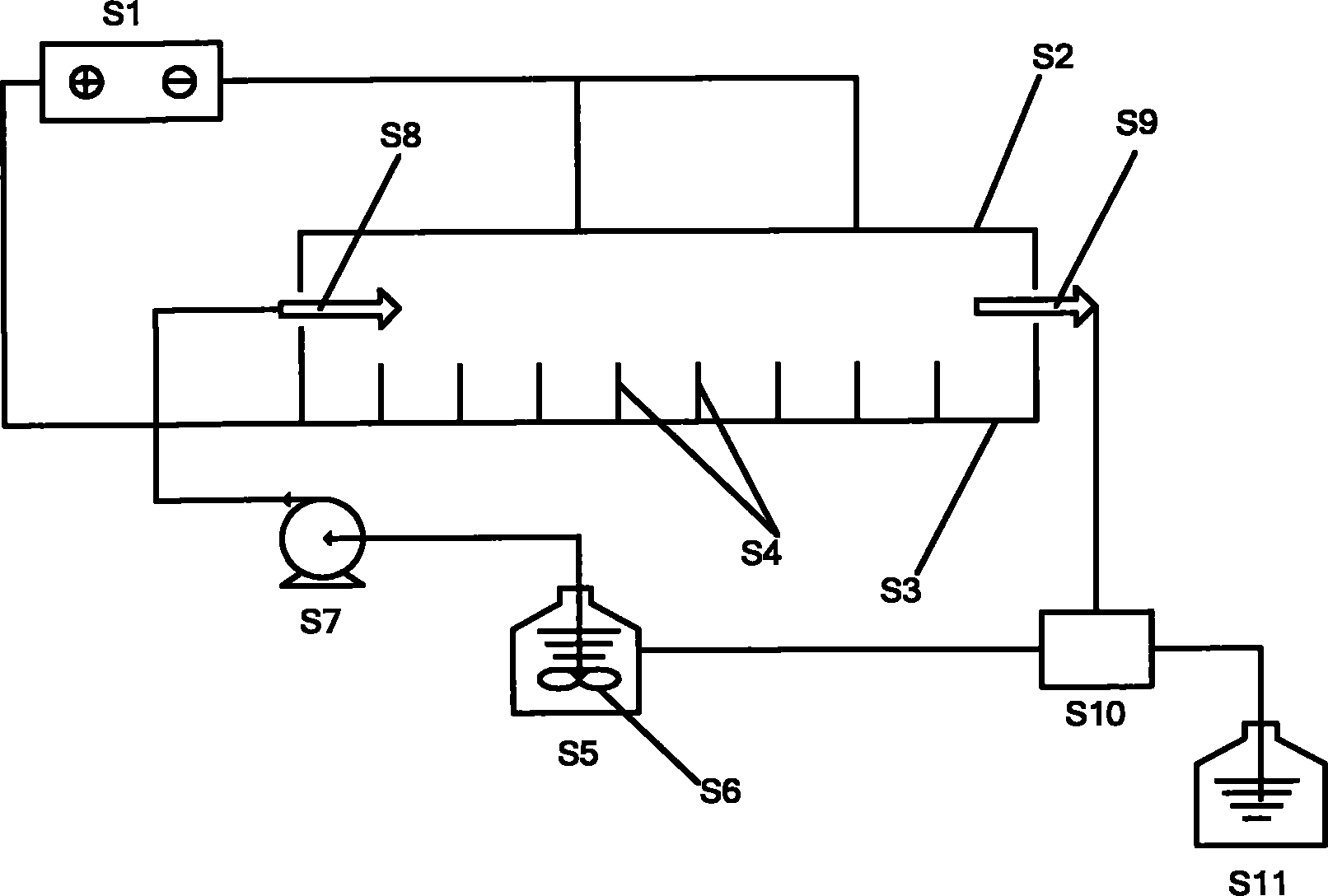

Method for cracking vegetable oil in oil-gas mixing way based on high-pressure pulse device

InactiveCN102031134BBurn fullyImprove combustion efficiencyLiquid hydrocarbon mixture productionBio-feedstockVegetable oilCombustion

