Plasma 3D fast forming and remanufacturing method and equipment of train wheels

A train wheel and plasma technology, applied in the field of ion 3D rapid prototyping remanufacturing equipment, can solve the problems of long time required, complex manufacturing process, size limitation of molded parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

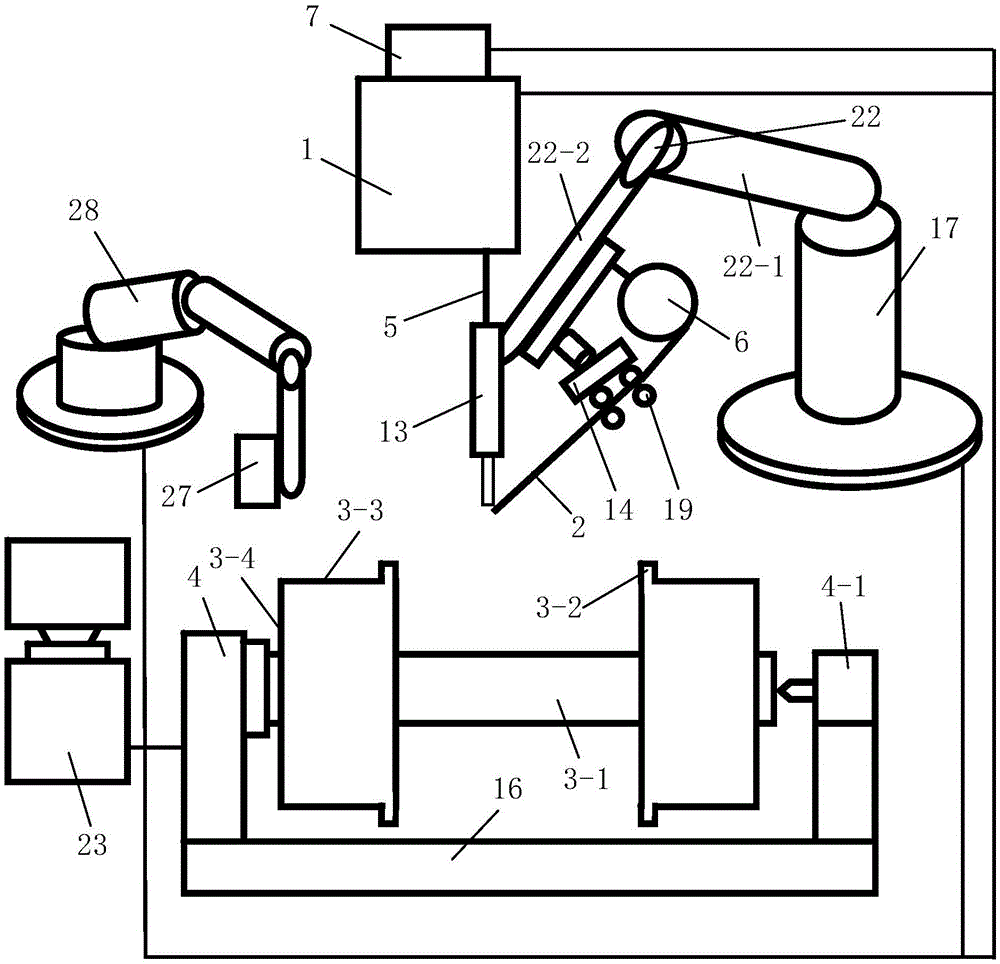

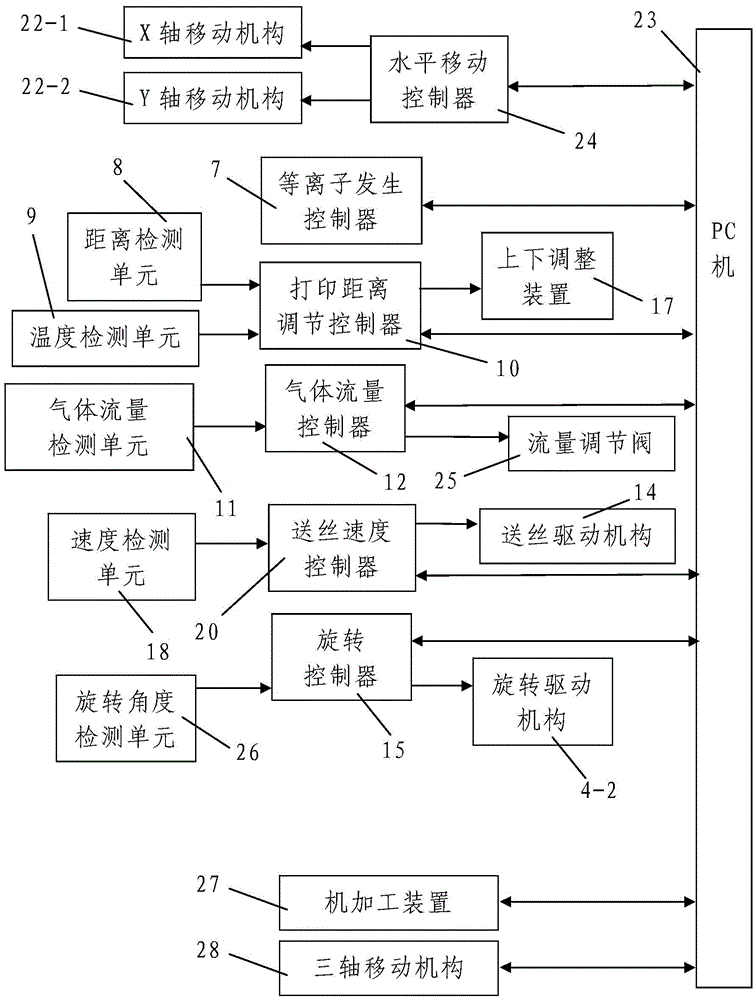

[0143] Such as figure 1 The train wheel plasma 3D rapid prototyping remanufacturing equipment shown is composed of a monitoring system, a plasma beam processing system, a machining device 27 for machining the train wheel to be repaired, and a three-axis moving mechanism that drives the machine processing device 27 to move 28 and a horizontal printing table for the train wheels to be repaired. The horizontal printing table includes a horizontal support mechanism 16 and a horizontal rotation mechanism 4 fixedly installed on the horizontal support mechanism 16 and driving the train wheel to be repaired to rotate around the central axis of its wheel shaft 3-1. The horizontal rotation mechanism 4 Located above the horizontal support mechanism 16 , the axle 3 - 1 is arranged horizontally and installed on the horizontal rotation mechanism 4 ; the machining device 27 is installed on the three-axis moving mechanism 28 and located above the horizontal rotation mechanism 4 .

[0144] Th...

Embodiment 2

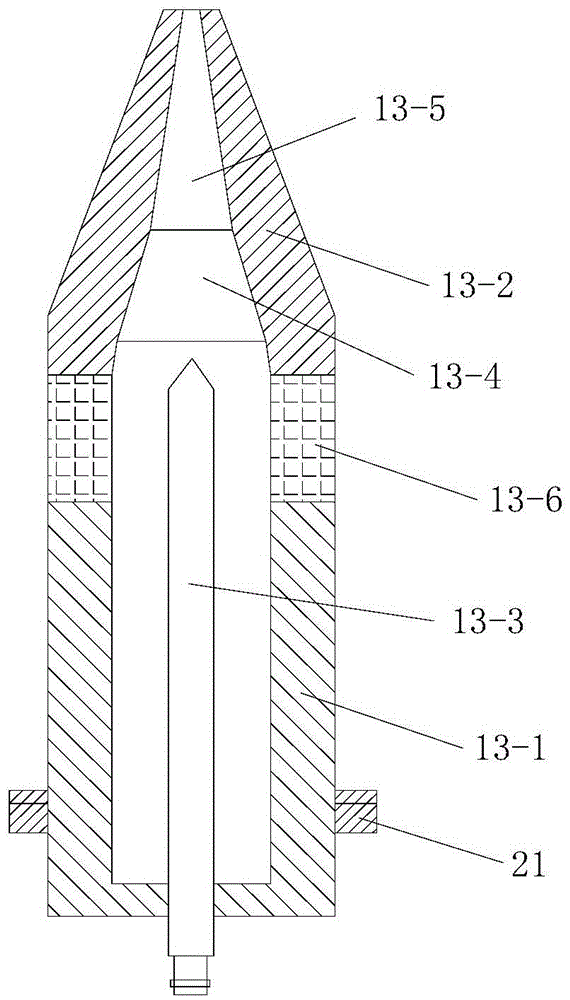

[0341] In this example, if Figure 7 As shown, the difference between the train wheel plasma 3D rapid prototyping and remanufacturing equipment used in Embodiment 1 is that the nozzle 13-5 and the powder circulation channel 14 are arranged coaxially.

