Device for cracking tar and method for cracking tar

A tar cracking and tar technology, which is applied in the multi-stage series cracking process treatment, petroleum industry, hydrocarbon oil treatment, etc. The effect of tar cracking efficiency, avoiding pipeline blockage and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

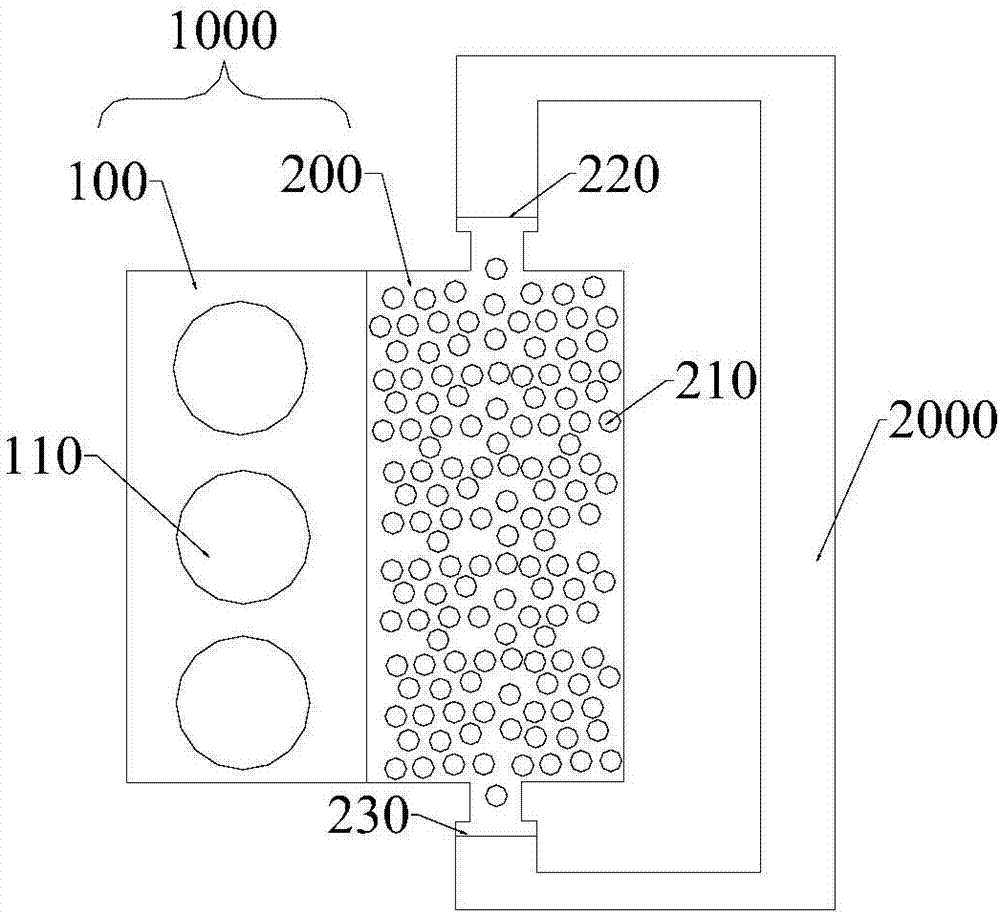

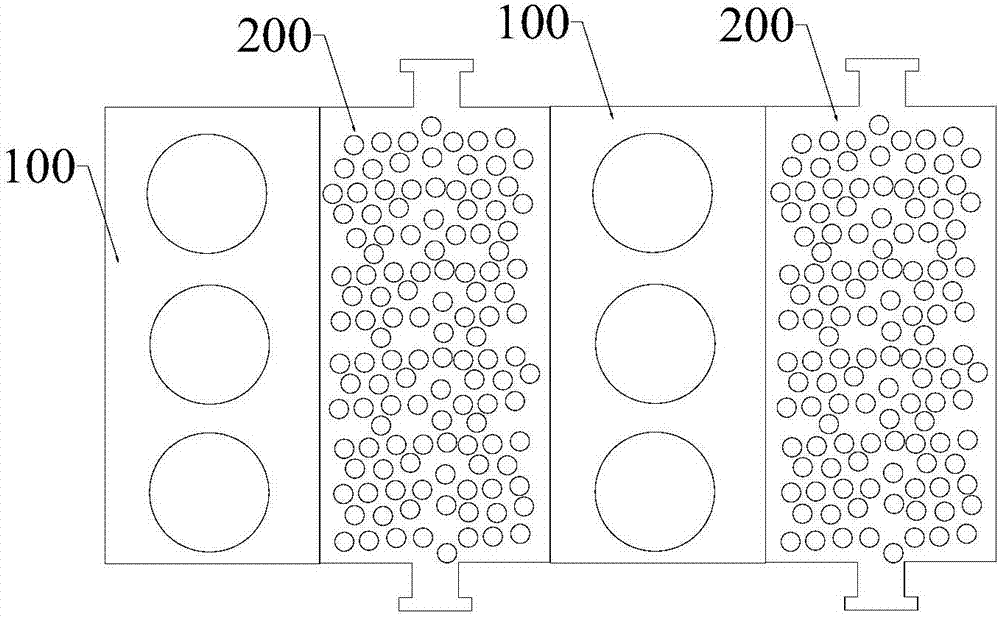

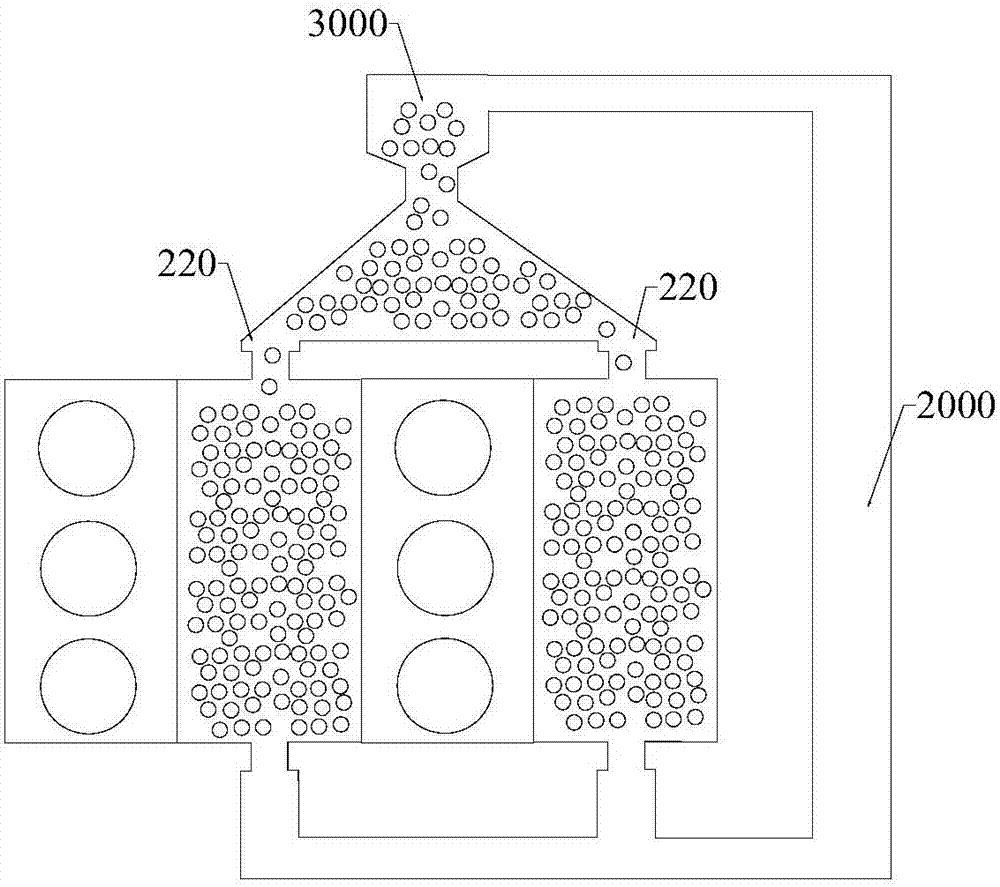

[0101] Tar-containing gas (tar content 550mg / Nm 3 ) enters the tar catalytic cracking device through the crude gas inlet 300, steam enters through the steam inlet 400, and the tar-containing gas and steam are mixed by the air distribution plate 600 and then uniformly enter the catalytic unit; the tar-containing gas passes through the thermal cracking chamber at 900 degrees Celsius and the 850 Celsius catalytic cracking chamber to achieve alternate cracking.

[0102] Among them, the catalyst is a spherical catalyst with a particle size of 2 mm, and the main component is Ni / Al 2 o 3 (Ni loading is 7.5 quality %), and catalyst layer pore diameter is 1mm; Through the cleavage product of alternate cracking (tar content 8mg / Nm 3 ) is discharged from the pyrolysis product outlet 500; the catalyst 210 in the catalytic cracking chamber 200 is sent into the catalyst activation pipeline 2000 via the catalyst transport assembly 2300, and the flue gas (1100°C) is blown into the catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com