The invention discloses a method for cracking vegetable oil in an oil-gas mixing way based on a high-pressure pulse device. In the traditional way, oil is directly cracked in a pulse electrolysis unit, but oil molecules can not be completely cracked, thus the purpose of great improvement on the combustion efficiency of the oil can not be achieved. The method of the invention makes oil and gas completely mix by a mixing device, gas molecules and the oil molecules are mixed to increase the ionization area of the oil molecules, the chains of oil are easier to break, the electrical conductivity of the gas also facilitates the crack capability of a pulse electric field on the chains of carbon, and the chains of oil are continuously cracked, and finally the cracked micro-molecular oil with highcombustion efficiency is separated. The invention greatly improves the cracking degree of vegetable oil molecules in the oil-gas mixing way so as to improve the combustion efficiency of the oil and make the oil combust more completely.

Owner:HANGZHOU DIANZI UNIV

Oil sludge cracking treatment method

ActiveCN110695057BAccelerate heat evaporationIncrease the degree of lysisSolid waste disposalTransportation and packagingSyngasHeating oil

The invention discloses an oil sludge cracking treatment method, which relates to the technical field of harmless treatment of solid waste, comprising: putting the oil sludge into a feed pretreatment device, and the feed pretreatment device heats the oil sludge while transporting materials to make the water and light in the sludge The heavy components are evaporated and cracked by heat to obtain heavy oil residue; the feed pretreatment device outputs the heavy oil residue from its outlet to the high-temperature plasma melting device; the high-temperature plasma melting device processes the input heavy oil residue High-temperature plasma torch melting, transforming into vitreous waste slag and containing CO 2 , CO and H 2 of synthetic gas. The invention has the advantage of high degree of harmless treatment.

Owner:航天环保(北京)有限公司

A kind of lysate and method for extracting ancient biological bone dna

ActiveCN105420229BImprove scalabilityIncrease the degree of lysisDNA preparationProtein solutionLysis

The invention discloses a lysis solution and method for extracting ancient biological bone DNA. The lysis solution is prepared from 10 mM of Tris-HCl with pH of 8.5, 10-15 mM of EDTA, 1.0-1.5 wt% of SDS, 150 mM of NaCl and 0.3-0.5 mg / ml of protease K. By means of improving the components of the SDS, the EDTA and the protease K respectively, the lysis degree of the lysis solution on bone tissue can be obviously improved. Meanwhile, when the lysis solution is used, by means of protein solution removing, DNA wash liquid treatment and a DNA centrifugal column method, impurity composition in DNA samples can be obviously reduced, the improvement of PCR amplification effect is facilitated, and therefore high-purity ancient biological bone DNA can be obtained conveniently.

Owner:CENT SOUTH UNIV

A cell pretreatment method for electrochemical detection

ActiveCN105021671BIncrease the degree of lysisGood for activity detectionMaterial electrochemical variablesComplete rupturePretreatment method

Owner:JIAMUSI UNIVERSITY

Method for cracking vegetable oil through oil-water mixing mode based on high voltage pulse device

InactiveCN102041027AAlleviate the shortage of fuel resourcesIncrease the degree of lysisLiquid hydrocarbon mixture productionBio-feedstockHigh voltage pulseCarbon chain

The invention discloses a method for cracking vegetable oil through an oil-water mixing mode based on a high voltage pulse device. In the traditional method, oil is directly cracked in a pulse electrolysis device, but oil molecules cannot be fully cracked, so that the aim of greatly improving the combustion efficiency of the oil cannot be fulfilled. In the method, oil and water are fully mixed bya mixing agitator, and water molecules and oil molecules are mixed, so that ionization effect areas of the oil molecules are increased, oil chains are easier to break, and the conductivity of the water also can promote the cracking effect of a pulse electric field on carbon chains. The oil chains are continuously cracked, and the small molecular oil with high combustion efficiency obtained by cracking is separated out finally. By adopting the oil-water mixing mode, the cracking degree of the vegetable oil molecules is greatly improved, so that the combustion efficiency of the oil is improved and the oil is more fully combusted.