[0342] In this way, after changing the direction of the plasma beam through the nozzle 13-5, the thermal load impact of the plasma jet on the anode nozzle 13-2 can be effectively reduced, and the anode ablation condition is improved. At the same time, since the nozzle 13-5 is coaxially arranged with the powder circulation channel 14, the acceleration, heating and melting process of the powder will not be affected, and the use effect is very good.

[0343] In this embodiment, the rest of the structure, connection relationship and working principle of the train wheel plasma 3D rapid prototyping remanufacturing equipment are the same as those in Embodiment 1.

[0344] In this embodiment, the train wheel plasma 3D rapid prototyping...

Embodiment 3

[0346] In this example, if Figure 8 As shown, the difference between the train wheel plasma 3D rapid prototyping and remanufacturing equipment used in Example 1 is that the feeding device is the powder feeding device.

[0347] In this embodiment, the powder feeding device includes a powder feeding device 29-1 and a powder feeding nozzle 29-2, and the powder feeding port of the powder feeding device is the powder outlet of the powder feeding nozzle 6; the powder feeding device 29 -1 includes a casing with a feed inlet and a powder feeding outlet and a powder feeding wheel installed in the casing, the powder feeding wheel is driven by a powder feeding drive motor; the powder feeding outlet and powder feeding nozzle 29- 2 powder inlet connection. The printing material is powder, and there is no special requirement on the shape of the powder.

[0348] In this embodiment, the powder feeding drive motor is a DC motor. During actual use, by changing the rotation speed of the DC m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com