Owner:HANGZHOU DIANZI UNIV

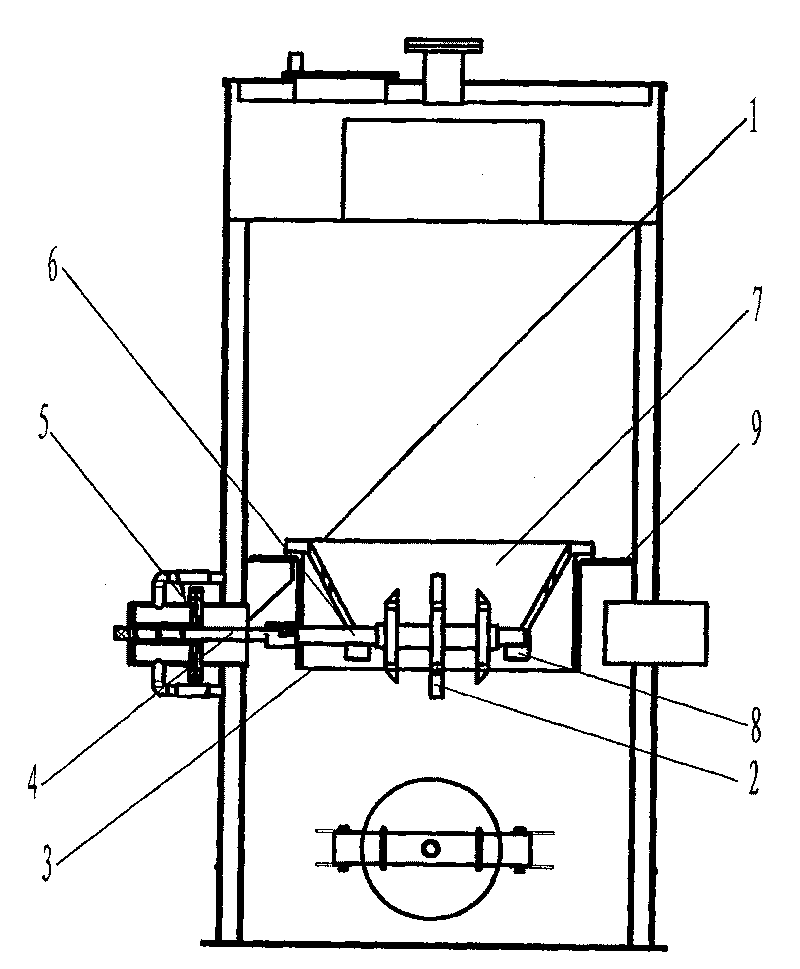

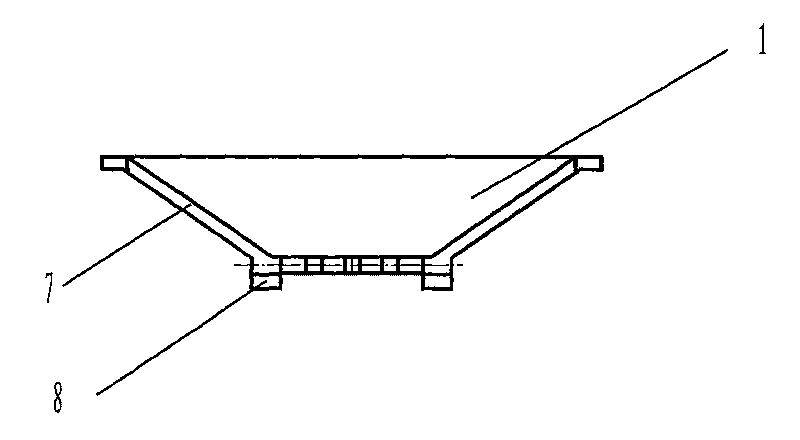

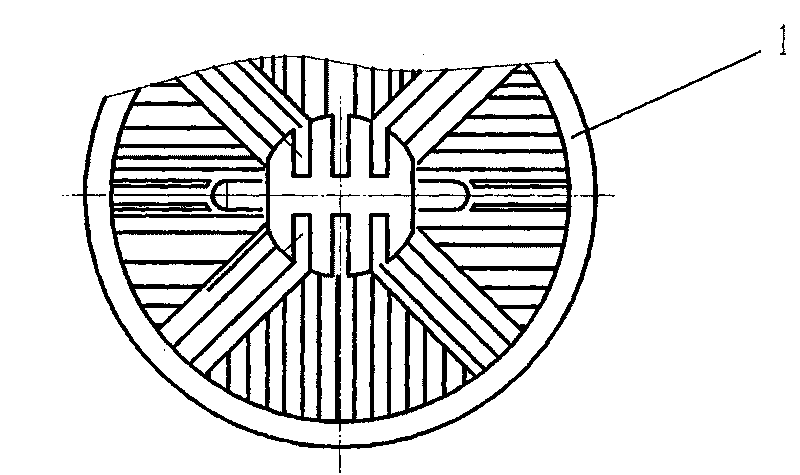

Fire grate assembly equipment of stalk gasification stove

InactiveCN101092568BStrong resistance to deformationProlong lysis timeSpecial form destructive distillationAutomatic transmissionDrive shaft

Owner:上海中英生物科技有限公司

A kind of auxiliary agent for biomass treatment and biomass gasification treatment method

ActiveCN111378513BReduce the degree of fractureInhibition formationGasification catalystsGasification processes detailsMANGANESE ACETATEManganese sulphate

The invention discloses an auxiliary agent for biomass treatment and a biomass gasification treatment method. The auxiliary agent includes component A, component B and component C; wherein, the component A includes Lewis acid, and any One or more of selected organic acids and protonic acids, the component B is a salt of IA, IIA, IIIA group metal and ammonium, and the component C is one of manganese acetate, manganese sulfate, manganese nitrate species or several. The gasification treatment method is to react the biomass raw material and the auxiliary agent after mixing, and obtain the volatile components and bio-semi-coke after the reaction; the solid-phase materials and bio-semi-coke obtained after the gas-solid separation of the volatile components are respectively fed into the After the biocoke microwave gasification reactor reacts, crude synthesis gas and activated carbon are obtained; the synthesis gas obtained after the gas-solid separation of the crude synthesis gas enters the purification reactor for treatment to obtain purified synthesis gas. The biomass gasification treatment method and system can increase the synthesis gas yield, and the tar content in the obtained synthesis gas product is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for cracking tar and method for cracking tar

ActiveCN105505451BIncrease the degree of lysisEasy to handleTreatment with plural serial cracking stages onlyTarPetroleum engineering

The invention provides a tar cracking device and method. The device comprises a cracker, radiant tubes, catalysts, catalyst feeding openings, catalyst discharging openings and catalyst activation pipelines, wherein the cracker is partitioned into thermal cracking chambers and catalytic cracking chambers by partition plates, and the partition plates are provided with through holes; the radiant tubes are arranged in the thermal cracking chambers; the catalysts are arranged in the catalytic cracking chambers; the catalyst feeding openings are formed in the tops of the catalytic cracking chambers; the catalyst discharging openings are formed in the bottoms of the catalytic cracking chambers; the catalyst activated pipelines are connected with the catalyst feeding openings and the catalyst discharging openings respectively. By means of the tar cracking device and method, tar cracking efficiency of the device is improved.

Owner:SHENWU TECH GRP CO LTD

Method for simultaneously extracting total DNA and RNA from compost

InactiveCN101845436BIncrease the degree of lysisIncrease productionDNA preparationAnhydrous ethanolSodium acetate

The invention discloses a method for simultaneously extracting total DNA and RNA from compost, which comprises the following steps of: adding corrosion removal buffer solution into a compost sample, shaking and uniformly mixing the solution and the compost, standing the mixture, and centrifuging the suspension; repeating the operation till the centrifuged supernatant is clarified; grinding the sample after corrosion removal by using liquid nitrogen till the sample is powdery, then placing the powdery sample in cracking solution, shaking and uniformly mixing the sample and the solution, putting the mixture in an ice bath, and centrifuging the mixture; taking the cracked supernatant, adding sodium acetate and extraction buffer solution into the supernatant, and centrifuging the mixture after shaking; adding chloroform-isoamylol into the extracted upper aqueous phase, and centrifuging the mixture after shaking; adding isopropanol into the mixture to settle RNA, and washing, drying and dissolving the settled RNA to obtain purified RNA; and adding Tris alkali solution into the extracted organic phase, adding chloroform-isoamylol into the centrifuged upper aqueous phase, centrifuging the mixture, then adding sodium acetate and anhydrous ethanol into the mixture to settle DNA, and washing and dissolving the mixture to obtain purified DNA. The method has the advantages of large yield,good quality, low cost and the like.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com